If you prefer natural building materials, pay attention to wooden beams: the best solution for a home in terms of environmental safety. The article will focus on the existing types of timber, the advantages and disadvantages of each of them. You will be able to estimate the construction costs using this or that material and make an informed choice, find out the cost of various types of timber and the prices for insulation materials.

Content

- 1 Specificity of projects of one-story houses from a bar and building prices

- 2 Common projects of houses from a bar: prices and photos

- 2.1 Features, photos and free drawings of projects of houses from a bar

- 2.2 Advantages and disadvantages of houses from a bar, how much does a turnkey finished building cost

- 2.3 Country houses from profiled timber: projects and prices for the purchase of material

- 2.4 Benefits of profiled timber structures and construction prices

- 2.5 Disadvantages of construction based on profiled material

- 2.6 Construction of houses from laminated veneer lumber: projects and prices for the purchase of blanks

- 2.7 Turnkey glued laminated timber houses: construction cost and material shortcomings

Specificity of projects of one-story houses from a bar and building prices

Experts recommend thinking before erecting a turnkey log house how much such a construction costs with all the costs of materials and payment for workers' services. Perhaps the purchase of a ready-made structure under some circumstances will not be so problematic and costly.

Useful advice! To come to some kind of informed decision, first you need to decide on the type of building, select the material and compare the prices for it.

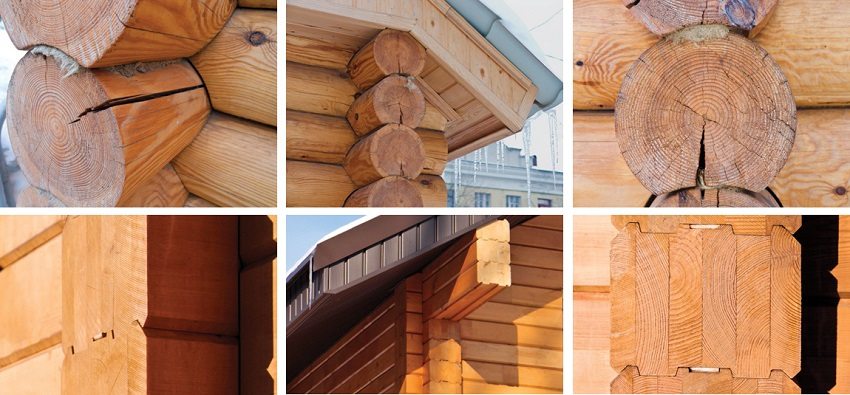

Wooden beams: the best solution for the home

The advantages of this construction technology are enough so that every year more and more of its supporters are found.

Advantages of timber cottages:

- environmental friendliness and cleanliness;

- high thermal insulation performance;

- simple construction system;

- affordability.

Most of the developers are attracted by the performance properties of the timber from which the timber blanks are made.

The construction market offers several varieties of timber:

- profiled;

- edged;

- glued;

- double.

Each of the listed types of material is accompanied by its own advantages and disadvantages. For example, an ordinary timber called edged timber allows you to build turnkey timber houses at the most budgetary cost.However, construction using this material requires shrinkage for at least one year. In addition, ordinary timber is prone to cracking.

The adhesive type of material is more resistant to deformation changes, however, the cost of such a construction is much higher. The main advantage of profiled products is the treatment with special impregnations that reduce flammability.

The use of profiled timber opens up wide design possibilities. The material is easy to handle and can be used to construct buildings of unusual shape.

Why is it more profitable to buy a house from a profiled bar than a frame house

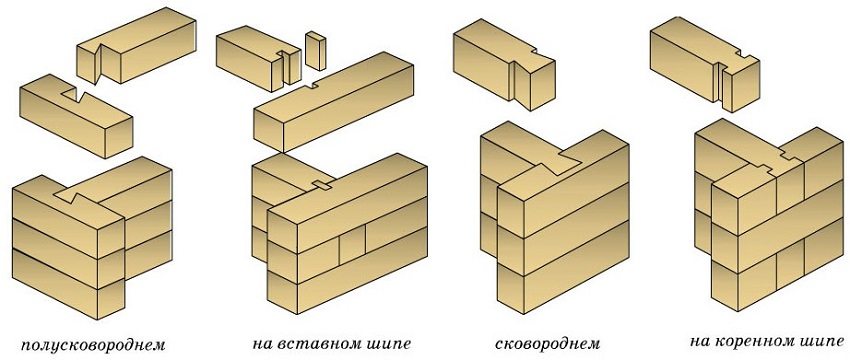

Due to the fact that the connection between the profiled elements is carried out by means of locks and a system of grooves, a tight fit is ensured and, as a result, the ability to retain heat increases. In terms of appearance, this material is very aesthetic.

Useful advice! Taking into account the high decorativeness of the material, the walls of the building can be left in their original form, abandoning the use of decoration. However, regular wood maintenance will be required. To do this, it will be necessary to impregnate the material from time to time with special protective agents that prevent blackening and rotting.

Frame buildings in the issue of sound insulation are significantly inferior to log houses. Natural wood has excellent sound absorption properties. If it is planned to build a building on the basis of a bar for year-round use, additional insulation must be performed. In this case, the thickness of the layer of heat-insulating material will be significantly less than the required indicator for frame construction.

The most minimal costs for insulation materials will be accompanied by construction on the basis of a bar 200x200 mm. So, the cost of a one-story house 6x6 m from it will be about 300 thousand rubles.

Related article:

Projects of houses from a bar for permanent residence: we build comfortable housing. Types of timber. Projects of houses from laminated veneer lumber. Finnish house, cottage with garage. Projects of houses from profiled timber.

Warming a house from a bar: how much does it cost to build a cottage, taking into account the cost of insulation

Insulation material must create a certain effect in order to perform its function at the proper level. Optimal climatic conditions for living are created when the indoor temperature does not decrease under the influence of changes in the external environment. However, in this case, the likelihood of the appearance of factors contributing to wood spoilage must be completely excluded.

In log houses, insulation is carried out almost everywhere:

- foundation;

- walls;

- window openings;

- doorways;

- floor;

- roof.

Average prices for heaters:

| Insulation type | Material name | unit of measurement | Cost, rub. |

| Mezhventsovy | Sheep's wool | running. m | 34 |

| Linen | m | 6 | |

| Jute | 8 | ||

| Flax | 4 | ||

| Polyurethane foam | Sprayed | m² | 600 |

| Penoplex | Extrol | m³ | 4500-5500 |

| Technoplex | 4000-5000 | ||

| Kinplast | 3400-4800 | ||

| Teploizoplit | 4000-4500 | ||

| Styrofoam | Styrofoam | 1700-3700 | |

| Mineral wool | Izovol | 2000-8500 | |

| Rockwool | 1800-2500 | ||

| Isoroc | 1900-7600 | ||

| Izobel | 1700-2000 |

The table shows the average prices for the purchase of insulation. If you do the procedure yourself, you can achieve significant savings.

Note! Mineral wool is a certified insulation. However, according to experts, it is not suitable for log houses and is considered hazardous to health, especially with incorrect installation.

Disadvantages of building houses based on timber

Compared with the frame construction technology, houses from a bar have some advantages, but there are some disadvantages here:

- buildings require time to shrink (at least a year);

- high probability of surface cracks;

- the negative effects of moisture can damage the building;

- there is a need for careful sealing of cracks;

- high level of fire hazard.

The shrinkage period itself does not pose any particular inconvenience for many owners, since such a scheme makes it possible to divide the costs into several parts. This is very beneficial in most situations. The negative attitude towards houses from a bar appeared due to cracks and deformation changes that occur during the drying process.

Modern developers often resort to savings, using materials with an insufficient level of drying for work. In some cases, cracks cause significant damage to the front of the house. We have to carry out work on grouting and finishing the building from the outside.

It is believed that houses based on timber are more environmentally friendly than frame houses. However, the construction of inexpensive turnkey houses from glued laminated timber cannot be called completely safe. The glued material is obtained by artificial drying. The wood is covered with special impregnations, due to which its natural properties are lost.

Useful advice! Due to the high fire hazard, the laying of wires and cables should be done carefully. Use a special flute. It is recommended that it be metal, since the walls in timber buildings have increased flammability properties.

Common projects of houses from a bar: prices and photos

Work on the construction of wooden houses is carried out using a bar as a building material. Opinions differ as to which raw material option is better, and experts cannot come to an unambiguous decision. The only thing that can be done is to analyze the characteristics of each of the materials, highlight the advantages and disadvantages and, based on the information received, come to a certain conclusion.

For the construction of cottages, the following types of timber are used:

- usual;

- profiled;

- glued.

Features, photos and free drawings of projects of houses from a bar

Construction work using conventional timber allows you to achieve an individual approach to project design. In this case, no preliminary adjustment of wooden elements is required; materials of various types and external characteristics can be used for interior decoration.

Many companies are selling ordinary timber for the construction of houses, since it is considered the simplest material of all varieties. This raw material is the most environmentally friendly, since in the process of obtaining it from the human side, the minimum amount of effort is applied.

The external characteristics of unplanned timber are quite modest and unpresentable in comparison with glued or profiled material. It is imperative that when working with it, you will need to carry out finishing and some preparatory procedures. However, buying an ordinary timber has its own advantages, since the price for unplaned material is more democratic than for other types of timber.

Note! The table below shows the average prices for the purchase of timber. These values may fluctuate depending on the region and the company selling building materials. In cities where the woodworking industry is developed, the cost of timber is much lower than where this industry is not developed.

Prices for the purchase of timber:

| Dimensional parameters of the workpiece, cm | The volume of raw materials in one piece, m³ | Number of blanks, pcs / m³ | Cost, rub / m³ |

| 10x10 | 0,06 | 16,6 | 6000 |

| 10x10 | 0,09 | 11,1 | 6000 |

| 10x20 | 0,12 | 8,5 | 6000 |

| 15x15 | 0,135 | 7,4 | 6100 |

| 15x20 | 0,18 | 5,5 | 6100 |

| 20x20 | 0,24 | 4,16 | 6100 |

Advantages and disadvantages of houses from a bar, how much does a turnkey finished building cost

Most people prefer to buy an inexpensive turnkey log house, since such buildings have many advantages:

- Affordable price - since the production of timber is accompanied by the minimum use of equipment and processing technologies, the cost of the material remains the lowest compared to other types of wood.

- Wide assortment - the material has various dimensional parameters, and it is also presented almost everywhere, which eliminates problems with the purchase.

- Simple wall construction system - construction is not only simplified as much as possible, but also reduced in time.

Useful advice! You can buy a ready-made house from a bar on the basis of carefully designed projects in any company that provides a turnkey house construction service. Most often, such firms can offer an extensive selection of ready-made projects.

Prices for two-storey log houses:

| Dimensional parameters, m | House area, m2 | price, rub. |

| 6x6 | 51,7 | 455400 |

| 6x9 | 72,4 | 753250 |

| 7x7 | 70,5 | 745750 |

| 7x8 | 77,5 | 802075 |

| 7x9 | 88,1 | 1175500 |

| 7.3x10 | 93,6 | 1250000 |

| 8x8 | 92,7 | 1200750 |

| 9x10 | 106 | 1433000 |

| 10x12 | 148,7 | 1834250 |

| 11x12 | 157,2 | 1842050 |

The disadvantages of a conventional bar are also available:

- cracks and deformation changes occur in the process of shrinkage and drying of the material;

- the execution of the outer cladding is mandatory;

- in the process of deformational changes during shrinkage, the walls are subject to distortion, gaps between the elements may form;

- treatment with antiseptic agents is required, otherwise the wood will turn blue.

Country houses from profiled timber: projects and prices for the purchase of material

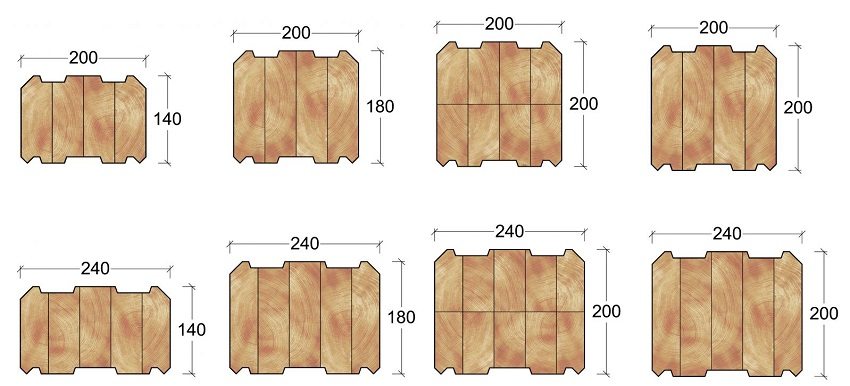

Profiled timber is a high-tech and natural building material. Coniferous trees serve as raw materials for its manufacture. After receiving the blanks, they lend themselves to special processing - milling. As a result of this manipulation, a certain shape of the products is obtained.

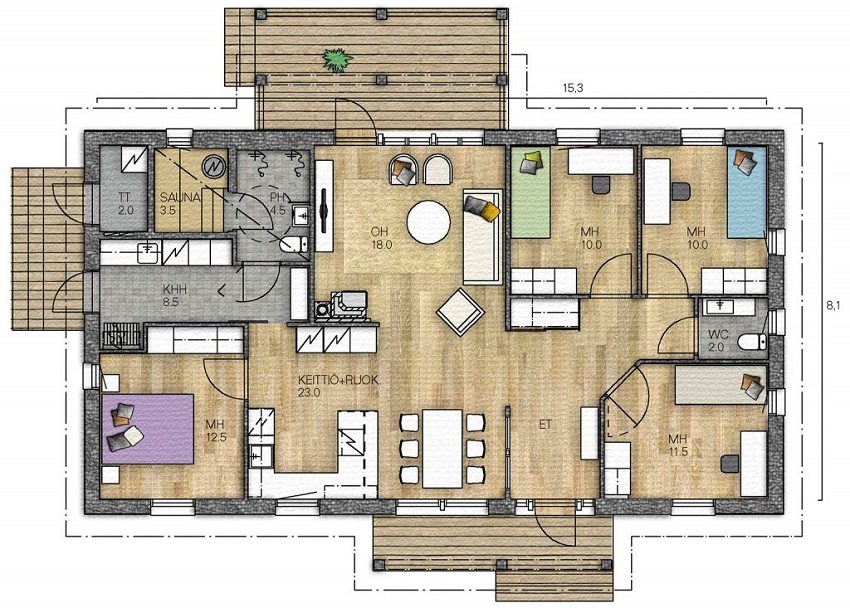

An interesting project of a large one-story timber houses with attic

Most often, protruding parts are located on the outside of the blanks, and flat on the inside, facing the house. However, some manufacturers produce flat products on both sides or, conversely, convex ones.

Prices for the purchase of profiled timber:

| Section size, cm | Overall dimensions of the workpiece, cm | The volume of raw materials in one piece, m³ | Number of blanks, pcs / m³ | Cost, rub / m³ |

| 10x15 | 9.2x14.2 | 0,09 | 11,1 | 7300 |

| 15x15 | 14.2x14.2 | 0,135 | 7,4 | 7300 |

| 15x20 | 14.2x19.2 | 0,18 | 5,5 | 7300 |

| 10x20 | 9.2x19.2 | 0,12 | 8,4 | 7300 |

| 20x20 | 19.2x19.2 | 0,24 | 4,16 | 7300 |

| Cutting bowls on material | ||||

| 10x15 | 9.2x14.2 | 0,09 | 11,1 | 9300 |

| 15x15 | 14.2x14.2 | 0,135 | 7,4 | 9300 |

| 15x20 | 14.2x19.2 | 0,18 | 5,5 | 9300 |

| 10x20 | 9.2x19.2 | 0,12 | 8,3 | 9300 |

| 20x20 | 19.2x19.2 | 0,24 | 4,16 | 9300 |

Profiled timber is solid wood that has undergone high-quality exterior processing. Due to the fact that the natural structure of the material is not disturbed, timber structures are able to "breathe".

Note! Profiled timber is a 100% natural material. It does not contain substances of chemical or synthetic origin.

Benefits of profiled timber structures and construction prices

Since the natural structure of wood is not disturbed during the production of blanks, all the natural properties of the material are preserved.

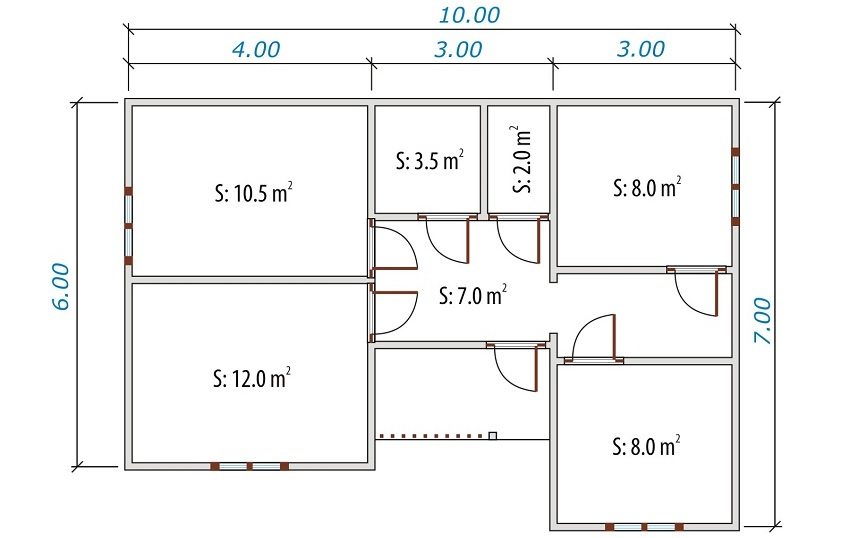

Project of a compact one-story house made of timber: 1 - terrace, 2 - vestibule, 3 - hall, 4 - living room, 5 - kitchen, 6 - bedroom, 7 - bathroom, 8 - children's

As a result, we get a lot of advantages from the construction of log houses:

- normal air exchange, natural humidity level and optimal climatic conditions inside the premises;

- attractive facade of the house, even without additional finishing;

- high level of thermal insulation;

- lack of drafts;

- the presence of grooves allows you to lay the workpieces as tightly as possible, thanks to which moisture cannot get into the gaps and cause foci of decay there;

- despite the high cost in comparison with ordinary timber, the profile material is much cheaper than glued;

- warmth of premises in winter;

- the total percentage of shrinkage is: larch - 4.5%, pine and cedar - only 3.5%;

- there is no need to caulk the joints;

- for insulation, it is enough to do with laying jute in grooves;

- simple and fast building construction scheme.

Prices for the construction of houses with an attic made of profiled timber:

| Dimensional parameters, m | House area, m2 | price, rub. |

| 6x6 | 50,4 | 505200 |

| 6x9 | 75,6 | 760250 |

| 7x7 | 68,6 | 743350 |

| 7x8 | 78,4 | 790100 |

| 7x9 | 88,2 | 870300 |

| 8x9 | 100,8 | 999350 |

| 8.5x9 | 76,5 | 1005350 |

| 8x14 | 107,1 | 1263850 |

| 9x9.8 | 123,2 | 1154200 |

Disadvantages of construction based on profiled material

Despite all the benefits that the construction of a house on the basis of a bar promises, the profiled material also has disadvantages:

- finishing can be carried out only after the timber has reached the required indicator of its relative humidity;

- after drying, cracks may appear, this moment depends on the time of year;

- construction of a building at low temperatures is accompanied by minimal cracks, which will be small. Heat, on the contrary, provokes the appearance of large damages on the material;

- on a square bar, cracks appear from different sides.

Note! The number of cracks can also be affected by the size of the material section. Billets have internal stress arising under the influence of uneven shrinkage, because of this, the material is covered with cracks in those places where the section has a large area.

Construction of houses from laminated veneer lumber: projects and prices for the purchase of blanks

Glued laminated timber is a material consisting of glued boards. The technology for creating such blanks is quite costly, both in terms of money and in terms of time. Therefore the cost houses made of laminated veneer lumber high enough.

Material advantages:

- due to the excellent decorative characteristics of the building, they do not need additional finishing;

- during operation, the timber does not undergo deformational changes, such as shrinkage, loss of shape, twisting or cracking;

- the workpieces do not have internal stress, like solid wood;

- the timber does not bend and does not shrink;

- has a dense structure and high strength (these values exceed those of a solid bar by 50-70%);

- deformation changes under the influence of moisture are excluded, since the boards are stacked on top of each other during the gluing process so that the direction of the wood grains is perpendicular;

- fast installation system;

- invulnerability to microorganisms and insects;

- durability and fire resistance.

Prices for the purchase of glued material:

| Section size, cm | Cost, rub./m. |

| 8x8 | 300 |

| 10x10 | 380 |

| 15x15 | 750 |

| 20x20 | 1110 |

| 10x15 | 570 |

| 15x20 | 970 |

| 20x25 | 1400 |

| 10x20 | 700 |

Turnkey glued laminated timber houses: construction cost and material shortcomings

The material does not have many drawbacks, but it still has them. Firstly, it is a high price, which exceeds the cost of a solid bar three times. Secondly, glued laminated timber is less environmentally friendly than conventional and profile.

Note! The presence of an adhesive in the workpieces reduces the breathability of the material.

Prices for the construction of two-storey houses made of glued material:

| Dimensional parameters, m | House area, m2 | price, rub. |

| 9.4x9.1 | 128,3 | 2938800 |

| 9.4x11.2 | 157,92 | 5009750 |

| 10.2x7.9 | 80,5 | 2843675 |

| 11.4x8.8 | 120,7 | 4954350 |

| 11.4x15.9 | 271,5 | 6103200 |

| 11.7x14.9 | 261 | 5706200 |

| 14.5x13 | 282,7 | 6159800 |

Features of a double bar: house designs, construction price

As a building material, double timber can provide several benefits:

- almost complete absence of shrinkage;

- light weight, which simplifies not only transportation, but also construction;

- absence of cracks and deformations;

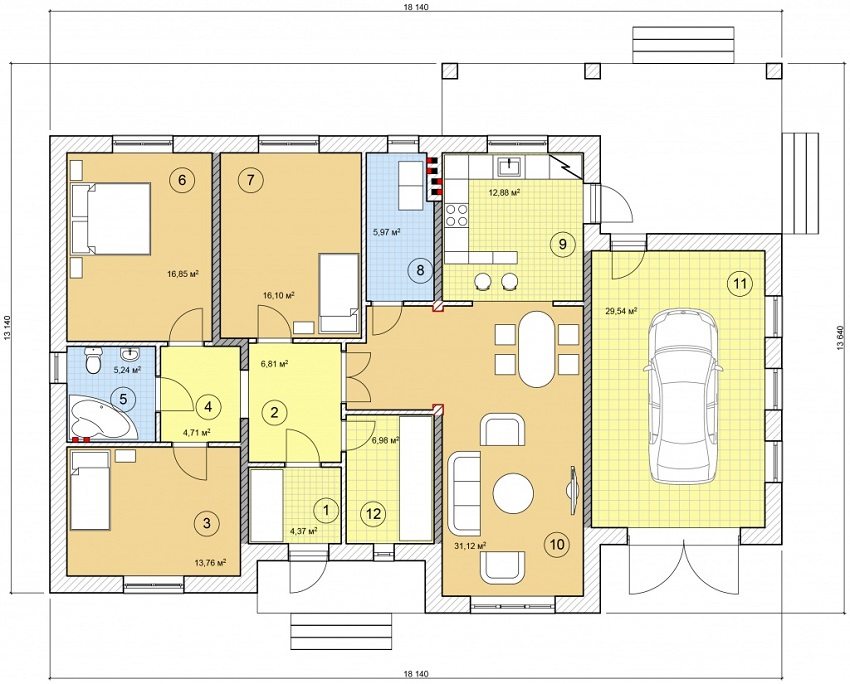

One-story project houses with garage and a convenient layout: 1 - vestibule, 2 - entrance hall, 3 - bedroom, 4 - hall, 5 - bathroom, 6 - bedroom, 7 - bedroom, 8 - laundry, 9 - kitchen, 10 - living-dining room, 11 - garage, 12 - wardrobe

- if it is planned to build a bath, there is no need to install a vapor barrier material;

- no need for pins and inter-lead seals;

- high ability to keep warm.

Prices for the construction of houses with a double bar attic:

| Dimensional parameters, m | House area, m2 | price, rub. |

| 6x8 | 62,4 | 4831500 |

| 7x7 | 63,7 | 5599000 |

| 8.4x13.7 | 149,5 | 6788000 |

| 8.4x17.8 | 194,3 | 7504000 |

| 8.5x8.5 | 93,6 | 6204500 |

| 9.3x6.5 | 78 | 6009600 |

| 11.6x7.7 | 115,7 | 6454500 |

Double timber allows you to finish building a house in 1-2 months. The walls obtained as a result of such construction do not need additional finishing, since the external characteristics of the house are the same as in the case of using glued material.

As an internal insulation, which is filled up between the elements of a double bar, it is used:

- ecowool;

- mineral wool;

- sawdust;

- bulk cellulose.

Taking into account the disadvantages and advantages of each of the materials, as well as the prices for the purchase and construction, we can conclude: the beneficial properties of materials have a direct impact on their cost and the final price of the building.

Plain timber is the simplest and most affordable material. Construction on the basis of a double beam is considered the most expensive and high quality. Profiled and glued material options in this chain occupy an average position, both in terms of durability and quality, and in terms of prices.