Natural wood flooring will always be popular, even despite the high cost. Such a surface looks attractive, and floors with proper care will last for decades. Scraping of floors consists in removing the top layer from the wooden floor, as a result of which scratches, damages and minor irregularities that have arisen during operation are eliminated. In the process of work, some elements are replaced, the varnish is updated.

Scraping is the removal of the top layer of a wooden floor, as a result of which scratches, minor irregularities and damage are eliminated

Content

Cycle the floor: what is it, some recommendations of experts

Despite the large number of floor coverings that imitate wood well, natural material still does not lose its relevance, and even, on the contrary, is gaining more and more popularity. Parquet has always been a sign of good taste and high status of the owner. In addition, it is this material that serves the longest. In some houses of the old foundation, you can see the parquet, which was laid over 50-60 years ago.

Helpful information! Natural wood, despite all the warmth and comfort that it radiates, will lose its attractive appearance over time without proper care. For this reason, it is required to periodically cycle the floors.

Scraping the old floor is not considered difficult or too costly. This treatment is very effective and prolongs the life of the material. That is why experts recommend it to be carried out so that the surfaces look neat. In fact, the procedure is a great alternative to varnishing, sanding or polishing the boards.

Looping floorboard consists in removing the upper small layer from the surface of the coating using a special device - a scraping machine. Sharp sharpened metal knives are attached to the tool, which remove the top layer of varnish and a thin layer of the wood itself. Basic tips for efficiently and quickly performing plank floor scraping:

- In case of significant damage and severe irregularities, it is more efficient to work with a drum machine, which gently removes a thin varnish layer and does not affect the deeper layers of the coating.

- If bitumen comes out in the cracks between the lags, the sandpaper will quickly clog up, so you will have to change it more often.

- The process also differs depending on the type of wood used to make the flooring. So, scraping a floor from a pine board, in contrast to oak, will be much easier due to the fact that the tree is softer and more pliable, but at the same time not as stable as oak.

- Before carrying out work, you should completely dry the floor, because even a slightly damp surface can deform. It is also necessary to dry the entire room.

When scraping a wooden floor is required

After processing, the parquet is brought to almost perfect condition and primary density. At the same time, there is absolutely no need to purchase expensive tools. It is enough to rent them as needed, especially since there is often no need to carry out work. The main reasons when it is required to perform floor scrapping include:

- the appearance of small damage to the floor of mechanical origin;

- the need to replace some boards or parquet elements;

- the presence of stains that cannot be removed using standard methods;

- partial abrasion of the surface;

- desire to block varnish or paint.

Not in all cases this work should be carried out. There are situations in which there is no point in scraping the parquet floor:

- the presence of large potholes and cracks, the depth of which is half the thickness of the board;

- strong drying of the boards;

- swelling of some parts and the appearance of large distances between the boards;

- severe surface wear;

- penetration of a woodworm beetle into the parquet, which spoils the internal structure.

It also makes no sense to carry out work on the restoration of the surface if the parquet is used incorrectly, for example, when high humidity is constantly present in the room, which is why the floor often gets wet. If the beginning of the decay process is observed, then the damaged boards should be immediately removed, and the rest must be covered with special antifungal solutions. Additionally, you need to take measures to dry the material.

How to identify damage that makes it useless to scrape hardwood floors

Before planning work, first of all, a thorough surface survey is required. As a rule, defects in the form of cracking and chips are visible to the naked eye, and it is also easy to determine the size of the slots, in which carrying out scraping will be ineffective.

Before starting work, it is necessary to carefully examine the surface for the presence of a woodworm beetle

Useful advice! You can detect the appearance of a woodworm beetle that destroys a tree by the presence of small holes in the boards, around which wood dust is observed. In this case, you will need to completely remove the damaged coating.

Excessive moisture on the surface is detected by using a piece of polyethylene that is placed on the floor and pressed against the edges. For greater reliability, it is better to glue the film with adhesive tape. If moisture forms under the polyethylene and at the same time the temperature in the room remains constant, this indicates a poor quality of waterproofing. In this case, scraping and shedding the floors will not be needed, because first you need to dismantle the log and dry the base.Then the waterproofing is redone and a new coating is laid.

If you suspect the appearance of mold and decay of the boards, you will need to use an awl, with the help of which punctures are made in the corner of the planks, while observing an inclination of 45 degrees. The action is performed in order to reach the end of the board with the tip of the needle. If the parquet is oak, the edge of the awl should not go more than 5 mm, in the covering made of birch, walnut, pine or ash - no deeper than 7 mm. Situations where the tip of the needle penetrates deeper indicates damage to the material by rot or the appearance of mold, which cannot be removed with a scraper.

Sometimes, when the floor is in poor condition, instead of scraping, the option of laying on top of ceramic tiles is chosen. It should also be borne in mind here that in case of severe damage, additional coating will not solve the problem. Because it is possible to put tiles on a wooden floor only if the coating is in good condition and treated with agents from fungus and pests. If the above defects are present, you should not do this.

Scraping floors: types of tools that are used when carrying out work

You can do the scraping of a wooden floor with your own hands mechanically or using a machine. The use of a scraper will significantly speed up and facilitate the process, but it will cost several times more, even if you do not purchase a tool, but rent it.

If you don't want to bother buying expensive equipment, you can do it yourself with a manual scraper. It should be borne in mind that working with this tool is rather difficult. Firstly, from constant tension, the hands will soon begin to hurt. Secondly, you will have to do the work in an uncomfortable position, from which your back will suffer in the first place. If such difficulties do not frighten, then it is quite possible to manually process the entire surface, including hard-to-reach places.

Helpful information! It will be possible to scrape the floor without dust only when using a manual cycle, but the disadvantage of such work is the removal of a large layer from the floor covering.

Instead of a manual cycle, some people use sandpaper to process parquet, which is fixed to the sole of the shoe, as a result of which it will be possible to relieve tension from the hands and back. However, when cleaning the floor with your feet, it is difficult to constantly control the level of pressure, so some areas are cleaned more and some less. It is for this reason that most owners prefer using looping machines to perform such work.

The main types of machines used for scraping painted wooden floor

Parquet processing is carried out in several stages, where a specific technique is used for each task. The drum parquet sander is primarily designed to remove old varnish and rough and deep sand the floor. The tool is used when working with any type of wood.

The processing of a wooden floor is carried out in several stages, for each of which a certain technique is used

When using the machine for work, you need to be careful, because the base is easily damaged by the heads of screws or other fasteners protruding on the surface of the parquet. You also need to take into account the cost of renting a car before scraping the painted wooden floor, which on average is 500-1000 rubles per day. Other types of tools used to process the coating:

- Surface grinder.It is used for fine sanding of a floor board before painting, and also suitable for intermediate sanding between varnish coats. Differs in accuracy of processing, and the rental price is similar to the previous version.

- Angle grinder. The main purpose is to finish corners and other hard-to-reach places under batteries and other communications. In this case, the rental price of the instrument varies from 300 to 1000 rubles per day.

- Dust collector of industrial type. When scraping floors, dust is generated in any case, and the amount depends on the type of tool used and the nature of the work. To remove dust from the floor, it is recommended to use an industrial vacuum cleaner, the rental of which will cost 400-900 rubles.

All types of scraping machines are expensive equipment that not only has a high price, but also requires constant maintenance. If you want to do cheap scraping of wooden floors, rent and independent work are considered the best option. If you are not confident in your abilities, in order to avoid problems and damage to the material, it is better to immediately seek help from professionals.

Other materials that will be required for sanding wooden floorboards

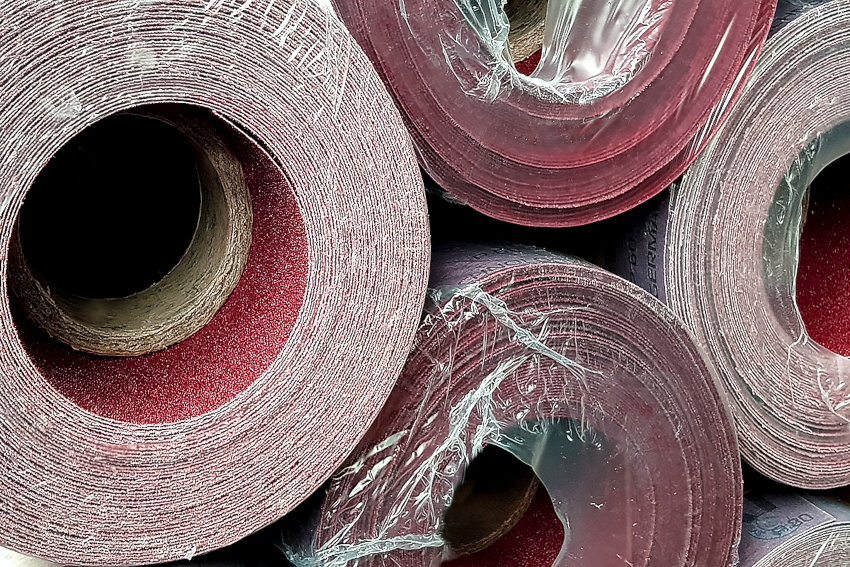

Before you start processing, in addition to purchasing the main tool, you need to take care of buying other items and materials, as well as arrange them in the area of the work being done, so as not to be distracted by unnecessary searches in the process. When calculating the final cost of scraping a wooden floor, you must first take into account the price of sandpaper.

To determine how much material is needed, it should be borne in mind that one running meter of sandpaper is enough to process 10 m², but depending on the type of wood, the amount may vary. For work, you need to purchase paper of various grain sizes:

- No. 40 - suitable for primary roughing;

- 60 and 80 - intended for fine grinding;

- 100-120 - removes the lint that has risen after varnishing.

Other materials that will be needed for sanding and painting floors:

- Discs for a surface grinder. Depending on the type of floor covering, up to 3 pieces are consumed. at 20 m² floor.

- Putty mixture. It is selected based on the shade of the wood, it is used for processing cracks. Many people make the composition on their own from dust from grinding and wood glue, as a result, it will be possible to get the perfect color.

- Rubber trowel with which the putty is applied.

- Parquet varnish and roller.

If you do not want to order scraping and patinating of a wooden floor in specialized firms and it was decided to carry out all the work on your own, you should additionally buy protective equipment. Despite the fact that most shoveling machines are equipped with dust collectors, dust will inevitably rise. For this reason, respiratory and eye protection measures must be taken. For this, several respirators and goggles are purchased; it is better to tie a scarf on your head.

Related article:

Sanding a wooden floor: a technology for obtaining a flat and smooth base

Features of manual and machine methods. Varieties of grinders. Stages of floor processing technology.

Working with a looping machine is accompanied by significant noise, which has a negative effect on the hearing organs, therefore it is recommended to carry out processing in special headphones that reduce the noise level. The old wooden floor should be scraped in tight, long-sleeved clothing that fastens with a zipper or buttons to the very top.During work, microparticles (from the varnish and the surface of old wood) are formed in the ambient air, which can cause irritation and manifestation of allergies on the skin.

All textiles and upholstered furniture should first be removed from the room. It is better to remove the cabinets, and if it is not possible, then they need to be closed with a thick plastic wrap, securing the edges with tape. Before starting work, you need to check the condition of the electrical wiring, because all the working equipment has a high power - up to 2.8 kW.

Useful advice! Before starting work, it is recommended to at least approximately calculate the price of scraping a painted wooden floor and make sure that it does not turn out the same as when laying a new material. In some cases, the coating is in such a deplorable state that it will take no less money to restore it than to buy parquet.

What determines the price of scraping a painted wooden floor

The main criteria affecting the cost of work (scraping a wooden floor) are the floor area and the shape of the room. Sometimes it is much easier to process in a spacious room of the correct shape than in a small room with many niches, bay windows or other irregularities.

Most often, the final price for scraping a wooden floor is announced after a visual inspection of the area. The cost also depends on the initial condition of the coating: the more surface defects, the more types of processing and effort will be needed. Therefore, the price formation will be influenced by the amount of work required to restore the appearance of the floor.

It should also be borne in mind that the material side of the issue also depends on the type of wood from which the floor is made. So, scraping an inexpensive pine floor will cost a little less, because, for example, oak or beech require a more careful attitude and a special approach. As a rule, it takes a little longer and with greater accuracy to process floors made of expensive materials.

Useful advice! Finding out how much it costs to scrape a wooden floor should be individually in each case, because this indicator varies based on many criteria. Even in one apartment, but in different rooms, depending on a combination of factors, there will be a different cost of work for 1 m².

If we consider the average indicators, then the price of scraping a wooden floor for m² in rubles looks like this:

- parquet - 150-350;

- plywood - 60-150;

- parquet board - 130-350;

- solid board - 350-550;

- varnishing - 80-120;

- putty of crevices - 50-100.

What is the technological process of scraping a painted floor

Regardless of where the scraping will be performed (in a private house or apartment), it is better to carry out preparatory work first. First of all, you should, if possible, completely free the room from furniture and other items, including skirting boards and door leaf. It is recommended to hang the doorway with a thick cloth or a piece of polyethylene to prevent dust from spreading through the rest of the house.

Then you need to inspect the coating for cracks and other flaws, which are recommended to be removed at this stage. The treatment of a painted floor begins with the removal of old paint from the surface, for which a solvent or mineral alcohol is used. Other recommendations:

- During work, the window should be kept open so that foreign odors and dust are quickly removed to the street.

- You must first wash the floor well with warm water without using detergents, and then let it dry for at least 24 hours.

- Boards that are too damaged or moldy must be replaced with new ones.

- Be sure to check the floor for nail caps or self-tapping screws.

At the end of the preparatory stage, re-inspect the base in good lighting to make sure there are no dirt, protrusions or protruding boards on the surface. After that, you can start removing the old coating.

First, rough scraping is carried out using a special tool with a correctly selected nozzle. At this stage, not only the old paint or varnish is removed, but also a thin layer of wood with mechanical damage is removed. When doing it, you should not rush, the work should be slow, the machine is moved in the direction of the length of the boards. A material with a wavy structure is only cycled diagonally. In this case, it is better to perform rough processing twice, and in opposite directions.

Useful advice! Depending on the type of coating, the work is carried out in different ways: the artistic parquet is sanded in a circular motion into the spiral. Often, decorative parquet details are made of fine-grained valuable wood, which will have to be processed manually using an angle grinder, repeating the pattern.

When finishing surfaces with a scraper near a wall, you will need to slightly raise the device on one side and turn it around an axis, after which the process continues in the opposite direction. Work is carried out until all defects are removed from the surface. It is important to note that for scraping pine floors, a medium hardness nozzle is more suitable, because softwood is processed quickly and easily.

The next step is to sand the board, which is performed in three steps using sandpaper of various sizes. Thanks to the gradual use of sandpaper, it is possible to achieve maximum smoothness of the boards, to restore the original color and shine. This type of work should be spent most of the time and effort in order to ultimately get a high-quality scraping.

Companies professionally engaged in the processing of wooden floors carry out the technological process in full

Features of processing hard-to-reach places and the final stage

Hard-to-reach places are usually processed last - after the bulk of the work has been completed. Here, most likely, in addition to the scraper, you will have to use a manual cycle. Using these two tools, it will work out the corners, niches and flooring under the batteries. Work should also begin with a rough scraping, after which grinding is performed using special attachments for an angle machine of the desired size. At the same time, do not forget to change the abrasive in time so that there are no islands of varnish that are easy to notice due to the dark shade.

At the final stage, all the gaps between the boards are putty, after which it is required to withstand the time until the material is completely dry. At the end of drying, additional scraping of the entire floor surface will be required with a surface grinder with sandpaper No. 80 or 100. Do not forget about using an angle grinder in hard-to-reach places. Fine grinding needed to give the floor perfect smoothness, which is checked by the method of holding the palm over the surface. After finishing the work, the floor covering should have a finished look - without any irregularities.

Important! The success of scrapping the floor depends largely on the quality of the sharpening of the tool and the choice of the correct blade width, based on the size of the parquet board.

The final touch after scraping the floor is to varnish the finished surface. At this stage, it is important not to rush and let each layer dry completely. Before applying the varnish, the finished parquet should be well vacuumed to avoid unevenness. In this case, you should vacuum not only the floor, but also the walls surrounding it, as well as the ceiling. The best way to do this is with an industrial vacuum cleaner.

The average drying time of the layer is 4-5 hours. It is better to apply varnish in at least 3-4 layers. Experts recommend varnishing using an expensive, high-quality microfiber roller, which will achieve the best result.

The regularity of scraping depends on the type of rock used to make the floor:

- a wooden base made of conifers needs to be processed every 7-10 years;

- if the floor is made of hardwood, it is enough to carry out work after 10-15 years;

- parquet flooring from laminated panels should be renewed no more than once every 15-20 years.

The floor occupies a significant area of any home; they always pay attention to it when they enter the room. Even expensive, but worn parquet will not please the eye. Scrolling the floor both with your own hands and with the involvement of specialists is a slow, labor-intensive process that requires an investment of funds. But the floor obtained as a result of such works will be impossible to distinguish from the newly built floor. It is pleasant to look at such a surface, you want to walk on it even with bare feet.