With the development of the construction industry, minor materials such as screed damper tape have become very popular. The reason for this is ease of use and the lack of the need to invent various devices from available tools.

When using self-adhesive damper tape, the protective layer is torn off as the material is applied to the walls

Content

Damper tape for screed: purpose and consumer parameters

Not everyone thoroughly knows how to make a floor screed with their own hands. Videos of this process often miss important details. One of these nuances is the need to provide protection against linear expansion of concrete when heated. From the school physics course, everyone knows that any substance expands with increasing temperature. Whatever the proportion of the mortar for the floor screed, when it cures, heat energy is released, which leads to a significant expansion of the screed.

It has already been calculated that each square meter causes an increase in linear dimensions by 0.5 mm. That is, in a room with an area of 20 m², concrete in the process of hardening can expand by 1 cm. What this will lead to is not difficult to guess. Pushing against harder walls screed it will swell and crack, destroying the already laid topcoat.

Previously, this problem was solved by placing wooden blocks of the required width along the perimeter of the walls at floor level. They served as shock absorbers. However, the tree has such disadvantages as susceptibility to decay and little shock-absorbing ability. In this regard, a damper tape for floor screed was developed. It is made of polyethylene foam. This material has excellent damping properties.

Related article:

|

The damping tape for the screed is produced in the form of a tape wound in rolls. Their length can be from 10 to 100 m. The width of the product is 5 - 15 cm, and its thickness is 3 - 10 mm. Along the entire length of the strip, there are perforated cuts every 10 mm. They are needed in order to easily tear off excess material flush with the surface. screeds after it has hardened.

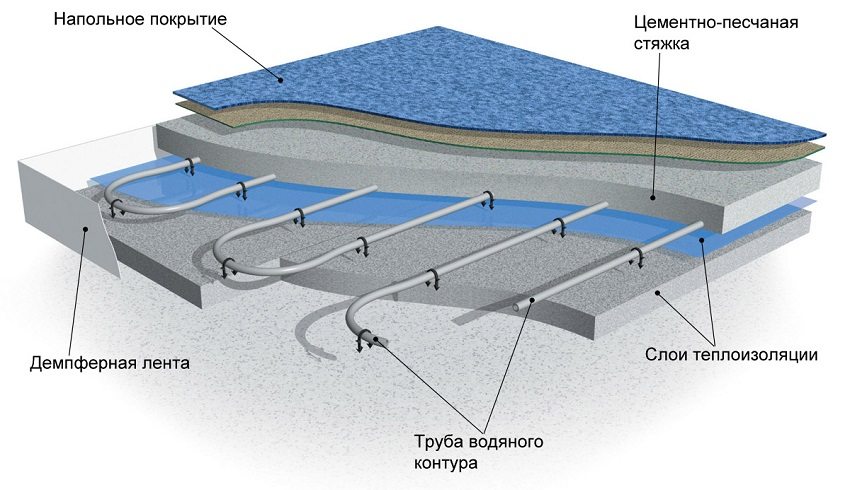

Water heated floorprepared for cement screed

The screed damper tape has many positive qualities that are especially appreciated by builders:

- very low thermal conductivity and poor sound permeability;

- moisture resistance and water resistance;

- the temperature drop is not terrible for her;

- environmental friendliness;

- long service life.

Among other things, this material is not expensive (from 0.5 USD per running meter).

Helpful advice! It is only necessary to cut off the excess damper tape after laying the topcoat. After that, the skirting boardsthat completely cover the seam.

Types of damper tape for screed

All manufacturers make various additions to the basic parameters of the material. Today there are 3 main types of screed damper tape:

- Straight or ordinary.

- Having a "skirt". In the lower part of such a tape there is a skirt made of a thinner waterproof material. It folds to the floor, preventing liquid from penetrating under the tape to the walls.

- Self-adhesive. There is an adhesive layer over the entire surface on one side under the film protection. It is very convenient to mount such a tape, as it does not need additional fixation.

Helpful advice! When applying self-adhesive tape, it is not necessary to immediately tear off the entire protective layer. This should be done as the material is pasted on the walls.

How to create a damping layer around the perimeter of the room

If the tape has an adhesive layer, then it is enough to simply glue it around the entire perimeter, bending around all architectural forms, ledges, niches, columns. If there is a "skirt", it is folded onto the floor so that no water can get under it.

Underfloor heating installation scheme using damper tape

If the damping tape for the screed is ordinary, then it is installed around the perimeter and fixed to the wall in any convenient way: with small nails, a construction stapler, or glued with glue. The task is to completely cover the entire perimeter with tape.

Helpful advice! The standard material is designed for the load from such a screed, the width of which does not exceed 10 m. If the room is larger, then the damping layer must be increased.

By using modern auxiliary building materials, you will avoid many inconveniences and disappointments.