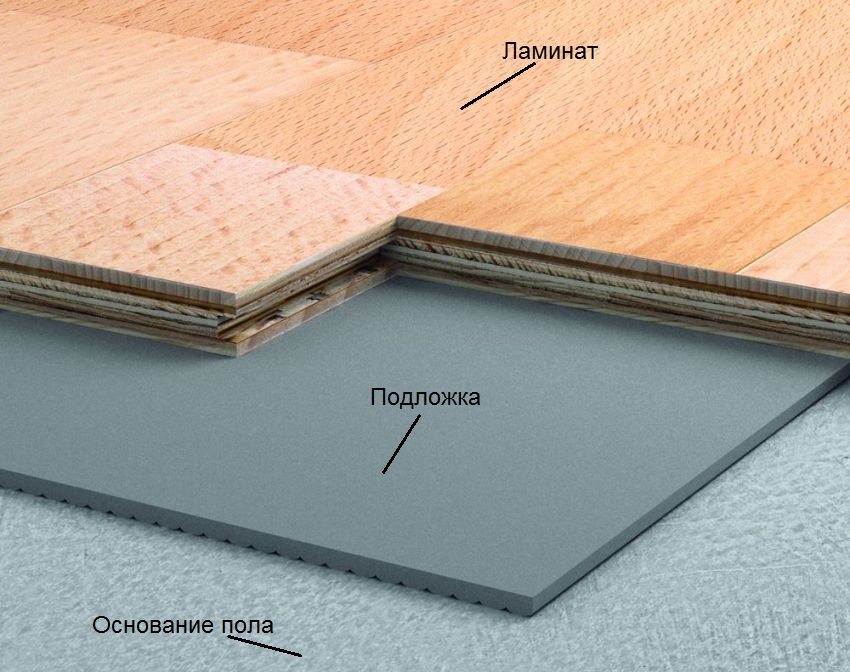

In the renovation of an apartment, flooring plays an important role. The comfort of those living in the house depends on the correct choice and quality of laying the material. Laminate has many advantages, it boasts an affordable price, which makes it the undisputed leader in flooring. However, a poor-quality substrate can negate all the advantages of even the most expensive panels. In the article, we will consider which substrate for the laminate is better and why.

Content

Basic functions of a laminate underlay

Home is the place where you want to relax after a hard day at work, to feel peace and tranquility. But how to do this if extraneous sounds interfere with rest all the time? Surrounded on all sides by neighbors, we have to endure certain inconveniences. However, there is a solution to this problem by placing an additional layer under the floor covering. Let's try to figure out what functions the substrate under the laminate performs, which one to choose and how to lay it correctly?

Soundproofing

When walking around the apartment, the sound of steps is heard quite loudly. This can be inconvenient for you and your neighbors. Such poor sound insulation is due to two characteristics of the laminate: the thickness of the panel and the method of installation.

The standard thickness of the laminated board is 8 mm. And this is not much at all, considering what loads she has to withstand. In this case, the laying method is mainly floating, which creates an additional membrane for sound transmission. However, this problem can be solved by laying an additional underlay that has good sound insulation.

Related article:

Waterproofing the floor in the apartment in front of the screed: types and details of installation. Types of waterproofing materials used under the screed: roll, liquid, dry and penetrating mixtures. Tips for self-arrangement.

Many manufacturers provide the laminate with a backing by gluing it to the back of each board.However, such a convenient addition is found mainly in the coating of 32 and 33 classes. The thickness of the laminate with the backing is greater, and accordingly the price for such a product is much higher. So the decision to stack backing do it yourself is a good way not to overpay. It would be much better to independently select and purchase a substrate that best suits you in terms of its characteristics.

Useful advice! Pay attention to the labeling of the purchased substrate. It is on the packaging that the manufacturer indicates all the characteristics of the material.

Additional surface leveling

Another important function that the underlay performs is to smooth out irregularities that are present on the screed used under the floor covering. Unfortunately, no matter how hard you try to level the floor to perfect condition, small differences will still remain. But even such modest deviations after a few months can negatively affect laminate.

Any deviations and differences in the base lead to the fact that "backlashes" appear between the panels and the concrete screed. Simply put, the coating sags where the gap is greatest. And although it seems that a few millimeters is not a problem, in reality it will be quite noticeable on the floor surface, both externally and when walking.

The solution to this problem also lies in the laying of the substrate. High-quality and correctly laid material allows you to hide flaws and achieve an almost perfectly flat surface of the subfloor. However, there are pitfalls here - do not assume that the thicker the material, the better it will level the surface.

The optimum substrate thickness for laminate is 3 mm. If you choose a material with a greater thickness, this can lead to the fact that deflections are formed at the joints of the planks. It can also negatively affect the serviceability of the locks between the panels.

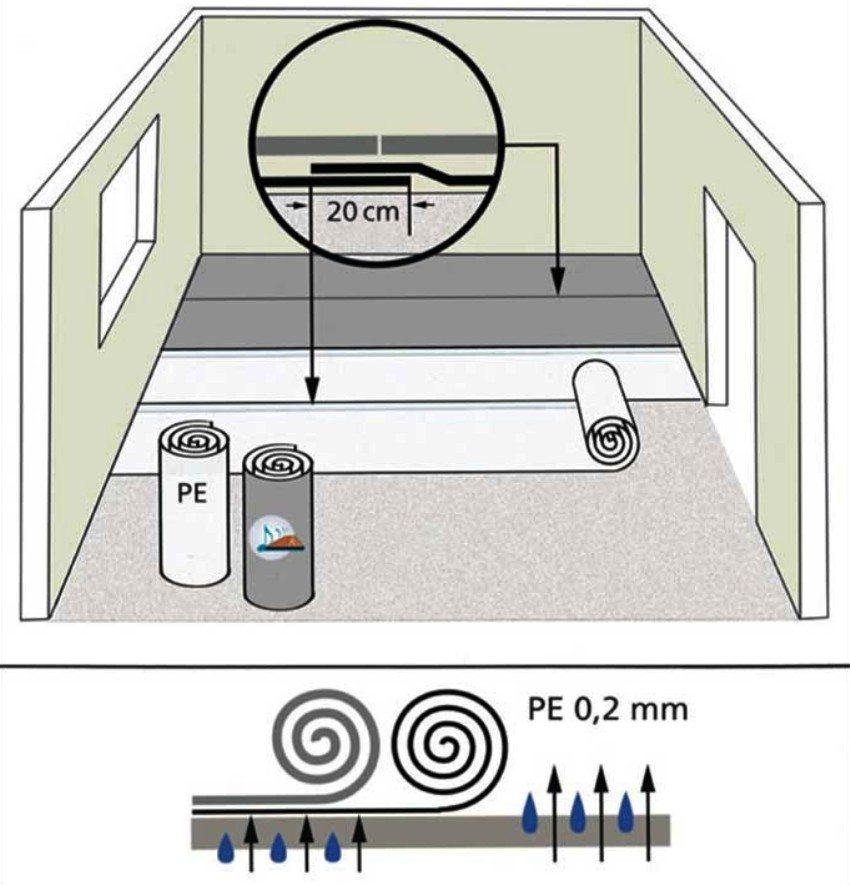

Waterproofing

Everybody knows that laminate - rather capricious material and does not tolerate water exposure. However, it is necessary to take care of the safety of the coating even before it is laid. Primarily a concrete screed prepared for laying laminatemust dry thoroughly before being used as a base. Sometimes this process takes up to one month. Here you should not rush to do everything as soon as possible, otherwise between the dry surface and laminate condensation may accumulate.

Useful advice! To find out if the screed is dry, leave a plastic bag on the floor in the evening. If the package remains dry by the morning, it means that the base is completely dry. If condensation appears, you will have to wait a little longer.

In this case, the substrate performs a moisture-protective function, maintaining the microclimate for both the concrete screed and the reverse side of the laminated coating.

Thermal insulation

In addition to the fact that the substrate itself performs insulating properties, retaining heat in the room and preventing it from being consumed through the concrete, itself laminate - also a fairly warm coating. Thus, the combination of a high-quality coating and the right underlay provides a warm floor that does not need any additions.

As for the installation of heating systems, they do not always turn out to be effective, since, being between two heat-insulating materials, they cannot fully reveal their capabilities. It is much more advisable to combine them with tiles or other "cold" material.

What is the best underlay for laminate: material requirements

Based on the above, it becomes clear that laying the substrate under the laminate is a necessary measure. And here it remains only to choose which material to give preference to.The cost of high-quality roll materials is quite high, therefore, before making a purchase, you must carefully weigh the pros and cons of each option. Otherwise, chasing a lower cost, you run the risk of facing problems with poor-quality coating installation soon.

What is the best laminate underlay to use? Consider what requirements are imposed on the substrate, and what criteria must be followed when choosing the best flooring:

- the material used must be neutral and not react with alkaline compounds;

- bactericidal properties also play an important role;

- it must have good thermal insulation properties;

- be moisture resistant;

- the substrate should not be a breeding ground for insects, rodents and bacteria;

- should facilitate the removal of accumulated moisture;

- should provide a reduction in the load that the laminate locks are subjected to when walking.

Focusing on these indicators, you can independently choose a substrate for the laminate. How to do this correctly - we will consider further.

Choosing a substrate for a laminate is not worth saving, and then the flooring will serve you for many years

Types of laminate substrates: which one to choose?

The large selection of materials recommended for use as a substrate can be confusing. And figuring out which option is better is not easy. Therefore, the first thing worth paying attention to is the condition of the concrete screed, prepared as a base. For a flat and high-quality surface, a 2 mm substrate is quite suitable. And if the base is flawed, it is better to align it using a material with a thickness of 3 mm.

Useful advice! Many manufacturers recommend using the same substrate as the laminate flooring. In reality, it does not matter at all, and absolutely any quality material will do.

Today, among the most popular types of substrates for laminate flooring are: polyethylene foam, polystyrene foam, combined, coniferous, as well as cork and bitumen-cork. Let's consider each of these options and try to draw a conclusion about which of these options is the most high-quality and profitable.

When choosing a substrate, you need to focus on the recommendations of the manufacturer of the laminate

Polyethylene foam backing

Due to their high thermal insulation and moisture resistance, polyethylene foam substrates are very popular. Their synthetic nature provides protection against rodents and harmful insects under the laminate. Cutting and stacking such material is very easy.

Some manufacturers produce polyethylene foam substrates, additionally equipped with another layer of metal film. Such foil materials are manufactured using aluminum. This option could be an ideal solution, if not for its lifespan. It is limited to a few years, after which the material begins to sag and lose its original shape.

Cork backing

Cork roll or sheet underlay for laminate perfectly copes with the function assigned to it. Why buy a cork backing for your laminate? Among the advantages of this option are:

- excellent heat and sound insulation characteristics;

- non-susceptibility of the material to decay processes, as well as the appearance of mold;

- convenient for installation dimensional parameters;

- considerable service life without losing its quality characteristics;

- possibility of using together with the systemwarm floor»And floating floors.

The main disadvantage of a cork underlay for a laminate is the price. Especially when it comes to laying inexpensive laminate with a fairly limited service life.Also, this material is characterized by the appearance of condensation on the back of the laminate, which can adversely affect its condition.

Bituminous cork underlay

Kraft paper with the addition of bitumen is used as a basis for the manufacture of this material. On top of such a base, a layer of cork chips is laid, consisting of elements 2-3 mm long. The positive side of use can be called the provision of proper sound insulation, as well as high-quality protection against moisture ingress.

It is one of the best materials for air exchange and condensation prevention. The only thing worth noting is that using such a high-quality and expensive substrate with a simple and cheap laminate is simply inappropriate. This option is more suitable for laying a durable and expensive coating.

Laying laminate on a cork backing

Expanded polystyrene backing

Another common option for a laminate substrate is expanded polystyrene. The film, made of extruded polystyrene foam, has the best characteristics when it comes to the resistance of the coating to all kinds of loads. This material is indispensable for rooms that are actively used and, as a result, have an increased load on laminate... Moreover, the film perfectly evens out all the unevenness of the concrete base.

The elasticity and initial thickness of this material can be maintained for many years, and the ability to absorb vibrations when walking makes the laminated flooring virtually silent. The cellular structure of expanded polystyrene provides high moisture resistance and prevents condensation. As a substrate for laminate flooring, polystyrene is an inexpensive and very high quality option.

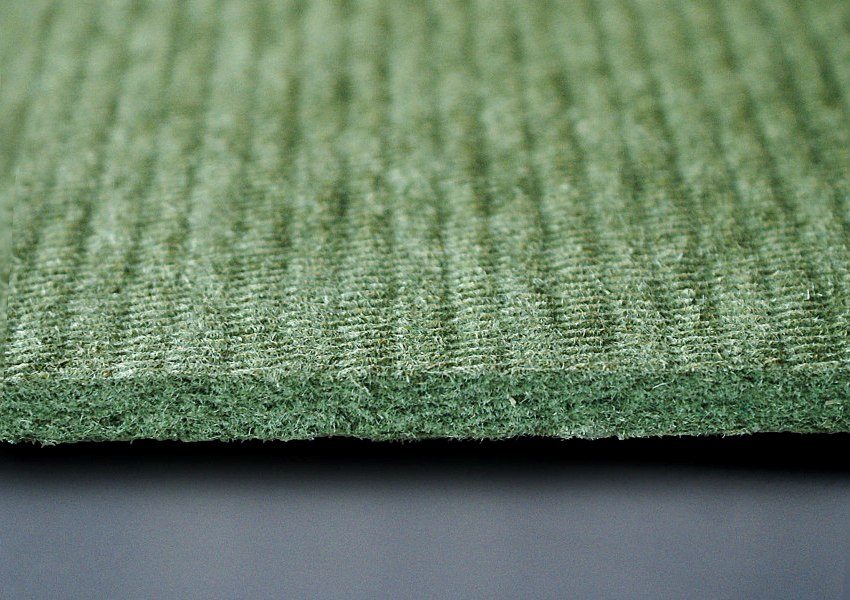

Coniferous underlay for laminate

Almost all the proposed materials cannot boast of a high level of environmental friendliness. However, there are exceptions among them. The coniferous substrate for the laminate is made from wood and leaves behind all other materials by its naturalness. Due to the porous structure, such a substrate does an excellent job of soundproofing, while providing the floor with natural air exchange.

Installation also presents no problems even for a beginner. After reading reviews about coniferous laminate flooring, you will see hundreds of satisfied owners who have provided their home with a reliable and environmentally friendly floor.

The only thing that can cause confusion is the price of the material. Softwood backing is expensive to produce and you will likely have to pay a lot to buy it. But if you consider in detail all the pros and cons of a coniferous substrate for a laminate, then you can see that it is worth it.

Combined underlays

The composite substrate is based on a combination of synthetic materials such as polyethylene and expanded polystyrene. The brightest representative of this type of laminate underlay is Tuplex. Many have seen her more than once, or at least heard about her. Externally, the combined substrate consists of two polyethylene layers, between which a layer of polystyrene foam balls is located. This structure provides good air exchange.

This "sandwich" is sold mainly in rolls and has a standard thickness of 2-3 mm. Two layers of polyethylene have different characteristics: the upper one does not allow water to penetrate to the base of the floor, while the lower one, on the contrary, allows moisture to pass from the concrete base to the balls. From there, due to the presence of technological gaps, the condensate is discharged outside.

The advantages of the combined substrate also include high strength, flexibility, the ability to hide defects in the concrete base and maintain its original thickness throughout the entire service life.

How to install the underlayment under the laminate

High-quality laying of the substrate under the laminate can be done independently.No fancy building tools are needed either. All you need is to strictly adhere to the algorithm of actions. Indeed, the duration and quality of service of your flooring will depend on how accurately you follow all the recommendations.

Preparatory work

Before placing the underlayment under the laminate, the base must be cleaned and prepared. Best used for this construction vacuum cleaner... So screed avoid unnecessary contact with water. You can cut the selected material using a construction knife or ordinary scissors. To simplify the task, all measurements can be transferred to the substrate using a simple pencil or marker.

Note! If you are dealing with uneven concrete surfaces, it is strictly forbidden to lay multiple layers of underlay.

What thickness to choose a substrate for the laminate is up to you. This largely depends on the quality of the base preparation, as well as the required heat and sound insulation characteristics of the layer.

If you do not heed the manufacturer's recommendations about the thickness of the substrate under the laminate of your chosen brand, then soon you will encounter floor deflection while walking, as well as the fact that the locks on the panels begin to break one after the other.

Basic work on laying the substrate

The first and main rule of laying the substrate under the laminate is to place it in the opposite direction to the one in which it will creep laminate... This requirement is due to the risk that in the future, in case of careless movement, part of the floor may move out of its place.

The second thing to remember is that the substrate must be installed on the walls. This will provide the coating with greater reliability and extend its service life.

Useful advice! Never use a backing that is damaged. It is better to replace this area right away than to run into problems after the entire laminate has been installed.

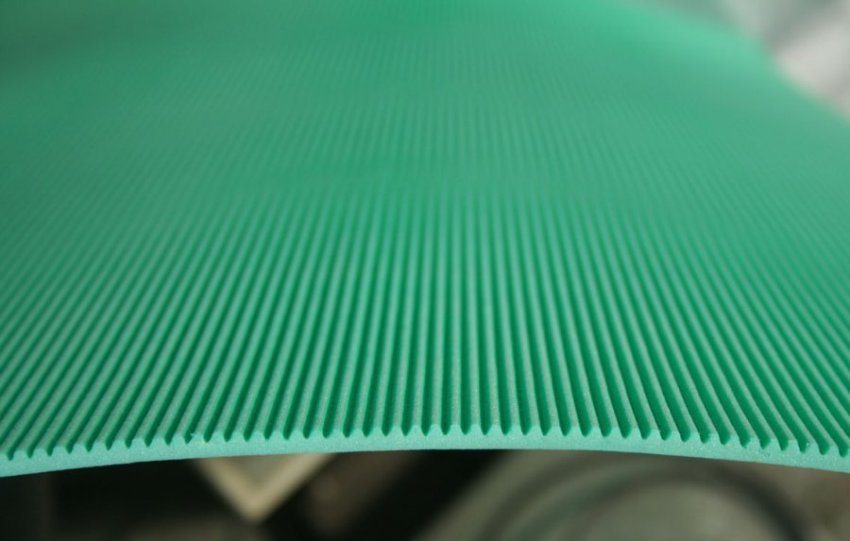

Another important point is to figure out which side to put the substrate under the laminate. If you are dealing with a relief film, then it must be laid with the corrugated side down. Due to this, you can better eliminate the defects in the base. If you are working with an aluminum-based material, then it should always be on top.

After the substrate is laid over the entire surface of the floor, you can safely proceed with the installation of the laminate. If something remains incomprehensible in the process of laying the substrate under the laminate, video clips will always help you figure out what and how to do it right.

Rating of laminate substrates: 5 best options

As in any other field, there are leaders and outsiders in construction. And thinking about what kind of substrate to choose for a laminate, I want to understand which manufacturers are the best in this matter. Consider the 5 most popular and at the same time high-quality substrates that meet all the selection criteria.

Premium Cork underlay

High quality workmanship and durability of the material have been tested over the years. The backing is not deformed. Extremely low thermal conductivity allows you to effectively insulate floors with it, even in fairly cool rooms. Ideal for a nursery or living room where floors have to withstand significant loads.

The only drawback is that Cork is not designed to level the base with it. Such a substrate requires a quality base and waterproofing.

The guaranteed operational period is 25 years, the country of origin is Spain, the average price for 1 m² is 90 rubles. with a thickness of 2 mm, and 145 rubles. with a thickness of 3 mm.

Parkolag underlay

It combines all the necessary qualities and provides natural ventilation of the floor. Like the first option, it is not subject to deformation.The only drawback of this product is that it cannot be used together with the "warm floor" system. However, this does not matter, because the high-quality composition itself provides such thermal insulation that additional heating is simply not needed. In addition, the substrate is not susceptible to mold, mildew, etc.

Country of origin - Russia. With the thickness of this bitumen-cork substrate under the laminate of 3 mm, the price will be 95 rubles / m².

Isoplaat Startfloor Barlinek underlay

Substrate option, ideal for the arrangement of the "warm floor" system. For laying under the laminate, you can choose a product with a thickness of 4, 5, 6 and 7 mm. The flooring of this brand is capable of withstanding the load from heavy furniture without deformation and damage.

The material reacts perfectly to heating, while it has all the characteristics necessary for an ideal substrate: sound and heat insulation, natural air circulation, condensate drainage and resistance to fungal and mold damage. The average cost of this option is also pleasantly pleasing - 55 rubles / m².

Substrate Tuplex

The technical characteristics of this material meet all the requirements for a quality substrate. It has very high sound insulation qualities. It has a low compression rate (compared to foamed materials - up to 14 times less) and, as a result, retains its shape and keeps the laminate in a stable state.

As mentioned earlier in the article, this substrate perfectly wicks away moisture thanks to its design, and provides natural air circulation.

Among the shortcomings is only the fact that it is irrational to use Tuplex together with the "warm floor" system. And yet it is one of the most popular domestic substrates, which costs about 99 rubles / m².

Substrate Izolon PPE

An inexpensive substrate with acceptable characteristics, including heat and sound insulation. This option is often used in public spaces where price is critical. Izolon is not subject to deformation, does not burn and has increased resistance to moisture.

In addition, the manufacturer indicates its service life of 25 years, which is quite a lot for a material with such a cost. With a thickness of 2 mm, the price is only 35 rubles / m². Country of origin Russia.

Summing up, we can say that you still have to decide which substrate for the laminate is best for you. It all depends on the goals that you pursue and the characteristics of the material, which are decisive for you. Also, a lot depends on whether you plan to lay the substrate under the laminate with your own hands or with the help of specialists. As practice shows, a high-quality substrate is easy to lay on your own, plus it will provide a long service life even for the simplest and most inexpensive laminate.