In the autumn-winter period, staying in an unheated garage is not a pleasant process, and installing traditional heating is an expensive pleasure. Therefore, for the most part, the owners choose economical options and install compact energy-efficient ovens for the garage. The structure should warm up well, warm the air evenly and be safe at the same time.

Content

- 1 What should be a stove in a garage: device power requirements

- 2 Varieties of stoves for the garage: choosing the best option

- 3 A long burning wood burning garage oven: types and principle of operation

- 4 Stove stove for a garage: the principle of operation and manufacturing features

- 5 DIY brick garage oven

- 6 Economical and energy efficient furnaces for the mining garage

What should be a stove in a garage: device power requirements

Most garages are designed without a heating system. At the same time, low temperatures in winter not only create discomfort for car owners, but are also undesirable for vehicles. As practice shows, the use of traditional portable electric heating devices is ineffective and results in a round penny in the form of electricity bills. To solve the problem is quite simple - you need to build a stove in the garage with your own hands, choosing the best option.

At the heart of the garage heating problem are two things:

- lack of effective thermal insulation;

- the square-cube law, implying the ratio of the size of the surface of a body to its volume.

The mentioned law is reflected in the form of heat loss. To heat one cubic meter of a room with a small area, much more heat is required than when heating a spacious structure. For example, a 10 kW device is sufficient to heat a two-story house, while a standard-sized garage requires a device with a heat output of 2.5 kW.

In order to maintain a temperature of 16 ° C in the garage, you can install a 2 kW unit, and for a temperature of 8 ° C, provided for storing a car, a 1.2 kW unit is sufficient. Accordingly, in order to warm up the entire area, much more thermal energy will be required, therefore it is better to heat not the entire room, but the so-called workplace.

How to make a stove in a garage: maximum placement efficiency and insulation system

The air heated by a heating stove for a garage should be concentrated in the center of the room, spreading around in such a way that a small layer of cool air forms between the walls and the ceiling. Thus, the vehicle and its owner will stay in a comfortable temperature zone, and heat consumption will be significantly reduced. The so-called heat cap is formed by natural convection: a strong stream of warm air rises upward, where it collides with a cold dense layer.

The appearance of a garage stove is not as important as its energy efficiency, but a beautiful design will not be superfluous.

Helpful advice! According to the rules (regarding car parking), regulated by document SP 113.13330.2012, the optimum temperature for storing a car should be at least 5 ° C, and during repair work - 18 ° C.

Thanks to the physical convection process, which is the diffusion of streams of warm air, efficient heating of almost the entire garage is provided. You can even get this result with a homemade garage oven with low power.

The insulation system plays an important role in the heating process and heat preservation. One of the tricks used by builders of garage cooperatives is the dense arrangement of neighboring buildings, which allows you to keep warm as much as possible. In individual buildings, you can use various available materials for external insulation, for example, fiberboard.

Insulating a metal garage inside can be problematic, since a dew point appears at the point of contact of materials, where condensation accumulates. As a result, this can lead to rapid wear of both the base material and the insulation. Therefore, it is necessary to maintain an air cushion between the main and additional walls of 30-50 mm, retreating from the floor by about 60 mm.

Varieties of stoves for the garage: choosing the best option

In the garage, it is allowed to install a variety of heating systems that run on different types of fuel: liquid, solid, electric or gas. The main conditions are that the unit must have high efficiency, while having a low cost and low level of resource consumption. In addition, the device must be mobile and secure.

For heating the garage, various units are used, which differ in the principle of operation, the type of fuel and the features of operation.

Stoves for a garage on long burning wood. The principle of operation of such devices is converter fuel combustion. The unit requires professional installation, but experienced craftsmen can make it themselves. Firewood, pellets, peat, coal and other types of exclusively solid fuels are used as fuel. Gas and liquid combustible materials are not applicable. Additionally, it is necessary to install a chimney and an insulation system. Refers to the category of expensive devices.

Potbelly stoves for the garage. Compact, convenient and affordable variant of the stove, which is easy to build yourself using a basic drawing. The main disadvantage of bourgeois is the increased threat of fire.

Garage furnaces for mining are the most economical option, operating on engine oil that has already worked out its resource in the engine.

A brick oven for a garage allows you to receive soft heat for a long time, but subject to full warming up. Therefore, this option is suitable for people who work in the garage every day.

Infrared heaters. Such equipment is not suitable for metal structures and half-brick structures.Metal reflects poorly, and brick absorbs such energy, which leads to low efficiency of this type of heating.

Important! In the process of installing a heating system, it is imperative to build a high-quality and reliable ventilation system and chimneys.

A long burning wood burning garage oven: types and principle of operation

Any version of garage stoves has its pros and cons, and each of them can be made by hand. To have an idea of the process of creating an aggregate and to calculate your strength and resources, it is worth getting to know in more detail each type of device.

The popularity of long-burning garage stoves lies in their efficiency, since when burning ordinary firewood, you can get the maximum amount of heat. The principle of operation is that a large amount of fuel is loaded one-time into the combustion chamber, where the process of prolonged combustion is due to poor access of oxygen. Thus, the wood does not burn instantly, but gradually smolders, giving off flammable gas.

Long-burning garage furnaces can be different in their design features, a popular variety is Bubafonya. The name of the unit comes from the name of its inventor. The high efficiency of the design lies in the fact that such a long-burning furnace can operate on sawdust. If you try, then Bubafonya can be connected to a water heating system. In this case, the principle of operation of the device will be to create a water jacket around the boiler.

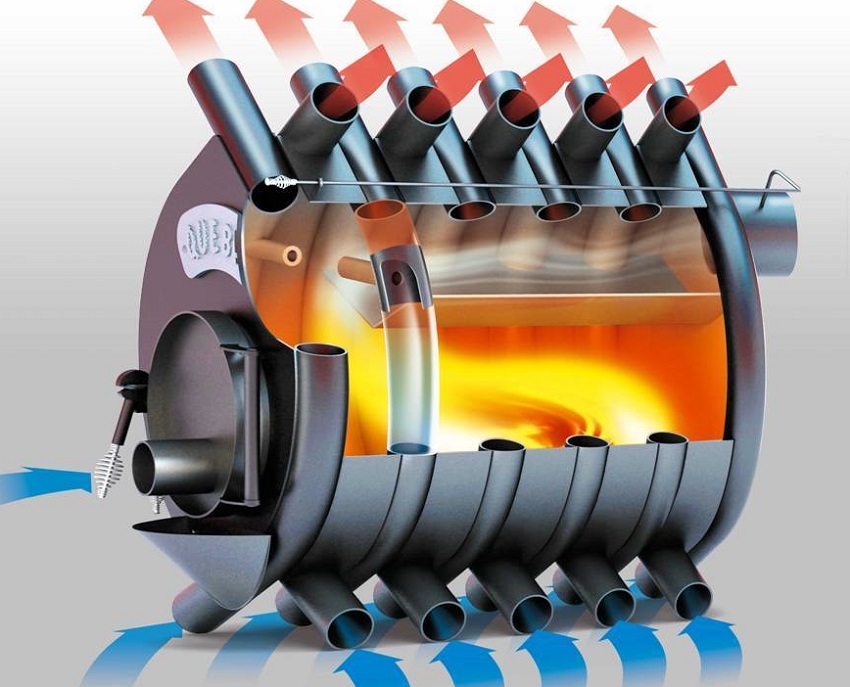

Buleryan is also a popular model of a long-burning furnace, its design is very unusual. The device is widely used not only for office, but also for residential premises. This is a kind of modern hybrid of a classic potbelly stove and a long burning stove. The unit works by forced convection. Several curved pipes run to the top and bottom of the firebox. Cold air enters through the lower ones, which instantly heats up in the firebox and comes out hot from the top.

Do-it-yourself long burning oven for a garage

Despite the relatively complex design, a long-burning furnace can be made independently. Such a model will have one, but a significant drawback: to rake out the ash, you will have to turn the rather weighty body upside down. To build the unit, you need a metal cylinder, a welding machine. You can take a square container as a basis, but subject to the normal provision of smoldering firewood. In this case, the manufacturing process itself will take several hours.

Most often, a thick-walled metal barrel with a capacity of about 200 liters is used for the production of a long-burning furnace. Above, they make fastenings under the cover with a chimney, and also make a small hole necessary for the access of oxygen, which is needed for the combustion process. The diameter of the chimney is approximately 15 cm, and the duct is 10 cm. Often the chimney is taken out from the side, and a place for air is left on top.

Helpful advice! For a wood-fired garage stove, you need to purchase dry fuel. You should choose wood species that emit a minimum amount of resin during combustion.

An important detail of a wood-burning stove for a long-burning garage is a load to provide a press for smoldering wood. It can be made from a metal circle, the diameter of which should be a few millimeters less than the size of the combustion chamber, and two sections of channels that act as a weighting agent. In the circle of weighting, it is necessary to make an air duct and weld a pipe with a section of 10 cm to it. Its length should exceed the height of the stove body ...

A hole with a door for loading firewood into a garage stove with their own hands is made on the side, and a grate and a container for ash are installed below. The final touch is to weld on the legs at the bottom of the finished oven.

Stove stove for a garage: the principle of operation and manufacturing features

An ordinary potbelly stove, popular in the 20s of the last century, is considered the most popular option for a garage stove with wood and other solid fuels. It can be made from a variety of materials at hand. Here, both sheet metal and a piece of pipe, an old barrel or a spent gas cylinder will be appropriate. For successful production, the material must meet the following requirements:

- metal thickness - at least 5 mm;

- the capacity of a cylindrical shape in cross-section must exceed 30 cm.

The composition of a classic potbelly stove includes the following elements:

- case with a lattice;

- loading door;

- ash pan;

- side or vertical chimney.

For the manufacture of a chimney, a 3 mm thick metal pipe with a cross section of at least 12 cm is used. The combustion chamber is cut from a selected workpiece. The grate for fuel is installed at the bottom, and under it there is a 3 mm thick metal ash collection box. The chamber is closed from above and the chimney is removed. Stove legs are made of metal corners.

Before you make a potbelly stove in the garage, you need to decide on its shape, which depends on the base material. It can be round or square. It's also important to think about safety rules. Install the stove on a flat and solid base made of fire-resistant materials. The walls also need to be protected from sunburn. There should be no foreign objects near the stove.

It is important to consider that the metal surface of the stove during operation will be very hot, therefore, in order to avoid serious burns, it is necessary to exclude the possibility of people and animals touching it.

The procedure for making a vertical potbelly stove in a garage with your own hands

The most popular do-it-yourself stove stove for a garage is a metal stove. In order to make a vertical unit, the workpiece is conventionally divided into two parts. The smaller one will be located at the bottom and serve as a place for collecting ash, and the upper part (base) will be a furnace, into which firewood will be laid.

Helpful advice! When working with an old gas cylinder, you need to be extremely careful. First of all, you should make sure that there is no gas inside the container. It can be completely displaced by filling the cylinder with water. There are cases when gas residues in the process of sawing a cylinder provoked an explosion.

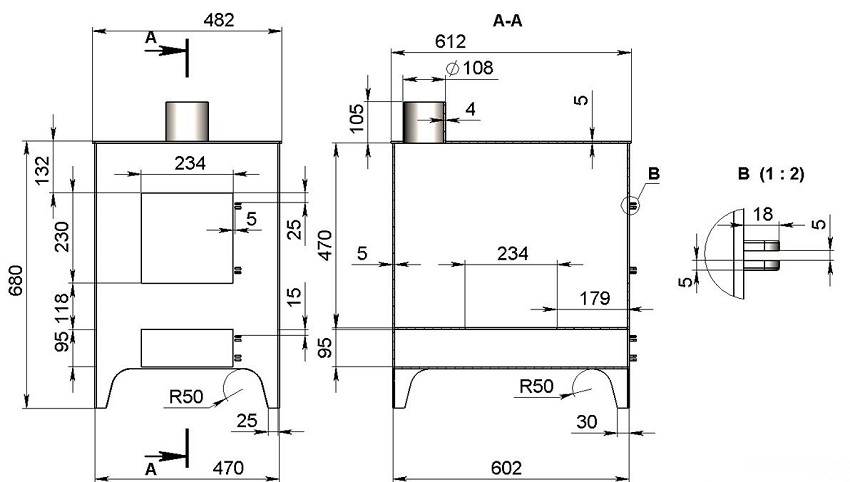

The diagram for the manufacture of a vertical stove in the garage shows all the necessary dimensions

As an illustrative example, consider the procedure for manufacturing a furnace for a garage from a gas cylinder:

- Cutting out doors: upper - for the firebox, lower - for ash collection. This is done with a grinder. The cut pieces are not thrown away, they will serve as doors.

- Welding of grates. To do this, use pieces of steel reinforcement of appropriate length, 13-15 mm thick. A distance of 20 mm is left between the grates.

- Chimney construction. For this purpose, a metal pipe about 10 cm high is attached to the top of the structure.

- Locks and hinges are welded to the door blanks. Connect all the details. To create a seal on the outside of the door, metal strips 20 mm wide can be welded.

- Installation of legs at the bottom of the product from metal corners.

By the same principle, a stove-stove is made in a garage from a pipe. The difference lies in the need to weld the bottom and top cover, where a hole for the chimney is prepared in advance. You can also build a heat efficient rocket stove for your garage from a gas cylinder.

Related article:

Heating in the garage: finding the most efficient and economical way

Advantages and disadvantages. Heating requirements. Types of heating systems: water, electric, gas and others.

Instructions for making a horizontal oven for a garage with your own hands

The horizontal design is considered more convenient in terms of loading long logs, but at the same time, it takes up more space in the garage, so it is not suitable for a small room. In a horizontal potbelly stove, a box for collecting ash is placed from below. For this, a blank is made from a piece of channel, and holes are made in the furnace part. Thus, the grate and ash collector are obtained.

The chimney is placed at the top of the body. For this purpose, a piece of pipe of the corresponding diameter is welded. For the legs of the product, pieces of a metal corner with welded flat blanks of sheet iron are used. This is necessary in order for the structure to become stable. The blower is placed on the side - in the opposite part from the chimney. For this, a piece of metal is cut out in the wall, which is subsequently used as a door.

You can build an original, more practical and safe oven for heating a garage from two barrels. A metal potbelly stove, unlike its cast-iron predecessor, heats up much faster and it is almost impossible to be near it. This problem can be solved by using two barrels of different diameters, installing one of them inside the other. In this case, the inner barrel is a firebox, and the outer one is an additional frame. The space between the walls can be covered with sand or pebbles.

Such a stove will heat up much longer, but at the same time it will cool down much more slowly. Therefore, the required temperature will remain in the garage for much longer, and the stay in it will be more comfortable.

Helpful advice! Small wings welded to the sides of the stove from the pipe will help to increase the heating efficiency of the stove. These parts will increase the contact area of the heated metal with air, which will help warm the room faster.

DIY brick garage oven

Homemade brick ovens are also used to heat the garage, albeit much less frequently. This design radiates heat for a long time, but it will take a lot of time to warm up. Such a unit is suitable for those owners who spend a long time in the garage and visit it every day. In this case, you can simply keep the fire in the furnace by throwing firewood.

To equip a small brick oven in a garage with a hob you will need:

- ceramic refractory bricks - 290 pcs .;

- door for the combustion chamber 250X200 mm - 1 pc .;

- grate for grates 250X250 mm - 1pc .;

- blower door 120X120 mm - 1 pc .;

- gate valve 120X120 mm - 1 pc .;

- cast iron plate 70X30 cm.

For laying bricks, it is necessary to prepare a clay mortar. The thickness of the seams should be between 5 and 15 mm. Before installing the stove in the garage, you need to take care of preparing the foundation. Its horizontal dimensions should be approximately 20 cm wider than the device itself.

For the firebox, it is necessary to carry out a lining, providing for laying fireclay bricks on a similar solution. Under the casting of the furnace, the bricks are undermined, and under the grates, stove and doors, the base should be wider than the dimensions of the casting. In order to ensure thermal insulation, an asbestos cord is used; mineral wool strips are also acceptable, which can withstand temperatures up to 1200 ° C.

Brickwork, carried out according to the established scheme, on average consists of 15 rows. A valve is installed in approximately 6 of them, which allows the furnace to be switched to different operating temperatures, which is especially convenient in the off-season.In order to have an idea of the future brick stove and so that you do not have to correct mistakes later, it is better to carry out preliminary laying without mortar.

Economical and energy efficient furnaces for the mining garage

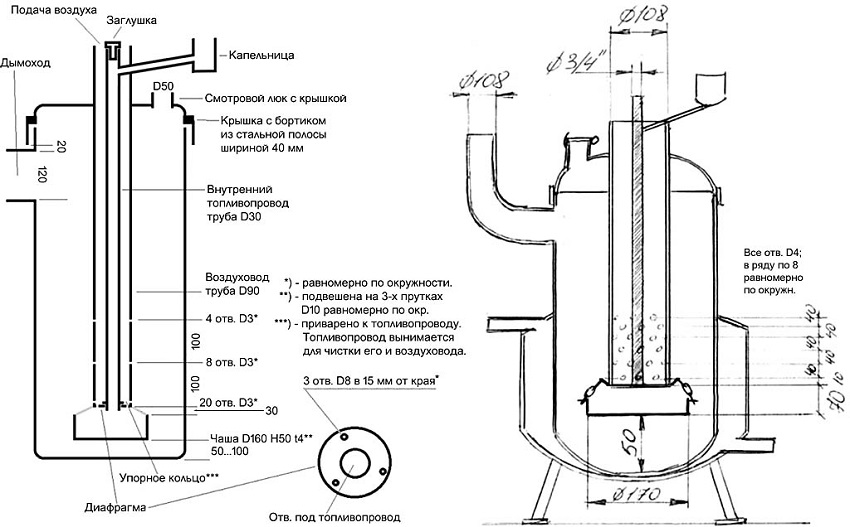

Waste oil furnace is considered the most economical, as it eliminates additional fuel costs. If you correctly calculate the materials and strictly follow the manufacturing instructions, then it will not smoke and excessively pollute the air. The operation of such furnaces is provided for on transmission, machine or transformer oil. A diesel oven for a garage works on the same principle.

Structurally, the unit consists of two containers, which are interconnected by a perforated pipe with many holes. If a decision is made in favor of installing a furnace in the garage for mining, then it is necessary that it meet the following requirements:

- maximum weight - 30 kg;

- capacity - up to 12 liters;

- standard size - 70x50x30 cm;

- average fuel consumption - 1 l / h;

- exhaust pipe diameter - 100 mm.

It is quite simple to build such a structure. Nozzles and droppers are not required to create, therefore, special knowledge, skills or experience are not required for its manufacture.

Helpful advice! Before you build a stove for mining, it is advisable to first agree with the owners of neighboring garages on the collection of used oil. The container must be made of at least 3 mm thick metal.

The following materials will be required directly for the manufacture of the furnace:

- steel pipe;

- two metal containers;

- steel corner.

The capacity can be the body of an old unusable refrigerator compressor or a gas cylinder. A furnace for a garage for mining should be made of a material with a thickness of at least 4 mm, since it is supposed to heat up to 900 ° C, so the thin metal will simply burn out.

The sequence of manufacturing a stove in a garage, operating on testing

Oven for a mining garage is profitable in the presence of large reserves

The process of creating this type of stove in the garage with your own hands includes the following stages:

- Installation of the lower container on the legs. For this purpose, parts of 20 cm in size are produced from a metal corner, onto which the container is welded in a horizontal position.

- Cutting a hole in the middle of the lower part of the body, which serves as a firebox and a fuel tank, welding a vertical pipe to it connecting both containers. It is desirable that the upper part is removable. This is necessary for cleaning the burner.

- Drilling about a dozen holes in the pipe at half a meter height. The first hole must be at least 10 cm from the main body of the oven.

- Making a hole on the upper part of the furnace for filling oil and a cover that will help regulate the heating level of the room and the combustion process itself.

- Welding the pipe on the upper container.

- Construction of a galvanized steel exhaust pipe with a length of at least 4 meters and its fasteners to the branch pipe.

Painting will give a presentable look to the garage stove. For this purpose, a mixture of silicate glue, chalk chalk and aluminum powder is used.

Disadvantages of a furnace for a mining garage, operating features

To use such a stove, in order to avoid accidents, it is necessary in accordance with clear instructions. To do this, put a small amount of kindling paper in the fuel tank using the lower opening of the furnace. Next, approximately 1 liter of used oil is poured. The paper is set on fire and allowed to wait for a couple of minutes until the butter boils. When the oil starts to burn slowly, it must be added as needed in the amount of 3-4 liters.

Despite the many advantages of this type of garage furnace, it is necessary to mention their disadvantages, in particular:

- a very long chimney, which must be at least 4 meters high;

- it is required that the chimney device is strictly vertical, without bends and horizontal sections;

- The oil containers and chimney must be cleaned regularly - about once a week.

Helpful advice! A design with removable parts will help to avoid the inconvenience associated with frequent cleaning of the tank and chimney.

The oil consumption in the furnace during mining is regulated by the air supply damper and is 0.3 - 1 liter. in hour

The process of creating a heating system in the garage must be approached responsibly so that structures such as a working boiler, a brick oven, a do-it-yourself stove are profitable and bring maximum heat. It should be borne in mind that economical options must be carefully looked after, and brick structures require a certain amount of time to kindle. To create a long burning metal furnace, certain skills and knowledge are required. At the same time, any of the options considered, under the conditions of the correct structure and subject to the rules of operation, will make the garage warm and comfortable.