Expanded clay by its many positive characteristics is a versatile material. Due to the high degree of sound insulation and heat saving, it is used to insulate floors, walls and even the ceiling. It is most often used as a screed component when it is necessary to create a warm and strong base. This article will tell you about the advantages and disadvantages of the material, how to use it and how the floor screed with expanded clay is produced.

Content

- 1 Floor screed in the apartment: features of the process and its need

- 2 What determines the price of expanded clay for floor screed

- 2.1 The cost of expanded clay per 1 m3 or per bag: which is more profitable

- 2.2 The price of expanded clay for floor screed by dry and bulk method: what is the difference

- 2.3 The choice of expanded clay for floor screed: fraction, type and volume

- 2.4 Calculation of expanded clay for floor screed: online calculator

- 3 Thermal insulation of the floor, ceiling and walls with expanded clay: the versatility of the material

- 4 Expanded clay as floor insulation: various uses

- 5 Types of screed with expanded clay and their features

- 6 Filling the floor with expanded clay: the use of expanded clay concrete

- 7 DIY dry screed with expanded clay

- 8 How to properly perform a floor screed with your own hands in an apartment: typesetting technology

- 9 Floor insulation with expanded clay: user and expert reviews

- 10 Screed floor with expanded clay: useful tips

Floor screed in the apartment: features of the process and its need

Replacing an old floor or installing a new one in a newly built house is a very important and time-consuming stage of renovation work. After all, the general appearance of housing, comfort and coziness to a large extent depends on how the flooring will look. It is very important that the surface is level. Therefore, it is advisable to make a screed before laying any kind of floor covering.

There are two traditional types of screed - wet and dry.The first option involves a relatively large amount of work. The process is long, laborious and messy. In this regard, in recent years, builders prefer dry technology of screed with expanded clay. Such laying is relatively simple and consists in pouring special granular material into logs or between the walls of the ceiling. Next, special sheets are laid.

When choosing a screed option, you should take into account the surface condition and the characteristics of a particular room. Self-installation requires precision adherence to the technology to make the floor as strong and durable as possible. One of the most effective and widespread methods of leveling the surface is a floor screed with expanded clay. The technology is not easy, even in the case of using ready-made mixtures.

Expanded clay production technology

Expanded clay is a material that is lightweight, practical and environmentally friendly. The positive qualities include a high level of heat and sound insulation. It is made by firing clay at a very high temperature, therefore, translated from Greek, the word "expanded clay" sounds like burnt clay.

To make the screed as strong as possible, it is necessary to take expanded clay with granules of the correct shape

The production technology itself implies exposing the prepared clay to extreme heat. As a result, the raw material swells and becomes porous. In this case, the outer part of the shell is melted, which leads to sealing and high strength of the material.

Sedimentary clay rocks are most often used as raw materials, less often - metamorphic ones. They are distinguished by a complex composition, which includes hydromica or kaolin, as well as feldspar, carbonates and other impurities. The most suitable clay for expanded clay contains no more than a third of quartz. The raw materials are mixed with special additives, which provide better expanded clay puffing. To do this, use diesel fuel, fuel oil, ferrous substances, perlite and similar materials.

Helpful advice! When choosing expanded clay, you should give preference to certified products. Special GOST 9759-76 includes the parameters of granules, requirements for the weight and strength of expanded clay. It is strength that is the main indicator on the basis of which the material is allowed to operate.

Raw granules of a certain size are subjected to special processing, including drying, roasting and cooling. Further, expanded clay is sorted and, if necessary, crushed into smaller fractions. After that, the material is packed and prepared for transportation.

Expanded clay is obtained from clay by firing it in a kiln, due to which the material acquires a light and porous structure

Floor screed with expanded clay: pros and cons

Expanded clay floor screed is resistant to high temperatures and frost resistance at the same time. This feature allows its use in different temperature conditions. In addition, it is resistant to fire, it does not develop putrefactive bacteria and mold. One of the most important advantages is its low specific gravity. The lightness of the material makes it easy to ship. In addition, leveling the floor with expanded clay will help eliminate any flaws that other materials cannot cope with (or their use is simply unprofitable).

The material has the following positive characteristics:

- high degree of thermal insulation;

- good level of sound insulation;

- sufficient strength;

- low cost in comparison with other materials;

- it is durable;

- easy to transport.

Among the shortcomings, it should be noted that the moisture resistance is weak in the case of using the dry screed method, therefore, in some cases, expanded clay is better not to use. The material will not be affected directly, but moisture will linger under the concrete. Subsequently, this will lead to increased humidity in the room. This factor is favorable for the development of fungi and mold.The disadvantages of the material also include the fact that for insulation it will be necessary to make a screed of great thickness. A layer less than 10 cm will be ineffective.

Expanded clay is a very light material and therefore does not make the screed heavier and does not give additional load on the foundation

Expanded clay concrete screed in many points outperforms other fillers. In addition to the maximum level of heat and noise insulation, it has good air permeability and is durable. The material is suitable for any floor covering. The maximum effect from all the listed positive qualities can be achieved only if all the requirements of the expanded clay laying technology are met.

Expanded clay or mineral wool: what is better to choose as insulation

Various materials are used to insulate floors, walls and floors of buildings. In addition to expanded clay, the most popular materials also include expanded polystyrene, polystyrene foam and mineral wool. They are characterized by such qualities as lightness, high thermal insulation and low price. However, due to their versatility, expanded clay or mineral wool is most often used. Floor insulation with these materials is most effective.

Expanded clay, as an environmentally friendly material, does not pose a threat to health and serves for several decades. It is inexpensive, versatile, and resistant to fire, moisture and rodents. However, its application requires a number of preparatory work, so it is not suitable for creating "warm floors".

Helpful advice! Mineral wool is more effective as a thermal insulation material, but it is not as durable and strong as expanded clay. Therefore, it is advisable to use it for wall insulation. While expanded clay is more suitable for the floor.

Warming the walls with expanded clay outside the house is a rather laborious and inconvenient process. It is in this that expanded clay is inferior to mineral wool, which is suitable for insulating facades, roofs and pipes in hard-to-reach places. It is easy to cut the required shape from it using a knife.

It is impossible to say unequivocally which material is better, and even more so to make a categorical choice in favor of one of them. Insulation should be chosen based on the specific conditions of the construction site and material capabilities. Most often, experienced builders combine mineral wool with expanded clay, which has a positive effect on the cost of work and increases the degree of thermal insulation. Both heaters are distinguished by the simplicity of the installation process and low cost, giving an excellent result at the output.

Types of expanded clay backfill for the floor

For expanded clay screed, various types of fractions are used. Material with different density levels is presented on the modern construction market. The weight of a cube of expanded clay ranges from 260 to 600 kg / m³. The specific gravity of expanded clay is the weight of the cube of the material. It depends on the grain size: the larger the grain, the lower the specific gravity. It is the mass of 1 m³ of expanded clay and its density that underlie the classification of the material given below:

- Expanded clay crushed stone has a size of 10-14 mm. Such material is taken for the manufacture of concrete.

- Expanded clay gravel is used in the installation of floors of varying degrees of strength. Most often used for thin but durable floorings. This is expanded clay of 5-10 mm, 10-20 mm and 20-40 mm fractions.

- Expanded clay sand is the finest material. The maximum fraction of expanded clay is 0.5 mm, it is used in the process of creating thin screeds.

The table will help to clearly demonstrate the specific and volumetric weight of expanded clay, depending on the type and fraction:

| View | Fraction, mm | Specific weight (g / cm³) | Expanded clay weight in 1 m3, (kg) |

| expanded clay sand | 0-5 | 0,5-0,6 | 500-600 |

| expanded clay gravel | 5-10 | 0,4-0,45 | 400-450 |

| expanded clay gravel | 10-20 | 0,3-0,4 | 300-400 |

| expanded clay crushed stone | 20-40 | 0,2-0,35 | 200-350 |

In accordance with the table, the approximate weight of 1 m3 of expanded clay with fraction 10-20 is 350-400 kg.

The specific gravity also depends on the grade of density. According to the existing GOST, the higher the density of expanded clay, the greater the weight of the material.

It is impossible to accurately determine the specific gravity of expanded clay, but the average value is quite simple to establish. The average value is 400 kg / m³ (0.4 g / cm³). Moreover, each faction has its own specific indicator. For example, expanded clay 10-20 in bags weighs approximately 16.8 kg.

What determines the price of expanded clay for floor screed

It should be noted that loose clay granules are widely used not only in construction, but also in utilities and agriculture. Therefore, the price range for this material is quite wide and ranges from 1000 to 2000 rubles per cubic meter.

Helpful advice! In order to save money, you can purchase second-hand expanded clay. Such material has almost not lost its positive properties, but at the same time it costs two or even three times cheaper.

The producers of expanded clay dictate the pricing policy on the market. In setting prices, they are guided by the following criteria:

- indicators of the condition of raw materials from clay;

- features of production technology;

- volumes and production capacity;

- storage features;

- energy consumption;

- the speed of turnover.

Enterprises selling expanded clay, in the process of price formation, take into account other factors. For example, packaging, granule size and porosity. The first criterion includes a list of additional costs for purchasing additional equipment and hiring workers for batching, weighing and packaging material.

The size and porosity of the material determine such qualities of expanded clay as thermal insulation, strength, and moisture absorption. All these criteria have a corresponding effect on price formation. For example, the size of the granules forms the price in inverse proportion: the finer the grain, the higher the cost. The price of small expanded clay in bags is much higher, since the material itself is much heavier in comparison with the weight of expanded clay of large fractions of the same volume.

The cost of expanded clay per 1 m3 or per bag: which is more profitable

Sales agents in the construction market offer the purchase of expanded clay wholesale and retail, packaged or in bulk. It is much more profitable to buy material by weight or per cubic meter, since when packing, labor costs and the cost of packaging affect the price formation. If the question is about purchasing expanded clay for floor insulation, and not for filling the site as a decorative element in landscape design, then it is enough to purchase just a couple of cubes of material.

The packaged expanded clay is of a higher quality, as it undergoes special cleaning. In addition, the packaging is more convenient to transport and protects the material from moisture, while maintaining its quality characteristics.

When buying expanded clay, you should take into account another important factor - seasonality. Usually, after the end of the construction season, the price of the material drops by about a quarter. Thus, granular building materials can be bought much cheaper in winter.

If it is important to purchase high-quality, clean, solid and certified material, you should give preference to expanded clay in the package. Since it has passed the certification, it will be free of impurities, debris and foreign matter. The strength of the granules can be checked by simple squeezing, and the porosity is determined by breaking the grains.

If you need to purchase high quality cleaned material, you should give preference to expanded clay in bags

The price of expanded clay for floor screed by dry and bulk method: what is the difference

Dry screed is more advantageous than other technologies. First of all, saving money lies in the absence of the need to attract professionals, because most dry screeds can be made by hand.

Helpful advice! If quality is more important than price, then it is worth buying expanded clay for dry floor screed in the form of a special mixture "Compavit" - this is the backfill used in Knauf technology. It was developed as insulation, but in combination with gypsum fiber sheets, excellent horizontal surface was noted. Compavit contains various granules (up to 5 mm) of high quality. The only drawback of this material is its high cost.

When it comes to expanded clay, the method of its use also affects the total cost. For a dry screed material of different fractions is taken - and its price may be low. While the bulk method requires fine-grained expanded clay, which is much more expensive.

Related article:

Which floor screed is better: wet, dry, semi-dry or self-leveling

Varieties of floor screeds. Which screed to give priority in this or that case. The device of various types of floor screeds.

The best price for products can be found from the direct manufacturers of the material. Intermediaries typically charge a 15 to 30% markup, which includes shipping and storage costs. Therefore, to purchase large volumes, it is better to spend time on the road and bring expanded clay from the manufacturing plant yourself.

If we are talking about small batches of goods, then it is better to refuse self-pickup and buy material in specialized stores with delivery. The seller guarantees timely transportation, safety and quality of products. In any case, in order to avoid unnecessary costs, you should correctly calculate the required amount of material.

The choice of expanded clay for floor screed: fraction, type and volume

When choosing which fraction of expanded clay is needed for floor screed, they are guided by the room in which the material is planned to be used. The choice also depends on the technology used for backfilling. According to the traditional method, which provides for subsequent pouring with concrete, the size of the material does not really matter. Anyone will do, including fine expanded clay.

Helpful advice! Fine sand is ideal for leveling floors with large level differences. It is advisable to use such material in areas with significant surface damage and for installing block parquet.

For a better screed, expanded clay of different fractions is taken, since this gives the required backfill density

At the same time, the opinion regarding the choice of a 0.5 mm fraction with a minimum weight for the basis of expanded clay is erroneous. After all, such a filler has a high density, therefore it fills the space better, thereby making the screed layer heavier.

Experienced builders recommend taking expanded clay for screed of different fractions - from 5 mm to 20 mm in appropriate proportions. The recommendation is based on the fact that during the laying of a layer of expanded clay, grains of various sizes are well combined with each other. This feature has a positive effect on the further exploitation of the floor, which will not shrink or deform.

Calculation of expanded clay for floor screed: online calculator

Expanded clay is a very ergonomic and economical material. Its use allows you to reduce financial costs, minimizes the load on concrete floors and increases the level of thermal conductivity. For the result to be as effective as possible, it is necessary to accurately calculate the required amount of expanded clay for work.

Builders use the traditional technique in calculating how much expanded clay is needed for floor screed. If the layer thickness is 1 cm, then 0.01 m³ of material is needed for 1 m². The weight of a cube of expanded clay is generally not taken into account, since the density of expanded clay calculated in kg / m3 differs for different types of material. Therefore, for convenience, the sale is carried out in liters, based on the calculations: for 1 m2 of a screed 1 cm thick, 10 liters will be needed.

To accurately calculate the consumption of expanded clay, you should measure the thickness of the insulation layer. In dwellings located on the lower floors or above unheated rooms, the thickness of the screed made of this material should be at least 10 cm.For the purpose of maximum thermal insulation in residential premises, expanded clay is laid in a layer averaging 4 cm.

Based on the calculations given above, we come to the conclusion that for the installation of a screed in a standard apartment, at least 0.04 m³ (or 40 liters per m²) of material will be required. As a result of multiplying this indicator by the size of the area of the room, you will get the total volume of expanded clay required for the screed.

For example, you should calculate how much expanded clay is needed to insulate a floor with a layer of 4 cm in a room with an area of 15 m². The calculation will look like this:

15 m² * 0.04 m³ = 0.6 m³ (in cubic meters)

or 15 m² * 40 l = 600 l (in liters).

This is equivalent to 16 bags of 50 liters each. That is, one bag of expanded clay is consumed per 1 m² of the screed. You can calculate exactly how much expanded clay is needed for floor insulation using a special online calculator.

Thermal insulation of the floor, ceiling and walls with expanded clay: the versatility of the material

This material has been used as a reliable insulation for a long time. The heat-insulating effect of expanded clay granules is provided by their porous structure.

Important! The process of insulating walls with expanded clay is more laborious and requires more time, since it involves the construction of a special high frame or the assembly of material in portable containers.

Expanded clay grains are similar in structure to expanded polystyrene. But there is also a significant difference: expanded polystyrene is made from polymers and is used mainly for wall decoration. Expanded clay is a natural material, the raw material for which is organic clay.

Due to the high degree of thermal insulation, the use of expanded clay for insulating floors, walls, ceilings and supporting structures is very effective. The material is often used to insulate the attic due to its increased fire resistance (compared to expanded polystyrene). This advantage of the material allows its use in fire hazardous facilities: in a bathhouse, on the roof and on wooden floors.

However, the use of expanded clay on a horizontal base is more convenient than on flat or vertical surfaces, since it is a bulk material. To level and insulate the floor with expanded clay under the screed, it is enough to simply fill and level the material, and insulating the walls and ceiling will require more time and effort.

Thermal insulation of a frame house with expanded clay

Expanded clay is usually used to insulate the floor, ceiling and walls of wooden houses. Its use in brick and concrete buildings is very advisable. Most often, the technology of warming the floor of a frame house with expanded clay is used. This is due to the fact that it is one of the most affordable, convenient and effective materials on the construction market.

Warming the walls of a frame house with expanded clay is a laborious and rather problematic process, therefore the use of this material for this task is less advisable. Although, in terms of its thermal insulation characteristics, expanded clay will well protect any wall - both from bricks and from blocks.But the main condition for use is the three-layer structure, which will provide the possibility of filling the material between the rows.

In aerated concrete blocks, the distance from the inner to the front layer should be at least 10 cm. The material is poured as the masonry is built. It is carefully tamped and poured with cement milk. Consumption per 1 m3 of expanded clay binder M 300 will be 260-300 kg. It should be noted that in this case, water will be needed about three times more than cement.

Insulation of frame walls with expanded clay: expanded clay blocks in construction

Provided that the thickness of the side surfaces of the sandwich panels is correctly selected, additional insulation with expanded clay even of frame walls is possible, since during compaction the load on them increases significantly. In order to insulate the walls of a wooden house, it is necessary to prepare an insulating layer of at least 20 cm. For this purpose, you will have to build special sheds for filling.

Helpful advice! Insulation of walls with expanded clay in terms of thermal efficiency is no worse than the use of modern materials. The main condition for success is the choice of quality material and its careful compaction.

The necessary thermal insulation properties are possessed by special expanded clay blocks used for the construction of walls. These are hollow structures, which include expanded clay, sand and cement. In such buildings, it is warm in winter and cool in summer. This material is characterized by low strength, therefore, it is suitable for the construction of one-story buildings and partitions between rooms.

Slotted blocks have good ductility, which allows you to create different shapes. They are laid with voids down on a sand-cement mortar in order to save heat. Structural and thermal insulation blocks are a hollow material used for thermal insulation during the construction of walls. Depending on the size of expanded clay blocks, they are divided into wall, partition and facing.

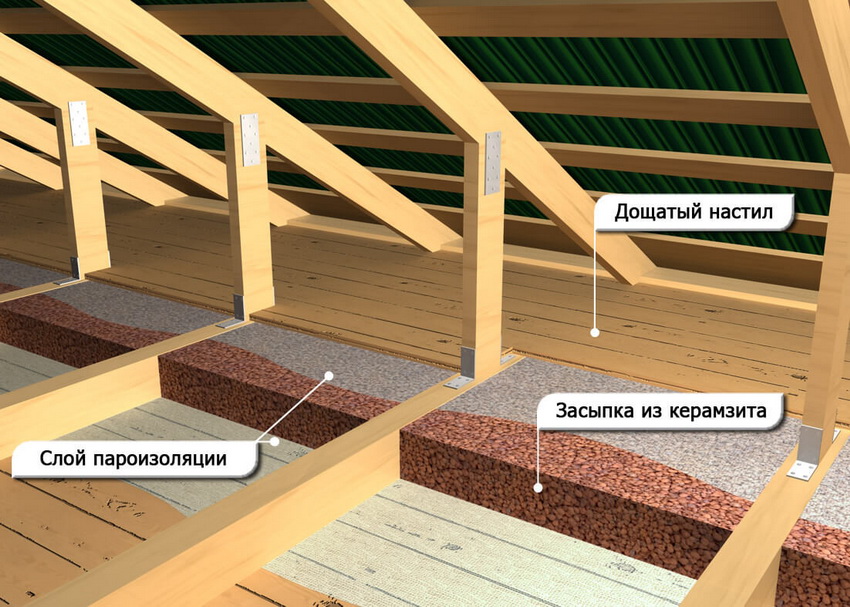

Ceiling insulation with expanded clay: technology features

Due to poor insulation, about 15% of the heat goes through the ceiling, so during construction you need to take this factor into account and take care of the insulation of the ceiling or floor in the attic. For this purpose, mineral wool and foam are often used, but expanded clay is deservedly considered the most popular material.

Insulation work begins with laying layers of vapor and waterproofing. A layer of vapor barrier film is attached to the finished ceiling. To do this, you can use a self-adhesive roofing felt and foil, but if there is a lack of funds, a simple plastic wrap is quite suitable. The technology is simple: a roll of the selected material is rolled out on the floor, marking and cutting are made. The strips should be approximately 10 cm wider than the distance between the beams.

With a large ceiling area, it is advisable to lay the canvases with an overlap of 8-10 cm.

The seams are glued with special tape or construction tape. When insulating the ceiling in a bath with expanded clay, the vapor barrier of the beams and the chimney should be provided. The canvases are fixed above the expanded clay layer with masking tape or a construction stapler.

It is recommended to lay crushed clay over the waterproofing layer. Now you can start laying the main insulation - the material with a layer of 10 to 16 cm.

To insulate the roof with expanded clay, it is better to use a combined method, that is, take large and small granules. This will increase the density of the coating, and the level of granule sagging will decrease, which will contribute to the even filling of the material over the entire surface that needs to be insulated.

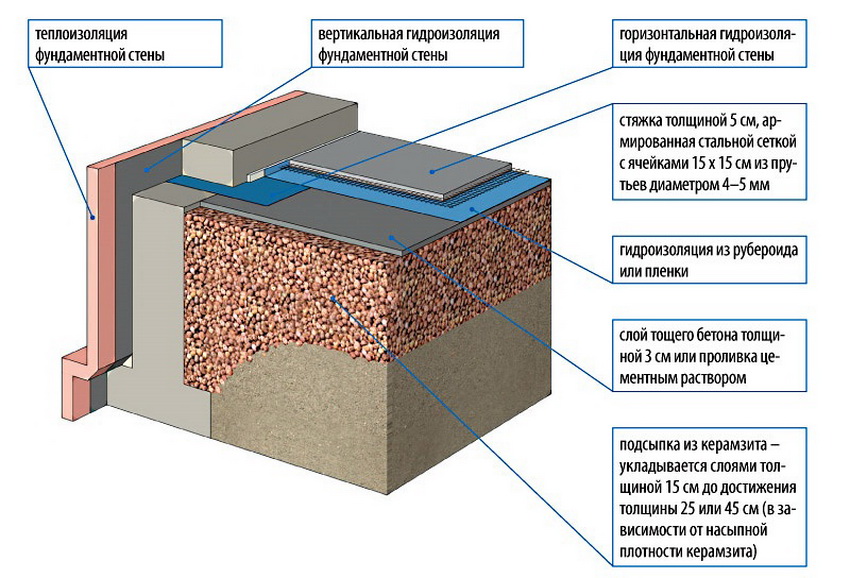

Expanded clay as floor insulation: various uses

Most often, expanded clay is used to insulate floors in different rooms. If you strictly follow the technology of using the material, you can achieve a positive effect even in a house with a very cold floor. It should also be noted that it is on the floor that the greatest load falls, therefore much depends on what layer of expanded clay is needed for floor insulation.

Helpful advice! When choosing expanded clay for the floor, it is advisable to take a mixture of three fractions of this material. The use of exclusively expanded clay crushed stone can ultimately lead to subsidence of the floor, and the small material makes the entire insulation layer heavier.

The correct calculation of the thickness of the insulation will help to avoid subsequent subsidence and deformation of the surface. It is also important to consider what kind of expanded clay to use for floor screed. The most effective is the use of granules of different fractions. Then smaller ones will enter the space formed by large grains, evenly filling the entire surface.

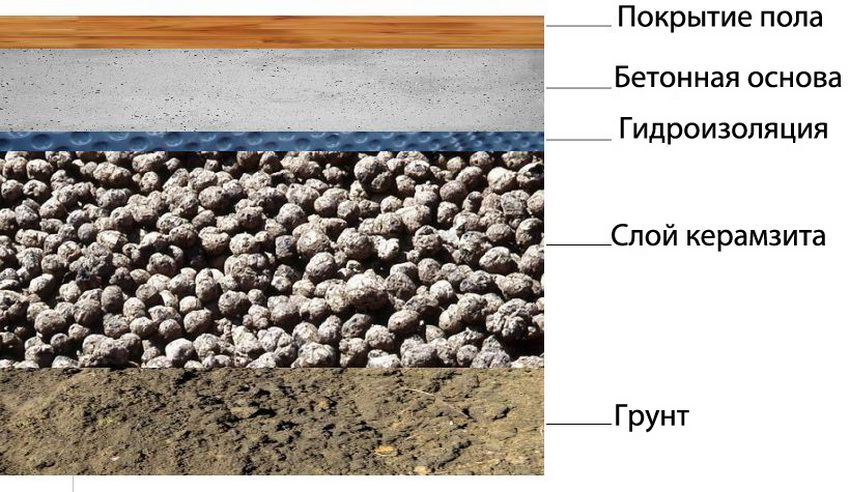

A screed with expanded clay plays a very important role. There are several technologies for its application. The screed provides fixation of the material and serves as an upper waterproofing layer. Usually, a two-level solution application method is used. First, a layer of material is poured in order to fill in empty spaces and displace air. Expanded clay under the screed is reliably protected from moisture and physical exertion. The final screed is made for the final leveling of the floor, which will be the ideal base for installing any type of floor covering.

Despite the fact that insulation with expanded clay (it does not matter - the floor or ceiling of the house) is performed several times easier than using the same foam or mineral wool, the technology has a number of features. It is important to observe them, otherwise the layer of insulation may be saturated with moisture.

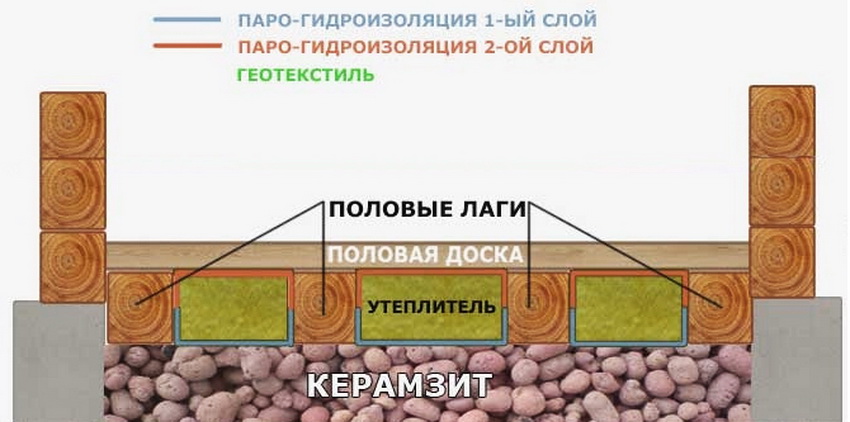

Warming the floor with expanded clay in a wooden house

There are many technologies for insulating wooden houses using this material. We have already figured out how to insulate the ceiling and walls, but the most frequent use of expanded clay is floor insulation in a private house. There are many technologies and methods. This is a simple backfill, and pouring of expanded clay layer, and covering the material with a concrete screed.

In any case, the surface is prepared first. To do this, dismantle the old coating, clean the surface from dirt, debris and dust. Next, proceed to the process itself. The most popular method of insulating a wooden floor with expanded clay is filling directly on the ground, between the laid logs. Most often, this technology is used in the construction of country houses, but it is also acceptable in the arrangement of residential cottages.

The sequence of such works includes several stages:

- Compact the soil if necessary.

- Laying lags.

- A waterproofing material is laid directly on the ground between the lags. It can be an ordinary roofing material, preferably laid in several layers with overlaps and overlapping walls.

- Filling expanded clay - we take a mixture of three fractions.

- Laying a vapor barrier layer. The use of polyethylene film is permissible here.

- Plank flooring and finishing works.

This is the easiest way to insulate the floor in a wooden house from the bottom with expanded clay. This method is also used to insulate the ceiling from the attic side.

Helpful advice! The optimal thickness of expanded clay for floor insulation on the ground floor is from 10 to 16 cm. A lower value does not guarantee complete thermal insulation, and a thicker layer will be unnecessary.

Warming the floor with expanded clay on the balcony

Often in multi-storey buildings, the initial project assumes the presence of an open balcony or loggia, but most owners make their own insulation of the structure by installing reliable thermal insulating glass units. Then the question arises about the need for floor insulation in this room. There are a number of methods, in particular with the use of expanded clay screed.

Considering how much expanded clay weighs, it is suitable as an insulating material for the floor on the balcony and loggia. The process itself is quite simple. First, the cement-sand mortar is kneaded, then the entire surface of the concrete base is covered with an even layer of expanded clay 3-5 cm thick. After that, beacons are installed and, guided by them, the expanded clay layer is poured with concrete mortar.

It is important that the cement mixture is thick in order to prevent light clay granules from floating up, thereby impairing the thermal insulation effect. In addition, such a screed will be quite problematic to align.

It is important to take into account the fact that an ordinary balcony slab is installed with a slight slope towards the outside. This is done so that rain and melt water flows freely from the balcony. Therefore, before insulating the floor with expanded clay, you need to take care of leveling the surface. The easiest way is with a concrete screed.

Features of warming with expanded clay floor in a bath

Quite often, expanded clay is used as a reliable material for thermal insulation of the floor in a bath. The required layer thickness is calculated taking into account the expected loads. They use beacon fill technology. The simple method of falling asleep in logs is not suitable, since there is an increased level of humidity in the bath.

When insulating the floor in a bath, a number of features should be taken into account:

- it is necessary to avoid slopes and irregularities on the floor, otherwise the insulation will lose its meaning;

- in order to maximize the compaction of the heat-insulating layer, expanded clay is poured with a thick cement mortar;

- reinforced mesh will help give stability to the structure;

- The floor acquires maximum strength in a month, therefore, earlier use of the bath is not recommended.

Insulation of the floor using expanded clay in buildings on piles significantly extends the service life of the premises and makes the bath warm, reliable and comfortable. The main condition is compliance with all technological requirements during the repair. We will describe in more detail about each type of screed with expanded clay below.

Helpful advice! When buying expanded clay, it is better to purchase a little more material than planned, since during transportation and backfilling, individual granules may crumble.

Types of screed with expanded clay and their features

The versatility of the material allows its use in different ways. The main criteria for choosing a laying technology are the type of room and the corresponding circumstances. At the moment, there are three main installation of expanded clay screed:

- Bulk technology (or expanded clay concrete) includes the use of various bulk-type mixtures. This method is used to achieve the maximum leveling level of a thin layer. This method is practiced in apartment buildings.

- The dry method is used for the construction of communications at floor level when the screed readiness time is tight (in this case, it is permissible to apply the topcoat after a day) or if a screed with a minimum weight is needed (over thin floors). In addition, this method is as clean as possible and is suitable for achieving a high level of floor insulation.

- Typesetting technology is a covering of expanded clay layer with concrete. It features a thick leveling layer.This option is ideal for areas subject to heavy traffic. In addition, this method does not require large material costs.

Regardless of the type of screed application technology chosen, the base should be prepared in advance. This is a separate stage that requires special attention.

Helpful advice! To prevent damage to the expanded clay layer, it is necessary to apply a cement-sand screed on top.

Expanded clay screed: choosing tools

The list of necessary tools depends on the choice of the type of screed. It should be noted that in any case you will need:

- expanded clay of the corresponding or different fraction;

- volumetric container for mixing the solution;

- polyethylene film for waterproofing;

- any level (water can be used, but laser is better);

- an aluminum rule with a length of at least two meters for leveling the mixture along the beacons;

- construction mixer or concrete mixer;

- grid;

- beacons;

- Master OK;

- ordinary shovel;

- Scotch;

- large roller with needles;

- cement and sand or a special mixture for pouring;

- alabaster or plaster mortar.

You should also provide a sufficient amount of water, especially for the implementation of filling and typesetting technology. You may need self-tapping screws for setting beacons and, accordingly, a screwdriver or screwdriver. Ordinary mastic is suitable for smoothing seams. Do not forget about the presence of a building tape for calculating material and marking lighthouses.

This kind of construction work is quite time consuming and messy. Therefore, you should take care of the appropriate clothing, footwear and personal protective equipment in advance.

Expanded clay screed: calculation of sand-concrete mixture

Starting work on floor insulation with expanded clay, it is necessary to calculate not only the mass of the required material, but also the expected load on the screed. To do this, calculate the height of the expanded clay layer and the thickness of the cement-sand floor screed. For example, for effective floor insulation on the ground floor, the layer thickness should be at least 10 cm.

To prepare the solution, it is better to take a ready-made sand-concrete mixture, where the proportions are clearly calculated. It contains plasticizers that prevent the screed from spreading and make the solution more plastic. The amount of material for a sand-concrete screed is calculated by the formula:

AxBxS / D = K

Where:

- A is the area of the room;

- B - the amount of solution (in kilograms) that is required for 1 m²;

- С - floor screed width in mm;

- D - weight in kg of one bag of the mixture;

- K is the number of bags.

For example, the estimated area is 20 m², for a screed you need 2 kg of ready-made mortar per 1 m². The screed thickness is 10 cm, and the weight of one bag is 25 kg.

As a result, we get the following calculation of the material: 20 × 2 × 100/25 = 80 bags of dry mix. Accordingly, with a smaller layer of concrete and in a small room, much less material will be required.

Important! A screed made of expanded clay concrete, in comparison with a screed made of cement and gravel, has higher thermal insulation qualities.

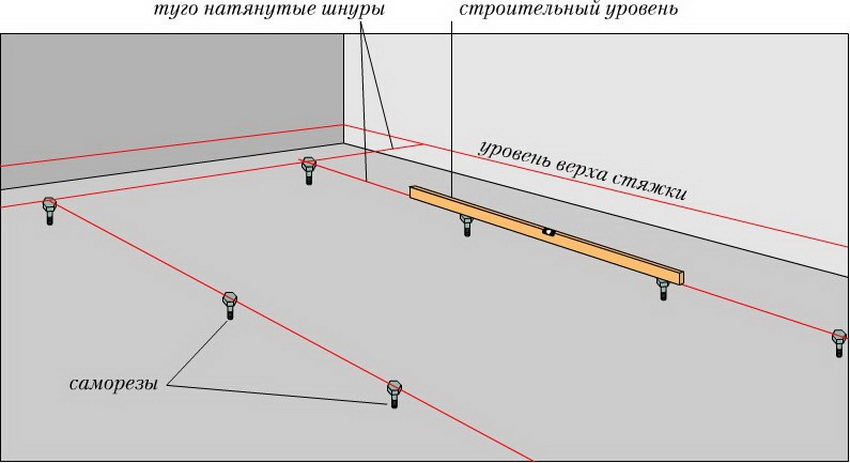

Floor screed on beacons: technology and features

Before starting work, a reinforcing or masonry mesh is laid on the floor. Further, at a distance of one and a half meters, beacons are installed, fixing them in level with alabaster. You can indent less, but this will make it difficult to work with the rule. The floor is marked using a level. Better to take a water or laser. First, marks are made at the desired height around the perimeter of the room, and then the required distance is measured from them.

The base for the screed must first be prepared by leveling the surface, and then waterproofing. For this, ordinary plastic wrap is suitable.It is placed with an overlap of at least 10 cm if laid in strips. Wall allowances should be slightly higher than the screed height. Consideration should be given to such points as the film thickness, and the overlap of the strips should be 50 cm.

Waterproofing can be achieved using hydrosol or bitumen-polymer liquid mastic. The material is applied with a brush to the floor and the lower part of the wall just above the screed border. The surface is covered with mastic twice with a three-hour interval.

As part of the preparatory work, it may be necessary to install fittings. Its installation is simplified by multi-layer filling. Installation is carried out before applying the leveling layer.

Further, beacons are installed along the fill levels. They are made from any material at hand, for example, from straight profiles for drywall. The beacons are installed on the base in the solution. The fastest and most effective solution is gypsum. The rule is also easy to make yourself from a piece of board.

An edge damper tape is fixed along the perimeter of the walls, which compensates for temperature fluctuations. It is better to take a product with a self-adhesive side. A simple tape is attached in any other way. Reliable fixation is not needed - the tape is only needed for pouring.

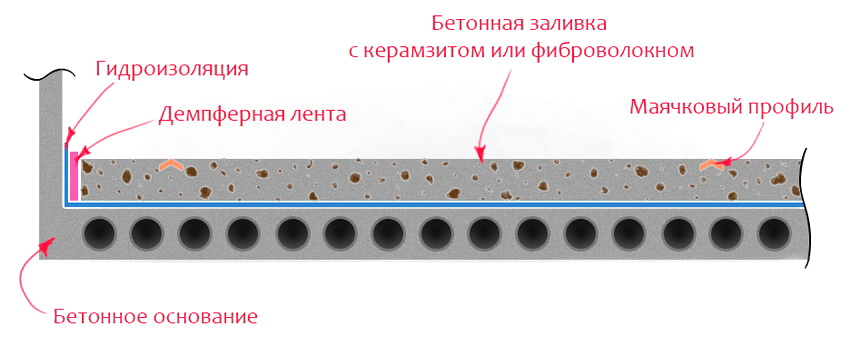

Filling the floor with expanded clay: the use of expanded clay concrete

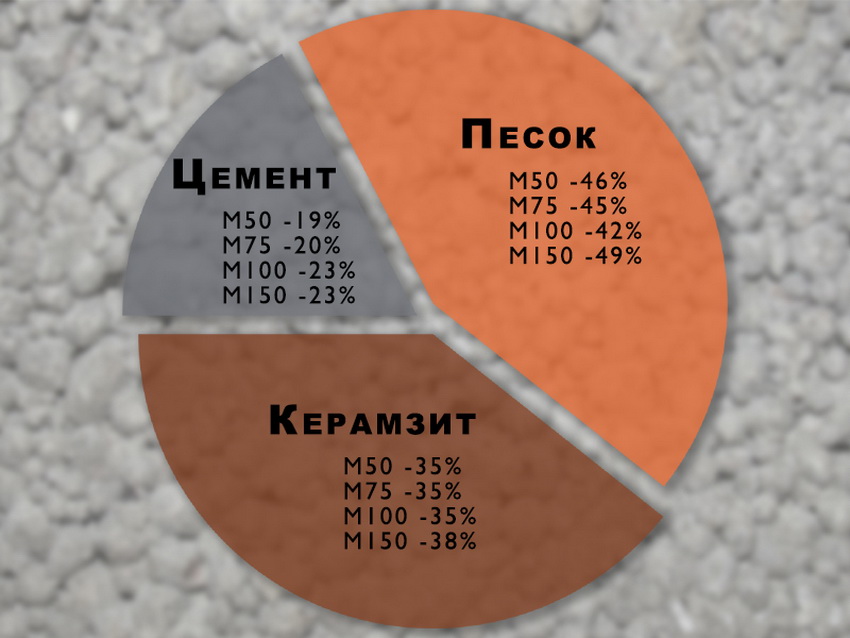

To prepare the solution, take expanded clay of the corresponding fraction. For this purpose, the following proportions are used:

- one part of cement (Grade 400);

- three pieces of sand;

- four parts of expanded clay.

Before preparing the solution, expanded clay is soaked in water. Dry and poorly soaked granules can simply float to the surface of the mixture. Next, fill and align the solution with the beacons.

If the pouring of the floor with expanded clay is multi-layer, then in order to obtain a homogeneous screed, it is necessary to pour the leveling layer immediately after the first layer. Thus, the process of laying a screed from expanded clay concrete is identical to the process of laying a conventional screed. The differences are only in the preparation of the mixture.

The thickness of the screed itself is of great importance. If it exceeds 6 cm, then it is poured into two layers. Moreover, the first of them is about 4 cm, the second is thinner. It is applied to the required floor level. The solution of the finishing layer itself is thicker, it is poured in small batches. If it is planned to insulate with expanded clay under a ceramic tile floor, then this method is the most acceptable.

Note! It is difficult to even out large drops in the lower layer of expanded clay, so you need to worry about an even base in advance. Before starting work, the surface is checked with a level. If there are holes and depressions, they are leveled with concrete.

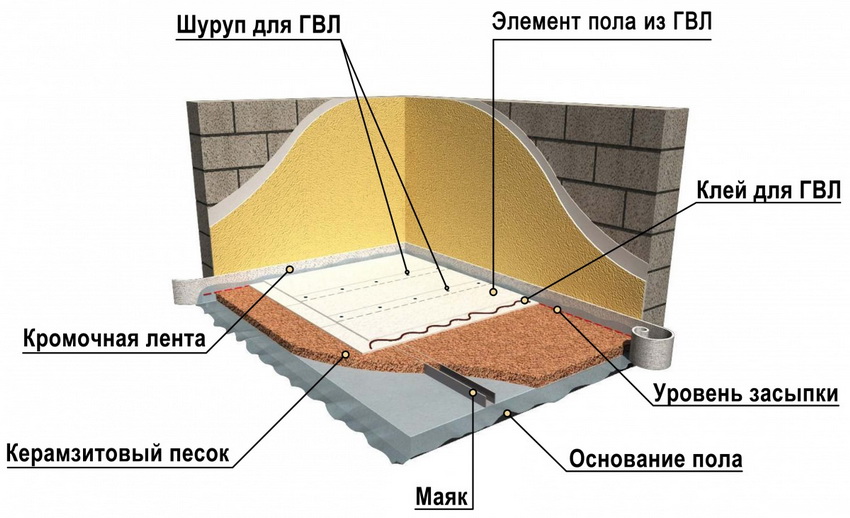

DIY dry screed with expanded clay

The dry screed technology is relatively simple and therefore very popular. Its essence lies in the fact that expanded clay is poured onto a polyethylene film, the surface is leveled, and boards or gypsum-fiber sheets are laid on top. However, the procedure itself includes a lot of nuances. To do everything right, you must adhere to the instructions, and carry out the work in stages. The screed process includes the following steps:

- Waterproofing. It is carried out by laying a plastic wrap. The material is taken with a margin of 20 cm on both sides for an overlap and another 10 cm on the sides. The joints are connected with construction tape.

- The damper tape is attached around the entire perimeter.

- Installation of beacons. For this purpose, a construction laser level is best suited. It is mounted in the center of the room and guided by a screw screwed in at a distance of half a centimeter from the corner opposite the door. To do this, we establish a rule and fix the place of intersection with the level.Having retreated 20 cm, we screw in the second self-tapping screw so that it clearly passes along the sketched line. We perform such actions around the entire perimeter of the room. Parallel lines must be placed no more than the length of the rule.

- A cement mixture is applied to the screws, then a profile. The remains of the solution are removed with a spatula.

- After the mixture has completely dried, part of the expanded clay is poured under the lighthouses. The surface is carefully leveled. Profiles are checked by rule. There should be no deflections.

- For better compaction of the material, a polyurethane foam grater is added to the backfill. After leveling the first section, you can start laying GVL-plates. It is better to place them in two layers, fastening with glue and self-tapping screws.

- Sealing with putty.

- Cutting off film and tape residues.

Advantages of dry backfilling of the floor with expanded clay

The dry method of applying expanded clay screed has its advantages in comparison with other methods, in particular:

- the ability to get a perfectly flat base of the floor, capable of withstanding a load of up to 500 kg per 1 m²;

- hypoallergenic insulation without harmful volatile substances in the air;

- absence of cracks, breaks and chips, which are often formed with an ordinary screed;

- the surface does not require prolonged drying, but is immediately ready for use;

- there is good sound insulation of the floor with expanded clay under the screed by the dry method;

- no additional insulation methods are required. Such a floor already has maximum thermal insulation;

- dry screed - the fastest in comparison with other methods. It will take about 3 hours to completely fill a room of 20 squares;

- any cover can be laid on the mounted base, from parquet to linoleum. It is also possible to cover with ceramic tiles, provided that a thin screed is created over the base plates.

The value of such a screed lies in the fact that it practically does not exert pressure on the floor slabs, since expanded clay is not weighted down with concrete mortar.

Features of the choice of expanded clay for dry screed and craftsmen for work

As for any other type of screed, for the dry method it is better to take expanded clay of different fractions in different proportions. The main disadvantage of a dry screed is that it is likely to install only an electric or film floor heating on it. It is impossible to mount a water heating system under such a screed.

Helpful advice! In rooms with a large area, it is recommended to backfill the floor by dividing the room into several separate parts, and it is also necessary to consistently screed in the frames.

You should not trust inexperienced craftsmen to perform the screed, because the slightest violation of technology can lead to irreversible consequences. In the best case, the floor will simply make sounds when walking, in the worst case, it will lead to subsidence and deformation of the coating. Unscrupulous workers resort to a number of tricks, for example, they use crushed expanded clay, and instead of gypsum fiber sheets, other plates are used that are unsuitable for such work.

Also, the owners should be alerted if a significant gap is noticeable between the sheets and the wall or the folds are not cut at the point of contact. The sheets are connected and fixed with polyurethane foam, and not with glue.

There are also cases when the unprofessional use of even very high-quality materials leads to rapid deformation of the floor, and it sags under the weight of people. Such actions of amateurs discredit the dry screed method itself, making the leaders a semi-dry method or pouring. In fact, a successful result depends on the correct approach to business and experience in this field of construction.

How to properly perform a floor screed with your own hands in an apartment: typesetting technology

The filling or type-setting method is a middle option between dry technology and expanded clay concrete pouring. Based on the intended purpose, different fractions of the material and their combinations are used. To achieve the maximum thermal insulation effect, the expanded clay layer should be at least 10 cm, the fraction of granules - 20 mm. For the preparation of the filling, a finer-grained material with a fraction of 5-10 mm is used.

Typesetting technology is not suitable for rooms where water ingress is not excluded. Therefore, on the first and basement floors, it is imperative to carry out moisture-proof measures.

The type-setting method of screed floors with expanded clay is best used in rooms where high humidity is not expected

The technology itself is the filling of expanded clay under the floor screed and includes the following stages:

- level floor markings;

- preparatory work, consisting of leveling the base frame;

- fixing beacons at the fill level;

- filling of expanded clay and its leveling. In order to increase the thermal insulation effect, it is possible to lay an additional waterproofing layer between expanded clay and mortar. Regular polyethylene film will do. It will also prevent the granules from floating up when filled with a liquid solution;

- installation of fittings. This stage is not at all mandatory, but desirable in rooms with a large area;

- pouring expanded clay from above with a concrete screed. To prevent the first layer from floating up, the solution, including small granules of expanded clay, must have the maximum level of density, so it must be prepared in small batches.

Helpful advice! If there are wires under the tie, then they need to be wrapped with plastic wrap and fixed with tape.

Expanded clay of any fraction is suitable for dry backfilling of the floor, the main thing is that the granules are of the correct shape

This "averaged" technology between dry and wet way of laying expanded clay makes it versatile in the use of both an independent screed and as part of "pies" of several layers.

Alternative methods of backfilling expanded clay on the floor: Knauf technology

Recently, a new type of dry backfill "Compavit" has enjoyed particular popularity. This material is used during the installation of a dry screed according to the Knauf method. Initially, the material was developed as a floor insulation, but its further use has shown that it is excellent for leveling surfaces.

The Compavit mixture is very small expanded clay grains (up to 5 mm), which are easily distributed on any surface. The main requirements for such granules: they must be finely crushed and round. If they do not meet the specified requirements, then you should not use them. Otherwise, after laying the base with GVL-plates, expanded clay crumb will shrink, and the flooring itself will be deformed.

The oval and asymmetric shape of the granules also negatively affects the shrinkage of the material.

The Knauf method using Compavita has a number of advantages, namely:

- due to their lightness, expanded clay granules do not exert unnecessary stress on the floor, which is important when insulating floors in high-rise buildings;

- the low price of the material allows it to be used in large quantities and, accordingly, to be used on large areas;

- Compavit can be used for the installation of underfloor heating, since when heated it does not lose its qualities and dimensions.

The main advantage of such a floor is the ability to withstand a high load without deformation - up to 900 kg per 1 m². Thus, a reasonable price combined with high quality and ease of installation will ensure a long service life of the floor.

Floor insulation with expanded clay: user and expert reviews

The scope of use of expanded clay is quite wide.But the main direction is the use as a heater. At the same time, most of the positive feedback from consumers concerns precisely such an area of application as a floor screed. If during the insulation of ceilings and walls people have certain difficulties, then they practically do not exist when pouring floors.

A special place is given to filling with this method of attic rooms, as well as the floor between the logs during the construction of private houses and country houses. In addition, they point to such a positive quality of the material as its low cost. In practice, floor insulation with expanded clay is 4 times cheaper than using other materials, and the result will be no worse.

Important! Expanded clay at a relatively low price has a number of positive qualities that make it a popular material in construction. It is used not only as a heater, but also for leveling bases and soundproofing walls and floors.

Expanded clay receives negative reviews mainly due to the fact that a large amount of material is required for work. To achieve the maximum insulation effect, you need to use a fairly thick expanded clay layer, which takes up a significant part of the space.

Experts advise using the material in accordance with technology in private homes, utility rooms and garages. Expanded clay is not suitable for high-rise buildings due to its heavy weight. The first and basement floors are an exception.

Screed floor with expanded clay: useful tips

Experts and seasoned craftsmen recommend using a number of tricks:

- before proceeding with the screed, it is advisable to take care of waterproofing. This layer will not be superfluous, but after pouring the floor, it will no longer be possible to complete it. For waterproofing, you can use liquid mastic, dense polyethylene or waterproofing;

- an ordinary metal profile or thin slats are used as beacons;

- the finished screed, made with a wet method, must be allowed time to dry. You can use the premises after a month;

- so that cracks do not form during pouring, it is advisable to constantly wet the surface with water;

- the appearance of cracks is prevented by a special plasticizer. It is recommended to add it to the finishing solution;

- when buying gypsum fiber board, it is better to take sheets that have a water-repellent treatment;

- the price of expanded clay does not necessarily indicate quality. It is worth trusting the products of well-known manufacturers;

- very large granules are subject to more rapid destruction and threaten the base with rapid deformation;

- for fixing GVL-plates it is better to take self-tapping screws with "recessed" caps.

Subject to all the rules and technologies, it is quite possible to make a floor screed with expanded clay with your own hands. Video materials, of which there are many on the Internet, will help facilitate the process. As a result, you can forget about repairing the floors of the house for a long time, while ensuring maximum heat and sound insulation. In addition, you can easily eliminate all unevenness in the floor with expanded clay. The photos clearly demonstrate both the installation process and the positive result obtained.