Metal roofing sheet imitating shingles is very popular in both industrial and civil construction. He found particular recognition from individual developers. What types of this roofing material can be found on sale and how to properly close the roof with it? What are the features of creating waterproofing and lathing for metal tiles: step, materials and technology? Everyone who is going to carry out the installation of metal tiles with their own hands should receive answers to all these questions.

Content

Sheets of metal roofing: sizes, prices and types

The production of profiled sheet imitating tiles is carried out in several stages:

- the hot-rolled method is used to produce rolled sheet steel;

- it is galvanized and coated with anti-corrosion protection. On top of these layers, a decorative coating is applied in various colors;

- using the method of cold rolling and simultaneous stamping, the metal is given the familiar shape of the tile;

- the metal is cut into sheets of the required length.

Width - 1250 mm, length - no more than 8 m. The thickness of products ranges from 0.45 to 0.55 (sometimes up to 0.6) mm. it standard sizes of metal roofing sheets. Price them depend on the area, surface, material thickness, manufacturer, quality of protection and varies from 3.5 to 5.5 cu. per m².

Depending on the material from which the product is made, there is metal tile: steel with zinc or aluzinc coating, aluminum and copper. The last two options are too expensive to be widely used in construction, so it is worth dwelling in detail only on steel sheets.

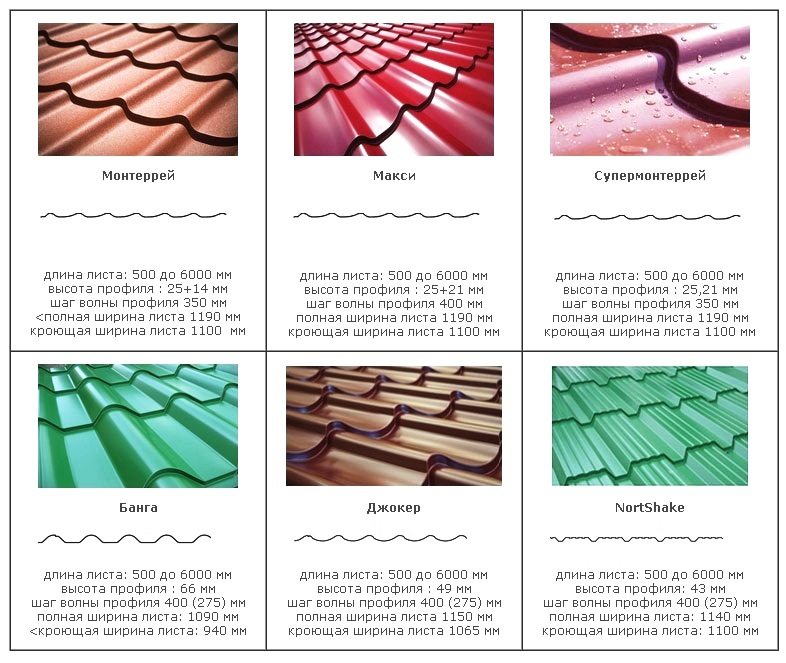

Depending on the geometric features of the profile, the metal tile is divided into several types with beautiful names:

- Monterrey is the most famous species. Outwardly, the profile of such a sheet resembles a real tile with rounded edges;

- cascade - strict classical look. The profile resembles a bar of chocolate. Straight lines make it easier to cover complex roofs;

- joker - the waves of such a coating resemble the correct tiles. In section, they look like an ideal hemisphere;

- banga - a modern profile view that, due to its height, creates a three-dimensional effect;

- andalusia - the features of the profile of such a sheet allow you to fix the metal tile on the roof with the help of special locks, which also hide the screws;

- Shanghai is a Chinese profile that is completely symmetrical.

These are only the most famous, with a wave height of various sizes, sheets of metal for the roof. Their price also depends on the shape of the profile. The features of the relief of the roofing sheets make it necessary to observe a certain technology for constructing a roof made of metal tiles.

Metal roofing technology

The simplest case is the installation of a gable roof. There is nothing difficult in this work. First, a crate is prepared for a metal tile, the step of which depends on the type of profile, sheet thickness and slope angle. It is constructed from boards up to 25 mm thick and can be covered with plywood in some cases.

Then they choose which side to start laying the sheets on. There is no big difference in this, but it is still more convenient to do this from the side where the sheet does not have a capillary groove. In this case, each next sheet will lay on top of the previous one. Otherwise, you will have to slip it. The first sheet must be laid absolutely exactly in relation to the plane of the crate and parallel to the cornice with an allowance of 2 - 3 cm. The result of all the work depends on how it will be laid. After all, a deviation of only 1 degree in the beginning will lead at the end to a significant departure from the desired direction.

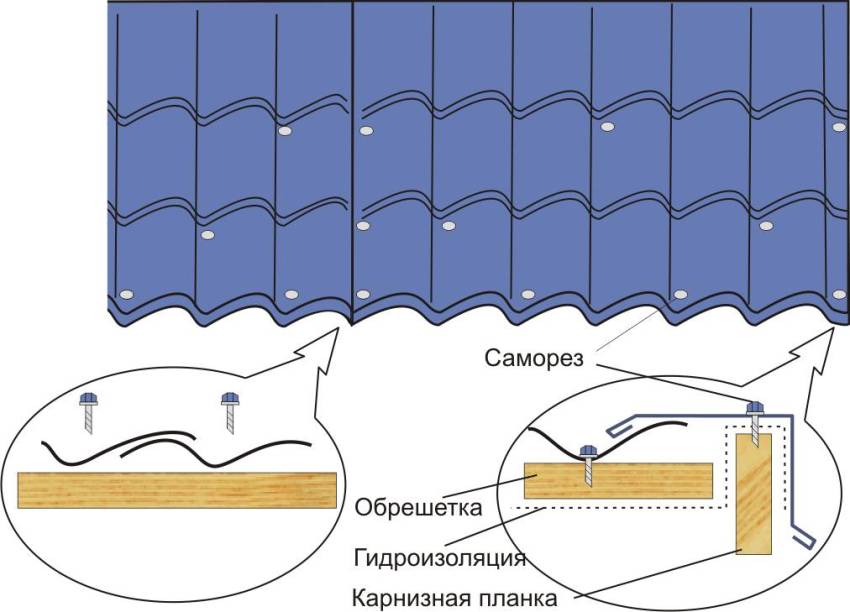

The sheets are fastened using special roofing screws with rubber gaskets. They are screwed with a screwdriver into the cavity between the waves without force, since the gasket can be damaged. Then wind and ridge elements are mounted. These are the main stages of metal roofing technology. Some important nuances of this process need to be analyzed in more detail.

Helpful advice! When installing metal tiles with your own hands, you cannot use a grinder, but only scissors or a hacksaw for metal. When working with a grinder, the protective polymer layer is destroyed from heating, which leads to premature corrosion.

Process installation of metal tiles

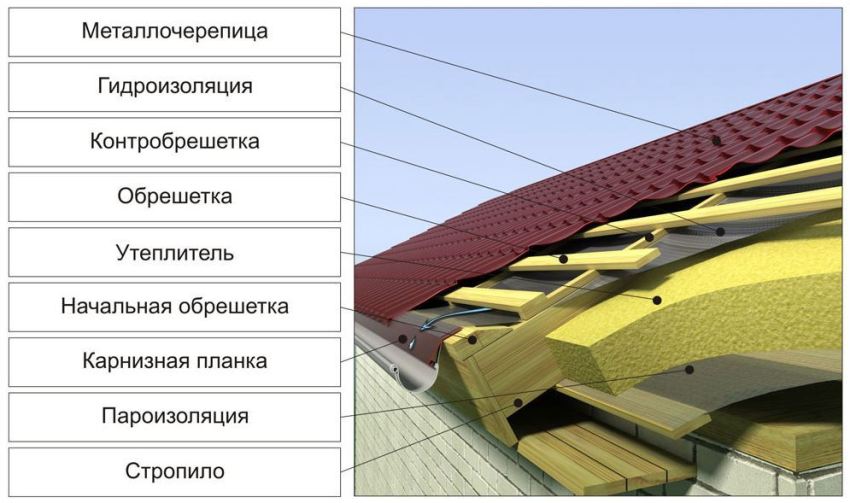

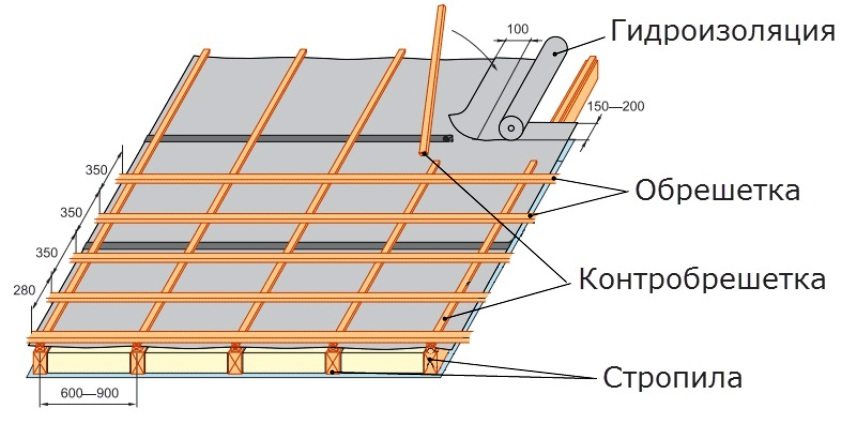

Sheathing device for metal tiles: step, materials and technology

In construction, there are 3 types of roof sheathing: solid, thinned and sheet materials. Solid assumes fastening the boards in a joint to each other, which requires a large amount of material.

Construction of sheet materials such as plywood and OSB sheet, is universal and quite suitable for laying metal tiles on it. However, the most suitable for it is a sparse crate for metal tiles, the step of which must be calculated individually for each type of profile.

Related article:

Roofing materials for the roof: types and prices of modern coatings. Varieties of coatings. Comparative characteristics, disadvantages and advantages. Classification of materials for the construction of roofs.

To calculate this step, it is necessary to nail the first edged board parallel to the cornice and the last parallel to the ridge at the very top of the ramp. Then the sheet is laid in such a way that its lower spade rested against the end of the first sheathing board. The top of the sheet should rest on the board closest to the ridge.

Then a place is marked for all intermediate boards of the crate. They should be nailed in such a step that the sheet rests on each of them with the top of the steps. Bending points should not be between the boards. Strictly speaking, the step of the sheathing under the metal tile should be equal to the step of its transverse wave.

Waterproofing the roof of a house for metal tiles

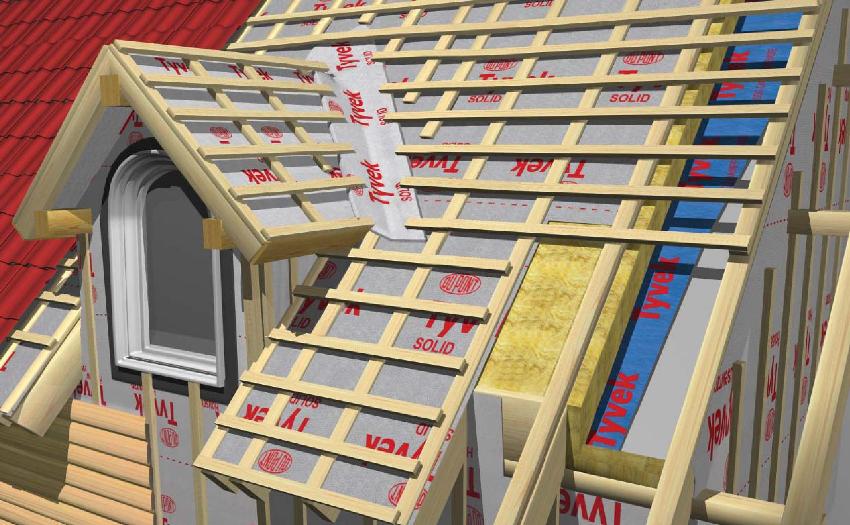

After the crate is ready, it is time to waterproof the roof of the house under the metal tile. This stage cannot be excluded from the whole process. It protects the rafters from moisture that can get under the coating, and also prevents condensation from accumulating on the inner surface of the sheets.

There are a large number of modern effective and durable materials, such as membrane and anti-condensation films. It is not recommended to use bituminous materials such as roofing felt. The film has all the properties necessary to provide protection against moisture and complies with all building codes. It is easy to install. This does not require any additional tools and manipulations. It has fire-fighting properties, as it is used on wooden floors, which cannot be said about roofing material.

It is necessary to lay the film parallel to the cornice, starting from the bottom. Each subsequent roll is rolled with an overlap on the previous one. You can fix the material with an ordinary construction stapler to the sheathing boards. Correctly mounted waterproofing of the roof of the house under the metal tile will provide high-quality protection of wooden structures from moisture and wind.

Helpful advice! If the plastic film was damaged during the laying of sheets, then it must be covered with paint. It can be purchased at the same store where all the material is.

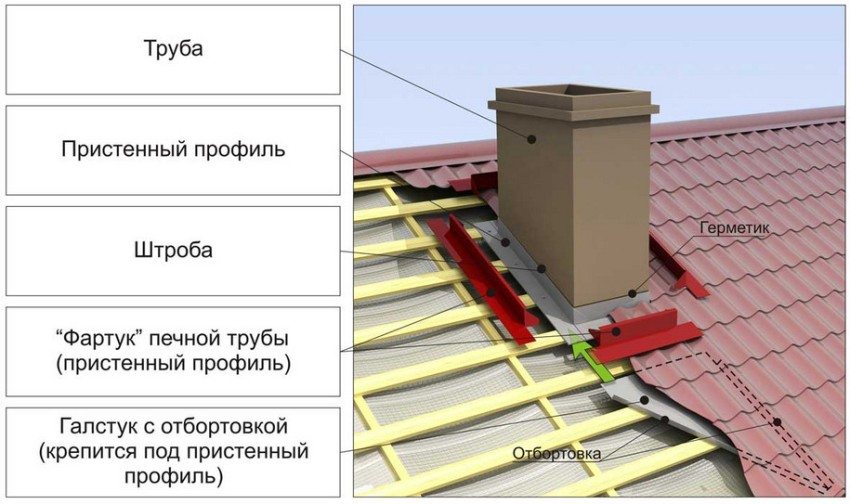

Chimney design in metal roofing

Features of installing metal tiles with your own hands

If you want to save money on the construction or replacement of the roof of your house, you can do the installation of metal tiles yourself. This is not as difficult as it seems at first glance. The most important is the first sheet, which must be laid as flat as possible. Its bottom edge should be parallel to the cornice. This sheet is fixed in the middle with one single self-tapping screw so that you can turn it.

Then another 2 - 3 sheets are laid, observing the features of their relief. They are not attached to the crate, but only fastened together. Then the entire structure of several sheets is aligned parallel to the cornice and finally fixed with self-tapping screws. Subsequent sheets are stacked without any problems. Align only their bottom edges relative to each other.

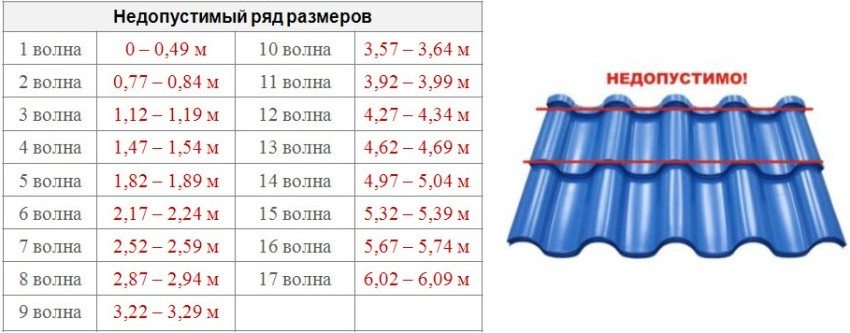

When calculating metal tiles, it is necessary to take into account the unacceptable dimensions. Sheets with such dimensions will not be joined vertically due to the peculiarities of cutting the locks of the tile sheet

Helpful advice! It is necessary to nail a cornice corner on the cornice board, which is an additional element of the metal tile. It will protect the boards from moisture that can drip from the edges of the sheets.

When choosing a sheet of metal for a roof: dimensions, price and shape of the profile are the main criteria. When laying it on the roof, the main thing is the correct installation of the battens and waterproofing, as well as the even position of the first sheet.