One of the common and important problems of a private timber house is a cold floor. This is due to the outflow of cold air currents from the ground, which penetrate through the cracks. In order for the room to be warm and comfortable, it is necessary to insulate the floor in a wooden house from below. How to do this, what materials are used for this and the main points of installation work are described in this article.

Content

Why you need to do floor insulation in a wooden house from below

Warming wooden floors in a private house, it is technically correct to carry out from below, which is due to a number of reasons:

- this avoids resizing the room in height on the ground floor;

- you do not need to choose a hard insulation that can withstand the weight of furniture and home appliances;

- thus, the owner protects the entire wooden floor from freezing;

- the line of condensate settling outside the structure is reduced. This prevents the whole house from rotting.

Nuances of floor insulation in the house

The choice of materials and methods of floor insulation in the house depends entirely on the design features of the structure, the individual capabilities and preferences of the owner. The nuances of installation and the specifics of the operation of the wood itself must be taken into account.

Wooden houses can be:

- frame type;

- on screw piles;

- on a strip foundation;

- on a pile foundation.

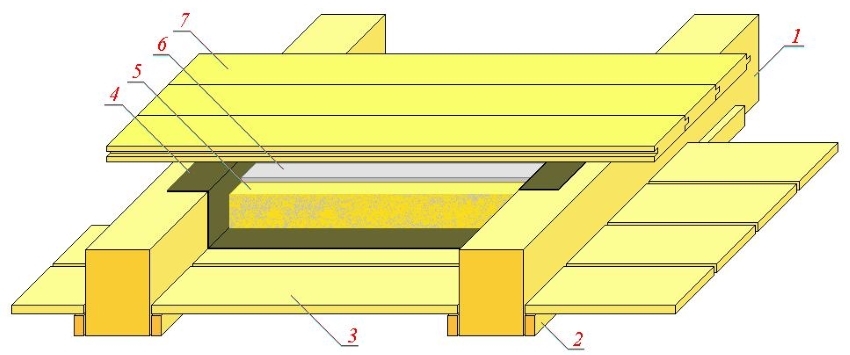

Scheme of floor insulation in a wooden house: 1 - beams (logs), 2 - cranial bar, 3 - subfloor boards, 4 - glassine or lutrasil, 5 - backfill from shavings or sawdust, 6 - filling with a lime mixture, 7 - finishing floor boards

Regardless of what type the structure is, the insulation of a wooden floor in a private house has general specific nuances:

- the use of waterproofing is a must. This will prevent the boards from swelling. The best material for waterproofing is single sided fiber;

- to provide warmth in the room, it is necessary to make a two-layer insulation of the wooden floor from below in a private house. In such buildings, the flooring consists of boards tightly fitted to each other.This material is constantly exposed to changes in temperature and moisture. Therefore, wood for the floor must be processed with special means;

- the performance characteristics of the insulation should not change upon contact with wood.

All of the above points must be observed when carrying out floor insulation in the country and in a private country cottage.

Materials for floor insulation in a private house

The construction market offers a wide range of materials for floor insulation. They differ in cost, installation technology, optimal operating conditions, etc.

Materials used for floor insulation in a wooden house from below:

- mineral wool;

- ceramisite;

- penofol;

- polystyrene or expanded polystyrene;

- sawdust;

- penoplex;

- ecowool.

Each of the materials has its own advantages and disadvantages. The choice of it as a heater depends on the characteristics of the house, the financial capabilities of the owner and the type of flooring.

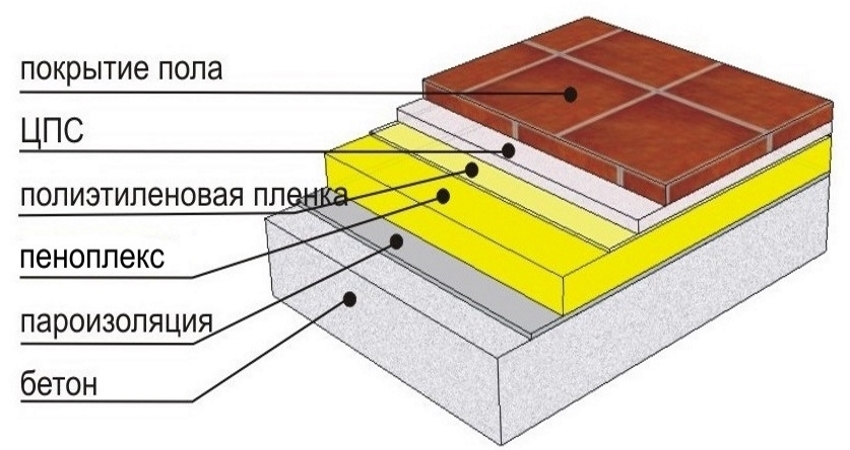

Features of floor insulation with penoplex

Penoplex is a common foamed polymer. It is distinguished by high strength, ability to keep its shape well. For the production of foam, the extrusion method is used. This allows for a strong structure with a large number of small cells inside for better heat transfer. Moisture does not penetrate inside the holes, so the material does not need additional waterproofing. Penoplex does not load the foundation of the building. Due to this feature of the material, it is most often used for floor insulation in a frame house on piles.

Mineral wool

Mineral wool is used most often as a heater. It is lightweight, does not burn, and has a high degree of protection against extraneous sounds.

There are three types of this material:

- glass;

- slag;

- stone.

This material is produced in the form of a dense plate or flexible mat. For ease of installation, the plates are marked with a blue stripe. This allows you to position the sheets in the desired direction.

The big disadvantage of this material is the ability to absorb moisture. Therefore, when insulating the floor in a private house with your own hands, you need to conduct a good vapor barrier.

Helpful advice! Working with cotton wool requires special protective clothing for the body, gloves and glasses. This is due to the fact that during installation work, small fibers are separated from the plates. They can irritate and itch the skin.

Insulation of the floor with expanded clay

Expanded clay is a small round porous balls of shale or clay. They are obtained by firing materials in a furnace at a high temperature. Expanded clay is considered a safe and environmentally friendly material. Among its advantages are:

- high sound insulation;

- resistance to low temperatures;

- environmental safety for humans.

A noticeable disadvantage of this material is its own weight seal. Expanded clay balls are pressed together. This leads to an increase in the weight of the substance and a decrease in thermal insulation properties.

Helpful advice! You should not choose this material for floor insulation in a wooden house on screw piles. An increase in the mass of the flooring can lead to subsidence of the foundation of the structure.

Using sawdust for floor insulation

Sawdust is a waste product of the woodworking industry. They have good steam and sound insulation characteristics, retain heat, and are environmentally friendly for humans. Sawdust is of low cost. The resulting thermal effect is not worse than that of expensive materials.Due to the cement component, they are also well suited for floor insulation in a ground floor apartment. Subsequently, such a screed can be used for laying laminate, linoleum, tiles, etc.

Sawdust is subjected to special treatment before use. This prevents the appearance of rodents and beetles in them. After that, they are mixed with cement and water and evenly applied over the entire area of the flooring.

Helpful advice! Clay can be used instead of mortar. This material is environmentally friendly and has better thermal insulation characteristics than cement.

Sawdust is ideal for insulating floors on the ground, especially if the building does not have a solid and solid foundation.

Floor insulation with foam

Floor insulation with expanded polystyrene is popular. Most often this material is called foam. The advantages of this insulation:

- low vapor and sound permeability;

- low thermal conductivity;

- resistant to external factors and chemicals;

- does not lose its properties for a long time;

- easy to install.

A significant drawback of foam is its susceptibility to moisture. He can absorb it into himself. This negatively affects the basic performance characteristics. He is also afraid of exposure to fire and high temperatures. But a simple and inexpensive technology for insulating floors with polystyrene is its significant advantage. This is what, in most cases, the owner of the house is guided by.

Helpful advice! If your summer cottage or private house is located on land with a close occurrence of groundwater or a high risk of flooding, you should not choose polystyrene as a heater. If the choice has already been made, you should take care of good waterproofing.

Ecowool

Polyurethane foam (ecowool) is a great way to solve the problem of floor insulation in an apartment on the ground floor and in a private house (dacha). This material is blown into the free space using a compressor. Thus, it fills all the voids evenly. Small particles that make up the ecowool provide excellent vapor barrier. The material is not affected by moisture, therefore, during its installation, additional waterproofing is not needed. This allows you to reduce the cost of insulation.

Related article:

Insulation for the floor in a wooden house, which is better to choose and how to mount

How to lay it correctly. Features of different types of insulation. Floor care tips. Popular manufacturers and cost of materials.

After hardening, a solid, even layer is obtained. It has excellent load bearing capacity. Light weight does not increase the weight of the structure. The service life of this insulation is more than 20 years.

A significant disadvantage of ecowool is the need to use special industrial equipment.

Helpful advice! Professionals say that waterproofing is not needed when insulating with this material. However, when insulating the floor in a country house without a foundation, it is better to lay an additional waterproofing layer.

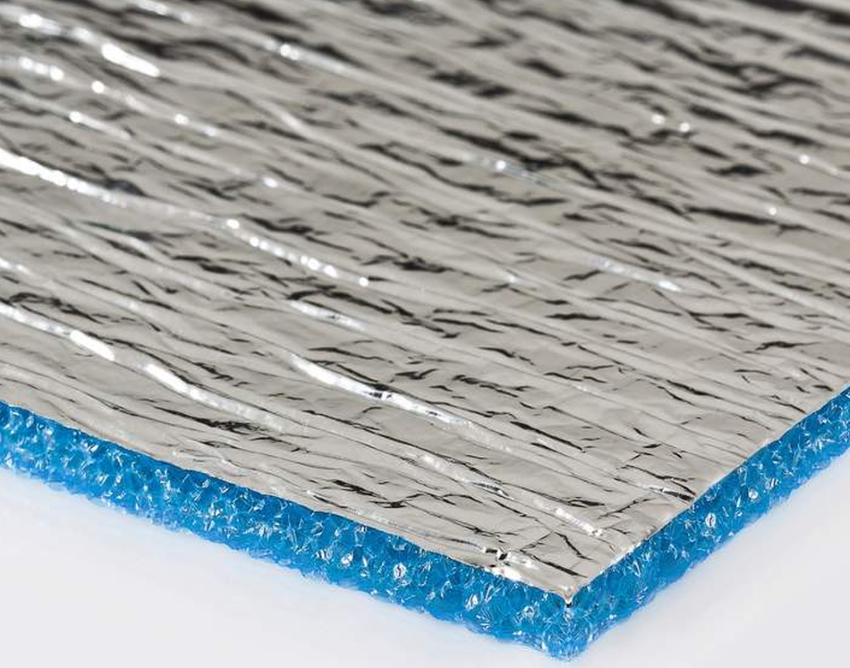

Penofol: floor insulation

The combination of polyethylene foam and a thin layer of aluminum foil is called penofol. It is sold as a rolled roll. The thickness of the seal is from 3 to 10 mm. Penofol retains heat well, is environmentally friendly, and has high sound insulation.

Penofol keeps warm well

The big disadvantage of this material is exposure to moisture due to the presence of aluminum foil in the composition. Another disadvantage is that penofol does not differ in long-term operation. After five years, it is necessary to re-insulate.

Highlights of the installation work

All materials used for floor insulation have their own fixing methods.However, there are highlights of the thermal protection device. They are recommended to be observed when installing any material.

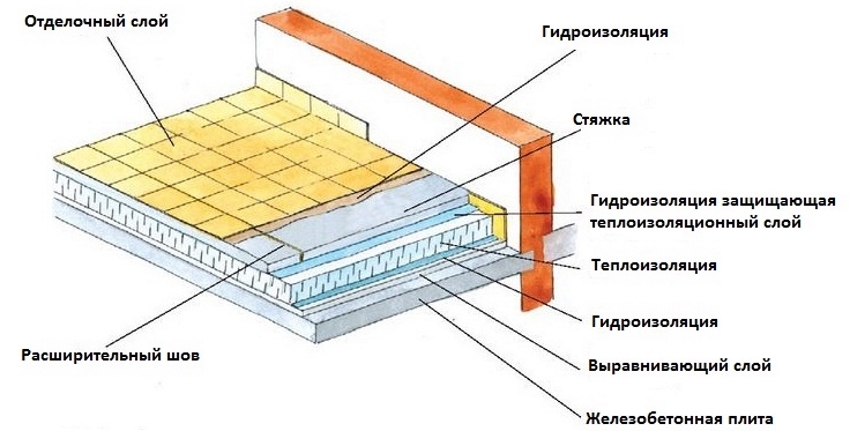

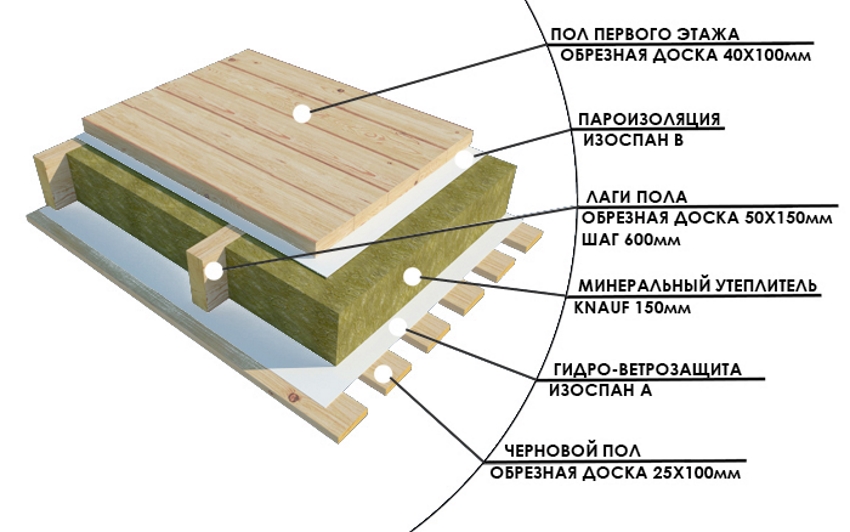

The order of the arrangement of the main layers when installing floor insulation in a wooden house with your own hands:

- waterproofing layer;

- thermal insulation layer;

- vapor barrier material;

- direct structural elements of the floor;

- flooring.

Experts say that such an arrangement of the main layers will allow an optimal thermal regime to be obtained inside the room. This technology maintains the necessary moisture circulation in the house.

Helpful advice! When insulating the basement floor in a wooden house, you can choose beams with a cross section from 50 to 100 mm. They are fixed from below, and a layer of insulation is laid between them. Additionally, the resulting "pie" should be sewn up with boards.

Waterproofing

When insulating the floor in a private house, you cannot do without waterproofing. Due to the ability of cold air to condense on a warm surface, wood floors are exposed to moisture. Its constant presence in the room leads to the active development of fungus, mold and causes rotting of the structure itself. Especially if no special means were used in the construction of the house.

When installing thermal insulation without a waterproofing layer, exposure to moisture negatively affects the heat-conducting properties of the material. The result is an increase in indoor humidity and a decrease in temperature. Waterproofing helps to avoid these unpleasant moments.

A waterproofing layer is laid on the side of exposure to cold air flows.

Vapor barrier gasket

Human heat and equipment operating in the home give off warm air. It passes through ceilings and condenses on impact with cold air. The problem with this phenomenon is that moisture settles inside the structure. As a result, the tree swells and begins to rot from the inside. It will not be possible to prevent this process by processing with special means. Therefore, when insulating the floor in a wooden house from below with penoplex or other material, a vapor barrier is required.

When carrying out installation work from below, the vapor barrier layer is laid first. The simplest and most affordable material for this is plastic wrap. It is excellent for both steam and waterproofing.

The presence of such layers in the flooring must be designed in advance. If this was not done on time, then it is necessary to lay the film immediately after putting the house into operation.

Helpful advice! An excellent material for waterproofing and vapor barrier are moisture-windproof membranes. This material allows air to circulate and retains moisture from it inside. It can be used when insulating the floor with penofol or other insulation.

The main stages of laying insulation

The best installation option is to lay the floor insulation along the joists. These cross boards are used for the subsequent laying of the flooring.

The main stages of work:

- a lag is installed on the finished foundation. The recommended distance between the beams is not more than 1-1.2 m;

- after that, the installation of thick plywood or chipboard sheets is carried out. They are fixed with self-tapping screws. This is how the base is prepared for laying the heat-insulating layer;

- insulation is laid between the wooden logs. The thickness of this layer may vary depending on the material used. In any case, it should not exceed the size of the lags themselves;

- then a layer of waterproofing is laid. Although this step is recommended by experts for maximum effect, it can be skipped.This is due to the resistance of some materials to moisture;

- the floor covering can now be laid. It may be old. Or it can be replaced with a new one.

Compliance with the specified sequence will allow you to insulate the wooden floor with penoplex or other insulation.

Features insulation with sawdust

Warming the floor with sawdust is an environmentally friendly and affordable way to keep warm in the house. When choosing this insulation, you must adhere to a number of recommendations:

- add broken glass to the prepared mixture of sawdust with cement or clay. This will avoid rodents. Do not forget about the use of special solutions;

- the mixture consists of five parts sawdust, one part cement (clay) and half water. This proportion must be respected. When mixing a steeper solution, you will receive a durable insulation, however, with a low thermal conductivity;

- carefully fill in the voids between the lags. This will allow you to get an even layer of insulation. If you do not withstand this technology, the insulation will be "leaky", and the floor will remain cold.

Helpful advice! Due to the presence on the market of a large number of insulation materials and the time spent on preparing the mixture, sawdust is rarely used for insulation. However, they will help solve the issue of isolation with a limited financial budget.

Features of foam insulation

Due to its high strength and affordable cost, floor insulation with penoplex in a wooden house is more common than other materials.

Among the features of the installation of this insulation, we note the following points:

- penoplex is laid between the logs and attached to the floor from below with mounting glue;

- it is necessary to fit the edges of the slabs precisely and tightly. This will avoid the penetration of cold air;

- the joints are additionally glued for maximum adhesion;

- obligatory laying of a waterproofing layer. This is especially important for a private house or summer cottage in a swampy area;

- before laying the penoplex, wooden beams and crossbars are treated with a special solution. This will avoid rotting and bugs.

Helpful advice! If you live in an apartment building, then the choice of penoplex as floor insulation is the best solution. This material is laid in a thin layer and does not affect the height of the room.

Due to its low weight, penoplex is excellent for floor insulation in a frame house. The load on the foundation of the building will be minimal. This will prevent the house from shrinking over time.

The main points of insulation with expanded clay

The laying of this insulation takes place according to the technology described above. However, there are a number of things to be aware of. To insulate the floor in a wooden house with expanded clay, you must:

- be sure to lay a sand pillow. It is poured in an even layer and carefully tamped;

- on top of this pillow a layer of liquid mastic is applied. It plays the role of waterproofing;

- now expanded clay is filled up. In order for the layer to be as even and without voids as possible, it is recommended to use a material of different fractions. This will allow the granules to adhere more tightly to each other;

- vapor barrier is required. Only after this can the basic flooring be laid.

Due to the tangible weight of this material, it is better to insulate a wooden floor with expanded clay with a solid foundation.

Do-it-yourself wood floor insulation in the house: video

Today, a great many training videos for self-installation of insulation are presented on the Internet. Viewing them will allow you to understand the technology for performing work, the principles of selection and the main stages of laying materials.In addition, such videos contain a large number of useful points. So you can find out, for example, about the correct filling of the floor screed with foam insulation.

In order for the floor in the house to turn out warm, many nuances must be taken into account. The correct choice of insulation plays an important role in this. When choosing material for yourself, you should not start from the price or installation technology. Take into account the type of building, the nuances of the landscape and the features of the operation of the house (permanent or seasonal). Based on this, you can choose the perfect floor insulation.