Building the foundation of a building is a serious and responsible process; waterproofing the basement from the inside from groundwater is one of its most important stages. This article describes the main advantages of this procedure, its features, as well as the implementation technology. The text contains reviews of popular materials used for waterproofing cellars and basements, as well as practical recommendations for their use.

Basement waterproofing from groundwater is the most important stage in the construction of the foundation

Content

- 1 Basement waterproofing from the inside from groundwater: procedure features

- 2 How to stop the water if the basement waterproofing is broken outside of the groundwater

- 3 What materials are used to waterproof the basement foundation

- 3.1 Characteristics of roll materials for waterproofing the cellar from the inside

- 3.2 Features of penetrating basement waterproofing from the inside from groundwater

- 3.3 The specificity of the basement membrane internal waterproofing

- 3.4 Materials for injection waterproofing basement from groundwater

- 3.5 Features of using liquid rubber and glass for waterproofing a basement at home

- 3.6 The use of materials of the Penetron system for waterproofing the basement with your own hands

- 4 How to waterproof a basement from the inside from groundwater: service price and processing technology

Basement waterproofing from the inside from groundwater: procedure features

The basement of a country house can perform several functions. This space is most often used for arranging technical rooms, underground garages or cellars designed for storing food and preserving. Therefore, it is very important to protect the basement from the penetration of groundwater, which has a destructive effect on the entire base of the building. If waterproofing work was not carried out during the construction phase of the house, you can limit yourself to internal protection.

If the basement was not waterproofed when the foundation was built, it can be carried out inside using various materials

Why do you need waterproofing of a cellar or basement

Waterproofing the foundation of a building has an important function. It protects the structure from the penetration of melt water. If this happens, then, under the influence of moisture, the reinforcing elements of the structure are covered with corrosion and are subject to destruction. This should not be allowed, since the base supports the weight of the entire building.

To prevent the destruction of the house, it is necessary to waterproof the basement from the outside or from the inside.Each of these procedures has its own specifics and technology of arrangement, which should be strictly adhered to, since not only the service life of the structure depends on this, but also its safety.

If protective measures are neglected, this can be fraught with serious consequences:

- corrosive damage to reinforcement;

- the appearance of fungi;

- mold growth;

- destruction of the foundation part of the building;

- violation of microclimatic conditions in residential premises;

- spoilage of food stored in the cellar.

Note! Before making a choice in favor of this or that method, it is imperative to determine the cause of the appearance of water in the soil and the level of its placement.

Waterproofing the basement inside will help avoid mold and mildew, as well as the destruction of the foundation

How groundwater penetrates into the basement: causes of high humidity

The near-surface soil contains water. Its amount varies depending on external factors. The upper soil layer up to 1 m deep accumulates melt and rainwater. At a level from 1 to 2-3 m, soils occur, characterized by a variable amount of moisture. This area can be completely dry or filled with water from underground streams. The lower areas are fed with moisture from the aquifers.

Water can enter the basement of a building in several ways:

- Condensation of water vapor - is the result of poor ventilation, and also occurs in cases where the room is located deep underground.

- Diffusion of surface water - the source of moisture are capillaries and microcracks in the waterproofing material and the walls of the building.

- Pressurizing groundwater - moisture penetrates the room under the influence of high pressure through loose seams and joints in waterproofing and walls.

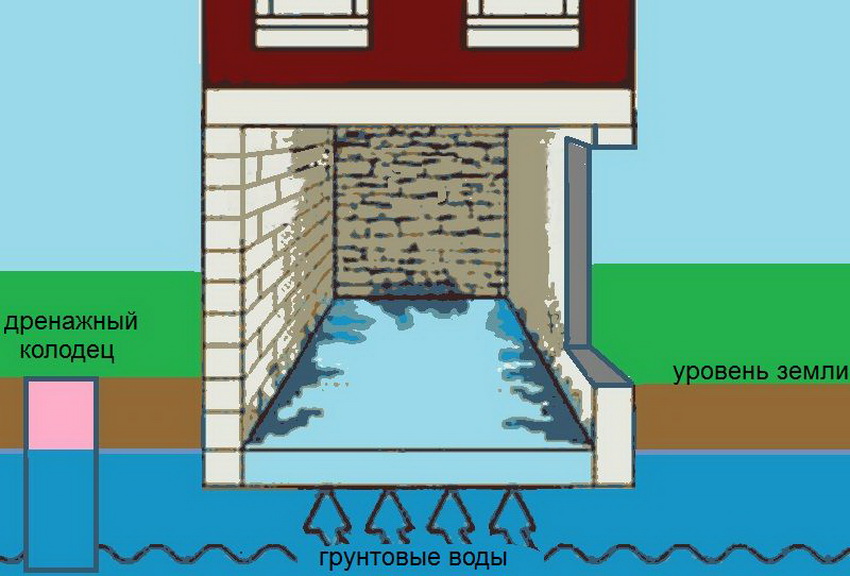

Squeezing groundwater is most dangerous for basements. Risks increase if moisture levels rise from precipitation. As a result, groundwater merges with surface streams, increasing the volume of liquid.

If the outer layer of waterproofing is broken, then a sharp increase in the amount of water will lead to the erosion of existing cracks. As a result, a salvo flooding of basements will occur. Despite this, there are effective ways to combat water pressure with the help of internal waterproofing, which copes with these consequences much easier than diffusion.

How to stop the water if the basement waterproofing is broken outside of the groundwater

The safest way to keep moisture out of your basement is to provide an outside protection. In this case, the liquid that rises will press the material against the building, providing the required level of insulation. Sometimes the outer protective layers, which are directed towards the concrete base, are unable to retain water.

There may be several reasons for this:

- poor-quality application of a waterproofing layer;

- violation of technology;

- soil movement as a result of swelling;

- building draft, etc.

Note! In 4 out of 10 cases, the cause of a violation of the external waterproofing is soil swelling or non-compliance with the foundation technology. In this case, only internal protection will help, which can be vertical or horizontal.

Features of vertical waterproofing basement walls

The vertical method of protection is used in cases where there is a need for waterproofing the walls of the basement. This method is used if the liquid enters through cracks and joints between the elements of the foundation, while an aquifer of soil lies at the level of the walls.

The basement walls are waterproofed from the inside in several ways:

- injection;

- membrane;

- coating (by applying bituminous mastic);

- plastering (using compounds of polymer origin);

- the formation of a barrier using rubber or liquid glass.

Experts recommend doing vertical waterproofing in cellars where there is no drainage system. Most often, this method is performed in conjunction with horizontal protection, which improves the effectiveness of the procedure.

The specificity of the basement floor horizontal waterproofing

Horizontal waterproofing is performed along the floor. This procedure eliminates the risk of groundwater rising into basements, and also prevents moisture from seeping through the capillaries.

Horizontal protection is performed in any case. Even if there is no urgent need for this procedure, the situation may change over time, for example, a large amount of precipitation will fall or soil movements will occur, which will increase the level of occurrence of the aquifer.

Several methods are used for protection:

- roll method;

- filling the base with polymer-based materials.

Basement floor waterproofing is always performed, it is best to combine it with vertical wall waterproofing

Useful advice! To prevent capillary penetration of moisture into basements, it is advisable to use horizontal waterproofing in combination with vertical protection. The latter is partially fulfilled. To do this, the walls should be processed to a height of at least 30 cm.

What materials are used to waterproof the basement foundation

Modern stores offer a wide range of materials for waterproofing basements. The foundation of the building suffers not only from groundwater, but also from leaking communication systems. When choosing waterproofing materials, it should be borne in mind that only penetrating protection can provide the necessary level of protection against melt and groundwater, as well as against capillary leakage. If a leak occurs in communication systems, it is advisable to use coating emulsions or mastics.

The following waterproofing materials are considered the most effective:

- roll-up protective products;

- penetrating formulations;

- rubber in liquid form;

- membrane film coating;

- liquid glass.

Characteristics of roll materials for waterproofing the cellar from the inside

Rolled waterproofing products are used in cases where it is necessary to protect the floors in the basement. Bitumen based materials are overlapped. The resulting seams must be melted with a blowtorch. Bitumen mastic can be used as an adhesive for fixing the material.

Roll-up protective materials include:

- hydroisol;

- roofing material;

- linocrome.

Further work is carried out taking into account the flood changes. If the rise of water is observed often, the surface is coated with bitumen in at least 4 layers. To protect the premises from rare floods, 2 layers are enough. After the material is completely dry, a concrete screed is made.

Unlike rubber, which has elastic properties, bitumen-based materials do not withstand water pressure as well. Under the influence of a pressure of more than 10 kPa, the waterproofing simply peels off. For this reason, bituminous materials and mastic masses are used as an addition to penetrating and other types of waterproofing.

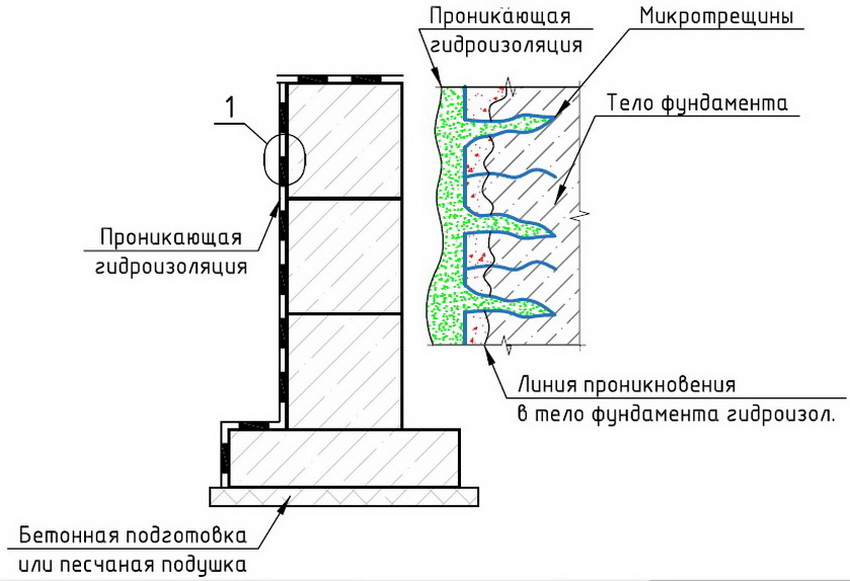

Features of penetrating basement waterproofing from the inside from groundwater

This method provides effective protection of the cellar in cases where the groundwater is high on the site. Waterproofing from the inside of the room is carried out using a mixture of materials.

This mixture consists of several components:

- fine sand;

- cement;

- chemically active elements.

The viscous properties of the composition allow it to penetrate 5 mm deep into the surface. The mixture then solidifies and crystallizes.

Benefits penetrating waterproofing basement:

- Liquid rise through capillaries is excluded.

- The risk of damage to structures by corrosion is reduced.

- The degree of frost resistance increases.

- Allowed to be used in rooms where food products are stored.

Useful advice! An excellent result is obtained if you use binary waterproofing systems. In this case, the surface is sequentially impregnated with two components, which react upon contact.

In most cases, quality penetrating agents are available as aqueous silicate solutions or mixtures of organic resins. Application is carried out with a roller or brush over a previously prepared and cleaned surface.

The application of the waterproofing mixture to the basement wall must be carried out on a cleaned and primed surface

Before proceeding with waterproofing the inner walls of the basement, you should make sure that they are completely dry. Otherwise, the capillary moisture that has accumulated in the cracks will not allow the solution to penetrate into the concrete. Sometimes it is necessary to resort to a flushing procedure in order to remove ingrained concrete dust from the surfaces.

Processing is carried out in 2-3 layers. Dry the surface after each application. The penetrating waterproofing of the basement walls prevents the penetration of capillary water into the room, but this method does not in all cases help to cope with the filling of cracks.

A binary waterproofing system involves the use of calcium chloride and an aqueous solution of sodium silicate. When mixed, a calcium silicate gel is formed, the strength characteristics of which are several times higher than the parameters of concrete. Before application, the surface is cleaned and rubbed with a metal brush. Then processing is performed with an aqueous solution of liquid glass. After waiting 3-4 hours, you can start applying calcium chloride, after which the result is fixed by repeated processing with liquid glass.

This type of penetrating basement waterproofing from the inside from groundwater is 6-7 times more effective than conventional impregnation.

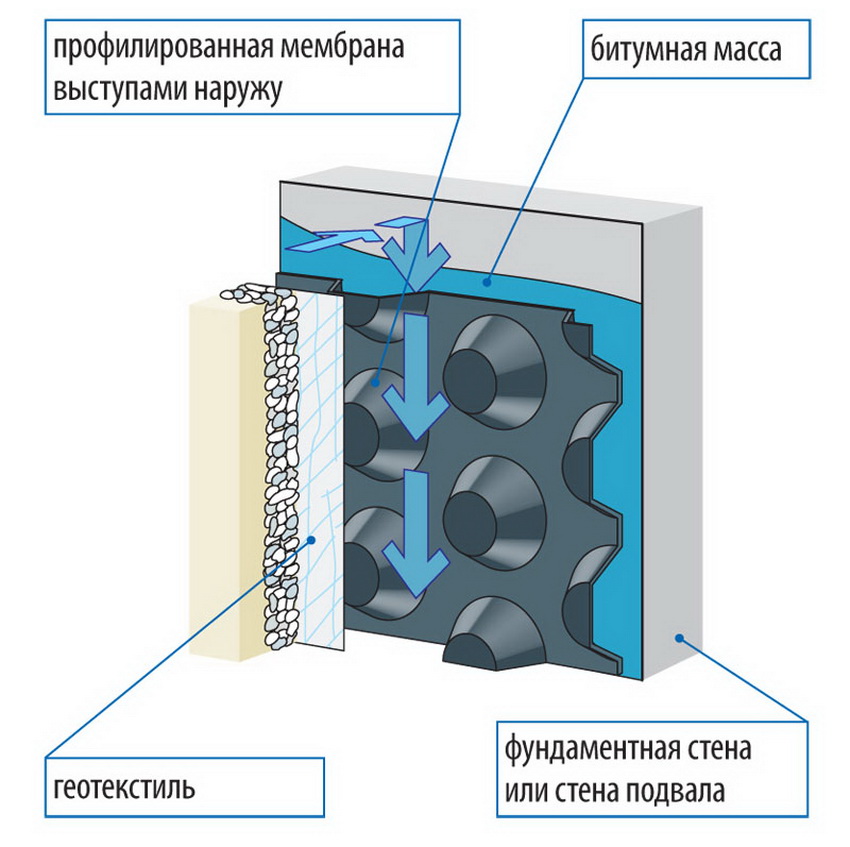

The specificity of the basement membrane internal waterproofing

The membrane method is no less effective than other protection methods. This coating looks like a 2 mm thick film. It is so light that it does not overload the foundation of the building at all. Due to the adhesive layer, the membrane insulation does not cause difficulties during the application process.

There are several types of membrane coatings:

- PVC - has a high degree of fire safety and prevents the penetration of groundwater into the room.

- TPO - membranes made of rubber and propylene. They are used to treat rooms with high levels of humidity, such as bathrooms, bathrooms and kitchens. They have a high cost, which is their only drawback.

- EPDM - membranes made of synthetic rubber. Provide effective protection of the room even at low temperatures.

Related article:

Waterproofing the foundation with roll materials

Selection of materials and methods for waterproofing the foundation. Performing waterproofing work on the foundation with roll materials of various types: detailed instructions.

Despite the fact that membranes are classified as roll materials, they are more efficient and durable. These products are in the form of a canvas with cone-shaped spikes, designed to drain water. The membrane coating is universal.It can be fixed to any surface. Can be used even on wet walls. Dowels are used for fixing.

Important! Hardware can be installed exclusively over insulating material. The remaining ends of the canvases are fixed with elements of horizontal waterproofing of the basement from groundwater, without which the use of a membrane coating is impossible.

Materials for injection waterproofing basement from groundwater

Injection insulation is considered one of the most reliable, since it protects not only the treated surfaces from moisture, but also the foundation structure as a whole. The application process is quite laborious, it will be necessary to make a large number of holes in the wall and, using special injection devices, inject the composition into them.

The following types of mixtures are used for waterproofing the basement:

- Cement - designed to increase the strength characteristics.

- Polyurethane - in the process of expansion, they push out moisture from the inside.

- Methyl acrylate - characterized by deep penetration, filling cavities well.

- Epoxy - applied locally in places where there are leaks.

Injection insulation belongs to the category of penetrating compounds. It has the form of a gel with a flowing consistency. This composition contains mastic:

- epoxy;

- polyurethane;

- microcement;

- acrylate.

The advantages of this method include cost-effectiveness (a small amount of gel is consumed), the ability to process hard-to-reach places, as well as the absence of the need for thorough preparation of the base. On the other hand, the application process is so complicated that it is almost impossible to do the job with your own hands.

Features of using liquid rubber and glass for waterproofing a basement at home

Liquid rubber is preferable for horizontal waterproofing. This material is made on the basis of bitumen, it contains latex, due to which a strong film forms on the treated surface. This flexible coating can also be applied to walls and ceilings. A 2 mm layer is sufficient to protect the premises.

How to waterproof a basement with liquid rubber:

- The surface is pre-cleaned and treated with a special compound that ensures high adhesion.

- The base is coated with rubber so that all cracks and joints are filled.

- The surface is dried.

- Plaster is applied, which tightly presses the film coating to the surface, preventing material destruction.

No less economical and easy to apply liquid glass... To prepare the composition for work, it should be diluted with water. The resulting mixture fills the pores in the surface well, after which it crystallizes.

Benefits of using liquid glass:

- increased resistance to the development of mold and fungi;

- the strength of the structure is increased;

- the possibility of moisture absorption is excluded;

- increased resistance to mechanical stress.

Note! With the help of liquid glass, decorative coatings can be protected from moisture without losing their appearance.

Liquid glass perfect for waterproofing walls already finished with plaster

The use of materials of the Penetron system for waterproofing the basement with your own hands

Penetron is used in cases where moisture appears on the walls of the basement. This product is in the form of a dry mix that is diluted with water and applied to the surface with a brush. Penetron penetrates deep into the walls, preventing moisture from entering the room. At the same time, the throughput is maintained, so the treated surface breathes.

Advantages of using Penetron system materials:

- convenient and simple application technology;

- no special preparation of surfaces is required;

- environmental friendliness and safety.

The solution is applied in 2 layers exclusively on a damp surface. This type of waterproofing can protect not only concrete walls, but also masonry as well as brickwork. The material is able to withstand any pressure exerted by the aquifer on the foundation.

How to waterproof a basement from the inside from groundwater: service price and processing technology

To properly waterproof a room with your own hands, you must adhere to certain rules.

The general processing technology is as follows:

- The depth of the groundwater is determined.

- The room is being surveyed for vulnerabilities.

- The places of leaks, zones of placement of cracks and voids are determined.

- Water is pumped out, if necessary.

- The surfaces are cleaned of dust and dirt.

- Existing cracks expand.

- The surface is treated with a primer to increase the adhesion properties.

- The material is selected, as well as the method of waterproofing protection.

- In accordance with the requirements of the technology, waterproofing is applied.

- The room is being dried.

- A good ventilation system is being equipped.

If you do the work yourself, then waterproofing the basement will be inexpensive, although in some cases it is better to resort to the services of specialists. When processing premises using Penetron system materials, the service price will be 900-1400 rubles / m². Liquid rubber has practically the same price range - 900-1200 rubles / m². The cost of penetrating waterproofing varies within 1700-2100 rubles / m². The most expensive is considered to be injection protection - 2200-2500 rubles / m².

Internal waterproofing provides excellent protection of the foundation against groundwater. All of these materials are effective in their own way, but they are used as a temporary measure. To achieve long-term results, it is advisable to eliminate the cause of the leaks. For this, external waterproofing is performed, as well as a drainage system and a blind area around the building.