Metal benches are less popular than wood-based garden designs. After all, the technological process of creating a wooden product does not require the use of specialized tools, and the benches themselves are lighter and more mobile. But if you are confident in your own abilities, you can always make metal garden benches with your own hands: drawings and photos of reliable structures can be used as a visual guide.

Content

DIY metal garden benches: drawings and photos, characteristics

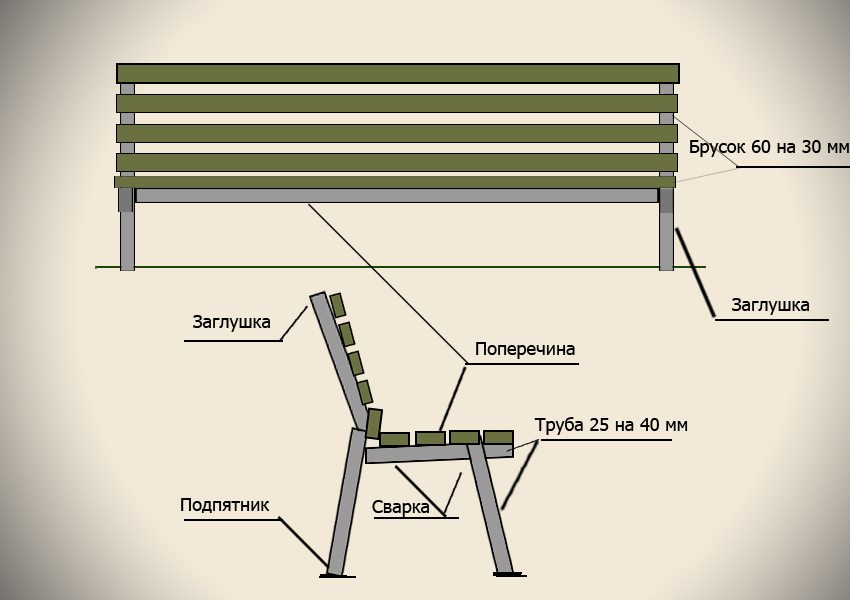

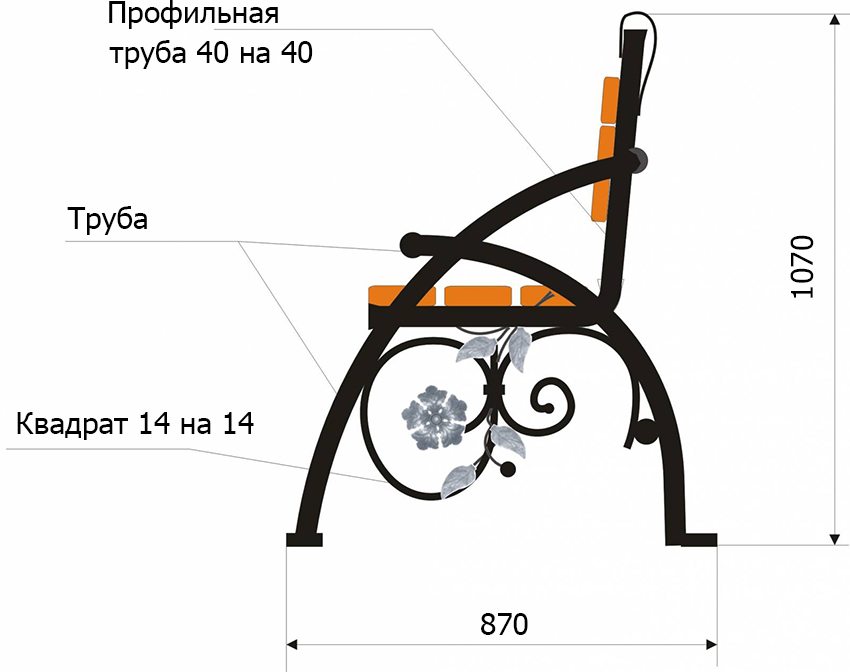

Despite the fact that this type of structure belongs to the category of metal, in most cases in the photo of do-it-yourself metal benches that are found on the Internet, products of a combined type are shown. In them, the frame part is made of metal, and wood is used as the material for the seat and backrest.

Thus, not only does the construction of a bench become cheaper, but the structure itself becomes more practical and comfortable, since a wooden seat, unlike a metal one, does not heat up under the sun.

The advantages of a do-it-yourself bench made of metal over products from other materials

Metal supports are devoid of those drawbacks that are inherent in the frame parts of benches made of other materials:

- cast iron is the most difficult type of structures, which is suitable for installation exclusively in park areas (products are characterized by high cost, decorative effect and complex manufacturing technology);

- concrete - benches are heavy and are accompanied by a number of difficulties during installation on the site;

- stone - products have a high cost and are significantly limited in terms of design;

- wood - despite the beauty, availability and low weight, the supports in these structures quickly become unusable, since the material is extremely vulnerable to the influence of weather and climatic conditions, as well as negative environmental factors (fungi, insects, mold).

Useful advice! Creating a shop from a profile pipe with your own hands solves the problem with the manufacture of parts for the structure. Profiled pipes are much lighter than cast iron and are very easy to use.

Often steel is used as a raw material to create a metal frame. It is this material that is considered the most suitable for benches and benches intended for installation in country-type plots and adjoining territories of country cottages. Steel is practically unaffected by corrosion processes and destruction. It offers many design options through the use of the decorative forging method.

Features of creating unusual designs

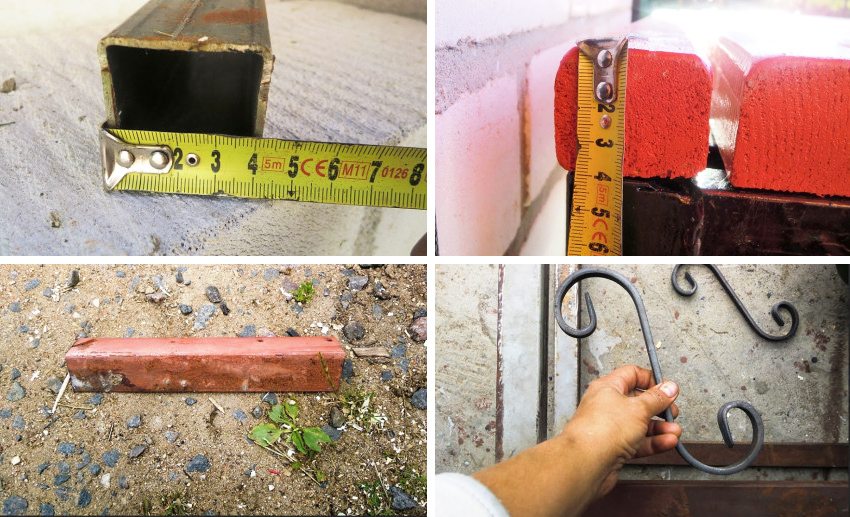

Profile pipes are also used to create decorative elements that can be used to complement a finished bench or bench. If you decide to create a unique design, you will need to add a few more items to the general list of required tools.

To form a steel decor, you will need to use:

- locksmith's vice;

- pipe bending instruments;

- mini-machine called "Snail".

To obtain symmetrical pipe bends, it is recommended to use a plasma. The basis for its manufacture is a piece of plywood sheet. On top of it, apply the contour part of the decorative element that you want to get. To create graceful and even curves, use the capabilities of a blowtorch, which softens the material and makes it pliable to bend. To do this, it is enough to act with the lamp on the required area.

Useful advice! Be sure to fill the profile with sand before starting the folding procedure.

The filled bending pipes must be placed on the machine by placing them between the stop and the center lug. Then you can get to work. The pipe bending process is carried out manually.

Do-it-yourself shop from a profile pipe: photo and process of creation

Looking for interesting ideas on the Internet, you can notice that do-it-yourself benches and metal garden benches, drawings and photos of which are posted on the network, are mostly made on the basis of shaped pipes. This type of material is presented on the market in a wide variety of shapes and sizes, making it much easier and more pleasant to work on a structure for a holiday in the country.

Profile pipes can have a cross-section of various shapes:

- rectangle;

- oval;

- square;

- rhombus.

Manufacturers use low-alloy or carbon steel as raw materials for the manufacture of shaped pipes. This type of product is intended for civil and industrial construction, so the pipes can be safely used when arranging a summer cottage.

Benefits of benches made of profiled tubes:

- increased strength characteristics (resistance to various types of impact, especially to physical loads);

- relatively low cost of material in the purchase;

- low weight of finished products;

- simplicity and ease of use.

DIY tools for benches and garden benches from a profile pipe

Regardless of the complexity of the design, you will need the same set of tools and consumables to create a bench or bench based on profiled pipes.

Useful advice! Use the profile to create other structures in your summer cottage.This type of material is suitable for the construction of gates, garden pavilions, fences, swings, vine arches, awnings and frames for creating a green fence.

Making a bench requires special tools for cutting and welding metal, drilling holes and sanding wood

In order to build a product from a metal profile, take care of the following consumables and tools:

- profiled pipes (diameter is selected on the basis of drawings and features of operation of the future structure);

- boards from which the seat and back will be made;

- welding machine;

- electrodes for the welding machine (3 mm);

- grinder (can be replaced with a hacksaw for metal surfaces);

- wheels for grinderintended for metal surfaces;

- drill;

- file (use of sanding paper is allowed);

- building level and meter or tape measure;

Preparation of materials for creating a structure without a back

In some photos of benches from a profile pipe with their own hands, there is no back. Such constructions are called benches.

Note! The bench is less comfortable than the bench, which allows you to lean on the back while sitting. Such products have a simpler structure and manufacturing technology, so they are easier to make. By installing a bench against the wall, for example, in a gazebo or near the house, you can solve the problem of the lack of a back.

The structure consists of 3 metal rectangles connected by a pair of pipes. These pipes form the bench seat.

Dimensional parameters of parts:

| Material | Quantity, pcs. | Dimensional parameters, cm |

| Square profile or rectangular (total number of profile) | 1 | 3 × 3 (section) 11000 (length) |

| Trumpet | 6 | 60 (length) |

| Trumpet | 6 | 45 (length) |

| Trumpet | 2 | 230 (length) |

| Rectangular wood block | 8 | 6 (width) |

In addition, you need a set of fasteners, consisting of bolts (24 pcs.) And the same number of nuts for them.

Related article:

Do-it-yourself wood bench for a personal plot. Interesting ideas to use to create wood products. Bench designs from scrap materials.

This design is so simple in execution that it will be enough for you to use a photo to create a bench from a profile pipe with your own hands, drawings are not needed for this.

Do-it-yourself technology for creating a garden bench from a profile pipe without a back

The principle of manufacture is that 3 rectangles are formed from pipe sections, which are connected to each other using guides. By installing these rails, a seat frame is formed.

Recommendations for work:

- features of the placement of pipe sections: long profiles are located horizontally, and short ones have a vertical position;

- the angles between the profiles forming the supports are 90 °;

- after welding, the seams should be processed (these places are cleaned with a grinder or file);

- treated seams must be covered with a primer;

Note! If desired, the length and width of the product can be increased. For this, additional supports will need to be added to the structure.

- after fixing the support part, 8 symmetrically located holes must be made in each element. They are designed to fix the seat boards;

- the frame part of the bench must be treated with a paint composition intended for metal surfaces. It will protect the material from rust;

- for impregnating wooden boards, use stain the shade you like;

- installation of the seat boards to the frame part is carried out at the very last turn, when the stain and the coloring composition are fully dry;

Creating a bench from a shaped pipe. Step 3: installation of forged elements; grinding of welded seams; painting the metal frame and wooden beams

- if the need arises, it is allowed to replace the wooden slats with rectangular pipes. With such a replacement, the seat profiles are welded to the frame with a welding machine, after which the structure is completely painted;

- to hide the sharp end part, you can place the slats inside the metal frame. To do this, you will need to additionally purchase another 120 cm of the profile;

- during rain or other precipitation, it is recommended to hide the structure under a canopy. If it has a stationary type of placement, you can build a canopy over the product itself.

Creating a bench from a shaped pipe. Step 4: using self-tapping screws, we fix the bars on the frame, close the legs with plastic plugs

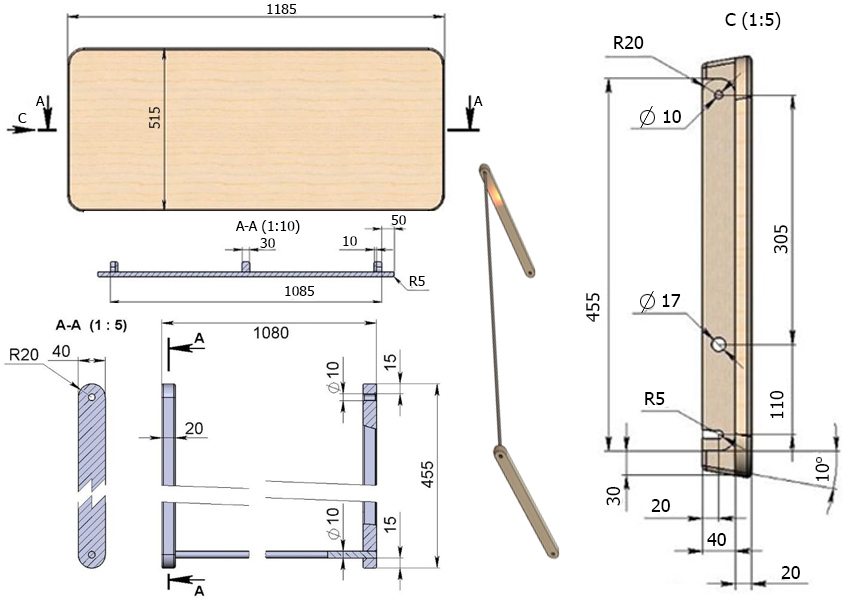

Drawings of a do-it-yourself transformer bench: dimensions and features of creation

Some benches have an extended range of functions and a complex structure. As a rule, they are made of wood and such products can be transformed from bench with back into a comfortable table with two benches.

Useful advice! You can create a similar structure using a profile based on the diagrams of wooden transforming benches, because the drawings of metal benches with your own hands are practically the same.

With the help of transforming benches, you can create a comfortable seating area in a small garden or on a small terrace. Use the dimensional data from the table to create a structure from metal profiles and timber.

Dimension chart for details:

| Item name | Dimensional parameters, cm |

| Connecting jumper | 2×2 |

| Position stop (length 3.5-4.9 cm) | 2×2 |

| Main pipe | 4×2 |

In addition, the structure uses support rods. They increase the level of structural rigidity.

Recommendations for creating a transformer structure

The frame is made of shaped tubes with thin walls and various cross-sectional sizes. The folded structure (bench) is large enough to accommodate 3 people on the seat. In the "table with benches" position, 3 people are seated on each side (the total number of those seated is 6).

- the assembly process is straightforward (even if you do not have the skills to handle a welding machine. Instead of fiddling with a saw, jigsaw and grinder when cutting out wooden elements, you just need to buy material and hire a welder, although you can do it yourself).

After the assembly of the metal frame is completed, as well as the protective treatment of metal and wood with the help of finishing compounds, the wooden elements of the seats and tabletops should be fixed, while leaving small gaps.Use self-tapping screws to fix the rails.

To make the structure mobile, it is enough to attach several wheels to it. This will allow you to move the bench to any place convenient for you.

Regardless of what type of construction you decide to make, shaped pipes reduce construction costs without compromising the appearance of the finished product.