Smoked products are a real delicacy. After such processing, meat and fish not only acquire a unique taste, but also extend their shelf life. Devices that allow you to get smoked meats at home are quite expensive. In this case, there is a way out - do it yourself smokehouse. In order to assemble such a device, you first need to familiarize yourself with the principles of its operation and the nuances of food processing.

It is possible to significantly expand the family's diet with high-quality products by building a stationary or portable smokehouse on the personal plot

Content

- 1 What are the options for smoking in home smokehouses?

- 2 DIY cold smokehouse: design features

- 3 How to make a hot smokehouse at home: differences from a cold unit

- 4 How to make a brick smokehouse at home?

- 5 How to make a portable smokehouse from the refrigerator

- 6 Smokehouse from a barrel: the easiest and most affordable option

- 7 Do-it-yourself smokehouse from a gas cylinder

- 8 Do-it-yourself smokehouse: a hiking variety

- 9 How to make a do-it-yourself smokehouse with barbecue?

What are the options for smoking in home smokehouses?

The most refined taste is acquired by products that have been prepared using the cold smoking method. The temperature range in this case varies from 30 to 50 ° C. Of course, such a slight effect is reflected in the duration of the preparation of smoked products. For example, small fish are smoked in this way for 6-7 hours on average. And it can take 2-3 days to cook massive meat products.

The length of this process is its main disadvantage. It should also be said that the products need careful preparation before starting smoking, which can also take from 1-2 hours to 2 days.

The shelf life of products prepared in a homemade cold smoker may vary. However, such processing has a significant impact on this indicator. For example, smoked chicken legs retain their flavor and do not spoil for up to one year in a cool, dry place. It should be said right away that it is not recommended to store such a food in the refrigerator, since in this case it deteriorates very quickly (in about 1 month).

Note! When smoking products, they are placed above the smoke source on a steel wire.

Another common way to get smoked food is hot smoking. The main difference with this method is the temperature required for this process, which can reach 120 ° C.The minimum value in this case is 70 ° C. A hot smokehouse for home allows you to get a delicacy in a completely acceptable period of time (from 15 minutes to 4 hours). Another advantage of this method is that the product does not need to be pre-processed.

Cold smoking prolongs the shelf life of products, but the process of making such a smokehouse is more complicated.

The disadvantage of the hot method is that the products obtained by this method do not have such a refined taste as meat and fish processed at a lower temperature. Their shelf life also cannot be compared with the shelf life of smoked meats obtained by the previous method, and is only about 32-36 hours.

Today there is another method of smoking - semi-hot. In this case, the cooking process is carried out at a temperature of 60-70 ° C. To put this method into practice, it is enough to make a homemade smokehouse with your own hands.

The taste of the product that has undergone this cooking procedure, as well as its shelf life, coincide with food cooked in a hot smokehouse. Most often, this method is used by hunters and fishermen.

DIY cold smokehouse: design features

The device, which allows you to cook a variety of foods in a cold way, includes a long pipe. This design feature makes the food less harmful, since the gases passing through the tube have time to completely burn out. As a result, the carcinogens contained in the smoke are deposited on the walls of the long pipe without harming food.

A cold-smoked smokehouse consists of three main blocks: a firebox, a smoking chamber and a chimney connecting them

Cold processed meat has a long shelf life. On average, it is stored for 2 months. This indicator depends on what kind of meat was cooked, on its volume, etc. Home-made smokehouses are conventionally divided into three parts:

- firebox;

- smoking chamber;

- chimney.

Photos of this type of smokehouse will help you understand its design faster. Various materials can be used to build a firebox. For these purposes, bricks, concrete blocks and galvanized steel sheets are excellent. An ash pan should be located in this tank.

Helpful information! A prerequisite for such a bunker is the ease of cleaning from ash. Some meat products have to be processed for several days, so the process of removing combustion products should be as simple as possible.

The cold smoking method is most commonly used in fish smokehouses. It is not so difficult to make such a unit with your own hands. All that is required for this is to have the necessary set of tools and follow the instructions.

It is important to remember that when wood chips or any other material are ignited, acrid smoke is emitted. To protect the product from it, you need to install a special shutter. In most cases, it is made in the form of a furnace bunker cover. It performs a very important demarcating function and can, depending on its position, regulate the direction of movement of the smoke.

How to make a cold type fish and meat smoker?

An old metal barrel is most often the basis for a homemade smokehouse of this type. Its design is ideal for cold smoking. But if desired, the camera can be made of almost any material that is suitable for the design. This is due to the low temperature inside the device, which does not require the organization of fire-resistant elements.

Experts do not advise constructing a smokehouse from materials that have a porous structure. They will absorb smoke and then moisture, leading to a build-up of foul-smelling sediment.The recommended material for the manufacture of the device is stainless steel. For this reason, the best option is to use a regular barrel. It is very simple to construct a smokehouse from it with your own hands.

In the bottom of the barrel, it is necessary to make a hole corresponding to the cross-sectional index of the chimney. Through it, the smoke necessary for the smoking procedure will enter the tank. At the top of the barrel, you need to place food holders. They can be made from simple metal rods or ordinary wire. And also popular is a metal mesh on which meat or fish is laid out.

The normal smoking process requires that the smoke be trapped inside the chamber. Experts recommend using burlap (wet) for this. In addition to retaining smoke, it will absorb excess moisture. Do-it-yourself lid for a smokehouse is organized in a similar way. Photos of finished designs will help you delve into this process faster.

One of the key points of self-assembly of a smokehouse is the arrangement of a chimney. It is also not recommended to assemble it from porous materials. It is advisable to purchase a metal pipe, however, when using it, you need to remember that it requires preventive cleaning, since it very quickly accumulates soot on the inner walls.

The best option is a chimney installed in the ground. But this design is most often disposable. That is why it is often used by hunters and fishermen.

Note! The size of the smokehouse must meet the needs of the owners. Therefore, it is recommended to determine in advance the number of products that will be processed in this design at a time.

For smoking food, you should not use wood chips or wood containing resin, that is, resinous tree species: pine and spruce. And also you can not use wood, which, when burned, emits tar (birch and maple). For smoking food, tree species such as oak, apple, cherry are best suited.

How to make a hot smokehouse at home: differences from a cold unit

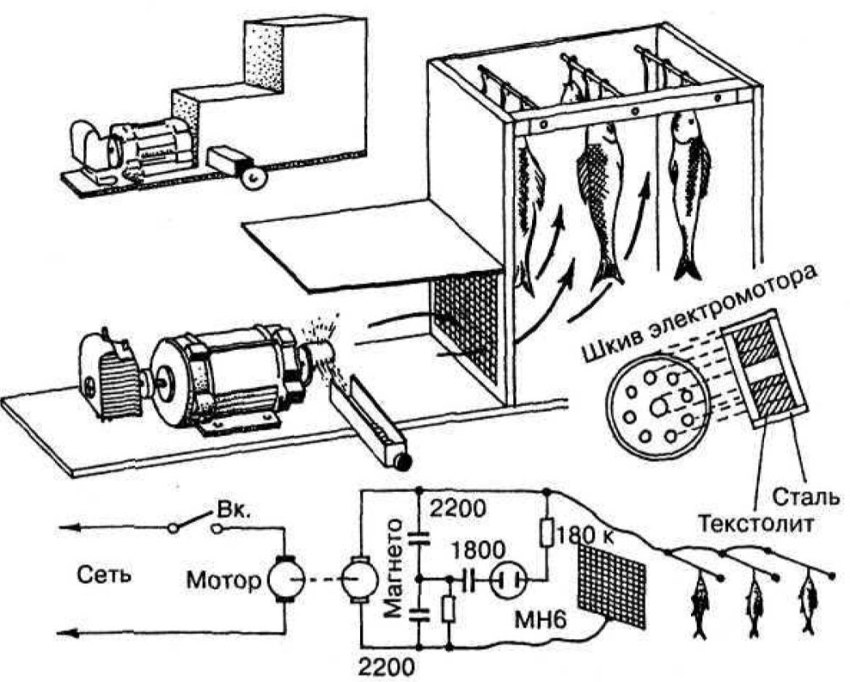

Hot smoking of fish and meat is a quick procedure that takes no more than 4 hours. In the case of processing small fish, this process can be carried out in just 15-20 minutes. The average smoke temperature during the preparation of smoked meats in this way is approximately 100 ºС. It is not customary to use wood to light a hot smokehouse, as wood chips are a more suitable fuel.

The use of wood chips is reflected in the design of such units. This device has its own characteristics. For example, the combustion tank in such structures is located directly below the chamber in which smoking is performed. Thus, there is no long smoke channel. This can be considered a plus, since it is easier to make a smokehouse of this type with your own hands.

Experts note that there is no need to carry out a firebox for wood. If desired, you can smoke food on gas or even an electric stove. It does not matter how the bottom of the barrel is heated (from below), but the temperature should be sufficient for the chips located at the bottom of the smokehouse to smolder.

It is important to note that the smoking tank must be completely sealed, otherwise the process will not be implemented correctly. Today you can find devices that include a lid equipped with a hydraulic seal. It is organized in the shape of the letter "P" and is located around the perimeter of the smoking tank. The odor trap should be slightly deepened and filled with water.This move allows you to solve two problems at once, providing protection from outside air and acting as a barrier for smoke.

Hot smoking is a fairly quick process, from 15 minutes to several hours, depending on the size of individual pieces of meat or fish

In this case, meat, fish and other products can be located at different levels. To do this, you need to prepare holders for them. These can be grates or standard rods. For convenience, it is recommended to equip the rods with hooks, which will allow the product to be strung on them. It will be useful to watch training videos. A do-it-yourself smokehouse is quite simple, but you still need to delve into the important nuances of its assembly.

And finally, another difference between such a smokehouse is that it must have a pallet. It is necessary to collect fat that will be released from food during cooking. The pallet is made in such a way that it is easy to remove and clean.

Note! It is important to remember that fish oil has a low combustion temperature. Therefore, when making a fish smokehouse with your own hands, it is recommended to equip the pallet with a discharge structure. It will remove the substance outside the chamber.

Hot smoking takes much less time, because the process takes place at smoke temperatures ranging from 50 ° C to 120 ° C

How to make a hot and semi-hot smokehouse yourself?

For a start, it is advisable to pay attention to the drawings of hot smokehouses. Such devices, as mentioned above, have some differences from cold smoking units. The most suitable material for a hot smokehouse is stainless steel. If you have an old metal barrel, then the assembly process is greatly simplified.

Dimensional structures made from a barrel are perfect for a summer cottage or a private house. But such smokehouses are stationary. To produce a mini-smokehouse with your own hands, you will need to independently assemble a small stainless steel chamber.

Related article:

Brick brazier: interesting design solutions and manufacturing technologies

Interesting design options and photos, popular projects with drawings and a step-by-step description of manufacturing technology.

The temperature in portable units most often corresponds to a semi-hot type of smoking. Such devices are made in the form of a box, which is equipped with a lid. The cooking process takes no more than 3-4 hours, and the storage time of the food is approximately 3 days.

In addition to a box with a lid, such a smoker includes a tray (for collecting fat) and special holders. The process of processing food is as follows: the reservoir is placed over a fire source and chips are poured onto its bottom. After a while, it will start to smolder and give off smoke. It is important to remember that the wall thickness of the box must be at least 1.5 mm. Otherwise, such a mobile smokehouse is deformed under the influence of high temperatures.

The choice of a hot or semi-hot type depends entirely on what you need such a device for. Therefore, it is recommended to focus on a specific situation.

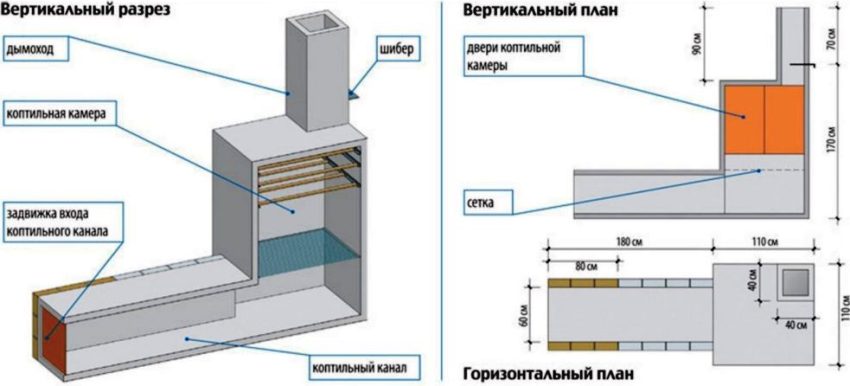

How to make a brick smokehouse at home?

The unit, made of brick material, can be classified as professional devices. Such a design requires the organization of the foundation, which affects the speed of its manufacture. It is stationary, it is impossible to move it from place to place, like more compact models.

The first thing to do before assembling a brick smoker is to draw up a sketch. It is worth immediately determining the type of future construction. For example, brick smokers are very popular. It is rather difficult to make them with your own hands, but you can still.

Ready-made drawings of brick structures can be easily found on the Internet. The stationary device for cooking smoked meats has the longest service life, which is its main advantage.

Note! It is important to note that ordinary brick is not suitable for assembling such a structure. In order to assemble a brick smokehouse with your own hands, you need to purchase a material that has refractory properties.

Refractory brick is the most acceptable material for the installation of stationary hot-type smoking structures. A very important point in this case is the selection of the place in which such a device will be located. In this case, one should be guided by fire safety rules. The distance from the smokehouse to any buildings (especially from flammable materials) must be at least 2 m.

Self-assembly of a stainless steel smokehouse

Outwardly, this unit is similar to a suitcase or box. In order to assemble a small steel structure, you need to familiarize yourself with the sketches of these devices. To assemble a smokehouse for an apartment or house of this type, it is not recommended to use sheets that are too thin (less than 1-1.5 mm).

You can take a small smokehouse for hunting, fishing, or just nature. The compactness of the device makes it easy to transport it from place to place. It is recommended to weld the corners inside the metal box, on which the grill can be placed. When drawing up a smokehouse scheme on your own, it is necessary to take into account all the small details and indicate them in the figure.

One of the main advantages of a stainless steel smoker is the low probability of carbon deposits on their inner surface.

This unit is one of the most common and is used everywhere. In this case, the hot type of smoking is most often used. However, there are similar models that process food at a lower temperature (semi-hot smoking). Such options are often suitable for use in the country. A semi-hot type smokehouse is usually portable.

The main disadvantage of a smokehouse made of metal is the inability to determine the temperature inside the chamber. This can cause the meat to bake and acquire an unpleasant aftertaste. This negative point is explained by the fact that this design does not provide for a single smoking technology. Chips from different tree species are used to ignite stainless steel units.

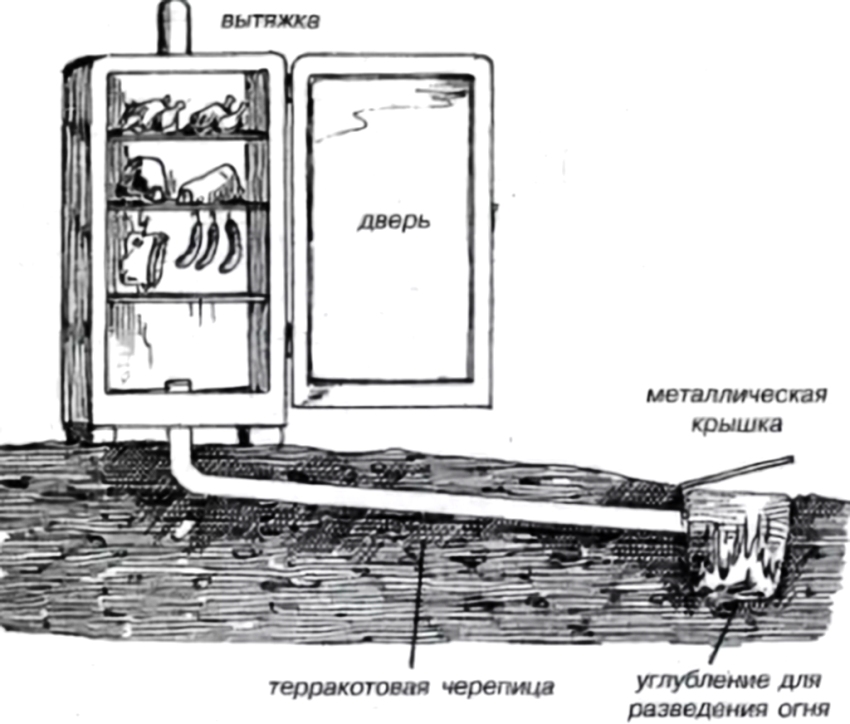

How to make a portable smokehouse from the refrigerator

A broken refrigerator in the country is most often adapted for a small cabinet in which tools and various parts are stored. However, there is a more useful use case for a non-working device. It can be used to make a small but very handy smoking chamber.

How to make a smokehouse at home from the refrigerator? In order to convert the refrigerator into a smokehouse, it is recommended to follow the instructions carefully. The first step is to free the device compartment from shelves and other elements. After removing the internal elements, a hole must be cut in the roof of the refrigerator. Its diameter should correspond to the size of the chimney that will be connected to this place.

Note! When assembling a smokehouse with your own hands from the refrigerator, you should pay attention to the photos showing the phased transformation of the device. This will allow you to more accurately understand the essence of the process.

In the next step, you will need to mount metal corners inside the chamber, on which holders for products will subsequently be installed. Experts recommend dividing the interior of the refrigerator into three parts. Then 3 pairs of corners are installed.The first and second pair will be used to hold the metal grates. The third is needed to fix the pallet in which fat and juice accumulate.

Further, a thick metal tray is installed at the bottom of the refrigerating chamber. It will be used as a substrate for wood fuel. It is important to remember that a detailed sketch should be drawn up before starting work. All dimensions should be noted in the smokehouse drawing. Lastly, an electric stove is installed on the floor of the chamber.

A prerequisite for self-assembly of a smokehouse from an old refrigerator is the tightness of the refrigerating chamber. If the door does not fit snugly against the body, then smoke will leak. This means that food cannot be cooked correctly.

Smokehouse from a barrel: the simplest and most affordable option

One of the easiest and most affordable ways to make a smokehouse at home involves using a metal barrel. It is desirable that its volume is at least 100 liters. There is a certain sequence of actions that you should pay attention to before self-assembly of a smokehouse from a barrel with your own hands.

First of all, you need to cut off the top cover. Further, the inner walls of the barrel are cleaned of dirt. A round hole is cut in the bottom of the product, to which the chimney is connected. The previously cut lid can be used as a pan for fat released from meat and fish during their processing. It is important that this element has a smaller diameter than the barrel. Otherwise, there will be a problem with the flow of smoke into the top of the homemade smoker.

To fasten the gratings, you can make loops or screw self-tapping screws into the walls of the barrel

Then you need to make food holders and install them on top of the barrel. For these purposes, you can use any suitable lattice, metal mesh or pieces of reinforcement equipped with hooks. In order to answer the question of how to make a smokehouse from a barrel with your own hands, you should familiarize yourself with the illustrated sequence of actions. This will visually assess the simplicity and advantages of this method.

Welding equipment is required to securely fix the pallet. With the help of welding, it is necessary to weld pieces of metal reinforcement to the walls of the barrel. This procedure is carried out in such a way that these segments intersect in the center of the barrel and form a cross. In turn, the fixation of the grilles is performed by means of metal corners. There is another option (the simplest) - the use of self-tapping screws.

To understand the essence of the process, it is recommended to study the drawings of the smokehouse with your own hands. Photos will also help you quickly understand how to proceed at each stage.

The last phase in the manufacture of the smokehouse is the installation of the lid. It can be made from burlap or wood. The second method requires the organization of holes that will be used to remove excess moisture from the tank. Deciduous trees are best suited for the lid of the smokehouse.

Do-it-yourself smokehouse from a gas cylinder

If you have an old gas cylinder, then it can be adapted for a homemade smokehouse. The transformation process seems complex, but it is quite feasible if you follow the instructions clearly and do not deviate from it. Before starting work, you should definitely check the cylinder. He must be completely emptied. If there is a small amount of gas, it must be removed from the cylinder. It is recommended to perform this operation away from residential buildings.

Note! You can check the cylinder for the presence of gas using soapy foam.If soap bubbles do not form at the outlet when the valve is open, then it is safe to say that the bottle is empty.

How to make a smokehouse for meat and fish from a gas cylinder? After emptying the chamber, it is necessary to drain the remaining gasoline from it and burn them in a metal container. Next, the balloon needs to be rinsed. To do this, fill it with plain water. It is recommended to repeat the procedure several times.

Then you can proceed to the direct manufacture of the smokehouse. First, you need to cut a door in the cylinder. The flap should be large enough (for easy loading of food). Then you need to fix the resulting door. For this, loops are used, which are fixed to the body of the cylinder using welding equipment. It should be noted that the solder spots should be cleaned before welding.

Before starting to cut the smokehouse, it is necessary to release gas from the cylinder, and also rinse it well with water

A smoking unit of this type is installed on a special stand. In order to combine the firebox with the reservoir, it is required to remove half of the bottom of the vessel. The firebox itself is made of thick stainless steel sheets. Thin-walled metal is not suitable for making a smokehouse from a gas cylinder with your own hands. It is recommended to watch the video, which demonstrates in detail each action, before starting the assembly of the device.

After assembling the firebox, you can proceed to the next stage. The firebox will need to be welded to the bottom of the cylinder. This is how the smokehouse is assembled from a gas tank. It is important to remember that before using such a homemade device for the first time, you must fire it with wood.

Do-it-yourself smokehouse: hiking variety

As mentioned earlier, the best option is a smoker equipped in the soil. It has a very simple design and allows you to smoke food without harming it. Unlike reusable devices made of bricks or metal, such a smokehouse absorbs all the carcinogens contained in the smoke. It is possible to organize such a smokehouse at home, but this solution is not always advisable.

Helpful information! The walls of the chimney dug in the soil absorb not only harmful substances, but also excess moisture.

Thus, this natural smokehouse is almost the best option for preparing smoked dishes that are delicious to taste. But such a smokehouse has one big drawback: it is not suitable for reusable use. It is used by hunters, fishermen and hikers on hikes (hence the name).

How to make a travel type smokehouse yourself? The process of its arrangement is quite simple. First of all, you need to find a suitable area of the terrain. It should be a small slope. At the bottom of the slope, a small area is excavated for the firebox, and a groove of the required size is made at the top. Both holes are connected by a channel made in the soil.

A smokehouse is placed on top of such a groove. It can have a different device, but, as a rule, it is a metal box that is convenient to transport from place to place.

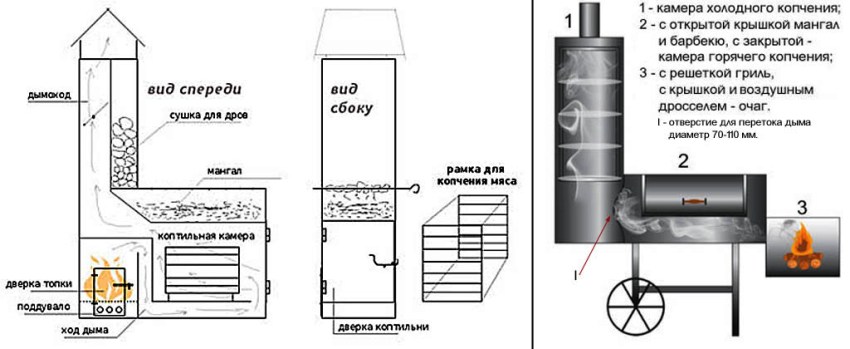

How to make a smokehouse with your own hands with barbecue?

A rather unusual solution is the organization of a smokehouse with barbecue. To do this, you will need to purchase a brazier or assemble it yourself, as well as find an old metal barrel. Most often, such a design is made portable, so it must be equipped with removable legs. All connections are made quite simply - using ordinary bolts.

There is another option - making a brazier-smokehouse made of bricks with your own hands. But such a unit is quite difficult to assemble on your own. It requires the organization of the foundation and certain building skills.

It is important to prefabricate all the individual elements of such a device. Among them are the following: lid, door, grate or holders, and a tray (for fat). The simplest technology for making a smoker-barbecue will seem simple even for those who do not have any construction skills. If you have an old gas cylinder, then you can also make a brazier-smokehouse from it yourself. An equally efficient unit is obtained from a gas cylinder.

First of all, you need to cut the door in the barrel. For this, a grinder is used. Then the resulting sash is fixed in the appropriate place on the hinge. At the next stage, the tank must be placed on top of the barbecue and fixed in order to exclude the possibility of movement. Before starting work, you should study the drawings of the smokehouses. It is very simple to make an assembly of this type with your own hands, but you need to understand the essence of the process.

Next, the grill or food holders are installed. They are fixed at the top of the barrel with metal corners. Fuel (wood chips) are poured into the bottom of the barrel. Thus, you can easily make your own smokehouse in a minimum period of time.

To make a high-quality grill-smokehouse, you need to pick up sheets of metal, no more than 2 mm thick

Currently, there are many options for self-made smoking chambers. The choice of design depends on what tools and materials you have. It is recommended that the assembly work of this unit be carried out following the instructions. Before starting production, be sure to study the video and photographic materials on this topic.