When replacing windows, in order to save money, you can sheathe the slopes on plastic windows with your own hands: a video with the nuances of this process will help you do this without problems. However, what material to choose for installation and how to fix it on the plane of the slopes, you need to know for sure.

The slopes on the windows are made of clinker tiles

Content

How can you sheathe slopes on plastic windows with your own hands: video and description of materials

Today, it has become commonplace to replace windows with plastic structures, which have excellent heat retention performance, fencing from street noise, and also an aesthetic and presentable appearance. The peculiarities of the installation of plastic windows involve the complete dismantling of old window blocks, during which the entire finishing of the slopes is often destroyed. Therefore, after the completion of the work, it remains for us to contemplate an unattractive picture of polyurethane foam sticking out from everywhere and plaster falling off from the disassembled slopes.

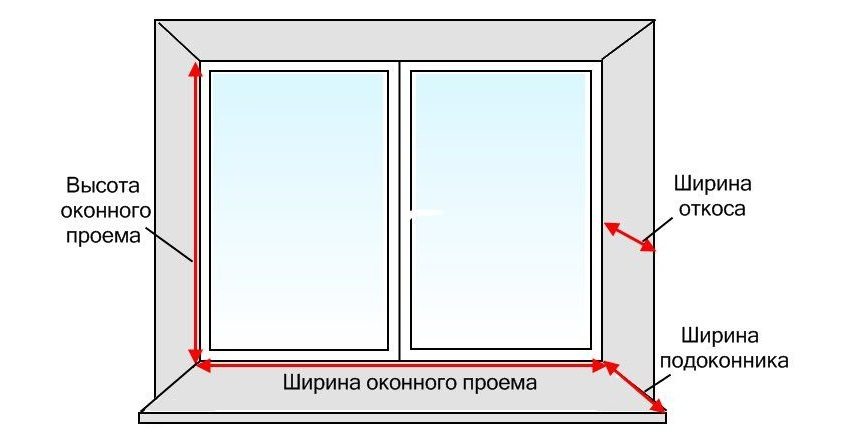

Before starting the installation of the slopes, it is necessary to make the appropriate measurements

Whatever material is used, the finishing of the slopes must be done efficiently and in a timely manner. Indeed, many are delaying with this, allowing moisture to penetrate into these places, forming a fungus there and attracting other unpleasant consequences. If you yourself know how to work with your own hands and control the tool, then it will not be difficult for you to sheathe slopes on plastic windows do it yourself. There are many videos with instructions for each material. We will look at three of the most popular ways to finish slopes here: plaster, plastic and drywall. Metal elements are also used on the outside of the window.

Useful advice! Before changing windows, decide in advance what material you will use to trim the slopes. This must be done immediately to avoid moisture penetration into the walls.

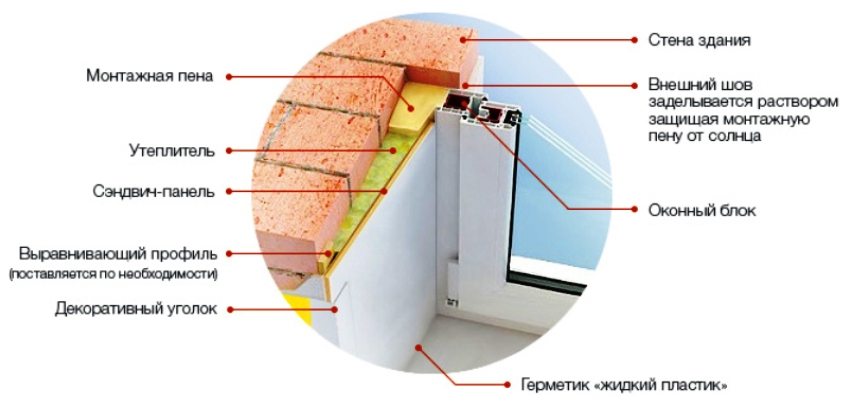

DIY sandwich panel slopes (video)

Distinctive features of slopes from various materials

The oldest and most proven method of finishing indoor slopes is plastering them. Today hardware stores abound in a wide variety of plaster mixes.The main advantage of plaster is its low price and the ability to apply any paint or finish to it with other facing materials. But don't try to do it yourself if you have never plastered. Before you make a flat surface yourself, you need a long training on less difficult areas, for example, on walls.

The most convenient material for mounting slopes is plastic. Wall panels made of it have different colors and sizes, which allows you to make the necessary choice without unnecessary problems. In addition, there is a whole set of corners and other details that allow you to design the slope in the best way. The advantages of plastic are: absolute flatness of the surface, ease of installation, a huge variety of decorative design, impermeability to moisture, the ability to replace an individual element without dismantling the entire structure.

The cost of plastic wall panels that are used for finishing slopes is low and suitable for low-budget repairs. Its combination with plastic window blocks just perfect. Slopes made of PVC panels have no pronounced disadvantages.

Installation diagram slope using sandwich panel

For the external finishing of the slopes of the windows, parts made of galvanized steel, covered with a polymer film with a dye, are used. Most often they are used on facades covered with metal siding. These parts are specially made for finishing the slopes on plastic windows with your own hands. The video of the installation of metal parts for the slopes perfectly illustrates the whole process from start to finish.

Corrosion resistance and attractive appearance play a decisive role in the choice of this material for outdoor slope finishes. Metal slopes have a slightly higher cost than all other types of them.

A very popular step is finishing the slopes with plasterboard sheets. For this purpose, choose a moisture-resistant drywall, since window slopes are traditionally considered places with high humidity. Condensation always forms on the windows, and such sheets are very resistant to it. You can, of course, use ordinary drywall sheets, but then they must first be coated with a primer several times or treated with a moisture-proof solution. Heat resistance, excellent thermal insulation and sufficient stiffness of the sheets allow them to be used without any fear for finishing window slopes.

Drywall is the cheapest material from all of the above, not counting plaster. If damaged, it can be easily repaired by simply covering the dent with putty and painting over. If the air humidity inside the room is high, then water vapor is absorbed by the drywall, and with a lack of moisture, they are released into the surrounding air, producing a kind of circulation.

Related article:

Adjusting plastic windows yourself: video instruction. Winter-summer mode. Setting the pressure mechanism. Buttonhole adjustment. Repair of metal-plastic windows.

Anyone who has ever made drywall slopes with their own hands knows that this material is afraid of excessive moisture. Already 75% of its content in the air is capable of stratifying sheets into components. In addition, slope damage is not uncommon. After all, a slight impact is enough for the sheet to break or a dent appears on it.Another "disease" of this material is that over time, various spots appear on it, which need to be painted over periodically.

How to plaster window slopes (video)

Do-it-yourself step-by-step instructions for the device of drywall slopes

Let's take a closer look at the process of finishing the slopes with plasterboard sheets. Note that there are several ways to attach them inside the window opening:

- over a wooden or metal lathing. This method is used in the case of finishing this wall with plasterboard completely;

- using polyurethane foam;

- by gluing to glue or putty.

Since the gluing method is the most common, we will describe it step by step:

- preparing the surface for finishing. To do this, we strip off all the excess foam, cutting it off with a knife. We remove pieces of plaster and various contaminants, after which we take a vacuum cleaner and remove dust from the entire window opening. We treat the entire plane of the slopes with a primer, simultaneously sealing cracks and potholes with the help of a plaster composition. Plasterboard sheets are treated with a moisture resistant substance. This will make it difficult for moisture to penetrate inside and mold formation there;

- gypsum plasterboard sheets are measured strictly in size and the workpieces are cut with a sharp knife. The length and width of the slope are subject to measurements. When cutting, take into account the slope angle of the slope plane in relation to the window plane. The sheet should be cut at the same angle so that the parts are fixed more reliably;

- a plastic starter strip is attached to the window block and window sill using self-tapping screws. The width of its gap should be equal to the thickness of the sheets. Most often it is 1 cm;

- assembly begins from the upper plane of the opening. The edges of the panel are well coated with glue. The width of the sticky layer should be at least 2 cm. One edge of the panel is inserted into the guide strip, and the other is pressed with force against the plane of the slope. Do the same with all three panels. In this case, the side ones are also inserted into the guides, which are screwed to the windowsill. All mating parts are processed with a sealant;

- the finished surface of the slopes is treated with putty twice or even three times for better quality. After it dries, grout the entire plane. The slopes are ready for finishing. They can be painted with any dye or pasted over with wallpaper.

Useful advice!When installing drywall slopes with your own hands, metal perforated corners should be installed on the corners. They will ensure their durability and give even lines.

Do-it-yourself high-quality design of slopes for plastic windows, the video of the options of which must be watched, is of decisive importance not only in the attractiveness of the entire window opening for the gaze, but also for effective heat conservation in the apartment.

DIY plasterboard slopes (video)