Why do we need wood-fired boilers for a long time? When building private housing, it is always necessary to build an autonomous heating system. It is good if gas is supplied to the construction site. Otherwise, you can, of course, use the electric option, but electricity is too expensive. The second option is the usual wood-burning stove with water circuit, but for heating a large area, you will need too much firewood, which is also not cheap. However, if you use wood-fired boilers for a long time at home, then most problems can be avoided.

Content

Wood burning boilers for home

Solid fuel heating installations are not new. They have been used in various variations since time immemorial. While burning fuel in huge quantities was not a problem for anyone, they did not lose their relevance. However, in modern conditions, such a wasteful attitude to resources is inappropriate. Because of this, long-burning wood-fired heating boilers have become widespread. For their operation in operating mode, several times less firewood is required than in direct-flow furnaces and boilers.

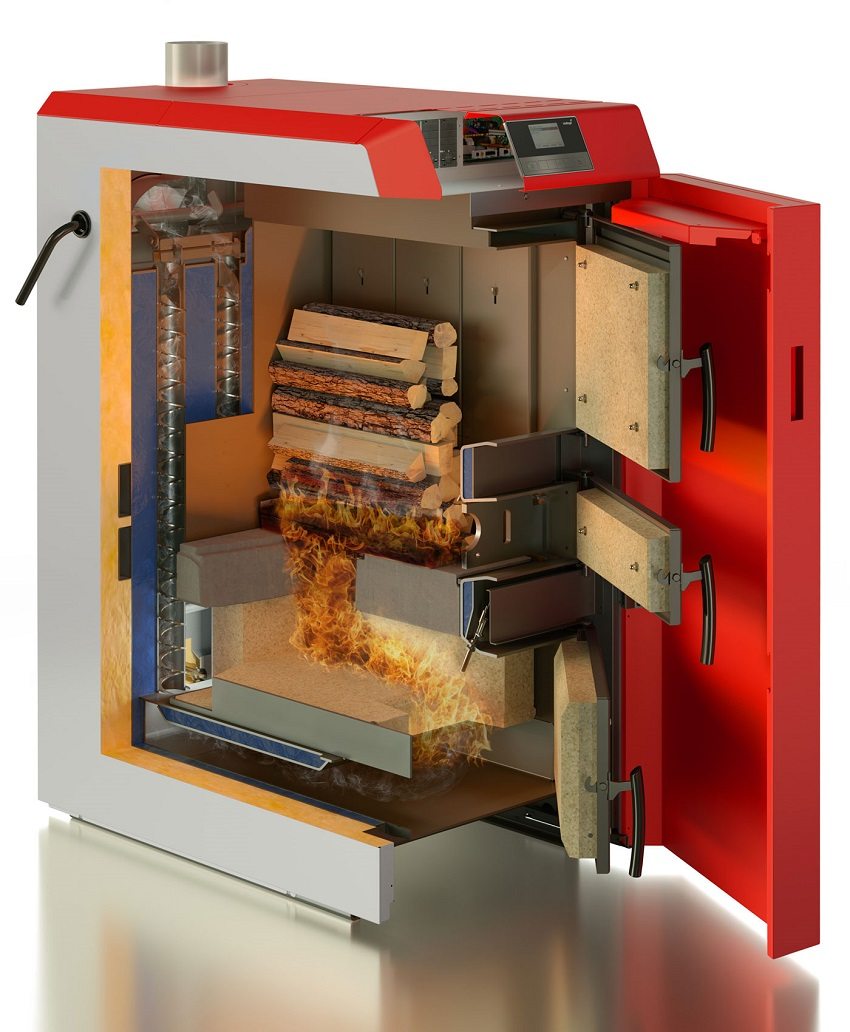

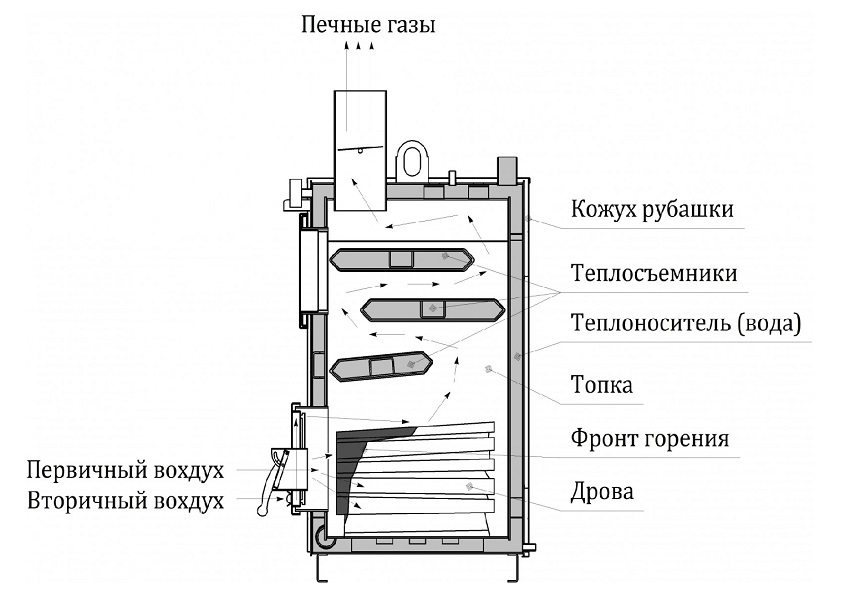

Installation is oven with two cameras. Firewood is loaded into one of them. They smolder slowly from top to bottom with minimal oxygen access. One portion of firewood is enough for 12-15 hours of boiler operation. As a result of this smoldering, pyrolysis gas is released, which is forced through the nozzles into the second chamber. There it is subjected to intense combustion. After all, enough air enters this compartment. During combustion, a large amount of heat is generated, which heats the liquid inside the circuit.

To increase the efficiency of the heating boiler, you need to take care of the insulation of the house.

In addition to being economical, these boilers are highly environmentally friendly, as they are able to break down organic matter from fuel with almost no residues. Therefore, the smoke from such stoves is completely safe for humans.

Helpful advice! To get the maximum benefit from long-burning wood-burning boilers, you need to purchase their combined options. Such installations are also capable of operating on conventional natural gas. Switching between modes in them is carried out automatically.

Varieties of solid fuel boilers with long burning

Wood burning boilers for the home are available in different modifications. There are simple and inexpensive devices, the device of which provides only the most important function - space heating. Such boilers do not require an electricity connection, they have full autonomy and can be used in summer cottages, baths or garages. They are not recommended for heating a residential building. The variant with electric motors required for forced air circulation and a water circuit in the combustion chamber is the most popular, as it combines sufficient functionality and reasonable price. Expensive versions of this heating technology are equipped with automation, emergency protection and many other additional functions.

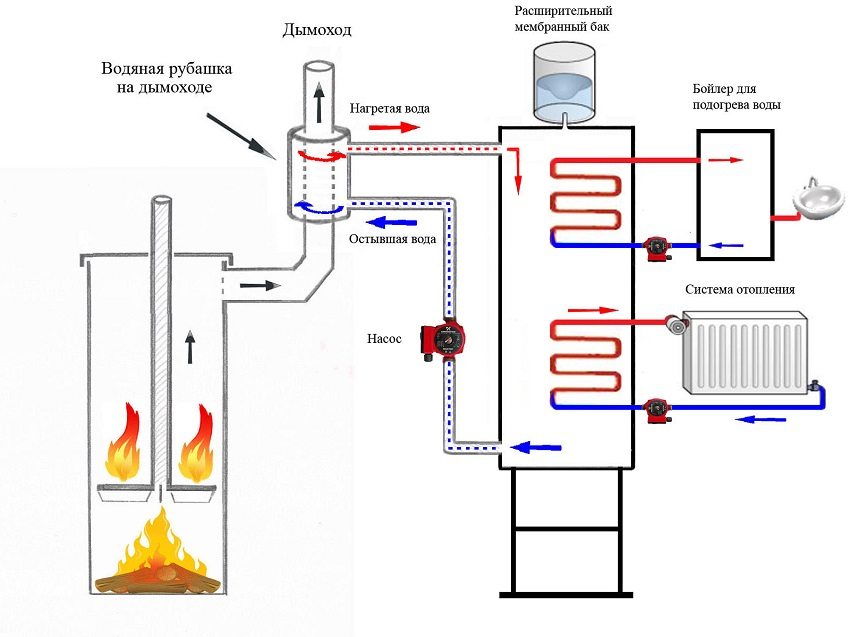

Boilers for long burning on wood for the home are single-circuit and double-circuit. The first ones carry out heating of water only for heating, and the second ones allow using hot water for domestic water supply. Some expensive models run perfectly on gaseous or liquid hydrocarbon fuels.

Double-circuit solid fuel boiler with automatic fuel supply

A wide variety of types of these economical boilers makes it possible to use them as independent heat sources for heating a house or household buildings, and as an alternative device that is turned on in the event of a gas supply interruption to the main unit.

Before purchasing the equipment, you must consider the following important characteristics:

- the boiler is completely autonomous or depends on electricity;

- what area he is able to heat;

- how available is the type of fuel used in your area;

- what are the indicators of thermal leaks for this model;

- what temperature the unit can maintain.

Considering that 1 kW of energy is required to maintain a temperature of 25 degrees on an area of 10 m², a boiler with a capacity of 10 kW is needed to heat a house with an area of 100 m². To the result obtained, you need to add another 20 to 30% power. The numbers depend on the quality of the insulation of the room and which double-glazed windows are installed.

Helpful advice! Living in an area where there are frequent power outages, it is not worth buying a volatile long-burning boiler on wood for your home. It is better to buy an option that has full autonomy.

In addition to industrial units, there are many options for home-made boilers for long burning on wood. Craftsmen make them from various materials at hand. Some samples may well compete with the factory ones in many respects. The quality of the boiler depends on the qualifications of the welder, as well as on the purpose of the device itself. Indeed, for heating domestic premises, a beautiful aesthetic appearance and a complex device are not required.

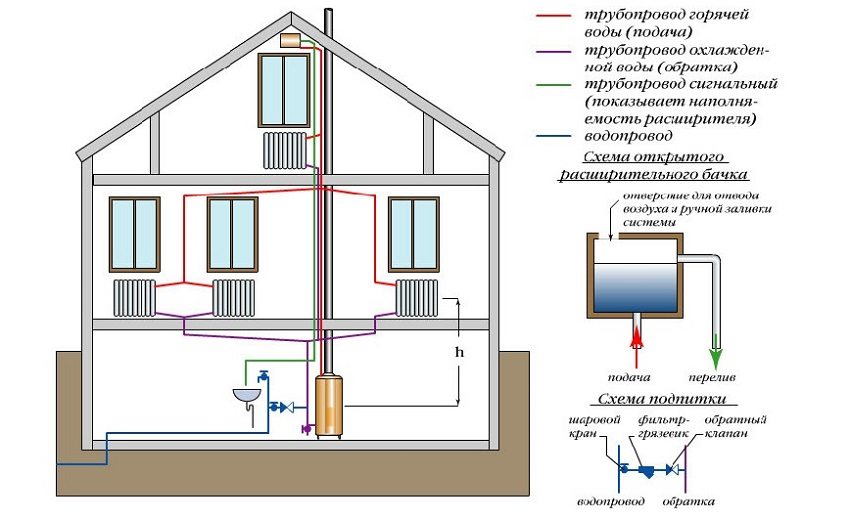

System diagram heating a private house using a solid fuel boiler

Any, even a very high-quality homemade boiler for long burning on wood, cannot be used for independent and constant heating of a residential building. Not a single fire authority will issue a permit without existing certificates of compliance with all fire requirements. They can only be obtained by a duly registered enterprise engaged in the manufacture of boilers, only after the equipment has passed all the necessary routine tests.

However, if you only need the device for heating a garage, bathhouse or garden house, then you can make do-it-yourself wood-fired boiler for long burning... It is not difficult to assemble it from scrap materials if you have the skills to use an electric welding machine and a grinder.

Do-it-yourself wood-fired boiler for long burning: step-by-step instructions

Manufacturing a solid fuel boiler from improvised means is not difficult. The main task is to design it so that the wood in the combustion chamber does not burn, but only smolders. Below is an example of making a cylindrical version of a wood-burning boiler, in which there is a water circuit for connecting a garage heating system:

- we take a piece of pipe with a diameter of 30 to 100 cm. The volume of the combustion chamber will depend on the size, and, consequently, the power. The length of this pipe can be from 70 to 130 cm;

- cut out three circles. Two should correspond in diameter to the pipe - they will be the bottom and the lid, and the third is smaller by about 5 mm. A piston will be made from it;

- we make the exhaust pipe up to 1.7 m long and up to 100 mm in diameter;

- in addition, you will need pieces of a heavy channel, grate bars, cuttings of a small diameter pipe, as well as a thin tube for making a water circuit;

- weld 4 legs made from pipe scraps to the circle, which will be the bottom. Their height should be 5 - 10 cm. The circle itself should find its place at the bottom of the main pipe. It must be welded very well so that there are no visible holes in the seam;

- in the circle for the piston, cut a hole in the center, along the edges of which we weld a pipe for removing smoke. On the opposite side, we attach the channels by welding, keeping the balance of the piston;

- in the upper cover we also make a hole for the pipe and weld it tightly, not forgetting to place the piston inside and mount the coil of the circuit, which should have an inlet and outlet with a fitting outward;

- we cut a square hole under the door and from this piece of metal we make it, using more massive canopies. We weld the corners inside, on which we install the grate;

- below the grate level, a hole is cut for the blower, which should have a door with the ability to adjust the air flow.

A self-made boiler on wood of long burning, ready to use.

Helpful advice! Fuel such oven better together. One person lifts the piston by the pipe, and the second puts a full furnace of firewood, after which he sets them on fire. When they light up, the air supply must be limited. The gas released during smoldering will intensively burn above the piston, heating the water circuit.

Boilers with long burning wood are an excellent alternative to traditional heating units.