Any repair is not only laborious, but also costly. Therefore, in order for the costs to be justified, special attention should be paid to high-quality finishing materials. One of the innovative developments in the construction industry is fiberglass. This material is used as a base for surface finishing. This article provides information on what constitutes a fiberglass for painting and what technology for its installation.

Content

- 1 What is paintable fiberglass

- 2 Advantages and disadvantages of painting cobwebs

- 3 Varieties of fiberglass for the ceiling and walls

- 4 Glass insulation characteristic: roll material based on fiberglass

- 5 Well-known manufacturers of spider webbing glass fiber

- 6 How to glue fiberglass: work algorithm

- 7 What to glue the fiberglass: choosing the right composition

- 8 Characteristics of Oscar glue for fiberglass

- 9 Preparing fiberglass for painting: important recommendations

- 10 Painting fiberglass on ceilings and walls

What is paintable fiberglass

The first step is to figure out what a fiberglass is. The material is represented by non-woven fabric, which is obtained from the smallest glass fibers using pressing technology. Due to its appearance in the form of a translucent thin product, it is called a painting cobweb. This can be seen in the photo of the fiberglass for painting. The threads are interconnected in a chaotic manner by means of an adhesive based on organic resins. The main raw material for the material is quartz sand.

Fiberglass is sold in rolls 1 m wide and 50 m long. The density of the material can vary between 25-50 g / m², which is selected depending on the plane of application of the material. For vertical surfaces, you need to take fiberglass of a lower density, and for walls, use a denser material.

The main purpose of the material is to prepare the base for finishing. The use of fiberglass makes it possible to exclude the formation of cracks on the surface. It allows you to level the base without the use of global and time-consuming work, such as plastering the ceiling and walls.

Its main function is surface reinforcement. The surface prepared in this way will retain its attractive pristine appearance for many years, eliminating the need to mask the cracks that have arisen. The material is fixed with a glue mixture, followed by painting or wallpapering.Fiberglass can be used for various substrates in rooms for any purpose.

The material is characterized by versatility and a wide range of applications in various areas of construction. It can be used when making drainage holes, for organizing waterproofing, making wall panels and floor cladding, preparing mastics when creating a roof and to increase the life of metal pipes.

Advantages and disadvantages of painting cobwebs

Fiberglass for wallpaper or painting is characterized by increased resistance to temperature extremes. Substrate preparation can be carried out at temperatures from -40 to +60 ° C without affecting the surface quality. The material is breathable and hygienic. The fiberglass mat does not attract or accumulate dust due to its antistatic properties. It eliminates the likelihood of condensation on the surface, which is the cause of the formation of fungi and mold.

Cobweb fiber glass is characterized by hypoallergenicity, which is especially valuable for young children and people with allergies. They do not have a negative impact on human health, which is due to their environmental friendliness.

One of the significant advantages of the material is its fire resistance. It is impossible not to highlight high wear-resistant qualities, due to which the base will retain its original appearance for a long time, which eliminates the need for frequent repairs. This surface can be painted repeatedly. Fiberglass is notable for its affordable cost, as a result of which repairs can be performed efficiently and inexpensively.

Despite a large number of positive factors, fiberglass has rather serious drawbacks. It is necessary to work with the material with extreme caution, since small fragments of glass may break off during its laying. This can be harmful to health.

On contact with the skin, the glass fragments cause itching. A more serious consequence, which will require a visit to a doctor, is the entry of elements into the respiratory and visual organs. Therefore, it is necessary to work in closed clothing, gloves, a respirator and goggles.

Varieties of fiberglass for the ceiling and walls

There are three main types of fiberglass used in construction. The first option, which is often called a ceiling spider web, has a density of 25 g / m². The weight of 1 m² of material is only 25 g. The use of fiberglass is justified for painting ceilings, since the fiberglass is lightweight, thanks to which it is convenient to glue.

The distinctive advantages of the material also include a small consumption of paint, which will be needed for the topcoat. However, low density fiberglass can be used for surfaces that do not have large cracks and irregularities.

Fiberglass with a density of 40 g / m2 is considered a universal spider web, the strength of which is twice as much as the previous version, but it has a lower cost than thicker counterparts. Such material is used for surfaces that are more exposed to mechanical stress, which is more typical for walls. However, it can also be glued to the ceiling, which is finished with dilapidated plaster. Such fiberglass is also suitable for finishing wall and ceiling coverings in rooms that are subject to high vibration loads.

Fiberglass for painting differ in different density levels

One of the most durable options is a fiberglass with a density of 50 g / m². The material is capable of sealing large cracks.It can withstand significant mechanical loads, so it is advisable to use such a cobweb when decorating industrial premises, workshops, garages, where there is a high probability of damage to the fence structures. The cost of installing such material is much higher than the cost of gluing previous analogues, which is associated with the large weight of the products and the significant consumption of glue for the cobweb.

Important! High strength fiberglass is not recommended for use in apartments and houses.

Glass insulation characteristic: roll material based on glass fiber

For roofing works, Tekhnonikol fiberglass has proven itself well, on the surface of which a highly oxidized bitumen composition with mineral additives is applied. As a protective coating, a polymer film or a coarse grain powder can be used.

The material is characterized by biological resistance, resistance to ultraviolet rays and temperature extremes, environmental safety, high insulating qualities, sound absorption, low thermal conductivity, strength, flexibility, elasticity, ease of installation and durability.

Stekloizol is available in several varieties. HPP material is characterized by low tensile strength. There is a specialized film on the fiberglass. Such a lining provides reliable protection of the base from moisture. The material can also be used as a waterproofing material for pipelines and underground structures.

TPP roll material is characterized by high tensile strength and increased resistance to significant mechanical stress. There is a low-melting polymer film on both sides of the web, which eliminates the possibility of material sticking during transportation and during storage. This type of glass insulating material is also used as an underlay for roofing.

Fiberglass HKP has a protective coating in the form of coarse shale chips, over which a protective polymer shell is applied. Such material is intended for the device of the upper layer of the roof.

Important! Fiberglass HKP is used for flat surfaces with a slight slope.

The most durable cloth is glass fiber TKP, the basis of which is a frame fiberglass with a coarse-fraction shale granulate applied on top and a protective polymer film. Such material is used for arranging roofs with a slope of up to 10 °.

Well-known manufacturers of spider webbing glass fiber

To select a quality material, you should pay attention to fiberglass fabrics made by well-known manufacturers. The companies Wellton, Spectrum, Oskar, Samtex have proven themselves well. Depending on the density of the material, the price of fiberglass for painting will be 800-1500 rubles. per roll.

The Swedish manufacturer Oskar offers quality products that are characterized by good wear resistance and affordable cost. You can tear or cut the cobweb only on purpose, with a sharp object. To paint such Oscar fiberglass you will need a minimum amount of paint, even when painting without using putty. You can buy Oskar fiberglass from 1200 rubles. per roll.

Samtex reinforcing material is in demand for protecting surfaces from cracks. The cobweb is durable, hypoallergenic, wear-resistant and has good energy-saving properties. You can buy such a universal material for decorating walls and ceilings from 800 rubles. per roll.

When performing painting and repair and construction works, glass fiber from the Finnish company Wellton is very popular.The spider web is characterized by increased fire safety, resistance to humidity, high temperatures and aggressive environments, high density, hypoallergenicity and a long period of operation. The cost of the material is 1000-1200 rubles. per roll.

The Dutch company Spеktrum specializes in the production of high-quality fiberglass fabrics at an affordable cost. The material can be applied to any surface. A special place in the range of products is given to dense fiberglass, which provide reliable protection of the wall surface from cracks and other damage. The price of fiberglass starts from 600 rubles. per roll.

How to glue fiberglass: work algorithm

Before gluing the fiberglass for painting, it is necessary to provide optimal working conditions. The walls should be inspected for visible imperfections such as cracks, potholes, and other defects. They must be removed with a plaster mixture or putty. Further, the base is treated with a special primer, which must have good penetrating power. Such a mixture helps to level the surface structure, bind dust and fill microcracks.

Important! Gluing fiberglass on the surface of the wall or ceiling is carried out at a temperature of 15-25 ° C, relative humidity not higher than 60%, excluding drafts and direct sunlight.

After applying the primer, it is necessary to allow time for it to dry completely. This is very important, since the formation of a fine crystal lattice with high adhesion occurs. This film will be broken if you do not wait until the base has dried.

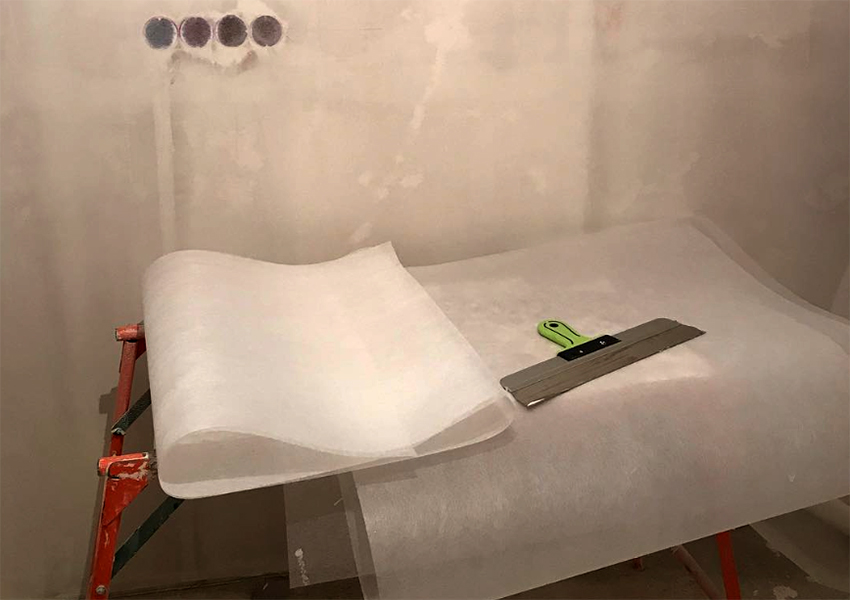

Before gluing the fiberglass to the ceiling or wall, you need to prepare the material. It is very inconvenient to work with long, solid panels. They are cut into elements convenient for work. In this case, the presence of allowances (1-2 cm) at the edges should be observed. Next, the glue is prepared. It is applied to the back side of the strip of material along the width and sides, distributing it in a thin layer - 1-1.5 mm.

Important! Material consumption is 10 g per 1 m² of cobweb.

Fiberglass for painting: installation technology

When performing work, it is important to consider how to properly glue the fiberglass. The process starts from the corner of the plane. It can be a wall or ceiling. After gluing the first overlap strip, the second element is fixed, which is subsequently trimmed. The pile on the material should point to one side. Otherwise, the surface after painting will be unaesthetic. Thus, the remaining parts of the finish are mounted.

The price of gluing the fiberglass depends on the plane of the finish. The cost of lining the ceiling will be slightly higher compared to the cost of pasting the wall.

When gluing glass fiber to drywall, the material should be positioned so that its butt joints do not coincide with the seams between the drywall sheets. To exclude such a moment, you must first mark the base.

Related article:

Photo wallpaper on the wall: how to glue different types of products

Rules for gluing different types of canvases. Preparation of walls, materials, tools. Step-by-step photo and video instructions for gluing wallpaper.

An important step is the careful joining of adjacent strips. The joints should be additionally impregnated with glue and pressed well with a spatula. The finished finish should dry completely, which will take 2 days. You can stick the material on your own or invite a specialist to finish the surface with fiberglass. Price per m2 starts from 150 rubles.

Helpful advice! For a more reliable fixation of the fiberglass, it is recommended to additionally coat the surface on top with glue of a liquid consistency.

For ease of installation, the fiberglass is cut into separate canvases, taking into account the allowance

What to glue the fiberglass: choosing the right composition

Two types of glue can be used for gluing to the surface of glass fiber: dry powder and ready-mixed. It is important to choose formulations designed specifically for this material. Wallpaper glue will not work. This is due to the fact that the fiberglass is heavier than paper, so the usual composition may not withstand this weight. In addition, fiberglass fabric has a structure of woven fibers that wallpaper glue will not bond.

The adhesive composition for fiberglass for painting on a ceiling or wall contains high quality components that do not have a negative effect on the human body. This glue is characterized by anti-fungal properties.

When buying ready-made glue, the date of manufacture of the composition is checked without fail. Expired goods will not provide the desired result. The surface may swell, causing the web to peel off. Opened containers must be used up as soon as possible. Therefore, when buying a ready-made composition, one should focus on the surface area and material consumption required to fill it. The cost of the finished mixture is in the range of 450-600 rubles. for 10 kg.

Helpful advice! The material consumption rate is indicated on the plastic container.

What fiberglass is glued to: other composition options

Dry powder glue is more advantageous to use. The finished composition can be prepared in the required volume. The powder should be diluted with warm water, which is carried out in accordance with the instructions. Dry composition can be bought for 400-450 rubles. for 0.5 kg.

Helpful advice! According to reviews, it is better to paste over glass fiber for painting with mixtures of recognized brands Wellton, Oskar, Pufas and Bostik.

You can glue the fiberglass with PVA glue. However, it should be borne in mind that the material has a low density, therefore, it transmits a large amount of ultraviolet radiation. After some time, the glue will turn yellow, which will affect the decorative effect of the final coating. Therefore, when gluing fiberglass to PVA glue, paint should be chosen in dark shades.

You can make the glue yourself. Before gluing the canvas with gelatin, a composition is prepared at the rate of 25 g of substance per 350 ml of water. After the gelatin is soaked for 1 hour, add ½ tablet of crushed aspirin and 1 tsp. glycerin or castor oil. The mixture is heated to a temperature of 40-45 ° C and removed from the fire. When the glue has cooled, it will have a medium-soft jelly consistency.

Characteristics of Oscar glue for fiberglass

According to numerous reviews, it is better to glue fiberglass with Oskar, a water-dispersible acrylic glue, which includes PVA, latex, modified starch and antiseptic additives. The glue can be presented in the form of a dry powder, which is easily diluted with cold water without the formation of lumps, and a ready-made composition.

The finished mixture is frost-resistant, so it can be stored at 50 ° C for 1 month. After the 5th defrost, the composition will not be suitable for use. The finished glue is available in 5 and 10 liter buckets. Stored unopened for up to 3 years. You can buy Oskar glass fiber glue from 500 rubles. The dry composition is stored for up to 2 months. It is produced in bags of 1 and 10 kg, in cardboard packages weighing 200 and 400 g. The cost of the smallest packaging is about 200 rubles.

The product is applied to the surface to be decorated. Thanks to the elastic base, the position of the blade can be easily adjusted until the glue dries.The mixture contains antiseptic additives that prevent the formation of mold, fungus and pathogens. Environmentally friendly composition It has no odor, is non-flammable, non-combustible, explosion-proof mixture. The adhesive has good breathability.

The composition is characterized by an economical consumption, which is 350 g per 1 m² of fiberglass. Once completely dry, Oskar glue becomes completely transparent. It provides high bond strength due to good adhesion properties. You can stick high-density fiberglass on it, which will not sag and will not fall off over time.

Important! Oskar glue can be used not only for glass mats, but also for paper, non-woven and fiberglass wallpapers.

Preparing fiberglass for painting: important recommendations

The solution to the question of the need to putty the surface causes some disagreement among the masters. The cobweb has a beautiful structure, which many want to preserve, but in this case, the paint consumption will be significant, since it will be necessary to paint the glass fiber without putty in 4-5 layers. In addition, joints will be noticeable on the surface, no matter how ideally they were made.

Another reason why it is necessary to putty the fiberglass is the likelihood that the smallest particles of glass that are harmful to human health will get into the air. A layer of plaster will completely eliminate this disadvantage.

Any good quality finishing mixture on a polymer or gypsum base is used to putty the glass fiber surface. The composition is applied after the surface has completely dried. The putty should be applied in two layers with a break of 24 hours. The first layer must be no more than 2 mm thick, the second must completely cover the initial base. After drying, the surface is rubbed with sandpaper to give it a smooth structure. Before painting or wallpapering, the cobweb must be primed again and wait until the surface is completely dry.

Painting fiberglass on ceilings and walls

Cobweb painting is carried out on the same principle as painting any other surface. Before painting fiberglass, you should choose a paint. To do this, you can use a water-based acrylic, silicone or latex mixture.

Latex paint is the most popular because it has many benefits. It is easily and quickly applied to the substrate, creating a durable, abrasion and water-resistant surface that will have an attractive matte finish. The paint is sold mainly in white, it can be tinted in any tone. The latex composition is affordable.

Latex paint is made on a water-dispersion basis, without the use of chemical components. Therefore, this material is best suited for children's rooms. The paint contains natural latex, thanks to which the final coating will be resistant to water and also durable. With the help of an acrylic agent, it is possible to obtain a glossy, matte and semi-glossy surface.

Silicone paints are also environmentally friendly as they do not contain harmful components. Thanks to such compositions, the surface is vapor-permeable, water-resistant, heat-resistant, not exposed to fungus, mold and ultraviolet radiation. The coating does not get dirty and can retain its original gloss for more than 15 years. The main disadvantage of this paint is its high cost.

Fiberglass painting is performed in two layers.However, an interval should be maintained between their application until the surface is completely dry. Otherwise, the paint will crumble and may peel off after a while in layers, exposing the fiberglass.

For high-quality staining of the surface, use a nap roller. It is better not to use a foam analogue, since it can crumble into pieces. You also need a brush to paint the corners and joints.

Fiberglass for filling and painting is a modern material that solves many problems in surface finishing. It not only acts as a protective coating on the base, extending its service life, but also as a decorative layer that is used for painting.