Natural wood is an environmentally friendly, strong, reliable and durable material that will never lose its popularity and demand. Various structures, pieces of furniture, elements of fencing and decor can be erected from wood. One of these interesting buildings is a log gazebo. Such a massive and presentable element will become a real decoration of any country house or suburban area.

Content

- 1 What is special about a log gazebo: characteristics of the structure

- 2 Positive and negative sides of a chopped arbor

- 3 Constructive varieties of log gazebos

- 4 The process of erecting a gazebo from logs with your own hands

- 5 Frequently made mistakes when erecting a gazebo from a log house with your own hands

What is special about a log gazebo: characteristics of the structure

The gazebo, which is often located on a suburban area, has a simple and cozy design. It can comfortably accommodate all family members and guests for a joint pastime. As a rule, the structure has a roof, which provides reliable protection of the internal space from precipitation and ultraviolet rays.

Various materials can be used to make a gazebo. It can be art forging, metal painted in any color or natural wood. The last option deserves special attention. The structure made of natural logs looks massive, original, distinctive, harmoniously fits into the general concept of the site, which is clearly shown in the photo of the arbors from the log house.

Useful advice! A log gazebo can be decorated with carved elements, thanks to which the structure turns into a unique, fabulous structure.

A log gazebo (photo is a clear confirmation of this) can have any modification. The structure is rounded, made in the form of a rectangle, square, rhombus or polygon with obtuse corners, which is determined by the personal preferences of the owner. A log gazebo is characterized by strengths and weaknesses, which should be familiarized with in advance - before the construction of the structure.

For the manufacture of such arbors, in addition to logs, a variety of materials can be used, for example, metal or glass.

Positive and negative sides of a chopped arbor

The round timber gazebo has an attractive and distinctive appearance. This design is in harmony with the general setting of the suburban area, demonstrating unity with nature. The structure is able to bring coziness and comfort, making the space more hospitable. Such a design will fit into any landscape design, as shown in the photo of chopped log arbors.

A log gazebo is an environmentally friendly structure that does not harm human health, since it does not emit harmful substances, but, on the contrary, has a beneficial effect on his well-being and mood. This is due to the fact that the logs have a pleasant natural aroma.

Constructions made of natural logs are able to "breathe". This feature helps maintain an adequate level of ventilation. Pathogens, molds and fungi do not develop on the surface of the structure. A distinctive advantage of the structure is its good sound-absorbing characteristics.

Arbors from a log house are environmentally friendly, in addition, they look beautiful and presentable

The construction of a gazebo from a log is a simple process that takes a minimum amount of time. Even a novice home craftsman can easily handle it. Also, don't worry too much about finishing this design. The wood can remain intact.

Important! For the durable operation of the building, all wooden elements should be treated with antiseptic compounds to protect them from the adverse effects of external factors.

The use of such impregnations should not be neglected. They are a guarantee of protection of wood from rot, mold, prevent cracking of the material and damage by insects.

Considering the positive aspects, one cannot fail to mention the negative nuances. In any case, a wooden structure will have a fire hazard. Therefore, it is not recommended to make fires near it.

Constructive varieties of log gazebos

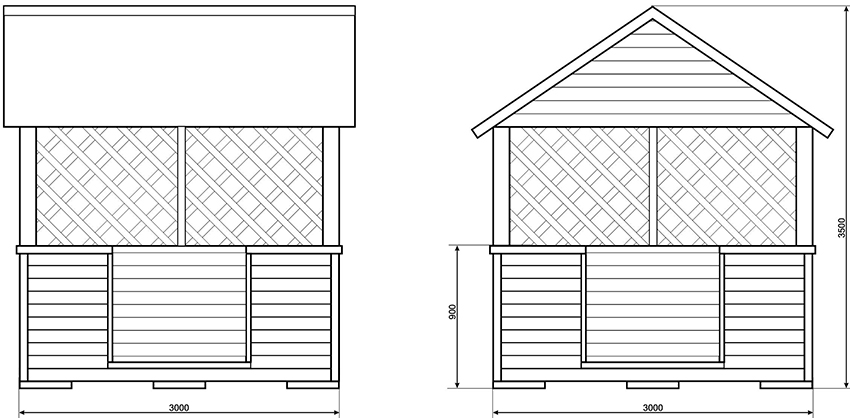

Log gazebos can have various shapes, which are selected based on the dimensions and characteristics of the land plot where they are installed. For a compact territory, the best solution would be a square building with a size of 3x3 m.For such gazebos, a two- or four-pitched roof is made from logs for a summer residence.

Useful advice! A construction adjacent to one wall of the house looks convenient and practical, which can be supplemented with a barbecue.

To decorate square gazebos, various grates or threaded elements are often used. For a more expressive appearance of an angular structure, when building a building, you can use a combination of dark and light logs.

Chopped gazebos made of rectangular logs are no less popular. Such structures usually have dimensions of 3x4 or 3x6 m. The buildings are massive, therefore they are equipped on spacious territories. Gazebos made of wooden logs in the shape of a six- or octahedron look spectacular and original. Thanks to this configuration (a large number of edges), the buildings look very compact, while being characterized by good spaciousness. Therefore, it is a viable option for small areas.

Interesting options for gazebos made of round logs

Very often, gazebos of bizarre configurations are erected, which will appeal to creative, extraordinary thinking people who want to get away from established standards. Such buildings can be made in the form of a trapezoid, an inverted cone, a carriage, a mushroom, a hut, as shown in the photo of log arbors. With the help of such a structure, it will be possible to give the site originality and uniqueness.However, an informal construction will require much more financial costs, which is associated with the laboriousness of the work.

Useful advice! In a limited space, you can build a compact structure in the form of a canopy and supports, where several people can sit.

According to numerous designs, log gazebos can be open, closed, or semi-open. The first option is devoid of walls and windows. This design has fences of varying degrees of openness and height, which ensures free air circulation in it. These are kind of summer wooden pavilions with awnings.

Closed gazebos look like compact houses with full walls, doors and windows. Such a building can be used as an outhouse for receiving guests. It is also possible to equip a summer kitchen here. The semi-open version consists of 2-3 walls and a canopy. This gazebo is used seasonally.

Log types: arbor made of rounded logs

There are five types of logs that can be used to construct various timber structures. Each of them has its own distinctive features.

The first type is represented by rounded material. Such logs are processed on a woodworking machine for sizing, where the bark is removed from them and the top layer is cut down. As a result, flat and smooth construction products of strictly the same diameter are obtained, which ranges from 180-320 mm. A groove is cut at the bottom of each calibrated log. It is used to quickly build a structure by stacking logs on top of each other. Different options for structures are shown in the photo of arbors made of rounded logs.

This type of timber is often used specifically for the construction of arbors. The log house is popular for its attractive appearance. The products have the same shape and size, are characterized by increased air exchange, low thermal conductivity, which contributes to a comfortable microclimate inside the building even in the cold season, as well as durability.

When erecting a gazebo from a cylindrical log, it is necessary to create a reliable foundation, since such wooden elements are characterized by considerable weight. The laying of the wooden products themselves begins with the arrangement of the first crown. Next, the walls of the gazebo are installed. The process is quite simple and fast.

For the production of rounded logs, pine, spruce, oak, linden or aspen can be used. Calibrated elements are characterized by high quality processing, providing a smooth surface and precisely measured dimensions. Buildings made of such material look natural and attractive. They do not need finishing, either outside or inside. To protect products from the negative effects of moisture, the invasion of insects and other microorganisms, it is customary to treat the logs with special antiseptic compounds. In addition, this type of log is notable for its affordable cost.

Of the negative characteristics, one can single out the possible shrinkage of the structure, which occurs after 2-3 years, as a result of which the wooden elements can become cracked. However, this option is possible when using low-quality and raw material. Also, after shrinkage, gaps may form between the logs.

Arbor made of planed logs or carriage-type material

For the construction of structures for summer cottages from a log house, a planed log is often used, from which the top layer is removed with an electric plane. This treatment helps to remove a smaller layer of wood than in the case of a rounded product.Thanks to this, planed logs are more reliable, warm and protected. The products have a perfectly smooth surface.

When erecting buildings, the logs should be matched to each other, ensuring a higher quality of the connection. However, the result is increased labor intensity and cost of work. Sliced logs do not differ in an ideal round shape and the same size of products, so the final structure will turn out to be less symmetrical and even.

Carriages are processed on both sides. The result is a cross between a bar and a log. This form of products allows you to create an even and symmetrical structure, which will be characterized by a low level of thermal conductivity, which also occurs due to the reliable connection of log cabins. A gazebo made of such a material is less prone to cracks than buildings made of planed and rounded products. Arbors from a gun carriage are characterized by a long period of operation. The disadvantage of the material is its high cost.

Related article:

Pergola: photos in landscape design, bright ideas for creating a lounge area

Metal and wood constructions for garden and terrace. Pergolas-arches, awnings, gazebos, awnings. Interesting and stylish ideas in different styles.

Distinctive advantages of scraped and solid logs

Another type of log is a scraped product. The bark is removed from the wood by hand using a cycle. Such processing allows you to preserve all the operational properties of the material. How to build a gazebo correctly? Despite the fact that the scraped logs are of high quality and reliability, it is necessary to carry out a number of additional measures in the form of adjusting products to each other, processing small knots, additional fastening and other works.

Chipped logs are characterized by a maximum service life. A structure made of such material can last up to 100 years. In addition, this type of log is characterized by low thermal conductivity and high resistance to mechanical damage. However, such material requires a large amount of additional manual work. In addition, scraped logs are expensive.

Elite and expensive buildings are being erected from a debarked log house, as do-it-yourself photos of log gazebos show. The material undergoes minimal processing, so such one-piece products have a rough appearance, but are as strong as possible. The construction of structures is complex and laborious, since uneven and asymmetrical elements must be adjusted to each other. Despite this, such a building will be characterized by reliability and durability. Solid logs have the highest value.

The process of erecting a gazebo from logs with your own hands

Work on the construction of a building begins with the creation of a project of a gazebo from a log, which displays detailed drawings of structural elements with an indication of dimensions. At this stage, the exact amount of materials for the construction of the foundation, the construction of walls, floors and floors of the structure is determined.

Before making a gazebo, you should choose a suitable foundation. The base must be strong and reliable, since the logs, regardless of their type, are characterized by significant weight.

A monolithic foundation is arranged for overall closed or semi-open arbors, which are erected from large cross-section logs. For him, a pit is pulled out, the depth of which should be higher than the level of soil freezing. On average, this value is 45-50 cm. A pillow of sand and gravel is placed on the bottom.Next, the formwork is mounted, into which a frame made of reinforcement is inserted, and concrete is poured.

Projects for gazebos made of rounded logs involve the arrangement of a strip foundation, which is ideal for lighter buildings with a simple geometric shape. To do this, a trench is being dug around the perimeter of the planned gazebo with an indent of 10 cm. The formwork is mounted in it. A sand cushion is placed on the bottom and compacted. A reinforcement cage is inserted into the formwork, which is poured with concrete mortar.

If you want to raise the gazebo to a certain height, you can equip a columnar foundation. This base is characterized by strength. The pillars are formed from a brick structure of a square design, under which there is a pillow made of non-flowing materials. After setting, the pillars are covered with a layer of roofing material waterproofing. For this, you can also use bored piles, which are characterized by a high bearing capacity. With a significant slope of the terrain or for a site with access to the water, screw piles are used.

How to build a gazebo with your own hands: stacking logs

The construction of the gazebo can be done independently, which will significantly save money. If there are no appropriate carpenter skills, it is better to entrust the work to specialists. This is especially true for complex structures. The price of a log gazebo depends on the type of structure, the complexity of execution, the type of roof and roof covering. The average cost of a small building measuring 3x3 m will be 100-160 thousand rubles. The price of a gazebo made of complex galvanized logs starts at 250 thousand rubles.

The final cost of the structure is affected by the need for additional processing of the log house, finishing the building with decorative elements, creating furniture from wood, connecting utilities.

For independent work, you will need to prepare a shovel, an electric saw, an ax, a drill, a screwdriver, hammers, knives, a level, a plumb line, a concrete mixture for arranging a foundation, fittings, logs, a wooden beam to create a frame for a gazebo and a roof, boards, roofing material, fasteners , personal protective equipment.

After the construction of the selected type of foundation, the lower strapping is performed. For this, a bar with a cross section of at least 150x150 mm is used, which has increased resistance to decay. The walls of the gazebo made of logs will fit on it. Installation of the lower harness allows you to tightly and reliably fix the gazebo at the base, supplementing it with logs on which the floor will creep.

The first log of a log house should be laid on a waterproofed base. For this, bituminous mixtures are used, which cover the upper surface of the foundation. Such a coating will prevent the penetration of moisture from the concrete into the wood. As a result, the period of operation of the building will increase.

Laying of logs is carried out without the use of nails and screws. Wooden elements for wall mounting are laid according to the "butt-to-top" technology. The bar is a truncated cone-shaped material. The butt is the end of the log with the largest diameter, and the top is the smallest. Such laying of log elements will allow achieving a uniform height of the sides of the gazebo.

The logs are installed horizontally. Each new row should be checked with a building level. Vertical connections are made using dowels.

How to quickly build a gazebo with your own hands: further algorithm of actions

Fastening logs at the corners when erecting a gazebo from a calibrated log or another type of timber can be done in one of two ways. The first one involves fixation "in the paw". This is a compound of wooden elements without residue.It is carried out using cut paws made in the form of a regular trapezoid. This technology provides a tight and reliable fixation of the elements to each other, which additionally strengthens the future building.

Important! Fastening logs "in the paw" requires certain skills and abilities, since it is quite difficult to correctly cut the elements for joining.

Another technology for assembling logs for a gazebo from a cylinder or another version of a log house is called "in a bowl". The elements are stacked on top of each other using a recess, which is moon-shaped. This method requires a large consumption of material, since the edges of the logs will protrude beyond its area in all corners. This option, in comparison with the previous one, is characterized by a simpler technology, therefore it is very popular among builders. This method allows you to get a real gazebo in the Russian style.

Some time after the structure shrinks, the structure is caulked. Next, the roof is installed. For this, the rafter base of a one-, two- or four-pitched roof is used. A crate is stuffed onto the rafters, on top of which the roofing material is laid. For this, slate, profiled sheet, metal tile or wood can be used.

The floor is laid on the joists. They are attached with metal corners to the lower rail from the bar. Boards are mounted on top. If the gazebo is an open structure, a gap must be left between the elements for excess moisture to escape.

At the final stage, the surfaces are treated with antiseptic impregnations and a refractory mixture, followed by finishing with decorative elements. For this, you can use forged or carved products. Often a weather vane is installed on the roof. Near the gazebo, you can place an outdoor fountain, garden sculptures or flower beds. The path to the building is laid out with pebbles or stones. Many people create a gazebo from logs with barbecue.

Frequently made mistakes when erecting a gazebo from a log house with your own hands

Many home craftsmen, when creating a gazebo from logs with their own hands, often make standard mistakes. To eliminate the occurrence of irreversible problems, you should familiarize yourself with them.

When choosing a place for a building, you must focus on the features of the area. The gazebo should be located on a flat area, preferably at some height. You should not build a structure in a lowland, since this area is characterized by high humidity. In such a place, water often stagnates, which flows from other territories after precipitation. These climatic features will significantly reduce the service life of the gazebo.

When choosing a roof type, you should focus on the option with a sufficient angle of inclination, which will exclude the likelihood of precipitation delay on it. The most expedient solutions are shown in the photo of arbors made of rounded logs. When arranging the floor, it is necessary to use moisture resistant wood. The logs should be treated with antiseptic impregnation. Between the foundation and the first crown, it is imperative to equip a waterproofing layer.

The construction of a gazebo from logs should be started in warm sunny weather, since during a period of high humidity or under the influence of light rainfall, the wood will swell. After it dries, the products are deformed, which can lead to cracking of wooden elements.

If you plan to organize engineering communications to the gazebo, you should take care of this in advance by drawing up an appropriate drawing.For a closed design, a ventilation system must be designed. When erecting a gazebo from old logs, each element should be treated with moisture-repellent and antiseptic impregnations.

A log gazebo will become a real decoration of any garden area, where you can comfortably sit down for all family members or spend time in a friendly company. From the many existing options, it is easy to choose the project you like, adding to it of your own free will. To create a reliable, durable and aesthetic design, it is important to choose the right quality logs with high performance characteristics.