When repairing a bathroom and a bathroom, it is often necessary to carry out waterproofing work. Their quality affects not only the durability of the repaired elements, but also reduces the risk of flooding of neighbors in case of emergency damage to the water supply fittings. In order for the waterproofing of the bathroom to last for many years, it is necessary to do it correctly, using materials designed only for this.

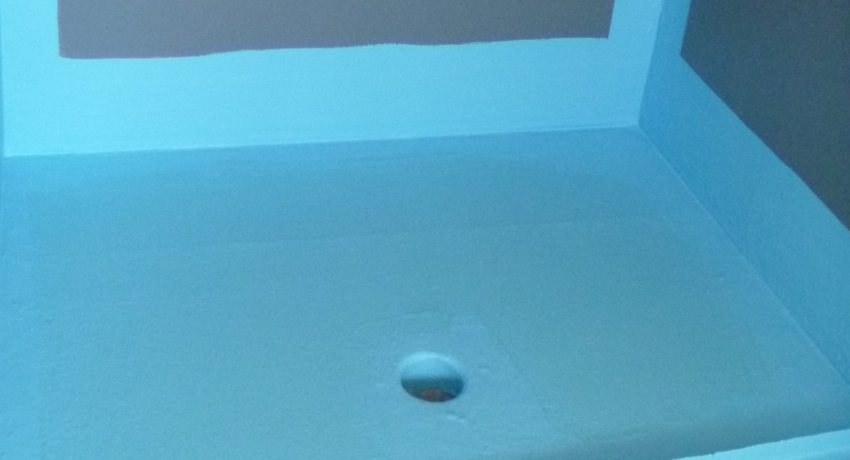

Floor shower cabin done below the bathroom floor

Content

Types of waterproofing

In no case should you save on waterproofing. This is fraught with dire consequences. After all, all material and labor costs can be in vain, and the claims of flooded neighbors are unaffordable.

Some would-be builders, in order to save money, put a thick plastic film under the floor instead of special materials, mistakenly believing that its ability to not let water through will last indefinitely. This is not true. Polyethylene under the influence of an aggressive environment is very quickly destroyed, turning into separate fragments that are no longer able to retain moisture.

To prevent these troubles from happening, it is necessary to use materials developed specifically for waterproofing work. These include:

- Bitumen based coating mastics.

- Mixtures of cement with polymer additives.

- Penetrating type water protection.

- Rubber hydro-barriers.

- Various roll materials with bituminous base.

All of them have a different chemical composition and method of laying, on which the characteristics of the obtained hydro-barrier and the technology of its device depend.

Useful advice! Don't skimp on waterproofing materials. High-quality brands made by well-known firms are best suited. They must be durable and environmentally friendly.

Bituminous mastics

This material is a viscous bitumen-based paste. It may contain various chemical additives, the composition of which depends on the manufacturer. Since bitumen is a low-melting substance, the plasticity of the paste increases with increasing temperature, which allows, operating with a burner or a construction hairdryer, to fill in all the surface irregularities. This is the most convenient way. With it, it is easier to fill everything, even the smallest voids in the treated surface.

Cement-polymer mixtures

Coating type material.The waterproofing effect is achieved due to the polymer particles contained in it, which, when dissolved in water, form a moisture-proof monolith. An aqueous solution of the desired consistency is prepared from the dry mixture and applied to the surface in several layers. More solution must be placed in the technological holes next to the utility pipes in order to avoid leakage.

Penetrating water protection

This type of waterproofing is often used as an additional one to the main one. These are polymeric substances that are added directly to concrete, giving it waterproofing properties. When is done waterproofing bathroom floors, materials of this type are added to the cement for the screed. This technique additionally provides water resistance.

Rubber-based hydro-barrier

It is a rubber or rubber based insulating coating. For its hardening, reagents supplied in the kit are used. This type of waterproofing is very convenient to use if the bathroom floors are wooden. This type is very reliable as the resulting coating is continuous and waterproof. Moreover, it is very elastic, which allows it to be used even in the construction of swimming pools.

Roll materials based on bitumen

The most convenient products to lay. They are supplied in rolls and look like a film impregnated on one side with a bituminous compound. They are glued to the surface by heating to a plastic state with a construction hair dryer or a burner. There are self-adhesive films. There is no need to heat them.

Waterproofing works and their order

Before directly starting work such as bathroom waterproofing, it is necessary to dismantle all the old coating along with the existing remnants of the old waterproofing. Everything should be removed, up to the floor slabs. It is advisable to vacuum the concrete in order to achieve the best adhesion to the waterproofing material.

At this stage, you need to make sure that during further construction the floor is 3-5 cm lower. This will allow you to avoid a flood in the apartment in the future in the event of a water pipe break. The water will simply stay in the bathroom, as in a sump, and will not damage other rooms.

Concrete slab slab waterproofing

If the base of the floor is concrete slabs, then they must be carefully putty. Particular attention should be paid to joints, deep potholes and places of passage of water supply and sewerage communications. Do not forget about the joints of walls and floor slabs. The putty is applied around the entire perimeter of the bathroom. Instead, you can use a cement mixture of the required consistency.

Useful advice! Whatever type of waterproofing is used, it is necessary to strictly observe the algorithm of its device.

Further, it all depends on the type of waterproofing material chosen. If it is a coating solution, then the solution is applied with a spatula or a brush over the entire surface of the floor and partially on the walls to a height of 10-15 cm. 2 or 3 layers are made depending on which waterproofing material is chosen. The result should be a surface similar to shower tray... This is done to prevent water from penetrating under the walls.

If roll materials are used, then they are heated by a burner or a construction hairdryer and unwind over the entire floor with an overlap. At the same time, one should not forget about the walls. In order to achieve the best effect of waterproofing the bathroom floor, the materials of these two types can be combined. In this case, gluing will be much more reliable. Particularly careful work needs to be done around the communication pipes.

When using cement-based mixtures, similar work is done. At the same time, it is desirable to add materials of a penetrating type to the screed solution to increase the waterproofing effect.

Useful advice!You need to pay close attention to the joints. This is the weakest point in any construction. It is necessary to coat them several times, not sparing the material.

Waterproofing for wooden floors

If the base of the floor is wooden, then the waterproofing device requires additional effort. Logs are fixed on boards cleaned of dirt. Then a vapor barrier film is placed on which the insulation is laid. For this, it is convenient to use polystyrene foam with a smooth and durable surface. Then the joints between the slabs and lags are coated with sealant.

After that, the liquid rubber is taken, mixed with the activator and, as soon as possible, applied with a roller to the entire surface, including the lower part of the walls. If necessary, another coat can be applied.

Related article:

Waterproofing the floor in the apartment in front of the screed: types and details of installation. Types of waterproofing materials used under the floor screed in rooms: roll, liquid, dry and penetrating mixtures.

When performing work by any of the listed methods, it is necessary to strictly follow the instructions for preparing and applying the solution developed by the material manufacturer. It is necessary to pay special attention to the drying times indicated in it. Otherwise, it can lead to the destruction of waterproofing ahead of time.

It must be borne in mind that all waterproofing materials have poor adhesion to the tile adhesive. For this reason, a cement screed is made on top of all layers using reinforcement. Only on it it is permissible to glue tiles or apply other coatings.

Waterproofing the bathroom floor: materials

Materials are selected very carefully. Before buying them, you must thoroughly study the instructions. The purpose of this is to find out which floor covering it suits best. There must be a perfect match, as a mismatch can lead to difficulties in applying it to the surface.

Having understood all the features of the work on the waterproofing of the bathroom, you can independently complete this task without resorting to outside help. This will save your budget and provide invaluable experience in carrying out such repairs.

Waterproofing the bathroom floor under the tiles (video)