The floor is an essential element of any space to which high demands are made. The surface must be of high quality, strong, reliable and durable. Many building materials that are used to equip the floor base meet these requirements. Particularly noteworthy is the self-leveling polyurethane floor, which is able to withstand any physical activity, without losing its original decorative appearance.

Content

- 1 Features of polymer coating for concrete floor

- 2 Comparative characteristics of epoxy, polyurethane floors

- 3 Negative sides of a polymer self-leveling floor

- 4 Varieties of polyurethane mixtures for self-leveling floors

- 5 How to equip a self-leveling polyurethane floor

- 6 Features of creating a self-leveling floor for warm floors

- 7 What impregnations can be used for a concrete base under a self-leveling floor

- 8 Characteristics of polyurethane floor varnish

Features of polymer coating for concrete floor

Self-leveling floor is a seamless coating that is made on the basis of several types of polymers. When they interact, chemical reactions take place, due to which the synthesis of a mass with certain technical characteristics is carried out. Self-leveling floor has a complex structure due to the presence of many auxiliary components that can affect the properties of the coating, giving it certain parameters.

Polyurethane floors - hard-elastic, shock-resistant, impermeable to water, have good sound insulation properties

Important! Polyurethane enamel for concrete floors is considered to be similar in properties and purpose to self-leveling floors, the price of which is lower.

The most popular are polyurethane and epoxy industrial self-leveling floors, which are characterized by a large number of common properties, but also have individual characteristics. Both materials are made on the basis of resin and hardener, which makes it possible to obtain a durable surface that exhibits increased resistance to various mechanical and physical influences.

Today, polymer floors can be found in warehouses, production halls, shopping and entertainment centers, health care facilities, refrigeration units, freezers, garages, parking lots, living rooms.

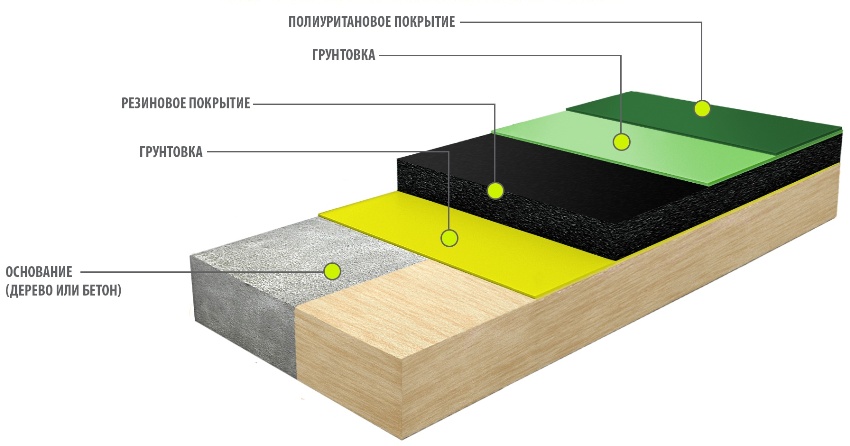

The polymeric coating in the form of a polyurethane floor is represented by a multilayer material, which consists of three layers. The lowest layer is a special impregnation, which has a homogeneous composition with minimum viscosity.This layer has good adhesion properties, which allows the coating to reliably adhere to wood, concrete or ceramic substrates.

The middle layer is a two-component polyurethane-based coating. The material is distinguished by good elasticity, high adhesion, and enhanced strengthening properties. The durability of the coating depends on this layer. The top layer is characterized by increased strength, wear resistance, endurance to mechanical and chemical influences, anti-corrosion and moisture resistance.

Important! To increase the strength characteristics, quartz sand can be added to some self-leveling floor compositions.

Comparative characteristics of epoxy, polyurethane floors

Both polymer floor coverings are characterized by wear resistance, strength, safety, resistance to chemical compounds and aggressive environments, easy application and ease of maintenance.

The epoxy composition is represented by a two-component material, which consists of a resin and a hardener, and polyurethane can also be one-component. The latter option is distinguished by greater elasticity, which contributes to the resistance of the finished coating to tension and shock loads. This coating is difficult to scratch, damage, or erase.

Both types of surfaces are characterized by high wear resistance and the ability to withstand any mechanical stress. However, in comparison with epoxy, polyurethane self-leveling floor is less durable.

The polymer floor will retain its original appearance for 10-15 years without losing its aesthetic qualities. Polyurethane, like epoxy resin, is characterized by moisture resistance, so the need for a high-quality protective substrate is eliminated.

Due to the high density of the material and the absolutely smooth surface, the polymer coating does not absorb dirt, and special components ensure that the coating is antistatic, which prevents dust from attracting. These qualities make it easier to maintain the surface.

Both polymer coatings exhibit increased resistance to chemical components, but behave differently with different acids. A polyurethane two-component self-leveling floor is more resistant to lactic acid, while the epoxy surface will turn yellow and begin to crack. However, this coating is more resistant to sulfuric acid.

Despite the fact that the self-leveling polyurethane layer has a smooth base after curing, it is not too slippery. Therefore, this coating can be used for inclined surfaces and stairs.

Self-leveling polyurethane floor tolerates high and low temperatures, exposure to aggressive environments. An epoxy coating without additional plasticizer cannot withstand severe frosts. Both materials are fireproof as they do not burn. When heated, the coating begins to melt, releasing toxic substances into the air.

Negative sides of a polymer self-leveling floor

It is impossible not to mention, considering the advantages of a self-leveling floor, and the disadvantages of such a surface. The arrangement of this coating requires high-quality preparation of the base. When installing indoors, it is necessary to ensure a positive temperature and no drafts. The duration of the process can reach 2-6 weeks, which is determined by the treated area and the quality of the composition.

Important! To get a good final result, it is better to entrust the flooring with a polymer composition to a specialist.

The arrangement of such a floor requires a significant amount of material, which will entail serious financial costs, which multiply when creating a reliable foundation. Installation of the coating is a complex and expensive process, for the high-quality performance of which it is recommended to use the services of specialists.

The polyurethane surface is cold enough to the touch, which can cause some discomfort during use. The coating is characterized by toxicity due to the fact that the material contains a large number of harmful components, among which phenol and formaldehyde can be distinguished. Such a floor is practically not amenable to restoration. It is possible to eliminate only a few small defects.

Varieties of polyurethane mixtures for self-leveling floors

Polymer mixtures for self-leveling floors, depending on the composition, are one-component and two-component. The first type of material is technically similar to oil paint. It is applied to the prepared surface with a thin layer less than 0.4 mm thick. Such floors are used for rooms with low levels of stress. They are quite easy to scratch, but light blows and exposure to household chemicals are tolerated without problems.

The composition of a two-component polyurethane self-leveling floor, the price of which is slightly higher than the cost of one-component mixtures, includes a polyol base and a hardener. To obtain a coating, the ingredients are mixed and applied to the substrate. This mixture is characterized by high viscosity, which does not allow it to easily spread over the surface. Therefore, the coating thickness can reach 2 mm. The composition is recommended for use in rooms with intensive loads. Such floors are able to withstand sudden temperature changes, and will serve steadily and durably even in workshops.

Depending on the amount of filler, the polymer self-leveling floor can be thin-layer, self-leveling and highly filled. The first option is characterized by a thickness of up to 1 mm. The percentage of filler in self-leveling coatings is 50%, which provides a layer thickness of up to 5 mm.

Important! There are special compositions of self-leveling polyurethane floors that have self-leveling qualities, which is achieved due to the presence of special substances that improve the fluidity and viscosity of the mixture.

In highly filled formulations, the filler takes up to 85% of the total volume. The thickness of this coating is at least 8 mm. Such mixtures are the strongest and most durable. This is due to the exclusion of the likelihood of flaking and surface cracking, which is more typical for the other two varieties. The price of a polyurethane floor starts from 15 thousand rubles. for 30 kg.

Important! The thicker the self-leveling polymer coating, the higher its resistance to various mechanical loads and the longer the period of operation.

Polyurethane compounds can be classified into elastic, elastic-rigid and rigid materials. The topcoat can be glossy or matte and come in a variety of transition shades.

how equip a self-leveling polyurethane floor

Installation of a polyurethane self-leveling floor, the price per m2 of which is determined by the laboriousness of the process, is a complex and lengthy operation, consisting of several successive stages. Initially, you need to prepare a very solid base. The ideal option is a concrete screed, which must be carried out using high grade cement.

In the case of installing a self-leveling floor on an old base, it is necessary to level it, seal all cracks and flaws. Then the coating is sanded with a special machine.The cost per m2 of turnkey self-leveling polyurethane flooring will depend on the condition of the concrete pavement.

Important! Before pouring the surface, there should be no greasy spots, dirt and dust on the surface of the base, as this will lead to the destruction of the floor, which will be removed in layers.

Before pouring the base with a polymer composition, the surface is carefully primed using a special impregnation for concrete floors. The mixture should be absorbed within 2-3 hours. Next, the intermediate layer is laid. The prepared composition is poured onto the surface in small portions, spreading and leveling with a squeegee or needle roller. According to the same principle, the finishing coat is laid after 5-6 hours. After complete drying, the finished surface is covered with a polyurethane-based varnish, which will provide the floor with additional protection.

Important! The price per square meter of a self-leveling polyurethane floor up to 30 mm thick starts from 250 rubles, more than 35 mm - 350 rubles.

The usual bulk polyurethane mixture is characterized by a uniform structure. There are several techniques to make the coating more decorative. It is possible to distribute paint between the layers of the floor in an original way, which will make it possible to imitate marble.

To obtain an unusual abstract image, you can use glitters, which are voluminous sequins made of aluminum foil or polyester. Items may vary in size and color. There are solid or fluorescent options.

The composition of the self-leveling floor is poured onto the surface in small portions, distributed and leveled

You can embed a picture between layers. For this, volumetric images are used, which allows you to create a realistic surface. Cost per m² a self-leveling polyurethane floor with a volumetric image starts from 600 rubles, which depends on the complexity of the technology for applying the pattern.

Features of creating a self-leveling floor for warm floors

One of the main disadvantages of a self-leveling floor is a surface cold to the touch, which, for example, in living quarters, will cause some discomfort during operation. You can eliminate this negative quality by arranging a warm self-leveling floor.

Related article:

Dedusting the concrete floor: how to extend the life of the base

Reasons for removing dust from the surface. Characteristics of impregnations for dedusting the floor. Benefits of topping coverage. Liquid glass from dust.

To do this, you should choose a heating system, which can be represented by a water, electric or infrared version, which depends on the coolant. The best solution is an electric floor. The cover is formed from a thin heating cable that is laid in a specific pattern. For this, a single-core or two-core version is used, which is determined by the power of the system.

The cable is laid on a special mesh-like base and fixed with a thin layer of mortar. The cost per m2 of a self-leveling polyurethane floor with the arrangement of electric surface heating starts from 1300 rubles.

First of all, before pouring the coating, you should choose the type of heating that is suitable for the self-leveling floor

Infrared underfloor heating is formed using thermal film equipped with thin heating elements. The system is laid on a thick concrete screed and fixed to the surface using ordinary tape. The price per m2 of a polyurethane floor with an infrared heating element starts from 1200 rubles. The water-heated floor is represented by pipelines that are laid in the form of a snake. It connects to the existing autonomous heating system. Installation cost starts from 1500 rubles.

Important! To regulate the temperature of the warm floor, any system is connected to a thermostat, which is located near the surface.

The least expensive option (in relation to the amount of materials for filling the finishing surface) is an infrared warm floor. The polymer mixture is laid on it in a thin layer. A water-heated floor requires a large consumption of material to form a self-leveling floor.

Self-leveling floors rating, detailed characteristics of the compositions

The polyurethane self-leveling floor Polymerstone-2, which has high mechanical strength and elasticity, is very popular among various compositions. It is advisable to use the material for objects that have special requirements regarding the chemical and abrasive resistance of the coating. It is also used in rooms with high humidity and where special sanitary and hygienic rules must be observed.

Floor Polymerstone-2 can be laid on a concrete screed, old coating or rigid metal structures. The surface is wear-resistant, shock-resistant, chemically resistant. The price of a polyurethane floor is 13 thousand rubles. for 30 kg.

Another good option is the Aquahim EPK self-leveling floor. Such a coating is distinguished by good elasticity, moisture resistance, shock resistance and intense mechanical stress. The material allows you to solve the issue of arranging waterproofing or replacing floor tiles. This coating can be used for swimming pools. The price of a polyurethane self-leveling floor is on average 9 thousand rubles. for 25 kg.

A good epoxy-based composition is the PolyTech System self-leveling floor, which can be used for any premises. The material is tinted, thanks to which it is used to create 3D surfaces. The coating has increased strength, wear resistance and mechanical stress resistance properties. The cost of the train is 11 thousand rubles. for 30 kg.

What impregnations can be used for a concrete base under a self-leveling floor

Before equipping self-leveling floors, it is necessary to treat the surface with a special impregnation, which will strengthen, dedust the base, and give it the necessary adhesive qualities for better adhesion to the bulk polymer mixture.

Reinforcing polyurethane impregnation for concrete floors has become widespread. It is characterized by its versatility, it can be applied to the surface in any room. The material gives the base good strength and water-repellent properties. This polyurethane concrete floor impregnation can be used for surfaces made of low grade cement. One of the significant disadvantages is the strong smell of the material. Therefore, it is necessary to treat the base with a polyurethane concrete floor primer in a well-ventilated area.

To harden concrete surfaces before pouring the floor, you can use an epoxy impregnation, which is environmentally friendly, odorless, good absorbency, which gives the base additional strength and durability. However, this material is expensive.

Water-based acrylic impregnation for concrete is environmentally friendly. It can be used for substrates made of low grade concrete. The treated surface will be durable, moisture resistant and hygienic.

Characteristics of polyurethane floor varnish

A polyurethane varnish is often used to protect concrete floors, polyurethane or epoxy screed surfaces. It can also be used to protect wood, stone flooring and furniture.The material is water-soluble or contains organic components.

This varnish is characterized by good plasticity and provides a high degree of surface protection against moisture, physical, mechanical and chemical stress. The surface becomes more wear-resistant, which ensures the preservation of the original decorative qualities for a long period.

Polyurethane varnish is characterized by increased plasticity and strength. The material is well resistant to the negative effects of ultraviolet rays, temperature changes, shock loads. The surface after application can be glossy, semi-gloss, semi-mat or matte.

Polyurethane varnish is available in one-component or two-component formulations. The first option is suitable for operation without prior preparation. A two-component material requires mixing of components, is more difficult to use, has a high cost, but the performance of such a composition is much higher.

The varnish is applied on a completely dry surface or after treatment of the base with an impregnation for concrete or concrete floors using brushes, felt rollers or a pneumatic spray gun in three layers.

Important! Before buying a varnish, you should make sure that the components of the material are compatible with the ingredients of the bulk coating.

Review of the best varnishes for polyurethane resin flooring

Perti is a leader in the production of polyurethane-based paints and varnishes. The material is distinguished by excellent performance, due to which the surface acquires high technical and operational characteristics. The varnish is completely safe for human health. It is characterized by a high drying rate, it is odorless, gives the coating an aesthetic appearance, which retains its original decorative qualities for a long period.

A good option is the varnish of the Russian company KrasKo. The material is environmentally friendly, water-based, adheres well to the surface, quickly sets and dries. The varnish gives the coating higher strength, resistance to mechanical and shock loads and durability. This topcoat can be used in a room for any purpose, which is characterized by significant mechanical and chemical influences.

The VGT Premium varnish on a polyurethane base is characterized by excellent decorative qualities. It is odorless and dries quickly. The material can be tinted with special VGT color pastes to give the surface a more aesthetic appearance.

A self-leveling polymer floor is a modern material, with the help of which a strong, wear-resistant, durable, decorative surface is created. Such a coating can be easily laid on a concrete base. To obtain a positive result, which will be a guarantee of durable operation, it is important to observe all stages of material installation.