It's no secret that it is almost impossible to find cheap housing in the modern world. Yes, this is understandable, because having started construction from scratch, you will inevitably face the high cost of consumables and labor. An alternative solution to this problem is a new round in the development of affordable housing - modular houses for year-round living. Every year, becoming more and more popular, frame houses provide an increasing number of people with their own homes.

Content

- 1 What are modular homes for year-round use

- 2 Advantages and disadvantages of a finished home from the factory

- 3 Turnkey construction of a modular house

- 4 Basic principles of building modular houses

- 5 Turnkey prefabricated houses: prices and stages of construction

- 6 Individual design of modular houses

- 7 Modular houses for year-round living in the country

What are modular homes for year-round use

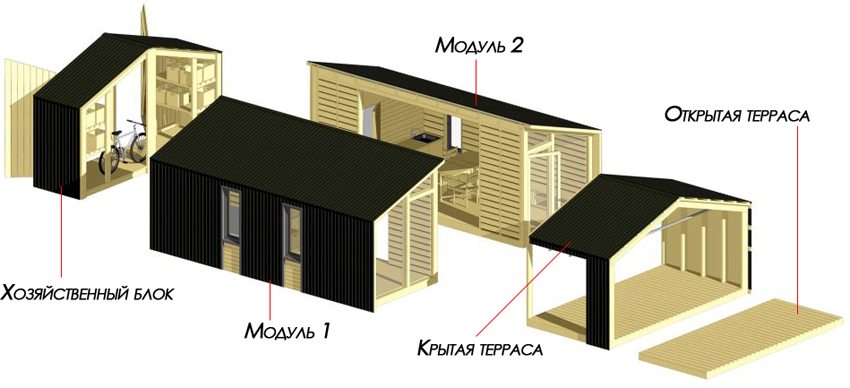

A modular house for permanent residence is a structure that is assembled from special modules, or so-called sections, which have their own individual purpose - a kitchen, a bathroom, a living room. Each part is autonomous in itself, but together they form a single structure that is great for living and is no different from traditional houses.

Modern modular houses are provided with all the amenities necessary for a long and comfortable stay, for example, ventilation, heating, sewerage, plumbing and others.

The history of the appearance of such structures began not so long ago. The initial versions of the modules created a rather rough, unsuitable for permanent residence house, deprived of many benefits of civilization. They were used to build mobile police or military posts, as observation posts for security in workshops and warehouses. Less often for the construction of rest houses for workers, fishermen or hunters, as well as structures in the commercial and entertainment sector.

Today everything has changed, and the scope of application of modular buildings has become much wider. Improving, this design has become one of the best representatives of affordable housing for the general population. Many industrial enterprises not only mastered the initial technology for the production of modules, but also improved it to such an extent that the result of the work surpasses even traditional houses in characteristics. Now housing has become even more comfortable, functional and practical.

Helpful advice! If none of the options for a modular house for year-round living offered for sale suits you, no problem.Many major manufacturers are ready to construct a model with a unique design for your order.

Modular houses: device and features

Modular homes designed for year-round use are made up of racks and panels. The dimensions of these components are always standard - 2400 x 4800 mm. If you decide to design your future home yourself, be sure to take these parameters into account, because to create modules, it is necessary that their area is a multiple of these numbers.

Related article:

Projects of country houses for 6 acres: photo, description and requirements. Construction technology. Materials from which you can build a country house, which can be successfully placed in it.

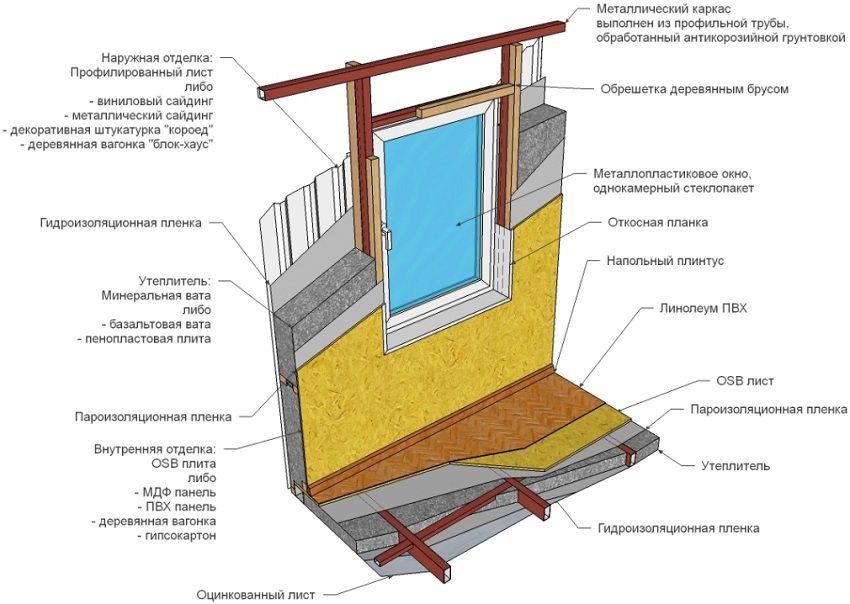

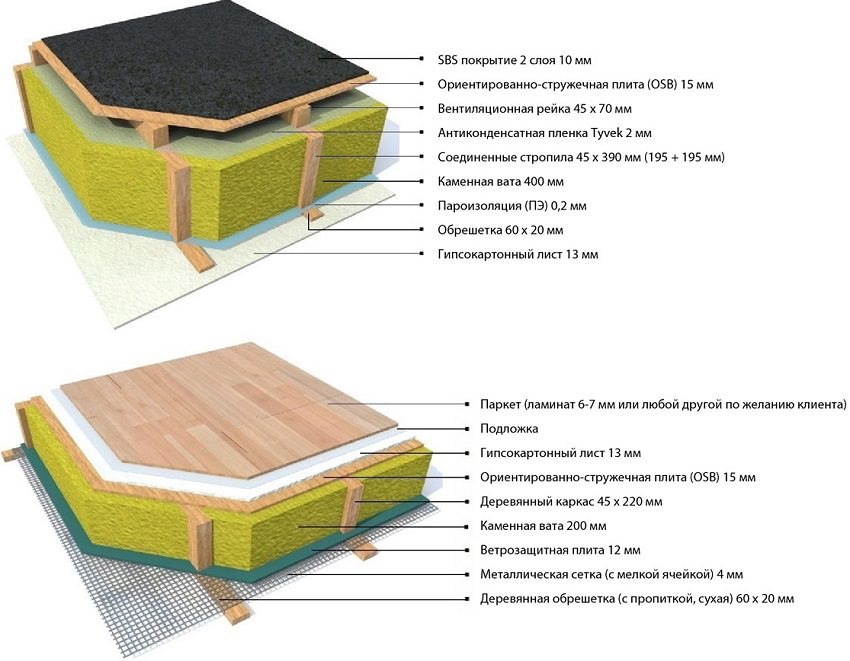

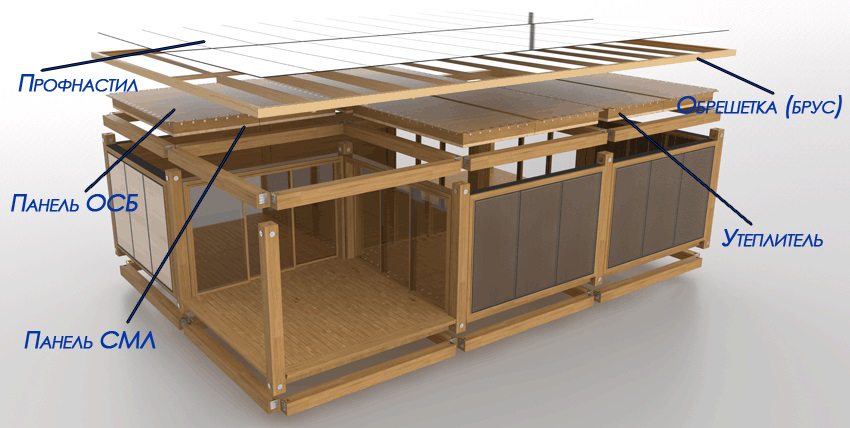

Outside, the panels are sheathed with moisture-resistant plywood, and inside - cement-bonded particle boards... In this case, plywood sheets are attached to a frame, which can be made of metal, wood, or both of these materials at the same time (combined). A layer of insulation must be laid under the cladding, in accordance with state standards and recommendations for each specific region of residence. In addition, each panel is treated with a special solution that improves its characteristics and ability to withstand external destructive factors.

If the soil on the construction site is suitable for such purposes, then a modular house is built on reinforced concrete slabs with the use of air cushions as prevention of shrinkage of the structure. The assembly process takes very little time, usually about a week. A team of workers and engineers goes to the site and assembles the structure, checking and measuring all the parameters necessary to create a strong and stable structure.

Helpful advice! A modular structure can become for you not only a residential building, but also a technical room or a garage.

Advantages and disadvantages of a finished home from the factory

Like any new technology, modular homes for year-round use have their own set of pros and cons. Having carefully studied and weighed each of these points, you can make a decision for yourself - whether to give preference to this type of housing, or to stay true to the traditional one.

Advantages of prefabricated houses:

- the fastest possible construction of a house;

- the possibility of building a new, beautiful and comfortable house, even on the most unsuitable land plots for construction;

- strength and durability of modular structures;

- excellent isolation from the factors of the outside world, which significantly saves energy costs for heating;

- the possibility of improvement and various modifications of the structure;

- the cost of such a house is much lower than even a one-room apartment;

- the weight of modular buildings can also be attributed to its advantages - one module weighs about 2.5-3 tons. This allows the installation of a building without the participation of heavy construction equipment. An ordinary crane will suffice. For transportation of the structure, minimal costs will also be required;

- an unusual advantage of modular designs, not available to other homes - mobility. As strange as it sounds, now you can move with your home. During the manufacture of modules, the possibility of reassembly and disassembly is laid in them. Therefore, by ordering a truck and a special crane, you can always take your home with you.

Disadvantages of modular designs:

- transportation can be expensive if the manufacturer is far enough from your construction site;

- multi-storey modular houses are losing their mobility due to their excessively large size;

- not all manufacturers are responsible for their work, which can negatively affect the quality of the finished product.

The variety of modular homes is not limited by any architectural or planning parameters. Due to the various combinations and joining of blocks, the structure can take on a wide variety of forms. Moreover, in any part of the frame module, you can easily cut an opening for a new door or window. In the same way, you can get rid of excess parts of the wall. The entrance to the house can also be modified by the presence of an end door, which can become the main entrance or exit to the veranda.

Turnkey construction of a modular house

How is the process of ordering and building a modular house for year-round living? We will analyze each point step by step, paying attention to the key points in choosing and buying a design.

First stage - market research of offers and manufacturers. At this point, check out the most popular construction companies that make modular homes. Feedback from those already living is the best guideline in choosing.

Having decided on the contractor, review all the models he offers or think over your own project of a modular house, which you can provide at a meeting. Keep in mind that the plan is not just the arrangement of rooms, windows and doors, but also the conduct of a lot of communications. Therefore, it may be better to entrust this business to a professional, taking into account your wishes.

Second phase - creation of documentation and an agreement with a construction company. It is necessary to prepare the site for construction and obtain permission from the relevant state authorities to bring various kinds of communications. This is followed by drawing up a plan for future expenses. After that, you can safely contact the construction company of your choice, where specialists will draw up an individual construction plan for you, as well as help you choose decorative elements and materials for finishing the house outside and inside.

Stage three - provision by the company of cost estimates for materials and work. Next, the construction project is approved by both parties, and work begins.

Of course, as elsewhere, there are clients of construction companies who were not satisfied with modular houses. However, the overwhelming majority of this is due to poor quality performers who manufacture non-certified products. That is why it is not recommended to try to save money by contacting little-known firms. Be careful in your choice and then you will not be disappointed.

Basic principles of building modular houses

The construction of modular structures is based on three principles that perfectly characterize this area:

- simplicity;

- profitability;

- construction speed.

After the approval of the work plan, construction of the structure begins. Due to the fact that most of the modules are manufactured in factories using modern automatic equipment and specialized conveyors, the process of creating sections is progressing extremely quickly. A typical house can be ready for installation in just one to two weeks. In the case of the development of an individual project by the customer himself, the deadlines are discussed separately. If a sufficiently complex structure is created according to the design plan, the construction still proceeds many times faster than the standard one, which requires many months.

Modular building with communications harmoniously blends with nature and does not cause unnecessary trouble

Stages of production of a modular house

Consider how exactly the manufacture of a modular house takes place in production:

- The plant manufactures special sections.

- Transport these modules individually to the construction site.

- Assembly and installation of individual components into a one-piece structure.

- Connecting all communications to the house: water supply, sewerage, heating, electricity, etc.

- Issuance of technical documentation by the manufacturer, which contains the characteristics of all modules, as well as guarantees for the specified periods.

Helpful advice! It is important to remember that each module requires its own set of documents from the manufacturer. There cannot be one certificate for the whole house!

Turnkey prefabricated houses: prices and stages of construction

The low cost of modular structures is one of the main advantages of this type of housing, thanks to which this project has become widespread. But what is the reason for this price difference between traditional and modular construction? What's the secret to being cheap? Consider all the stages of building a house and the elements of savings in them:

Laying the foundation. In order to build an ordinary reliable house, you must first prepare a solid foundation. It can be jellied or tape, made of stone quarry or brick, but in any case, these are considerable costs, which can be up to 30% of all costs.

A modular building does not require such a capital investment. It can be perfectly installed on a light foundation made of screw piles.

Walling. When building an ordinary house, you first need to erect the walls, then sheathe the surfaces with insulation, and only then proceed with the final finishing. One way or another, the loss of materials cannot be avoided in the process of work. On a construction scale, these losses can be very significant and noticeable. And this is considered normal, even if everything goes according to plan.

Modules are manufactured in factories where every piece and every grain of material is used. This allows you to significantly reduce the cost of the finished product.

Roof installation. In contrast to the traditional roof construction method, a special module is used in this case. This eliminates the need for installation costs.

Communications. All communications are assembled during the manufacture and assembly of modules at the factory. The more accurately the house plan with all the components is drawn up, the lower the cost of consumables will be.

Prices for the construction of small standard modular homes start at 200,000 rubles, and can increase depending on the size and complexity of the project.

Individual design of modular houses

Modular houses are a unique product of the modern construction market, high-tech and versatility of which meets all the requirements of modern housing.

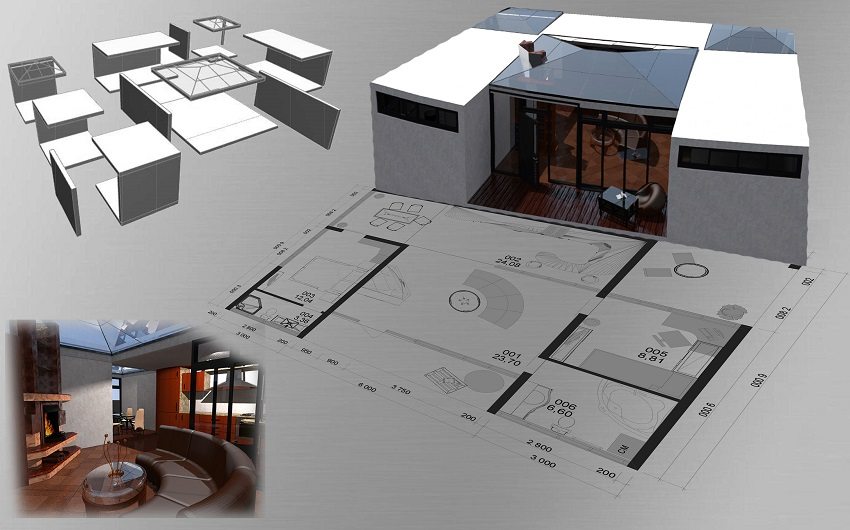

As mentioned earlier, there are now virtually no restrictions on size and design complexity for manufacturers. Sufficiently large construction companies that have all the advanced technologies and equipment can offer their customers the production of unique modules for design projects. The house can be made in absolutely any style and your wildest ideas can be realized in its design.

But not always individual sketches are just the wishes of the owners. Often you have to deal with complex environmental factors and reckon with the climate of the region, the landscape and the characteristics of the site. In this case, the task of specialists is to organically fit the structure into any environment, be it the foot of the mountains, the shore of a lake or river, a valley or a forest edge. In doing so, making house layout the most suitable for this type of conditions. A properly designed modular house will look good and appropriate everywhere.

Modular houses for year-round living in the country

A modular country house is also an excellent solution for building on a suburban area. To avoid unnecessary hassle and unnecessary expenses, many families prefer this type of housing. The presence of all communications makes the rest as comfortable as possible. And despite the fact that it is difficult to imagine a faster way of construction.

Many people have already discovered the possibility of owning their own home, using modular systems for construction. The prospects that opened up before these people are enormous, and most were satisfied with their choice.

Modular homes provide an opportunity to build your own home from scratch at affordable prices.