With the approach of cold weather, many craftsmen come up with various designs for heating a room and heating water. First of all, the question is about the type of fuel. In search of the most rational and cheapest option, many opt for development, the average consumption of which is about 2 liters per hour. The waste oil furnace has a number of advantages. Knowing all the subtleties of its manufacture, you can create a budgetary and efficient heat source in the house.

Content

- 1 Advantages and disadvantages of a waste oil stove

- 2 Waste oil furnace operation principle

- 3 Waste oil stove: types of designs

- 4 Requirements for the installation and operation of the oil oven

- 5 Do-it-yourself options for improving the efficiency of a mini-oven

- 6 Popular options for pre-assembled furnaces, their characteristics

- 7 Do-it-yourself step-by-step instructions for making a waste oil furnace from a cylinder

- 8 How to make a pyrolysis type stove

Advantages and disadvantages of a waste oil stove

A factory or homemade waste oil furnace has a number of advantages:

- provision of fast and efficient heating of closed rooms in the form of greenhouses, household buildings, storage and technical rooms;

- independence of the device from electricity and gas;

- unique design features of the device that allow for the cooking process;

- ease of use;

- lack of open flame;

- reliability of the structure, which is made of metal products joined by welding;

- while ensuring normal operation, the furnace does not create a lot of soot and burning;

- due to its low weight and dimensions, the device can be transported;

- the furnace can be made from scrap metal;

- during operation of the device, combustion of oil and its vapors is ensured;

- the stove can be combined with a water heating system by installing a tank on top.

The closed-type mining furnace is not without drawbacks, among which the following can be distinguished:

- the possibility of clogging the feed tube with used oil;

- the need to install a chimney with a length of at least 4 m;

- the presence of hot open surfaces;

- weekly cleaning of the chimney and oil tank from accumulated waste;

- high likelihood of contamination of clothing and premises during contact with fuel;

- a container with fuel should be located in a warm room;

- unpleasant smell of used oil;

- it is possible to extinguish the flame in the apparatus only after the fuel has completely burned out;

- with improper operation, the fire hazard increases;

- characteristic humming noise during furnace operation;

- fuel ignites only when it is heated to its flash point.

Important! Before pouring oil into the system, it must be filtered.

Principle of operation waste oil furnaces

The prototype for oil stoves operating on waste oil is kerosene gas, which was previously used in villages and dachas. It used kerosene as fuel, the vapors of which were afterburned in a separate chamber. To save on fuel, a waste oil combustion option has been developed. It can be purchased free of charge or at a reasonable cost at any service station.

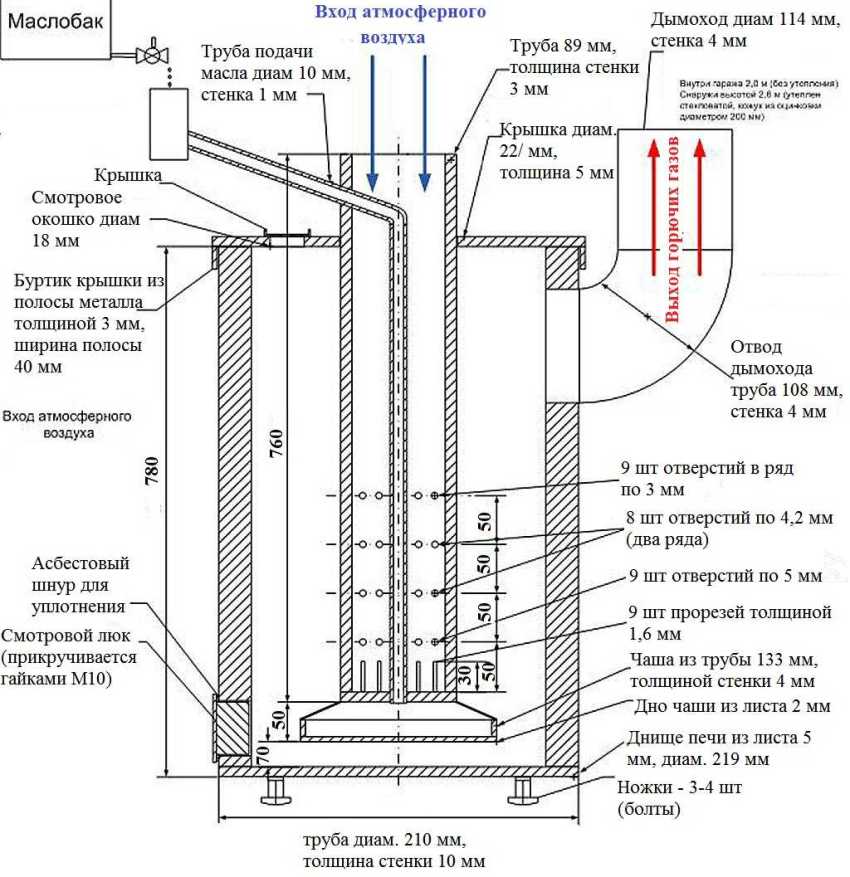

Making a homemade mining stove is not a difficult process. The main challenge is to properly organize the system for a productive oil combustion process. To ensure complete combustion of vapors, heavy components must first be split into light ones, which is carried out as a result of pyrolysis. For efficient evaporation, the oil is properly heated.

The principle of operation of an oil furnace during mining is as follows. First of all, the mining is ignited in the lower chamber of the apparatus. The combustion intensity is regulated by a throttle valve in the device body, through which air enters the chamber. Oil vapors, mixed with oxygen, rise upward through a vertical pipe. The pipe is connected to the upper tank, which is the afterburner chamber.

The mixture is stirred by the Coriolis force (inertial force). The intensity of the process is achieved by choosing the correct diameter and length of the combustion chamber. Sufficient air must flow through the damper to ensure complete combustion. For this, it is additionally sucked in through the holes made in the vertical perforated pipe connecting the tanks.

The gas stream is directed to the final combustion chamber, in which the upper part is expanded. During its manufacture, a horizontal spacing is performed between the inlet of the chimney and the outlet of the combustion chamber, which is necessary to ensure a temperature jump between the zones of nitric oxide and oxygen afterburning. At temperatures below 600 ° C, nitrogen oxides are more active than oxygen. As they decompose, they oxidize fuel particles. As the temperature rises, oxygen acts as the main oxidant. Harmful substances are discharged into the atmosphere through the chimney.

Important! To ensure efficient combustion of oil in the upper reservoir, the temperature must be low.

Waste oil oven: types of designs

There are several types of oil ovens that operate on waste oil. The classic model is the pyrolysis machine. It is made from ready-made containers in the form of barrels, pipes, cylinders or alloy sheets. Oil is poured into the lower vessel, which splits when there is insufficient air. In the upper tank, intensive combustion of its vapors occurs, due to which a lot of heat is released.

The temperature is controlled by air supply. Such a furnace needs constant cleaning of the chambers from the accumulated fractions. It lacks mechanical temperature control.

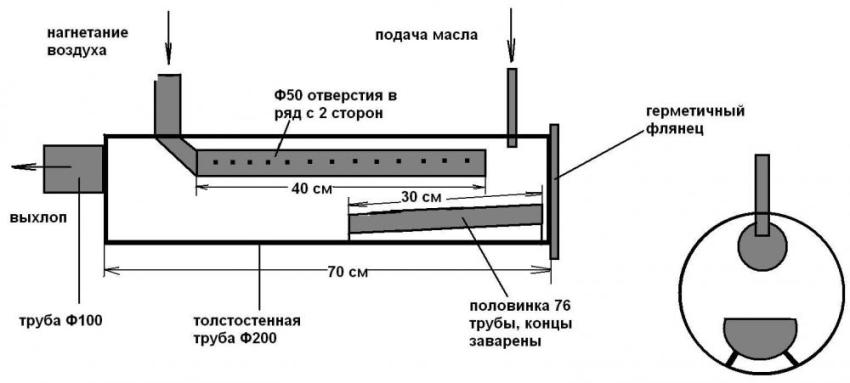

In the oil recovery stove with the help of a fan, a guaranteed air supply to the second chamber is realized. The combustion process is more efficient, so that warm air evenly enters the room.

The principle of operation of a drip-fed stove is similar to the mechanism of operation of diesel engines.It is economical. However, the independent manufacturing process of the device is very laborious, so it is better to purchase a factory device of this type. In addition, it should be borne in mind that homemade drip stoves are picky about the quality of oil, which must be preheated before being fed into the oven.

The most efficient model is the pressurized waste oil oven. It, in comparison with a potbelly stove, has a higher cost. Additional heat comes from the blower fans. The blowing can be done using the motor of the car cooler, and blowing the heater will provide a home propeller with a power of 220 V.

Requirements for the installation and operation of the oil oven

It is required that the oven is located in an empty room, near which there should be no flammable surfaces. Particular attention is paid to self-made devices. They should not be placed on a shelf or other support that could catch fire.

A self-made furnace for mining should be located on a flat base, which can be concrete or brick. It is necessary that the distance between the apparatus and the wall is at least 1 m. For the formation of good draft, the chimney must have a length of more than 4 m. On the outside, insulation should be provided to prevent the formation of acid condensate.

The used oil must be free from solvents or other flammable elements and must therefore be kept away from the oven. It is also unacceptable for moisture to enter a container with oil. This will cause a fire in the oven. In case of an emergency, use a fire extinguisher to extinguish the fire.

Important! In the room where the stove is located, a good system of natural supply and exhaust ventilation must be organized.

The principle of operation of a drip-fed stove is similar to the mechanism of operation of diesel engines

Before starting work, oil is poured into a container in an amount equal to half the volume of the tank, which will provide the necessary space for the formation of vapors. It is necessary to wait a while for the vapors to be enriched with oxygen. Then the fuel is ignited using long matches. As soon as the process of ignition of vapors begins, the damper is half closed.

To increase the performance of the mini-furnace during mining, a sealed tank with liquid can be installed above its upper chamber. To supply and drain water, fittings are attached to it, which are located at different levels. Another option for increasing productivity is the necessary air convection, which is carried out using a fan located near the upper chamber. Taking warm air from the stove, it helps to cool it, which has a positive effect on the service life of the device.

Do-it-yourself options for improving the efficiency of a mini-oven

Waste oil stoves are often used to heat a garage or small workshop. It is not recommended to use such a device in a building where people are constantly present. This is due to the fact that the stove absorbs oxygen, which has a negative effect on the human respiratory organs. If the appliance is intended to heat a living space, it must be located in a separate room.

Additional devices can be used to improve the efficiency of the device. A waste oil furnace with a water circuit is organized by tying the coil body or installing a water jacket on the chimney. In the first case, the coil is made of copper pipe. It is built into the home heating system.

The water jacket is made of sheet metal in the form of a container, which is located in the upper part of the body.It circulates the coolant fluid. For the oven to work effectively, the tank must contain up to 30 liters of water. Such a device will allow you to heat a large room.

A working furnace with a water circuit must be equipped with an expansion tank with an emergency drain, which is necessary in case of liquid boiling. It is not recommended to install a membrane vessel here.

Another option to increase the efficiency of the furnace is to use an air heat exchanger, which is represented by a fan. No structural changes are made to the device, and heating of the room is improved. The fan is located near the upper chamber. When it cools, the heated air spreads over the area of the room. You can also blow air through a box located on top of the stove, or through a pipe that is mounted in the afterburner.

The working furnace with a water circuit must be equipped with an expansion tank with an emergency drain

Popular options for pre-assembled furnaces, their characteristics

The Teplamos NT-612 stove is often chosen as an apparatus used for heating a garage. The power of such a fanless drip heater can vary within 5-15 kW. Fuel consumption is 0.5-1.5 l / h.

Related article:

Pellet boilers: prices and characteristics of models from different manufacturers

What is a pellet boiler? Pellet boiler arrangement. Varieties of pellet boilers. Tips for choosing. Review of the prices of pellet boilers.

This garage oven is a closed type device. It is equipped with a chimney, an air supply pipe and a built-in tank for 8 liters of fuel. Combustion occurs in the inner chamber. The operation of the apparatus begins with the electric heating of the plasma bowl. When the required temperature is reached, fuel is supplied and air is forced into the combustion chamber. The average cost of the device is 30 thousand rubles.

Important! For normal operation of the oven, it needs to be preheated with a small amount of diesel fuel, which is poured into a special bowl.

Another popular model is the Zhar-25 (MS-25) oven. This device can operate not only on waste oil, but also on diesel fuel. The device is powered by the mains supply, which powers the internal fan. The heat output of the furnace varies from 25 to 50 kW. It is designed to heat a room up to 500 sq. m. The maximum fuel consumption is 4.5 l / h. The device has large dimensions. Its weight reaches 130 kg. This stove needs to be equipped with a good chimney. You can buy it for 45 thousand rubles.

Do-it-yourself stove for working off sheet metal and pipe

Depending on the type of device, the structure can be created from pipes of different diameters or from iron sheets. To work you will need the following tools:

- grinder with cutting and grinding wheel;

- sheet metal and pipes;

- welding machine and electrodes;

- metal corners;

- paint for metal that can withstand high temperatures.

Before making the furnace for testing, a detailed drawing of the apparatus is performed. You can create it yourself or use ready-made options that are easy to find on sites on the Internet.

The first step is to manufacture the bottom of the chamber that connects to the fuel tank. It looks like a rounded or straight tank with a lid, where two pipes are located. The first is used to supply oil, and the second is used to strengthen the pipe that goes into the middle of the apparatus. Elements for the tank are cut out with a grinder and connected according to the drawing.

Depending on the type of device, the structure can be created from pipes of different diameters or from iron sheets

The bottom and metal corners are welded to the walls of the tank, which act as the legs of the structure. To create a cover, a sheet of metal is taken in which holes are made. The first, with a diameter of 100 mm, is located in the center; the second, 60 mm in size, is closer to the edge. The cover should be removable to make cleaning the stove easier.

To supply oxygen, a pipe about 37 cm long and 100 mm in diameter is used. In it, along the entire length of the element, holes are made that are necessary for the supply of oxygen. The pipe is welded perpendicular to the lid at the bottom of the apparatus. An air damper is fixed on it, which will be attached with rivets or bolts. The hole under the flap should be 6 cm in size. It is intended for oil supply and fuel ignition.

The design of the upper tank is carried out by analogy with the device of the lower tank according to the drawing of the furnace using waste oil with your own hands. The walls of the product must be at least 350 mm thick. In the bottom of the tank, a bottom with a diameter of 10 cm is cut out, which must be placed closer to the edge. A small piece of pipe with a diameter of 11 cm is welded to the bottom of the hole. This is necessary to connect the element to the gas combustion vessel.

Since the top cover of a blower furnace is subject to high temperatures, a metal sheet of at least 6 mm thickness should be used for its manufacture. An opening is made in the lid for the chimney, which must coincide with the opening at the bottom of the container. Between these elements, a thick metal sheet partition is mounted, located near the smoke hole. A pipe is attached to the upper part of the cover, which connects to the chimney part. In detail, the process of self-production can be seen on the video of the furnace being tested.

Important! To give the structure rigidity and stability, a metal spacer is welded between the chambers in the form of a piece of pipe with a diameter of 200-300 mm.

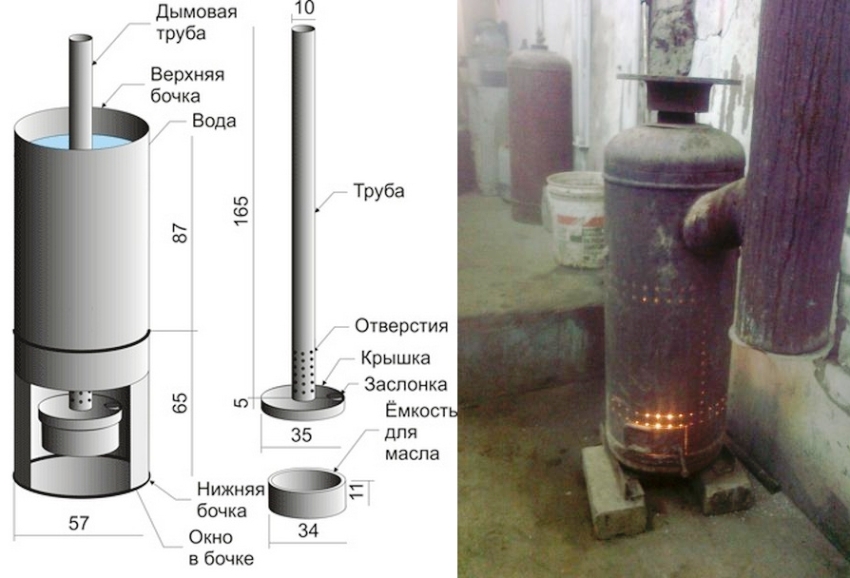

Do-it-yourself step-by-step instructions for making a waste oil furnace from a cylinder

The device can be made from old items using the presented drawings of the waste oil furnace. For this process, you will need a gas cylinder with a capacity of 50 liters. You should also prepare:

- a pipe with a diameter of 80-100 mm and a length of 4 m;

- steel corner for the manufacture of the stand and internal elements of the heat exchanger;

- sheet steel for the bottom of the upper chamber and the plug;

For the process of making a furnace using waste oil, you will need a gas cylinder with a capacity of 50 liters

- brake disk;

- fuel supply hose;

- clamps;

- half-inch valve;

- loops;

- half-inch oil supply pipe.

An empty gas cylinder is used for the manufacture of the body. It is necessary to unscrew the valve on it, after which you should leave it on the street overnight to weather the remaining gas. A hole is drilled in the bottom of the product. To prevent the formation of a spark, the drill must be moistened with oil. Through the hole, the cylinder is filled with water, which is then drained, washing away the remaining gas.

Two openings are cut in the cylinder. The upper one will be used for the combustion chamber, where the heat exchanger will be installed. The lower one acts as a burner with a pallet. The upper part of the chamber is specially made large. If necessary, it can be filled with other types of fuel in the form of wood or pressed briquettes.

Further, the bottom for the upper compartment of the apparatus is made from sheet metal 4 mm thick. A burner is made from a piece of pipe 200 mm long, which is shown in the drawing of a waste oil stove. A lot of holes are made around the circumference of the product, which are necessary for air to enter the fuel. Next, grind the inside of the burner.This will eliminate the possibility of accumulation of soot on ends and uneven surfaces.

Furnace burner on working off from a gas cylinder is welded to the bottom of the upper chamber. In the absence of mining reserves, wood can be laid on the formed shelf.

Making a pallet for working out and installing an oil stove chimney with your own hands

According to the drawing of the stove, a cast iron car brake disc is used to make the waste oil pan, which has good heat-resistant characteristics. In its lower part, a steel circle is welded, which forms the bottom. In the upper part, a cover is made through the opening of which air enters the furnace.

Helpful advice! It is better to make the opening wide. This will provide sufficient air draft to allow oil to flow into the sump.

The next step in the manufacture of a waste oil stove from a gas cylinder is to make a coupling from a 10 cm long pipe that connects the burner and the pan. Thanks to this element, the stove will be much easier to maintain. You can take out the pallet and clean the bottom of the burner. To ensure the supply of oil, a metal tube is inserted into the hole in the body, which is seized by welding. An emergency valve is installed on the pipe.

The chimney structure is made of a pipe with a diameter of 100 mm. One end of it is welded to the hole in the central upper part of the body, and the other is brought out into the street.

Helpful advice! The chimney must pass through the wall in a special fireproof glass.

Having watched the video "The furnace on the development from a gas cylinder", you can get acquainted with the sequence of actions in the manufacture of the apparatus.

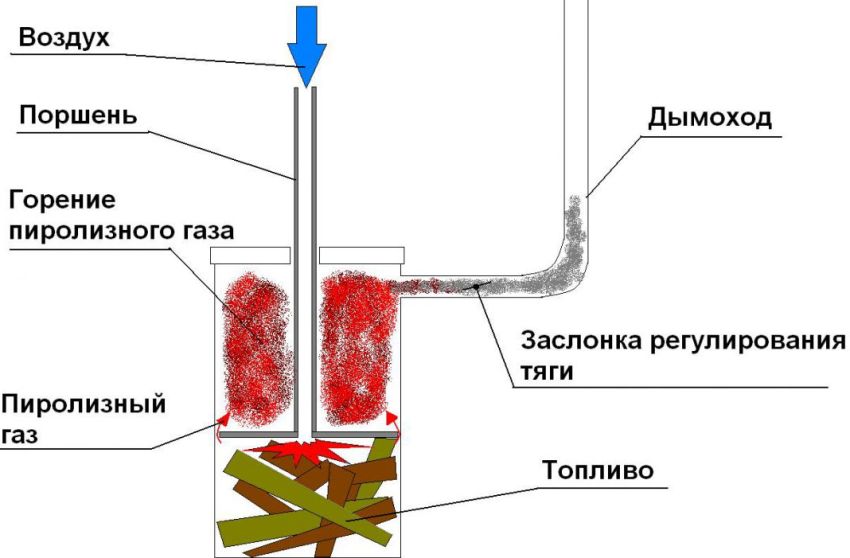

How to make a stove for testing pyrolysis type

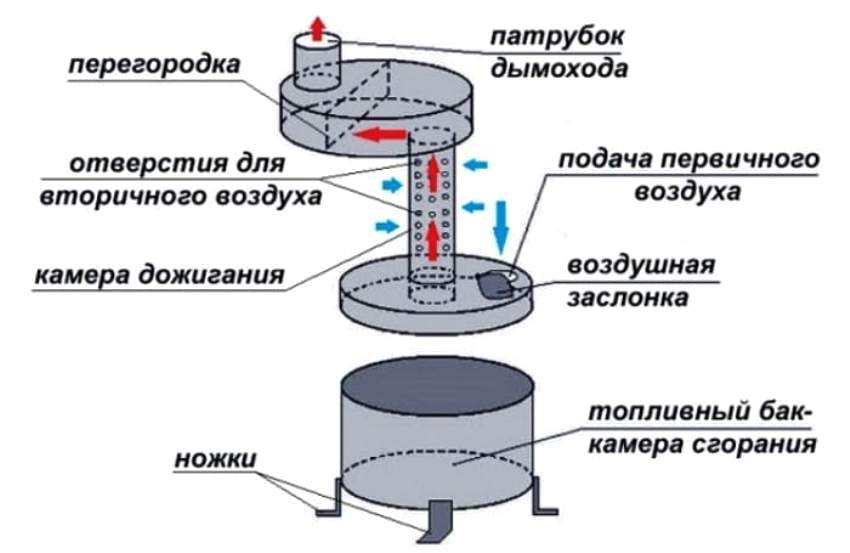

A potbelly stove for mining consists of three main elements:

- containers for oil with a lid and a flap;

- closed combustion chamber;

- afterburner chambers.

The stove must necessarily have a chimney, the length of which is at least 4 m. The oil container, according to the do-it-yourself stove drawing, is made from a piece of pipe 345 mm in diameter and 100 mm long. A sheet metal cover is welded to the bottom of it. The upper removable cover is made from a pipe with a diameter of 352 mm, to which it is necessary to attach the sides with a height of 600 mm by welding. A central hole of 100 mm in size is made in the lid, intended for the combustion chamber, as well as a side one (with a diameter of 60 mm) for air blowing, which is closed by a rotating lid.

Important! By adjusting the blower clearance, the intensity of the furnace combustion is selected, which affects the air temperature in the room.

According to the drawing of the stove being worked out, a pipe with a diameter of 352 mm and a height of 100 mm is used to manufacture the afterburner. In the lower and upper parts of it, holes of 100 mm are made. The first is for the combustion chamber pipe and the second is for the chimney. Closer to the chimney opening, a partition 70 mm high and 330 mm wide must be welded.

Holes are made in the combustion chamber pipe with a drill along its entire height, leaving the lower zone 20 mm high and the upper one (50 mm) unused. After completing all welding work, check the tightness and reliability of the seams. Next, a furnace test is organized. Working off is poured into the oil container. Kerosene is added on top. A careful ignition is carried out with an open blower, with the help of which, after heating the furnace, the heat intensity is regulated.

Important! The testing of the furnace should be carried out outdoors to avoid a fire in the room or other accident.

To heat a garage, a small workshop or living space, you can use a working oven, which has a number of advantages.The device can be purchased ready-made or made independently using drawings from the Internet. Before making an oven, you should study the sequence of actions in order to subsequently obtain a practical and effective device.