The convenient dimensions of the cinder block allow you to use this building material in a wide variety of areas. It is used to build private houses, trade pavilions, garages, premises for animals and other outbuildings. This masonry material has entered our everyday life so much that almost no one realizes that it appeared not so long ago by historical standards. The first building, which was built from cinder blocks in 1910, is the Hermitage garage in St. Petersburg.

Content

Manufacturing technology of cinder blocks, their types

The name cinder block comes from the fact that earlier in the manufacture of these blocks only ordinary slag was used, which was poured into a solution with concrete. Today, this artificial building stone is made from any available debris material found in almost any area:

- Slag remaining after coal combustion. Where there are boilers on this fuel.

- Volcanic ash in a seismically active area.

- Crushed granite or screenings in mountainous regions.

- River detrital crushed stone or gravel.

- Coarse sand

- Fragments of brick, concrete or cement.

- Shards of glass.

- Expanded clay or its crumb.

Any of these components are mixed with cement and water, after which the solution is poured into molds. The dimensions of the cinder block depend on the shape parameters. Solidification takes place on special vibration stands. The method is called vibrocompression.

Helpful advice! If you need perfectly flat and identical cinder blocks, then buy them from large manufacturers. If the main criterion is price, then you can purchase the material from private owners or even make it yourself.

There are two main types of standard cinder blocks: hollow and solid. The first type has soundproofing qualities, since there is an air gap inside it. Therefore, it is customary to make interior partitions from hollow blocks. Solid cinder blocks are used to erect external walls of a building and even foundations for lightweight structures.

What are the sizes of cinder blocks

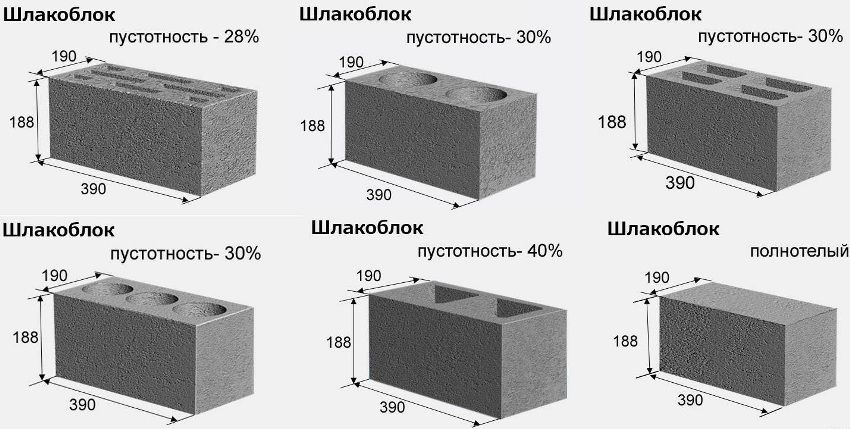

Both of these species have subspecies. The standard sizes of cinder blocks by subspecies are as follows:

- An ordinary or ordinary cinder block has dimensions of 390x190x188mm.

- Facing cinder block can be 390 x 120 x 188 or 390 x 90 x 188 mm.

Some manufacturers produce cinder blocks that differ in size from these. Most often it is 395 x 195 x 195 and 400 x 200 x 200 mm.Since this masonry building material is also produced in a handicraft way, products of other sizes can also be found on the market. It all depends on the manufacturer's matrix. Stones differ in the number of voids and their shape.

Cinder block dimensions and the percentage of its hollowness

Specifications, pros and cons of cinder blocks

Cinder block is a fairly warm building material. Its minimum thermal conductivity is within 0.27 W / m * K, and, for example, for a brick it is 0.8 W / m * K. This indicator is quite strongly dependent on the type of filler material. If it is denser, then the thermal conductivity also increases. In this case, the density can vary in the range of 750 - 1455 kg / m3.

There is such an indicator for cinder blocks as compressive strength. It is very important, and this is why: if you press on a stone with a press with a force of 50 kg, and the block collapses, then it will be assigned the M - 50 grade. The highest grade is M - 150, and the lowest M - 35.

This material is also divided into cycles of frost resistance. The highest cycle has cinder blocks for the northern regions - 50. Further in descending order - 25, 15. These figures are not abstract, but indicate the cycles of freezing and thawing, which corresponds to the seasons of the year.

Let's note the main positive characteristics of cinder blocks:

- Low cost.

- Low mortar consumption during laying.

- Ease of carrying out and speed of laying.

- There is no need to build a strong foundation.

- Universal application.

Speaking about the disadvantages of this simple but common material, we note:

- Poor sound insulation properties.

- Low strength.

- Low environmental friendliness.

Helpful advice! Cinder blocks are made from various wastes, including metallurgy, which suggests the presence of harmful components for the human body. For this reason, you should not build residential buildings from them. They are perfect for non-residential buildings.

It turns out that the material has enough advantages to be widely used. Low cost allows you to build garages and other buildings at low cost, especially if you do it yourself, without involving construction organizations. In the end, the size of the cinder blocks and their weight are quite sufficient to do this. In addition, you can set up the production of cinder blocks for your needs yourself, which will further reduce the cost of construction.

Cinder blocks: pros and cons (video)