Laminate flooring is a relatively new option for flooring that has already gained popularity with a large number of buyers. It differs not only in high performance characteristics, but also in significant ease of installation. Do-it-yourself step-by-step instructions for laying laminate flooring will allow you to mount the coating, even if you do not have the skills in the field of repair and finishing work.

Content

- 1 The structure of laminated panels

- 2 Laying laminate flooring: floor leveling schemes

- 3 Installation of substrate and insulating layer

- 4 DIY step-by-step instructions for laying laminate flooring: choosing a suitable layout and making calculations

- 5 DIY step-by-step video instructions for laying laminate flooring: various installation methods

The structure of laminated panels

Design laminate represents several layers that are connected in a panel. On each side of such a panel there are special locking devices that allow you to quickly and easily connect them together.

Due to this design feature, the coating is very sensitive to the base, that is, the slightest unevenness of the floor on which it is laid laminate, can lead to loosening and premature wear of the locks. And this, in turn, leads to the formation of cracks, the accumulation of dust and dirt in them, and to other unpleasant consequences.

The laminate consists of the following layers:

- top layer - consists of anti-static super-strong material, takes on the main mechanical load;

- acrylate resin layer - enriched with special mineral particles for greater strength;

- paper impregnated with a special composition - a decorative layer that provides an aesthetic appearance of the coating;

- adhesive layer - bonds the upper layers to the base;

- base made of plastic - the thickest layer equipped with waterproofing. It also houses the original laminate locking system.

The laminated panel consists of several layers - a base, an adhesive layer, decorative paper and a glossy top coating

Laying laminate flooring: floor leveling schemes

The permissible unevenness of the floor when laying the laminate should not exceed 2 mm for every 2 m² of surface area. A slope within 4 mm per 2 m² is also acceptable, but it is not recommended to install furniture and other interior items on such a floor.When laying the laminate on an uneven floor, a distortion will inevitably occur, due to which the cabinet doors may not close.

When preparing the floor for laying the laminate, the leveling option depends on the material from which the base is made. General tips for alignment boil down to the following points:

- old the concrete pavement is subject to major repairs... The cracks expand and are filled with cement mortar, large recesses must be filled with a self-leveling mixture. At the end, the floor is sanded or filled with a screed;

- in a wooden floor, defective boards are replaced or leveling with plywood is carried out;

The final result and durability of the flooring will depend on the quality of the preparation of the base.

- cement screed is primed with special compounds;

- plywood or board flooring is sanded using special equipment to eliminate small irregularities.

Helpful advice! All types of floors must be thoroughly washed and vacuumed before installing the laminate.

When choosing the best option for leveling the floor, you need to focus on criteria such as the amount of effort and time spent, as well as financial costs.

Installation of substrate and insulating layer

When laying laminate it is highly undesirable for the floor covering to come into contact with a surface that releases moisture. Therefore, additional installation of special layers is necessary, which will absorb water and prevent steam condensation. A special diffusion membrane or a polyethylene layer 20 mm thick is well suited as such layers. Sheets of material should be laid with an overlap of 20 cm, and it is best to connect them to each other with adhesive tape.

Cork backing characterized by high heat and sound insulation properties

Installing a waterproofing layer is mandatory if you are installing laminate flooring on a concrete base. The following base coverage options fall under this definition:

- directly the concrete floor, which is characterized by the presence of crushed stone or gravel in the solution;

- cement-sand screed;

- factory slabs and monolithic floors.

At the same time, the service life of the concrete floor is not of fundamental importance, since both new and old coatings can release moisture. Installing a waterproofing layer will protect the moisture-sensitive laminate from deformation, so this point must be taken into account when calculating the layout of the laminate.

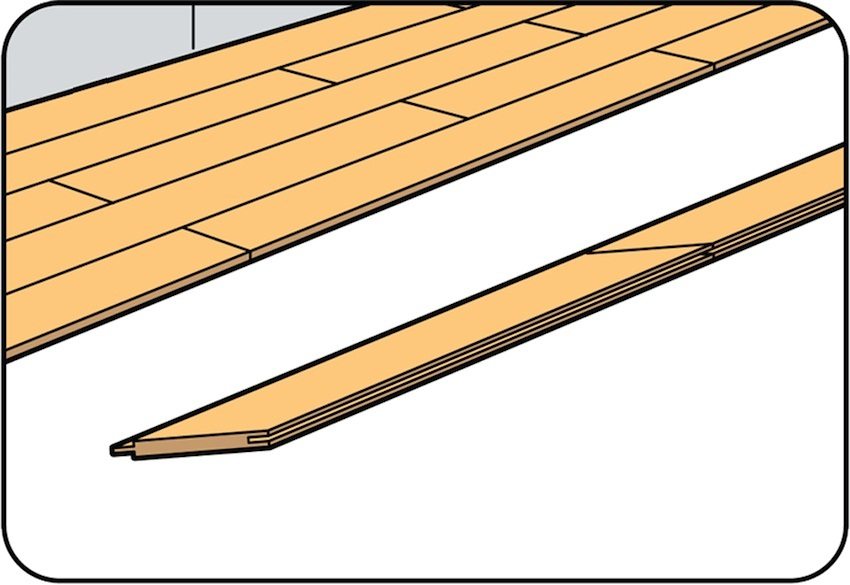

Almost all instructions for laying laminate flooring say that substrate should perform the following functions:

- soundproofing;

- ensuring the static floor;

- alignment of small defects in the base;

- moisture protection;

- protection of the underside of the laminate from abrasion.

Ordinary linoleum can act as such a layer.

Related article:

Tile and laminate gutter: how to put it right between coverings. Choice of decorative threshold. Laying laminate flooring in the kitchen. Combining tiles and laminates to create an original interior.

Step-by-step instructions: how to lay laminate flooring on linoleum with your own hands

Video instructions for laying laminate flooring on linoleum show that for a high-quality installation of the coating, you must strictly adhere to the established technology. You need to start flooring panels in the direction from the window, perpendicular to it. In order for there to be a gap between the laminate and the wall, it is necessary to install special spacer wedges.

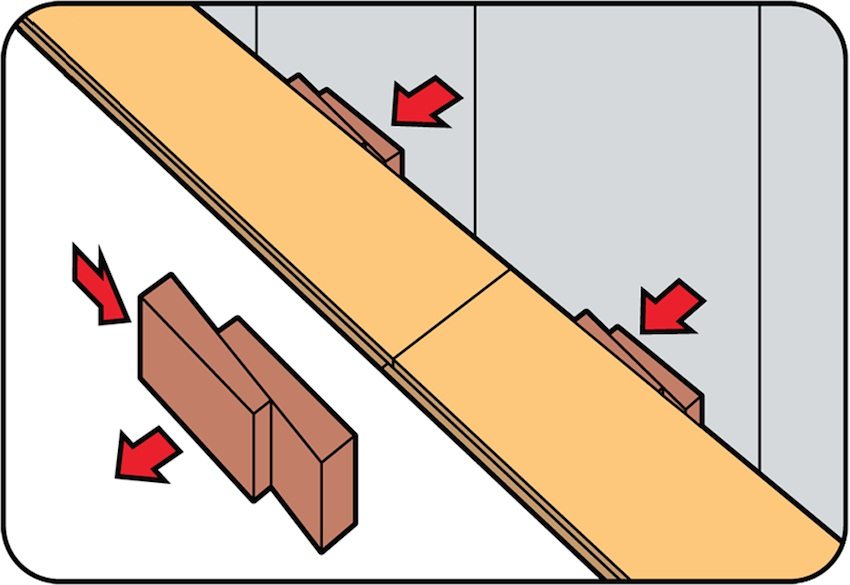

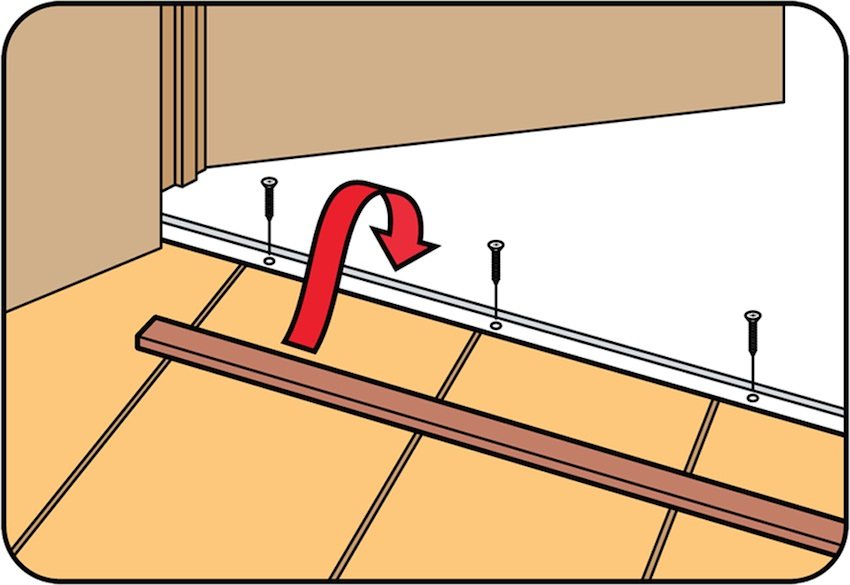

Helpful advice! The expansion gap should be within 10 mm. It serves so that the coating can expand and contract with temperature or humidity changes without deforming the surface.

Laying laminate produced perpendicular to the window

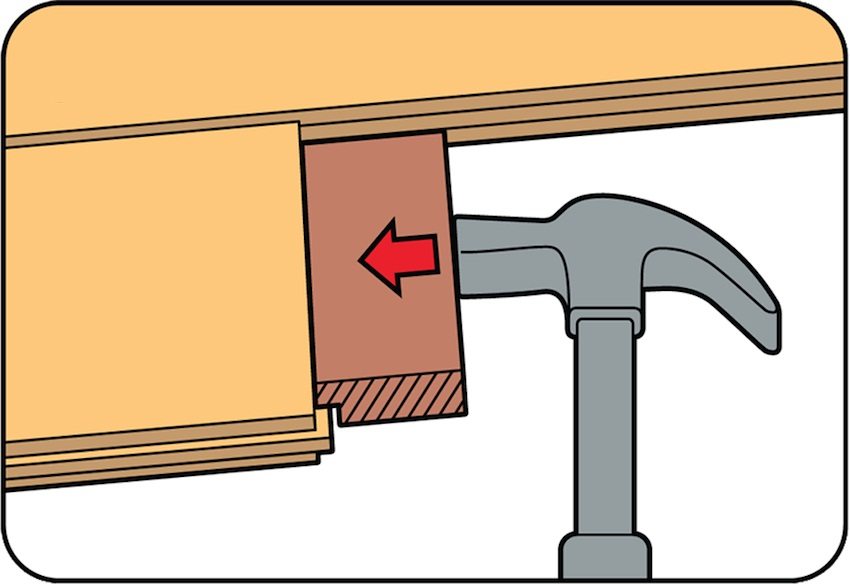

After the first row of cover is installed, it is necessary to trim the short panel.If the trimmed part is longer than 50 cm, then it can be stacked in the second row, thereby minimizing waste. The second row boards are applied to adjacent panels at an angle of 45 degrees. The last panel is mounted using a special clamp, which allows it to remain stationary.

In order to protect the expansion gap when laying the laminate, after installing all panels on linoleum skirting boards are installed. If you plan to hide wires and other communications under them, then it is recommended to use skirting boards with special channels.

The thickness of the backing depends on the thickness of the laminate panels. This means that for panels with a thickness of 9 mm, the substrate should be no thicker than 3 mm. The instructions that come with each specific flooring model have recommendations for choosing substrates, which should be guided by. In this case, it is necessary to take into account the peculiarities of laying the laminate in a floating way, that is, when the panels are connected only to each other, and not attached to the base or walls.

DIY step-by-step instructions for laying laminate flooring: choosing a suitable layout and making calculations

There are three main areas of laminate layout:

- Longitudinal - the cover is mounted parallel to the flow of sunlight from the window. The simplest and most popular layout option.

- Transverse - allows you to visually increase the area of the room, while the panels are located across the room (parallel to the wall with the window opening).

- Diagonal is the most difficult direction in terms of installation, which allows you to increase the area of the room even more than transversely.

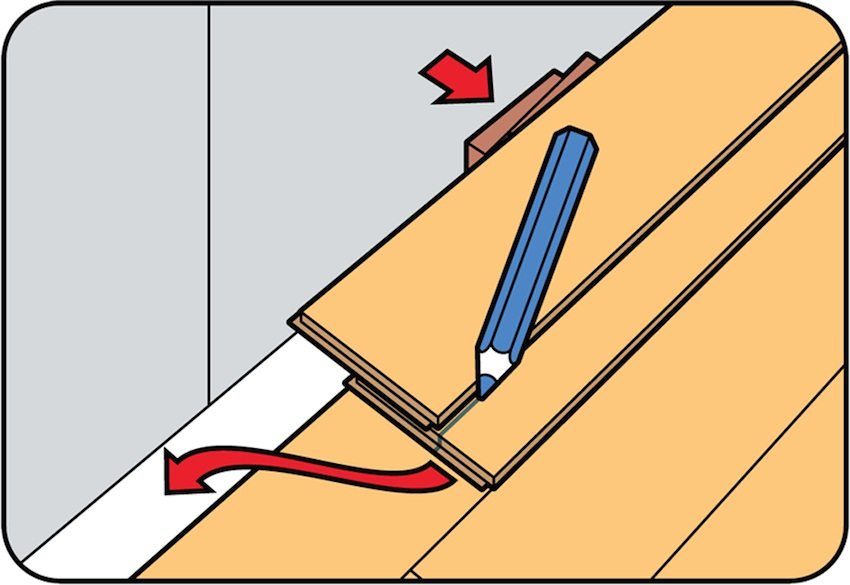

If a laminate is laid on a plank floor, the panels must be positioned perpendicular to the floorboards. And in order to minimize material consumption, it is recommended to draw a floor plan with its dimensions by hand before starting installation. All openings and niches are applied to it, a deformation protrusion is outlined, and then it is considered how many panels are needed for laying the coating. In this case, both the number of complete panels and the possible use of scraps must be taken into account.

Photos of laminate laying methods will help you understand which option is best suited for your room. Also, for calculations, you can use special construction calculators, which can be easily found on the Internet.

Required tools

What do you need to install laminate flooring as quickly and efficiently as possible? You will need the following set of tools:

- tape measure, building corner and level - to ensure an even installation;

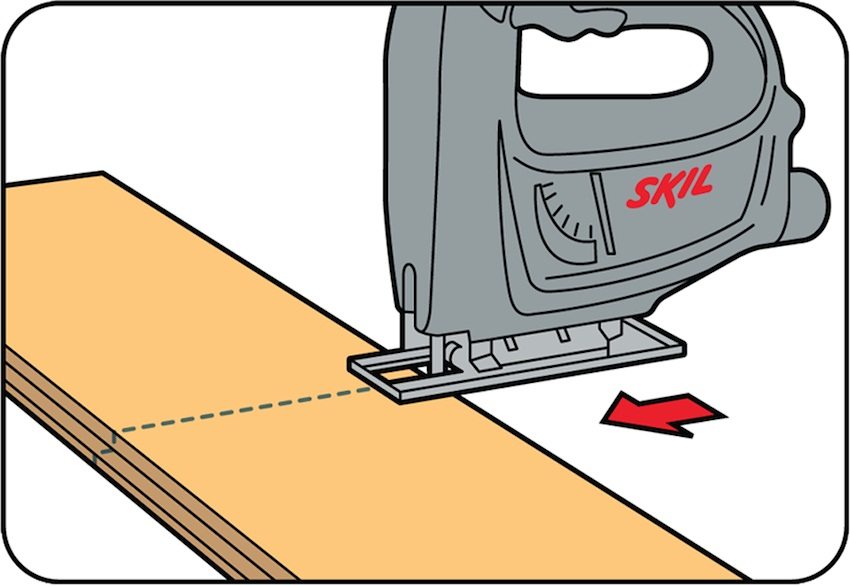

- construction knife, jigsaw or a hacksaw - for cutting panels, skirting boards and beams;

- pencil - mark walls and panels;

- hammer - to secure the panels.

You can buy a kit for laying laminate flooring at any hardware store, and the use of the above tools does not require special skills.

Possible ways of connecting panels

Laminate elements can be interconnected in several different ways:

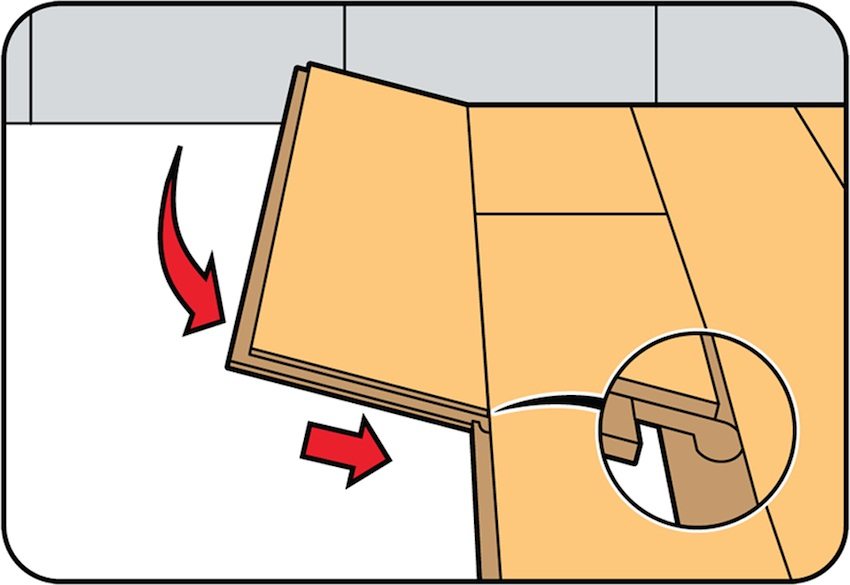

- lock-locks - special latches, when used, the comb of each next panel of the cover is inserted into the groove of the previous one. This is done strictly vertically or horizontally, and to increase the reliability of joining the joints, it is recommended to tap with a hammer or grease with glue;

- double click-locks - the ridge of the next panel is not only inserted into the groove, but also snaps into place with a little force. This type of connection is more reliable and does not require additional reinforcement;

- glue method - recently it has been used extremely rarely.When using this method, the front and side sides of each of the panels are pre-treated with glue.

When laying laminate flooring with your own hands, the step-by-step instructions have minor differences depending on how you are assembling - in rows, attaching a ready-made row, or in separate panels. The second option is easier to do alone, while the first requires less time.

DIY step-by-step video instructions for laying laminate flooring: various installation methods

Once you have leveled the floor, purchased all the necessary tools and decided on a suitable panel joining system, you can start laying the flooring directly.

Any type of installation, in which there is a serial connection of one board to another, is called laying the laminate in a deck manner. Deck laying is suitable for all types of laminate, and also differs from figured material savings and ease of work. Deck-laying does not require complex calculations and often trim panels.

If you do the styling one by one, then the sequence of actions will be as follows:

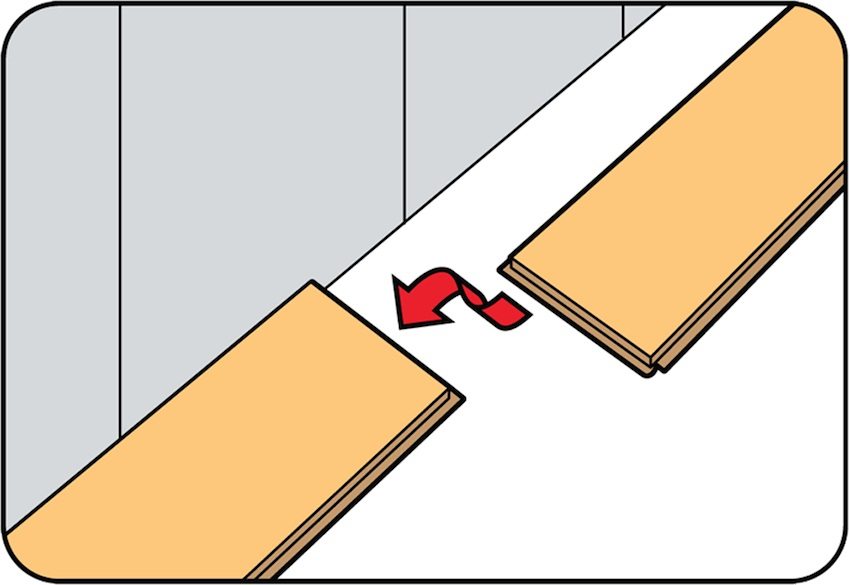

- the first panel is laid with a lock on itself, with a comb against the wall. Wedges are installed between the wall and the panels to form a gap;

- the second is attached to the first panel, and so on;

- there should be no gaps or differences in height between the combined panels. The longitudinal edge must also be flush;

- in order to make the connection along the side edge, the panels must first be inserted at an angle, and then brought by pressing until they click;

- end locks can be connected horizontally or vertically;

- the cut of the last panel in the first row is laid at the beginning of the second.

If a pipeline passes through the floor, then a hole with a diameter of 2 cm larger than the diameter of the pipe must be drilled in the place where it passes through the laminate. This is done so that the floor can “float” freely in the event of temperature or humidity changes.

Advantages of the floating installation method

When choosing any installation scheme for the coating, you can fix the laminate to the floor using special construction glue, or you can choose to install the laminate in a floating way. This method means that the panels of the material are held together, but are not fixed to the base in any way.

The nuance here is that for every 10-12 linear meters of the coating, expansion joints must be provided that will prevent the laminate from deforming when the temperature in the room changes.In addition, special gaps should also be provided between the wall and the laminate, which can be hidden under the skirting boards.

With a floating method of laying, the panels are connected only to each other, without attachment to the base

The floating method will give you the following benefits:

- if a mistake is made during assembly, then the finished coating can be easily disassembled and reassembled. Most manufacturers claim that this can be done up to three times;

- panels damaged or deformed during operation can be easily replaced with new ones;

- deck laying is easier than glue laying. In the photo of laying the laminate in this way, no differences with other installation options are visible;

- the use of the floor is possible immediately after the flooring and installation of the skirting boards, there is no need to wait until the glue dries.

In addition, floating installation is possible directly on a prepared screed, with the preliminary use of a heat-insulating substrate.

The subtleties of laying laminate diagonally

The main feature of the diagonal laying of the covering is that the panels are located at an angle of 45 degrees to the walls. In the video of laying the laminate diagonally with your own hands, you can see that the installation should start from the center of the room, and then move in any direction convenient for you. Near walls, as with other installation methods, it is necessary to leave an expansion gap of about 15 mm.

Also in the video of laying the laminate diagonally, you can see that before starting the installation, a thread is pulled between opposite corners of the room. This is done in order to lay the first row of uncut panels on it. To cut the subsequent ones, you can use a jigsaw or a hacksaw for metal.

Helpful advice! Do not discard the pieces of panels that you cut from the left side of the row, they will come in handy when installing the right side.

When laying diagonally, it is very important to take into account the deformation gap when cutting the corners, which will then be laid against the wall.

Installing beveled laminate

Beveled laminate flooring differs from conventional laminate in that the edges of the top are beveled on two or four sides. This allows the laminate to look like a natural wood flooring and also protects the edges of the panels from delamination and chipping during use.

In the video of installing a beveled laminate, it is noticeable that the installation of this type of flooring is no different from the installation of a conventional laminate. It is also necessary to mount a substrate layer under beveled panels, it is desirable to level the base as much as possible, and the panels can be laid in parallel, perpendicular or diagonally.

How to install laminate flooring without thresholds

Installation of cover without thresholds is one of the most popular methods of laying laminate in recent years. Before choosing this particular option, consider a number of nuances that arise:

- when laying laminate flooring without thresholds, expansion joints must be made throughout the apartment if the total area exceeds 50 m². Otherwise, the coating may swell, most often this occurs in doorways;

- it is strongly discouraged to use the no-threshold method if the area of the room exceeds 120 m²;

- before starting installation, it is imperative to measure the door height. The gap between the door leaf and the laminate should be approximately 1 cm;

- in the room in which the installation is carried out, there should be a low level of humidity, otherwise the coating will swell and deform, and the base of the floor should be as even as possible;

- as is the case with the usual laying laminate, the installation of the insulating substrate is required. It can be polyethylene foam, cork sheets or embossed cardboard, laid in several layers. The recommended substrate thickness is 2-4 mm.

Many videos of self-laying laminate flooring demonstrate that when installing a covering without thresholds, as with other methods, panels can be fastened together in different ways. It is worth choosing a connection with glue if the installation is carried out in a room with high humidity and high pollution. Then the joints will be airtight, dust and water will not get between them. The locking method is good because it is carried out faster, and the panels adhere more tightly to each other.

Helpful advice! Mounting with glue eliminates the possibility of disassembling the laminate, so try to avoid mistakes during installation.

The most difficult moment in installation without thresholds is the areas in the doorways. Firstly, the boards in adjacent rooms should be laid in the same direction, so you visually expand the space. Secondly, cuts should be made in the door frame where the covering will go under its racks. A video of self-installation of laminate without thresholds will help you do everything right and prevent common mistakes.

When choosing a suitable installation method for flooring such as laminate, it is worth considering all the nuances of the room, the features of the selected panels, and also taking into account your skills and capabilities in terms of construction. With all these points in mind, you can make the perfect do-it-yourself flooring.