One-story frame houses for permanent residence are becoming increasingly popular in our country due to the speed of construction and low financial costs. If desired, such a room can be assembled alone, with basic construction skills. This affordability prompts many people who want to acquire their own housing and immediately start construction. Consider the most popular projects of frame houses: photos and prices will also be presented below.

Content

Projects of frame houses: photos and prices, their device

Even at the design stage, it becomes clear that the construction scheme of a frame house is much more complex than a brick one. Therefore, despite the apparent lightness and simplicity, the assembly of such a building requires skill and adherence to all the nuances of technology. When creating a construction scheme, calculations of permissible loads, elasticity and other technical characteristics of materials selected for construction are necessarily carried out. High-quality design combined with professional installation is the key to a durable and stable frame house.

If in the construction of a building made of brick or wood we are dealing with primitive masonry, then here we need precision in the connection of every detail. In addition, the quality of all kinds of building materials used in the process plays a significant role. Special attention should be paid to the design of the joints in order to prevent blowing through the walls or possible subsidence of the insulation.

Another important step is fitting all parts of the sheathing to the desired size. This is a rather time-consuming process that takes a lot of time, especially if small shield elements are used. However, if the house is made correctly, then it will indeed have energy-saving properties. However, it is not so easy to achieve this on your own.

This requires experience and correct, rational selection of consumables. Therefore, if you doubt that you will be able to cope with the task at hand, it is better to seek help from specialists who can easily build an inexpensive turnkey frame house. Prices for this type of work start at 400,000 rubles and can reach 2 million rubles, depending on the complexity of the structure being built.

Average prices for frame houses:

| Project name | Total area of the house, m2 | Equipment, accommodation: | Cost, rubles |

| Frame house "Yantar" | 32 | seasonal | 351000 |

| year-round | 415000 | ||

| Frame house "Boyarin" | 74 | seasonal | 554000 |

| year-round | 665000 | ||

| Two-storey frame house "Dobrynya" | 79 | seasonal | 591000 |

| year-round | 708000 | ||

| Frame house "Lotus" | 85 | seasonal | 677000 |

| year-round | 819000 | ||

| Two-storey frame house "Gardener" | 118 | seasonal | 934000 |

| year-round | 1141000 | ||

| Two-storey frame house "Hephaestus" | 171 | seasonal | 1305000 |

| year-round | 1542000 |

Construction technologies and photo projects of frame houses

Among the most common, there are two types of technologies:

- panel board;

- frame-frame.

Consider the process of erecting a frame house using both technologies, determine their differences and highlight the necessary materials for construction such designs.

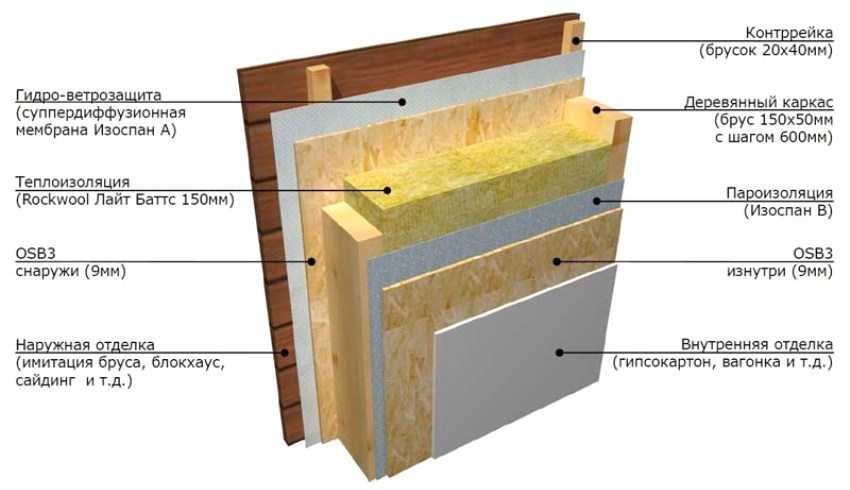

Foam concrete, gas silicate and even wood do a good job of thermal insulation, but it should be admitted that there are materials with less thermal conductivity. For example, mineral wool, which surpasses the characteristics of the above materials and at the same time provides windproofness, moisture resistance and has no seams.

Definitely, building a house from mineral wool will not work - the material is too soft, however, nothing prevents you from applying this principle. This is how rigid structures appeared, made of sheets of wood or metal, inside which insulation, steam and wind protection are laid.

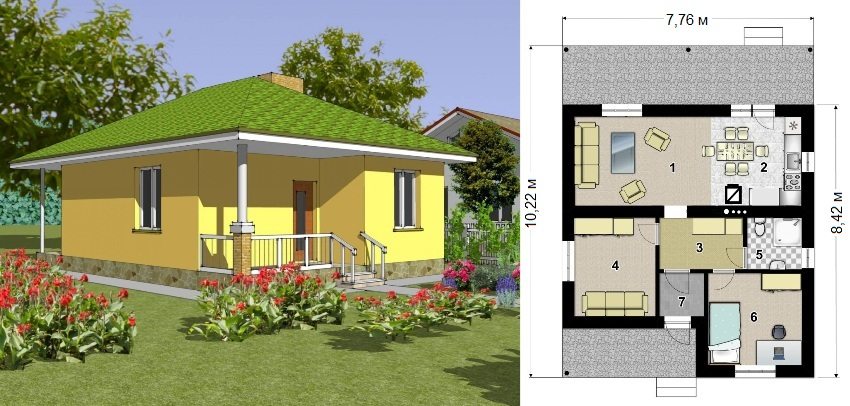

Project of a frame house with an area of 49.3 sq.m: 1 - living room, 2 - kitchen, 3 - entrance hall, 4 - bedroom, 5 - bathroom, 6 - bedroom, 7 - vestibule

The characteristics of the resulting material are in no way inferior to those of wood and even foam concrete. This is how the principle of erecting frame houses appeared. The only drawback of this design is the thermal conductivity of the materials that form the wall frame. They can act as "cold bridges" and contribute to heat loss.

Frame houses: projects, photos of finished houses

How are livable frame buildings erected? In the case of building a house of brick or foam concrete, the process is quite clear. Bricks, blocks and fittings together form a strong, reliable system. But how to assemble a frame structure that could stand for many years and not collapse is not an easy task. However, it is possible to do it yourself. Therefore, when building a frame house, there are two ways: to hire specialists or to build it yourself.

External cladding of a frame house SIP panels

In the case of hiring specialists for the construction of a panel structure, only professionals can be engaged in construction. The building box is assembled very quickly (no more than two weeks) and it consists of ready-made panels that are transported to the construction site. These panels are manufactured at the plant on the principle of "sandwich" panels. Between two layers of wood or metal sheathing, layers of thermal insulation and a vapor barrier are laid.

In the reviews, residents of frame-panel houses claim that this is quite enough for a comfortable stay even in the most severe conditions.

Related article:

DIY frame house. Step by step instructions for the stages of construction. Erection of foundations, floors, walls, roofs, installation of insulation. Advantages and disadvantages of frame houses.

In order to assemble a house from shields, it is necessary to take part in serious lifting equipment, which installs the component parts on a pre-prepared foundation. The roof of the house is made of the same "sandwich" panels with additional vapor protection, as well as roofing materials.

Project of a two-storey frame house with an area of 67 sq.m. Ground floor: 1 - kitchen-dining room, 2 - living room, 3 - bathroom. Attic: 1 and 2 - bedroom

No one forbids and independently try to build such a structure, but this will require serious financial costs and construction experience. In this case, it is better to leave the situation in the hands of professionals.

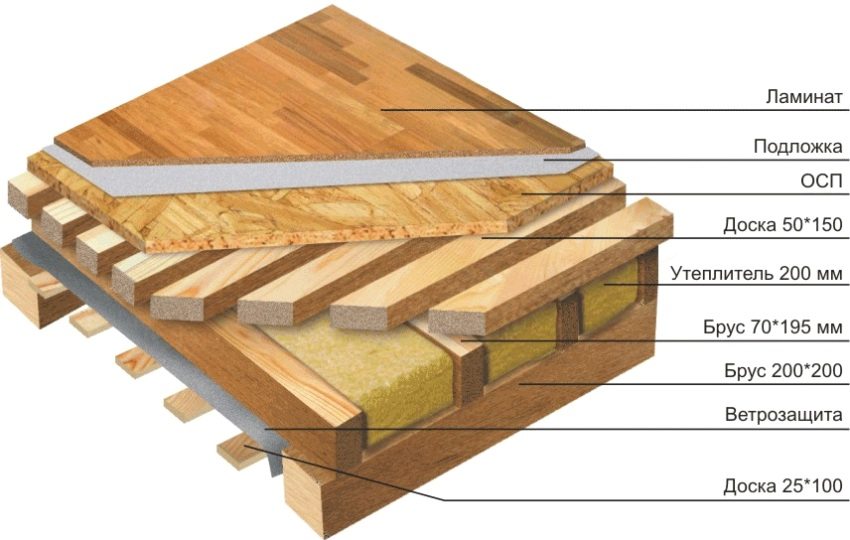

In the case of self-erection of a frame-frame structure for a future house, the construction principle is completely different. First, the internal structure is assembled, which is subsequently sheathed and insulated. Then windows and doors are mounted. The construction technology of this type is already quite available for self-construction of a house. Specialized stores can offer in abundance all types of materials necessary for work - metal fittings for fasteners, insulation, wall cladding and the roof frame of a frame house.

Project of a two-storey frame house with an area of 81 sq.m. Ground floor: 1 - living room, 2 - kitchen-dining room, 3 - bathroom, 4 - bedroom. Second floor: 1 - stairs, 2 - storage room, 3 - corridor, 4, 5 and 6 - bedroom

Helpful advice! Be careful when choosing cladding materials. Many unscrupulous manufacturers can offer you cheaper products, but at the same time they do not meet environmental standards.

The choice of materials for the construction of a frame house

Try to avoid particle board and styrofoam. If you can give preference to another material - great, if not - at least pay attention to the product labeling. Particleboard boards can emit formaldehyde due to the content of resin binder. This factor can have a negative impact on health.

In this case, the best option that you can use is Super E class boards. This is a European standard that meets all safety standards and has a corresponding certificate. It is also allowed to use E1 class materials for decoration, but E2 is unacceptable for residential premises.

The safety of using expanded polystyrene is also a controversial issue. It is believed that the decomposition products of this material under the influence of light and high temperatures are polystyrene and toxic gases that have a negative effect on the human body. Although American experts have repeatedly conducted research aimed at refuting this fact.

Most likely, self-extinguishing expanded polystyrene containing antipyrins can be considered the most unsafe, however, in this case, you should just pay attention to the product labeling. The letter C at the end of the name is unacceptable (for example, PSB-S).

Mineral wool also does not belong to the class of human carcinogens. This fact has been approved by the International Agency for Research on Cancer. They recognized this material as relatively safe. Why "relatively"? Because mineral wool, in the process of working with it, releases a huge amount of fibers into the environment, thus provoking irritation of the mucous membranes of the respiratory tract and even skin irritation. Nevertheless, after the isolation process (for example, inside a shield), cotton wool becomes an absolutely safe material for humans.

Project of a frame house with an area of 82 sq.m: 1 - vestibule, 2 - boiler room, 3 - corridor, 4 - bathroom, 5 - kitchen, 6 - living room, 7 and 8 - bedroom

Helpful advice! Before you finally decide on the choice, carefully study as many photos, projects and prices of frame houses offered on the network as possible. Objective information will help you make the right decision.

Advantages and disadvantages of frame houses: reviews of residents

Reviews indicate such advantages of frame construction:

- high speed of construction. Frame houses are perhaps the most rapidly erected type of housing;

- regardless of the technology according to which the house is being built (panel board or frame-frame), it can be erected at any time of the year;

- low price. The technology for the construction of frame houses is one of the cheapest today. If you compare, the costs will roughly correspond to the construction of a small country house from a bar. In this case, the walls of the house will be much thinner, and much more time and effort will be required;

- high level of thermal insulation.Despite the absence of thick walls, frame houses are in no way inferior to wooden ones in this indicator;

- frame houses have a very light structure, which makes it possible to use a simpler foundation and reinforcement for construction;

Project of a two-storey frame house for 2 apartments with an area of 103 sq.m. Ground floor: 1 and 5 - kitchen-dining room, 2 and 6 - bathroom, 3 and 7 - stairs, 4 and 8 - vestibule. Second floor: 1, 2, 4 and 5 - bedroom, 3 and 6 - corridor

- seismic resistance. Due to the fact that the structure is devoid of rigid connections, it perfectly plays out any movements of the soil. This allows you to safely erect frame houses even in the most seismically active regions;

- ease of finishing the surfaces of the house. Thanks to the use of panel board finishing materials, the walls are smooth. This allows you to easily complete finishing work and give the house a complete look;

- convenient communications. All the elements that provide you with water, electricity, gas and other benefits of civilization are built into the walls. This improves the appearance of the house and greatly facilitates the process of finishing work;

- simplicity and ease of reconstruction. At any time, you can rebuild or expand your own house, while not harming it in any way;

- ease of construction. For the construction of a frame house, the most common and readily available materials are used, such as timber, insulation, and accessories. Installation also requires only simple tools. As a result - the ability to easily and independently make repairs if necessary;

- thanks to the use of the same dry timber, the frame house does not shrink.

Two-story frame project houses with garage with an area of 112 sq.m. Ground floor: 1 - vestibule, 2 - entrance hall, 3 - bathroom, 4 - kitchen-dining room, 5 - bedroom, 6 - garage. Second floor: 1 - staircase, 2 - corridor, 3 - bathroom, 4 and 5 - bedroom, 6 - wardrobe

Disadvantages of frame construction:

- it is hardly possible to independently assemble a high-quality frame house. This will require a team of professionals;

- fragility. Frame houses are significantly inferior in terms of service life, for example, stone houses;

- the need for home care. Due to the fact that the bearing beams, structures and shields are all wood, constant supervision is required. Painting, as well as the use of special impregnation are mandatory measures;

Wireframe cottage lined with vinyl siding

- specialized ventilation. As a result of using vapor barrier materials for insulation, the walls of the house do not breathe at all. Therefore, it is worth carefully considering the ventilation system before starting the construction of a house;

- danger of depressurization. In cases where the integrity of the structure is violated, the service life of sheet or wadded heaters is significantly reduced.

Important! Rodents can live inside the foam or insulation! Be careful and take action at the first signs of animals in the house. Otherwise, they can cause irreparable damage to the structure.

Reviews on specialized forums and sites claim that the prices of inexpensive frame houses for permanent residence on a turnkey basis are so acceptable that they can more than cover all the modest disadvantages and hassles of further maintaining the premises.

The most common myths about frame housing

Today, there is a lot of debate about whether frame houses are worthy to compete with brick, wooden, modular and other buildings. However, the practice of using this technology by other countries demonstrates the full compliance of buildings with all standards necessary for a full-fledged living at any time of the year. Nevertheless, many myths are still actively discussed. Let's try to objectively consider the most popular ones.

Myth 1: increased fire hazard of frame houses

This myth appeared, it would seem, quite expected.After all, the first association that arises in connection with frame construction is wood. But this material lends itself well to combustion. But how, then, wooden houses that were built over many centuries and continue to be built today?

Yes, wooden buildings are indeed more fire hazardous than, for example, stone ones, but do not forget that all wooden components of structures are necessarily treated with special compounds that prevent fire.

In addition, the structure of the wall includes plasterboard sheets with which the walls are sheathed inside. They are a serious obstacle to fire. Therefore, subject to all fire safety rules, a frame house is no more dangerous than any other structure.

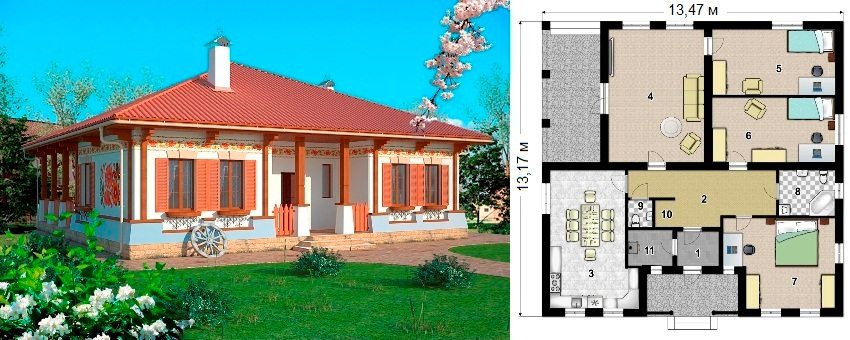

Project of a frame house with an area of 122 sq. M: 1 - vestibule, 2 - entrance hall, 3 - kitchen, 4 - living room, 5, 6 and 7 - bedroom, 8 - bathroom, 9 - bathroom, 10 - wardrobe, 11 - boiler room

Myth 2: a frame house cannot be sold

It is difficult to disagree with the statement that purchasing a finished house near the city is a profitable investment. Evidence of this is the many cottage townships and villages under construction.

Today, decisive indicators for choosing a house are remoteness from the city, the availability of communications, infrastructure, the area of the site and the house, and other external indicators. The material from which the house is made, if considered, is at the very end of this list. After all, no one will abandon a residential building with all the amenities just because it is not made in accordance with classical technologies.

Today we cannot draw any conclusions about the successful operation of the secondary market of frame housing or the inexpensive prices of turnkey panel houses for permanent residence, but this is only for the reason that this type of construction is a novelty for our society and is just beginning to gain popularity.

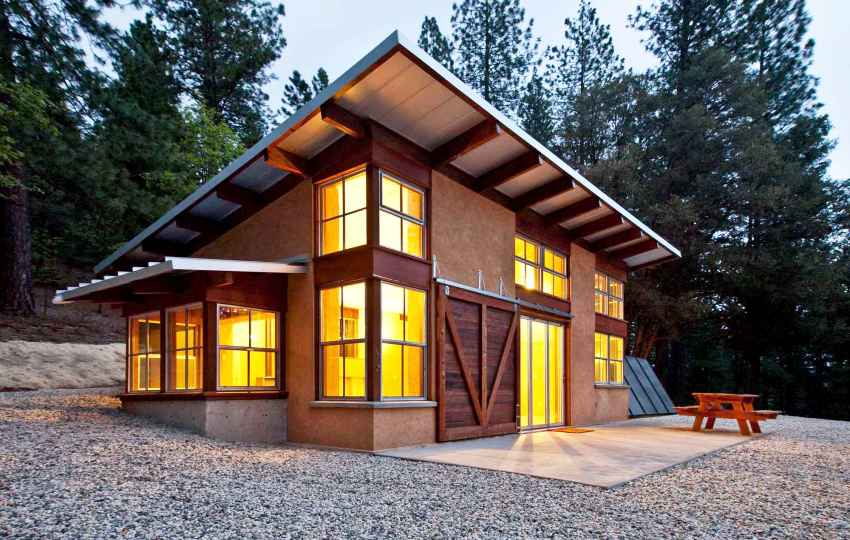

Myth 3: timber frame houses look worse than traditional ones.

If you get acquainted with the proposals of the modern market, then this myth will be refuted by itself. The variety of frame structures is simply huge, and how your house will look from the outside is only your decision. The decoration of external walls can be such that it will be simply impossible to distinguish a brick building from a frame building. Among the many options for facing materials, there is certainly a suitable one. Moreover, the finished house can be faced with bricks.

Summing up, we can say that all these myths have no practical basis. Frame construction is actively developing in developed countries, which, among other things, testifies in its favor.

Frame houses are a new word in modern construction technologies. And this type of housing is gaining popularity every year in our country. After reviewing the prices, projects and photos of frame houses offered on the Internet, as well as reading additional reviews, you can get a complete picture of the product and decide in favor of frame or traditional construction.