Summer is a picnic season that cannot be imagined without kebabs and grilled vegetables. There are many ways to prepare food in nature, which requires a grill. You can buy a ready-made structure in a store or place an order in a workshop. But it is better to make a brazier from a gas cylinder with your own hands. So you can get an exclusive product that meets the stated requirements and personal preferences.

Content

- 1 Advantages and disadvantages of a grill from a cylinder

- 2 Brazier from a gas cylinder: construction options

- 3 Necessary tools and materials for making a do-it-yourself barbecue from a cylinder

- 4 Preparatory stage before disassembling the cylinder

- 5 The optimal size of the barbecue: performing the markup

- 6 How to make a brazier with your own hands from a balloon: a sequence of actions

- 7 Making legs for a barbecue from a gas cylinder with your own hands

- 8 Barbecue painting from a propane cylinder

- 9 Brazier from a gas cylinder: photo of product varieties

- 10 How to make a brazier from car disks

- 11 How to make a barbecue from a barrel and pipe

- 12 Making a barbecue, grill, barbecue, smokehouse with your own hands from a gas cylinder: video instruction

Advantages and disadvantages of a grill from a cylinder

Braziers are made from propane or oxygen cylinders of high quality metal. They are characterized by solid standard dimensions, regular geometric shape, good capacity, and the ability to arrange a large number of skewers. The height of the structure can be adjusted to the owner's height, which cannot be obtained from factory models. This will enable the person not to bend when cooking meat, but to stand upright.

Experienced craftsmen can, using their own imagination, using welding, fittings and metal, create unusual products that will become an original decoration of the exterior of a country house or summer cottage, which is clearly demonstrated by photos of barbecues from a cylinder.

The design of such a product is easy to manufacture. It is enough to carefully study the drawing of the barbecue with your own hands from a cylinder and, if you have minimal skills, create a structure. This option is the most budgetary. After all, the product is made from an old unusable cylinder, so the design basis will be free. You can estimate how much a brazier made with your own hands costs based on the cost of additional constituent elements of the structure.

Since the gas cylinder has thick walls, the finished structure will be able to withstand high pressure and high temperature without the risk of deformation of the product. Therefore, the service life of the barbecue increases.In addition, the bottom does not burn out after prolonged contact with an open fire, which means that after cooking there is no need to fill the product with water. If you make a brazier with a hinged lid, you can leave it outside without fear of the negative effects of precipitation. In addition, a brazier with a lid can be used as a home smokehouse.

The structure can be completed with additional elements, which will increase its functionality. The brazier from the cylinder is easily transported and installed to another place.

The disadvantages are the following:

- due to its large dimensions, the structure may not fit into the interior of a small courtyard;

- the brazier has a significant weight, so two people will need to move it;

- the structure has a limited space for logs, therefore, it is better to use coal as a raw material.

This will make it possible not to wait too long for the wood to burn out and there will be enough space for placing the skewers.

Brazier from a gas cylinder: construction options

Several options for barbecues can be made from an old gas cylinder:

- traditional design without and with a lid;

- B-B-Q;

- smoker;

- smokehouse.

The last three varieties differ from the classic type of barbecue. The barbecue is represented by a simple design, consisting of a part of a container, inside which there is a grid for placing products and an area for charcoal. The cut off part of the balloon will act as a lid and will be hinged.

The smokehouse has a firebox. In order for the structure to cope with the task at hand, it must be airtight. For this, half of the bottom of the product is removed. The firebox is made of metal sheets and welded to the main structure. A chimney is attached to it by welding, which helps to remove smoke from the smokehouse. After the construction is finished, it should be heated several times with wood and only then start smoking.

Helpful advice! For the manufacture of the firebox, you can use another cylinder.

The smoker, which is also called a steam locomotive, is the most complex and multifunctional structure. To manufacture the structure, you will need several cylinders, each of which will perform its own function. This device combines the capabilities of a barbecue, barbecue, smokehouse and grill.

Necessary tools and materials for making a do-it-yourself barbecue from a cylinder

The design is based on a gas cylinder measuring 96 cm in length, 30 cm in width, with a volume of 50 liters. You can also create a brazier from a similar product of 80 liters, with an increased diameter, which contributes to increased comfort during lighting. Such a product is characterized by good capacity, allowing the use of the full length of standard skewers. This greatly facilitates the process of preparing barbecue for a large company.

There should be no external damage on the structure, contributing to the formation of small foci of corrosion, which, under the influence of open fire and high temperatures, will turn into holes. After a while, such a fate will befall the entire structure. Even if the grill is covered with heat-resistant paint, all defects will be found. Holes can be welded, but this will ruin the appearance of the product.

Helpful advice! To create a small mobile barbecue, you can use a traditional 27 liter cylinder.

Before making a brazier with your own hands, you should prepare the following materials and tools:

- electric drill with metal drills;

- welding machine;

- clamps for fixing metal components;

- pipe wrench;

- grinder;

- a hammer;

- chisel;

- screwdrivers;

- electrodes with a diameter of 4 mm;

- stripping and cutting wheels for grinder;

- scribe;

- drill brush attachment;

- sprayer or brush for further coloring the product;

- metal pipe with a diameter of 100 mm for the chimney;

- knee radius 900;

- door hinges;

- metal corner;

- metal handles that will be attached to the lid;

- barbecue grill;

- fasteners in the form of nuts, rivets, bolts;

- priming;

- paint;

- solvents;

- various decorative elements.

Preparatory stage before disassembling the cylinder

Before making the right brazier, you should prepare the balloon. It is necessary to remove gas residues from it by unscrewing the valve with an adjustable water wrench and a steel pipe used as a lever. It is quite problematic to remove the fitting on the cylinder, since it is securely soldered to the body. To prevent the container from turning, a stop angle should be attached to its bottom.

At the junction of the valve with the body, you can apply a "Vedashka" and wait a few hours until the thread loses off. This procedure should only be carried out outdoors, away from potential fire sources and other areas where fire could occur.

Helpful advice! To make sure the bottle is empty, soak the valve with soapy water. If it is bubbling, then the gas is still coming out.

After completely emptying the cylinder, it is recommended to turn it upside down so that all accumulated condensate will drain out. Further, the container is filled with water, which helps to displace all vapors and residues. For this, the water supply hose is connected to the place where the tap is installed. Water should be supplied under low pressure. This simple operation helps to prevent dangerous situations associated with disassembling the product. The tap is put in place, and the structure remains in this state for 2-3 days to remove all odors.

The optimal size of the barbecue: performing the markup

While the water is in the cylinder, marking is performed according to a previously developed drawing of a barbecue from a gas cylinder with the indicated dimensions. Usually, for the barbecue, a product with a volume of 50 liters with an outer diameter of 96 cm is used. The dimensions of the barbecue from a gas cylinder: length - 98 cm, width - 30 cm, height excluding legs - 30 cm. This design is enough to prepare six servings of barbecue.

It is convenient to mark out from the longitudinal seam. The diameter of the gas cylinder is divided into four equal parts - 24 cm each. From the seam, this value is deposited in both directions. To the right and left of the circular seams, 3 cm recede, and marks are placed every 8 cm.Thus, 6 marks are obtained for future placement of skewers. Holes with a diameter of 1 cm are drilled in them.

Helpful advice! Despite the fact that a brazier from a cylinder is a simple product, at the initial stage you should make a small drawing of a brazier from a gas cylinder with dimensions and an indication of the places of attachment of individual elements.

From the line on which the marking was carried out, 10 cm is laid up, i.e. from the middle of the seam it turns out 34 cm. At this point, the barbecue cover will end, which is marked in the next step. It takes the distance between the first drawn line and the one just marked. A straight line is drawn between them, stepping back 3 cm from the circular welds. Also, from the initial marked strip, they are moved 10 cm down for the future fastening of the legs, which should be placed parallel to each other.

Helpful advice! If there are metal rings inside the product, the cut should be made in such a way as not to damage them. In the future, they can become a cover support.

How to make a brazier with your own hands from a balloon: a sequence of actions

On the basis of the markings made, the product is cut. You can study the process in detail on the video "Brazier from a gas cylinder with your own hands." To do this, it is recommended to use a grinder or gas cutter. The cut should start from the middle and work towards one of the edges. The grinder disk must be held perpendicular to the cylinder. Since the product has a large wall thickness and the cutting process takes place at a high intensity, in order to avoid premature disc burning, it is recommended to cut in some places not completely. Such areas can then be eaten away with a chisel.

Related article:

Brick brazier: interesting design solutions and manufacturing technologies

Features and types of designs, interesting design options and photos, popular projects with drawings and a step-by-step description of manufacturing technology.

When cutting the balloon, it is necessary not to reach the circular seams by 3 cm. Having made a cut along one line, the loops should be welded. If you cut off the cover completely, the action will be more difficult, since the cover will have to be fixed at the same distance, which will be inconvenient to do alone.

To fasten the hinges, the seats must be cleaned and sanded. The elements are riveted and welded. Next, proceed to the installation of fasteners. After that, the cylinder is cut along the lines. In this case, the cover will rotate but not fall. At this stage, the water from the cylinder can be drained. It is recommended to do this away from residential areas, since methane has a pungent odor that lasts for several days.

When making a removable cover, you should take care that it does not fall inside. For this, metal strips are welded to the transverse edges of the product.

To prevent the lid from breaking the hinges in the open position, leaning back, along the cut line, it is required to weld a piece of the corner between the hinges. Its width can be 3-4 cm. Such stops are made on both sides of the cover - left and right. By unbending the corners, the distance required to open the lid is adjusted. It is selected in such a way that when closing this element it is not necessary to bend forward to reach the handle.

How to make a brazier from a gas cylinder: handles and openings for oxygen access

The next step is to weld on the handle. It can be of any kind and be made of various available materials that are resistant to heat. The most primitive option is to weld a piece of concave reinforcement properly. In this case, it is advisable to attach a piece of wood to it so that you can grab the handle. Such a part can be attached to the product using bolts.

To prevent the lid from falling inside, it is necessary to weld from the inside to the cutout around the entire perimeter of the product a metal strip 2-3 mm thick and 3-3.5 cm wide.On the previously applied marks for holes for skewers, holes with a diameter of at least 1 cm are drilled. products (opposite each of the holes), cuts are made to the welded plate, which are necessary for installing skewers.

The next step is to make slots for air intake to the bottom of the product. This must be done because the structure is closed. This means that coal and wood will burn badly in it without oxygen. To do this, the grill should be turned upside down. From the seam, 10 cm is deposited in both directions. A distance of 10-12 cm is measured from the resulting lines.Thus, longitudinal stripes of a given width are obtained. Slices are made across the strip every 5-7 cm for air intake. The strips can be replaced with holes, but a large number of them will be required, which will take a lot of time.

It is not recommended to make holes in the bottom of the cylinder. Firstly, the factory seam should not be touched - this can lead to a decrease in the rigidity of the structure. Secondly, at the bottom, any holes are clogged with grease mixed with ash and ash. In the future, such a mixture can clog the holes and impair air flow.

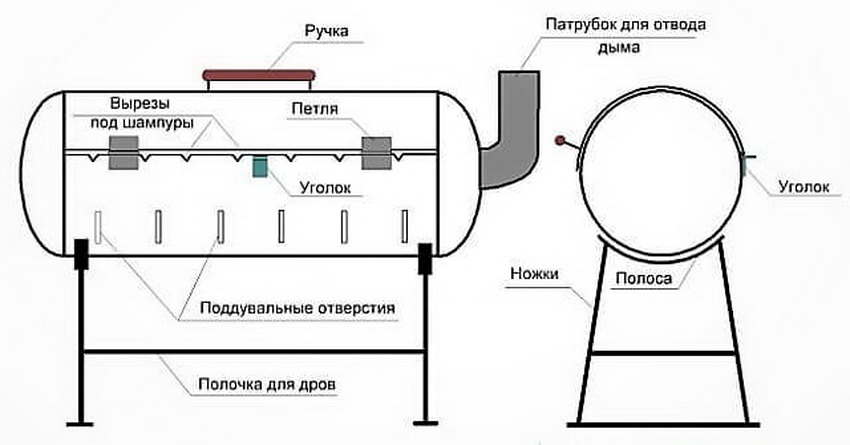

The final step is to cut the tap and weld the resulting hole. Also in this place, you can provide a metal pipe for removing smoke and airing the barbecue in a closed state. The brazier is ready, it remains to attach legs to it. You can see all the stages in detail on the photo selection "How to cook a brazier".

Making legs for a barbecue from a gas cylinder with your own hands

Do-it-yourself legs for a barbecue from a gas cylinder - the photo clearly confirms this - can be made from any material: fittings, a profile or round pipe, a strip of thick metal. The corners or pipes are sawn into four pieces about 50-70 cm long. The elements are welded to the body in previously marked places at the same distance from each other so that they form a rectangle of the correct shape.

At the ends of the support legs, it is necessary to weld square metal plates, thanks to which the brazier will be more stable on the surface. You can also use two metal profiles connected parallel to the other two legs at the bottom of the product.

When making legs from sheet metal, two strips 40 cm long and 20 cm wide should be cut. The ribbons are bent in the form of an arc along the diameter of the product. Legs are welded to their ends. Further, to create the necessary rigidity and strength, a transverse bar is attached to each pair of legs at the bottom. A corner with a length corresponding to the value of the product is welded between the two posts.

A popular and simple option for legs is a sewing machine design. The brazier can be installed on wheels, which will make it easy to move it around the yard.

If you use a profile pipe for the legs, they will look like an inverted "T", and they can also be welded to the middle of the product. You can make a support in the form of a frame with a shelf at the bottom for placing firewood, coal, bowls, etc.

A homemade brazier can be made in the form of an animal, a rocket or any other object - it all depends on the creative imagination of the author

A good option is to make legs from rebar and round pipe. In this case, you can get a portable design. Pieces of pipes of the required diameter are welded to the body of the barbecue, into which reinforcement bars of the required length are inserted. You can, on the contrary, weld pieces of reinforcement and stick pieces of pipes of a suitable diameter on them. However, it should be noted that when the barbecue moves, the legs may fall out. Therefore, it is recommended to cut threads for them. The manufacture of various support options can be studied in the video "Brazier from a gas cylinder: manufacturing of support structures".

Barbecue painting from a propane cylinder

To paint a barbecue, smokehouse, barbecue from a gas cylinder with your own hands, you should use heat-resistant paint, since the possible temperature in the barbecue can reach 800 0C. The painting should protect the metal from corrosion and temperature extremes when cold water hits the red-hot body. When heated, the coating should not emit elements harmful to human health and enter into a chemical reaction with other substances.

Before painting, the surface of the gas cylinder is cleaned of old paint. The procedure can be carried out using sandpaper or a special metal drill bit. Further, the entire surface is degreased with a solvent, acetone or alcohol and covered with a primer. The heat-resistant enamel should be mixed well before application until a homogeneous state is obtained. All clots and sediment must be removed from it. If the consistency is too thick, the paint is diluted with a small amount of solvent.

The paint is applied with a spray or a brush in several layers until a smooth and beautiful surface is obtained. Each coat must dry completely before applying the next one. The ambient temperature must be above 20 ° C.

The most popular heat-resistant paints are acrylic mixtures in spray cans. With a unique composition, they are safe, effective, quick-drying and durable. Also, the paint is characterized by anti-corrosion properties. It is sprayed at a distance of 20 cm and applied in several layers, each of which dries within 2 hours. The palette of shades is quite wide, but the most popular are silver and black.

Brazier from a gas cylinder: photo of product varieties

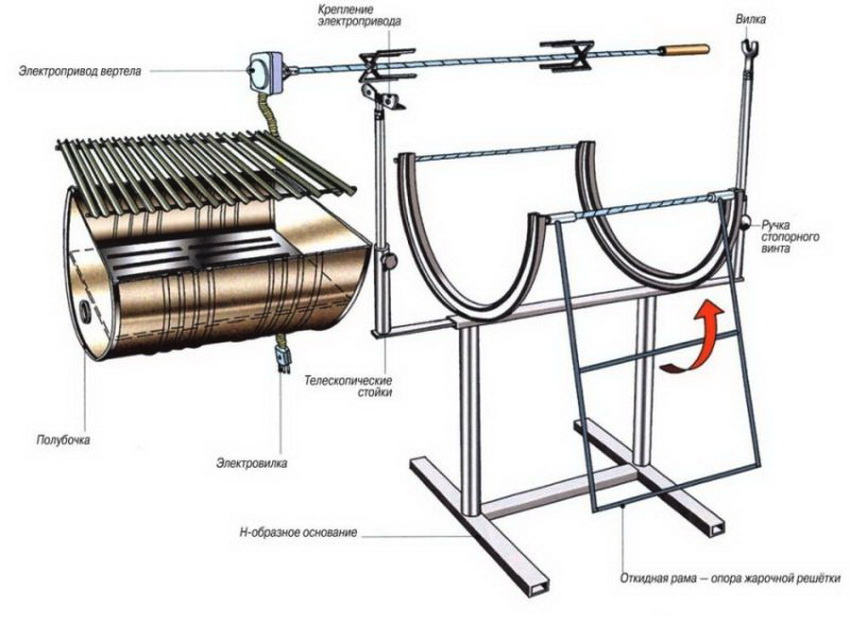

Using the instructions for making a barbecue with your own hands from a gas cylinder, which can be bought ready-made from experienced craftsmen, it is easy to make a barbecue. For this, a corner is welded along the long side of the product body. The result is a shelf on which a lattice welded from reinforcement rods will be located. A convenient option would be to divide the areas in the barbecue grill with a net and places for skewers. You can also create a stationary brazier. For this, small tables from the corners are welded on the sides and in front of the structure.

Another design option from a balloon is to create a brazier-smokehouse with your own hands. This device contains an additional element in the form of a firebox. To create it, strips are cut from the bottom of the cylinder, then half of the bottom is cut out. Thus, a place is obtained for organizing the furnace, which is made of dense metal sheets with a thickness of 2-3 mm and is welded to the bottom. The result is a one-piece sealed structure, which is clearly shown in the photo of the smokehouse.

It is also necessary to organize a chimney here. It can be purchased at a hardware store or made from a smaller diameter gas cylinder. It is recommended to improve the design and install a motor that will rotate the skewer with meat, which can be seen on the video "Brazier-smokehouse with your own hands from a gas cylinder". Drawings, photos of which there are a large number of the Internet, will also help to complete the structure and get a multifunctional structure.

It is recommended to start the smoking process after calcining the barbecue and destroying the smell of gasoline. Otherwise, the finished food will smell bad.

Another unique building is a steam locomotive. The design is made from several cylinders of different diameters, barrels and main pipes. Such a product combines a brazier, smokehouse, barbecue and grill do it yourself. The structure is complemented by forged elements that give the structure an original and aesthetic appearance.

Using imagination and a creative creative approach, you can make a brazier in the form of a pig, a dog, a house and even a submarine, which is clearly demonstrated by photos of braziers from a gas cylinder with your own hands.

How to make a brazier from car disks

The brazier from car disks combines a barbecue, a smokehouse, a hob and a grill from a gas cylinder. The metal structure can be made from old rims from a car. Take those that are made of solid steel, and not of aluminum alloy.

Brazier from car disks is made in various ways. For the simplest design, one element is sufficient. The inner part is cut out of it, forming a container similar to a kettle. If there are too large holes in the bottom, a metal plate must be provided. However, the openings should not be completely covered as the coals must be blown through to maintain the heat. On the sides of the bottom, you need to weld the legs from the pipe.

On such a grill, you can fry not only a kebab strung on a skewer, but also prepare a barbecue. For this, the structure should be covered with a metal grill. It would be more appropriate to make it removable. For the convenience of moving the barbecue, handles are welded symmetrically on the sides of the structure. To maintain the heat, a window can be made on the side of the disc.

To cook a brazier of a more complex design, you will need two discs of the same size. On one of them, a partition is cut with a gas cutter. The elements are placed on top of each other and welded around the perimeter. The baffle of the second disc is the bottom for the first. It will be convenient to place a bowler hat here. In the side of the lower disc there is a window for throwing firewood.

To get a ready-made barbecue, it is enough to paint the disc, weld a couple of legs and install the grate

Another noteworthy option is to weld two elements together with a pre-cut middle. In the side of the structure, a window is made through which firewood is fed into the firebox. The upper part of the structure is equipped with a grill that turns the grill into a barbecue.

How to make a barbecue from a barrel and pipe

To create a barbecue from a barrel, you need a container with a volume of 50-60 liters with a diameter of 40-50 cm. The product must have a wall with a thickness of 2-3 mm. You can create two grills from a barrel. For this, the product should be cut in half.

The manufacturing process of the structure is similar to the creation of a grill-smokehouse from a gas cylinder. Only the dimensions of the product will differ, on the basis of which the markings are made for future cutting. However, at the preparatory stage, you do not need to fill the container with water. In the side part, cut a round hole on top for the chimney, and below for ventilation.

A good solution is also to use another barrel mounted on the side cover as a pedestal, where a full-fledged smokehouse is organized. To create a structure, you can use the drawings found on the Internet.

Helpful advice! A 27L gas can can be attached next to the barrel, which can be used as a storage location for coal.

The design is quite often made of a metal pipe. This is a more time consuming option that requires the use of additional material. A metal sheet is used to create the walls of the structure. If a smoke evacuation pipe is provided, its diameter should be 70-100 mm.

Important! For the barbecue, you should not use a barrel of fuels and lubricants. The specific smell cannot be eliminated by anything.

Today you can buy a ready-made grill from a gas cylinder, the price of which is on average 5,000 rubles. However, a homemade design is even cheaper and can last for many years with proper use and proper care.Equipping the grill from a gas cylinder with additional elements, which can be bought in specialized stores, you will receive a multifunctional facility for smoking, grilling and barbecue. A creative approach to the design of the product will allow you to create an original design that can decorate the site.

Making a barbecue, grill, barbecue, smokehouse with your own hands from a gas cylinder: video instruction