Laminate is one of the first among floor coverings. This is due to its excellent characteristics, ease of maintenance and installation. In addition, the material looks good and is relatively inexpensive. The duration of operation directly depends on the adherence to the technology of laying the material. Cork underlay for laminate is attracting more and more attention of buyers. Details about the features of the material are contained in this publication.

Content

- 1 Cork underlay for laminate: a short about the material

- 2 Cork backing: purpose and varieties

- 3 Technical characteristics and properties of cork under the laminate

- 4 Cork underlay for laminate: the pros and cons of the material

- 5 How much is a substrate for a laminate: an overview of the construction market

- 6 How to lay the substrate under the laminate: expert recommendations

- 7 How to install laminate flooring on uneven floors without leveling

- 8 How to choose the thickness of the cork backing: 3mm, 4mm or more

- 9 How to install laminate flooring without thresholds throughout the apartment

Cork underlay for laminate: a short about the material

The strength of the laminate coating, as well as its durability, directly depend on the reliability of the lamellar locking system. Point pressure (for example, from the legs of large furniture) can cause the material to sag or break. The underlay allows you to evenly distribute the load on the floor area.

A laminate underlay made of natural cork is considered a particularly reliable and high-quality material. Today this raw material is elite, but it is not always advisable to choose it, since the cost is high. This means that the buyer of the cork backing needs to weigh the pros and cons.

Technical cork is produced from the bark of cork oak, which grows mainly in the European Mediterranean. Portugal is the main supplier of cork products.

The peculiarity of cork oak is that you can remove the bark from this tree about thirty times during the life of the plant. The bark is removed for the first time from a twenty-five year old oak tree. This tree has high regeneration, so it does not die, but is restored. Thanks to this feature, the bark can be removed again after nine years. Each time, the quality of the raw materials obtained improves.

To obtain a cork material, oak bark is dried in natural conditions, after which it is crushed. The resulting granules are pressed and processed with steam, under the influence of which natural glue - suberin is released, thanks to which the granules reliably bind together.

It is important! The answer to the question of whether it is possible to lay the laminate without a backing is rather negative.Only possible if the lamella structure has a damping layer. However, the cost of such material is very high, and it is extremely rare on the construction market.

Cork backing: purpose and varieties

When choosing what to put under the laminate, you must be guided by the following criteria:

- the value of the expected load on the floor covering;

- humidity level;

- indicators of ultraviolet radiation, temperature drops and heat.

Laminate is a rather sonorous floor covering, and this is its main disadvantage. The substrate, in addition to other positive characteristics, has the ability to absorb excess noise when walking or in the event of various objects falling onto the coating.

Adding additional substances to cork granules allows changing the technical characteristics of the substrate

Most substrates guarantee:

- depreciation;

- sound and heat insulation;

- alignment.

According to the material of manufacture of the substrate there are:

- synthetic;

- natural;

- combined.

Adding additional substances to cork granules allows you to change the technical characteristics of the main component in accordance with the purpose of the room.

Let's consider four types of cork backing depending on the constituent components.

Classic natural backing made of technical cork, made without synthetic additives. It happens in roll and sheet. The material is characterized by naturalness and absolute safety for health, as well as excellent performance in noise and heat insulation. In addition, it is lightweight. This substrate does not rot, but it is not recommended to use it in bathrooms. It should be remembered that laying a cork backing underneath the laminate requires an even surface. To improve performance, the material should be treated with antiseptic agents.

Bituminous cork substrate. The peculiarity of this material is that it consists of two layers applied to the craft base: the upper layer is bitumen, the lower one is cork chips. This combination turns the resulting raw material into an excellent waterproofing material. The joint must be glued with tape.

Rubber-cork backing. It is a flexible combination of crushed cork and synthetic rubber. Thanks to this, the material is indispensable in buildings with high humidity levels. In addition, this type of substrate has excellent heat and sound insulation characteristics. This material is suitable for use in the "warm floor" system.

Foil cork insulation. It is used to create so-called warm floors. The base is a cork material, to which a reflective foil film is attached.

Roll cork material with a thickness of 2 to 4 mm (and no more) is used as a substrate. A cork backing is used on the wall or ceiling, as well as as an independent floor covering. In this case, the material thickness is 4 to 10 mm. The appearance of the cork canvas is pretty decent, so it's not a shame to show it to guests.

An alternative material to cork is linen, polyethylene, jute backing for linoleum or laminate.

It is important! Experts do not recommend using a bitumen-cork substrate in living rooms, as well as for the "warm floor" system due to the presence of bitumen in the oil refining product.

Technical characteristics and properties of cork under the laminate

The cork substrate received positive reviews due to its excellent technical characteristics. When choosing a material, it is imperative to consider compliance with the indicators:

- density –180-260 kilograms per cubic meter;

- tensile strength - not less than 2 kilograms per square centimeter;

- compression deformation - no more than 10% at a pressure of 7 kilograms per square centimeter;

- residual deformation - about 0.2% 2 hours after the cessation of exposure;

- thermal conductivity coefficient - does not exceed 0.037-0.043 W / (m * K);

- sound absorption - on a scale from 0 to 1 is 0.85;

- fire resistance - class B2.

It should also be noted that the cork material contains natural antiseptic components, thanks to which the cork substrate does not rot or be damaged by rodents.

It is interesting! For tongue-and-groove slabs 10 cm thick, a special cork tape is produced in rolls of 1000x9.5x0.6 cm in size. It is attached with mounting glue along the perimeter of the partition on the walls, floor and ceiling. This material is used as a sound insulation material. The tape prevents the propagation of shock-type sound waves to adjacent structures.

Cork underlay for laminate: the pros and cons of the material

The cork material is absolutely hypoallergenic, so it can be safely used in the kitchen, living rooms and children's bedrooms. Even long-term use of the cork substrate does not lead to the release of harmful substances.

Since cork laminate underlays are expensive, the advantages and disadvantages must be carefully weighed before starting work to ensure that the material is really suitable for the room where the new flooring is planned.

The advantages of a cork backing are:

- durability - the life of a natural material is 30 years or more without loss of quality, if all the necessary requirements for laying a cork substrate are observed;

- excellent performance of thermal insulation - low weight and high density turn the cork into a wonderful insulation;

- a high level of fire safety - although the material is made of natural wood, it burns poorly, which provides increased resistance to flame;

- ease of installation;

- the material is very durable and elastic, resistant to damage and deformation;

- able to dampen penetrating and vibrational noise of high tones;

- the material is easy to transport as it is lightweight;

- does not accumulate static electricity;

- does not lose its characteristics at low temperatures;

- natural antiseptics are part of natural cork, thereby excluding the processes of decay, the appearance of fungus and mold;

- cork material in the room reduces the level of radiation, and also eliminates the negative influence of the external environment and the consequences of the use of low-quality building materials.

Like any building material, a cork substrate, in addition to advantages, also has disadvantages that you need to know. This is a rather fragile material, therefore, special attention must be paid to transportation and storage. The main disadvantage is the high price of a cork substrate, which is unacceptable for the average buyer, but considering all the unique characteristics, it can be considered quite justified.

It is not recommended to use cork backing in damp areas such as kitchens and bathrooms. This material also does not save from structure-borne noise caused by the operation of a drill, elevator, etc.

Before laying cork insulation, you should take care of an additional waterproofing layer. Cork backing and the "warm floor" system are incompatible with each other. Although the material has excellent characteristics, experts do not recommend installing too massive pieces of furniture on the surface where the cork backing is laid.

It is interesting! In the building materials market, you can buy cork laminate, which does not need a substrate.It appeared not very long ago, but it is increasingly common in houses and apartments.

How much is a substrate for a laminate: an overview of the construction market

The cork laminate underlay belongs to expensive materials, the cost of which depends on its thickness and on the degree of brand awareness. Manufactured in many European countries, as well as at Russian enterprises.

The most common cork backing made in Portugal is Vintage, Amorim Group, Egen, Wicanders and Sedacor.

Related article:

What is the best laminate substrate: types, properties and technical characteristics

The main criteria for choosing a material. Varieties of substrates. How to do it yourself. Rating of the 5 best manufacturing firms.

The manufacturer Vintage offers a roll of cork underlay for 3 mm laminate, priced from 318 to 374 rubles. behind m², as well as material with a thickness of 2 mm (price - about 150-168 rubles per square meter) and 4 mm (cost - 260-294 rubles per m²).

The Amorim Group label produces roll products Premium Cork, Cork4U and Floorwood Portugal Cork. The price of a cork substrate 3 mm by Premium Cork is 189-243 rubles per square meter. A 2 mm thick substrate will cost the buyer an average of 89-173 rubles per m²... Cork substrate 2 mm from the manufacturer Cork4U costs 99-115 rubles per square meter, 3 mm thick - 180-230 rubles, 4 mm - 248-290 rubles. Floorwood Portugal Cork offers customers a 2 mm cork underlay at a price of 145-175 rubles per sq. m and 3 mm thick, costing 213-320 rubles.

Also on the Russian building materials market there are products of the German firms Parkolag and Tarkett, the Polish company Decora and the Spanish manufacturer Ibercork, as well as many other manufacturers. The cost varies from 49 to 576 rubles per square meter.

First of all, the price of a substrate for a laminate depends on the thickness. The formation of the cost is also influenced by the density of the material, the type of technological method of manufacturing, the cost of raw materials and the transportation costs of the manufacturer. That is why one can observe sharp jumps in prices for the same type of technical traffic jam.

Cork underlays for laminate are available in two types - roll and sheet. The length of a cork roll is usually 10 m, width - 1 or 1.4 m. The sheet substrate has the following parameters: width - 61 cm, length - 91 cm. The thickness of the roll and sheet fabric varies from 2 to 10 mm.

When buying a material, you need to pay attention to where it is stored, whether the edges of the substrate are not damaged and whether the package is sealed. It is also important to consider the quality and class of laminate lamellas. If you are installing a 31-32 grade laminate, you can use an inexpensive foam backing or other alternative materials. If the material is more expensive and of high quality, for example, a 33 class coating, then buying cork insulation will extend the life of the floor.

When choosing a cork backing, you need to pay attention to whether the packaging is not tight and the edges of the product are not damaged.

It is important! Experts say that buying a cork backing is economically justified and fully justified if the flooring is laid in a dry room with a base difference of no more than 1 mm.

How to lay the substrate under the laminate: expert recommendations

For laying laminate or any other similar coating, it is necessary to prepare a base - a screed on the floor. What is placed under the laminate on the concrete floor? The best solution is to use a cork backing. Even the most inexperienced builder will be able to lay it correctly. However, there are quite important facts that must be taken into account.

Cork rolls need to be cut to fit the room before laying.It is recommended to leave the finished pieces in an unfolded position for a day or two so that the substrate straightens and fits without waves and swelling.

The distance between the material and the wall of the house along the perimeter of the room should be 1 cm. During cutting, this rule must also be observed. To make this easier, you can put a 0.8-1 cm thick bar between the wall and the substrate. Some craftsmen fix the material near the wall with tape, but this technique does not always help to maintain the required location of the substrate.

Sheets of cork material must be laid tightly to each other, and the resulting joints should be connected with construction tape. Laying the second row should be done according to the brickwork principle: you should start with half a sheet to offset the joints of the joint, and the third row - again from a whole sheet.

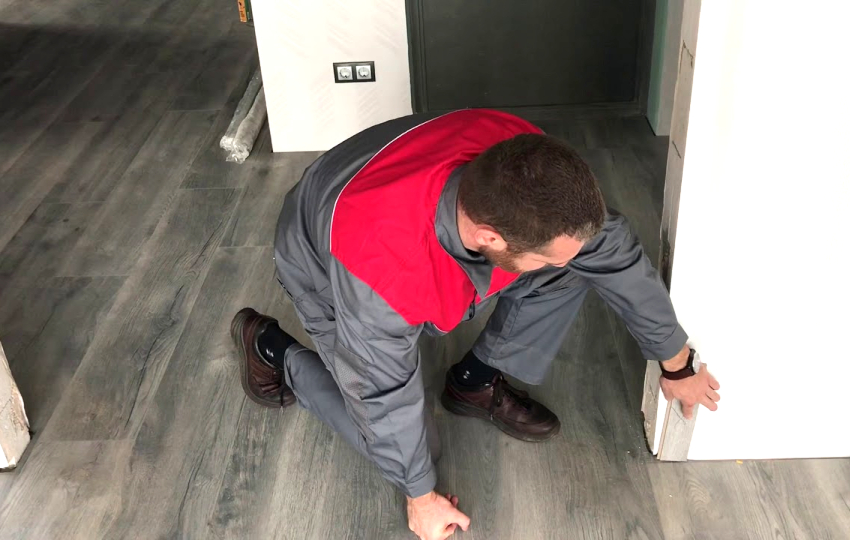

The cork backing is easily damaged, so the installation should be done according to the following scheme: first, place a backing sheet, which is covered with several rows of laminate, then install the next cork sheet, and so on. It is better to carry out installation work not from the screed, but from the already laid floor covering.

It is interesting! Many are interested in the question of which side to put the substrate under the laminate. For a material made of pure technical cork, there is no difference, but the bitumen-cork substrate is always laid with the cork layer down.

How to install laminate flooring on uneven floors without leveling

It is very important to choose the correct substrate thickness. When choosing a material, consider the thickness of the laminate. If the flooring is less than 8 mm thick, a 2 mm underlay will do. If the lamellas are thicker, it is better to choose a material with a thickness of 3 mm. Cork backing 4 mm or more is not recommended for use.

Material with a thickness of 3-4 mm is quite enough to level out unevenness of the base, not exceeding 2 mm. If the differences and defects in the floor are more significant, then additional actions must be taken. In the case of a concrete base, it should be leveled with a leveling mortar or thin screed. The wooden covering needs to be sorted out and tightened the boards. If necessary, it is worth replacing damaged boards with new ones, if necessary, they need to be looped or sanded.

The cork backing can be laid on plastic sheeting or directly on a concrete base. In the first case, the film should be dense (100-150 microns). The joints of the two canvases are overlapped (3-5 cm). Whether it is necessary to put a film under the laminate, everyone decides for himself.

It is important! To determine the level of the base drop, a long building level is used, applied in different places. Thus, the maximum deviation is determined.

How to choose the thickness of the cork backing: 3mm, 4mm or more

The durability of the flooring depends on the correct thickness of the substrate for the laminate. An error in the selection of the thickness of the damper layer becomes the cause of breakage of the interlocking joints of the laminate coating. When choosing a material, it is important to rely on the following facts:

- The 2 mm thick underlay is suitable for use in rooms with a perfectly smooth surface. This material is not suitable for leveling even the smallest curvature (1 mm).

- A 3 mm backing layer is used for medium thickness laminates to correct unevenness of 2 mm.

- The 4 mm plug is placed under thicker and more expensive lamellas. It makes it possible to level irregularities with a height of 3 mm.

- Cork backing 5 mm and thicker is practically not used in multi-storey residential buildings and individual buildings.

It is important! The opinion that the thicker the substrate, the better is wrong. Technical cork more than 4 mm thick deforms quickly and breaks down as a result of static loads from heavy furniture. Such deflections lead to breakage of the lamella locks. In addition, the thick lining does not damp vibration well.

How to install laminate flooring without thresholds throughout the apartment

The laminate, laid with a continuous sheet, has a solid and aesthetic appearance. Such laying to form a single floor covering is a complex job that requires the use of high quality materials, as well as professional skills.

When laying laminate with thresholds between rooms, you can choose lamellas of different strength classes separately for each room, and in the case of continuous laying, its class is determined by the maximum load. Usually, for laying lamellas without thresholds, it is necessary to choose a laminate of 33 strength class and higher.

When installing laminate flooring without thresholds, it is imperative to lay the underlay first. The optimum substrate thickness is 3 mm. Cork material is perfect for this. It is very important to prepare the base - it should be as even, smooth and dry as possible.

Helpful advice! Manufacturers of building materials do not recommend continuous laying of laminate flooring over a large area. This is due to the property of the panels to change their linear dimensions under the influence of humidity and temperature in the house.

The use of a cork backing for a laminate makes it possible to keep the locking joints of the planks intact for as long as possible. The material is also able to perfectly reduce the level of various external noise, prevent heat loss through the floor covering. Many users have left positive feedback on the cork underlayment under the laminate.

The material has no significant drawbacks. Mass use is hampered only by the high price of cork insulation. However, the cost is fully justified by a number of advantages. There is one more weak side of the cork substrate - waterproofing, so it is necessary to ensure that the material does not come into contact with moisture for a long time.

It is very important not to forget that a backing that is too thick is not a sign of quality laminate material. Care should be taken to select the substrate, taking into account the characteristics of the floor covering.