In a private house, it is important to pay special attention to the correct organization of the heating system. Installing a gas boiler is considered the ideal way to heat a residential building. The popularity of the heater is due to the fact that it practically does not emit harmful substances and does not require special care. A gas boiler for heating a private house is considered not only efficient, but also economical, because it has a high efficiency of 90%.

Content

- 1 What is a gas boiler: what does the device consist of?

- 2 The principle of operation of gas boilers for heating residential premises

- 3 What are the boilers for heating a private house, depending on the principle of operation

- 4 Gas boiler for heating a private house: types and features of various types of heat exchangers

- 5 Classification of gas boilers: boilers with different types of burners and combustion chambers

- 6 What are burners, in what parameters they differ

- 7 Review of gas boilers for heating a private house: manufacturers and models

What is a gas boiler: what does the device consist of?

Individual heating in a house or apartment is considered a significant advantage, which allows you to save money on heating your home. After installing and piping a gas boiler for heating a private house, residents have the opportunity, if necessary, to turn on / off the heating and adjust the required temperature in the house. Often, in the presence of central heating, you have to open the windows due to excessive heat or, conversely, freeze due to the low temperature in the room.

It is interesting! Gas type boiler refers to equipment used to convert fuel into thermal energy.

The main part of the device is considered to be the case, which is rarely characterized by large dimensions and is most often made of metal. The attractive appearance of most devices allows them to be installed in a conspicuous place.In addition to the aesthetic, the body also plays a protective function. Strong walls protect the inside of the system from water or dust ingress, as well as from mechanical stress. The surrounding objects, in turn, are protected from fire and the formation of soot.

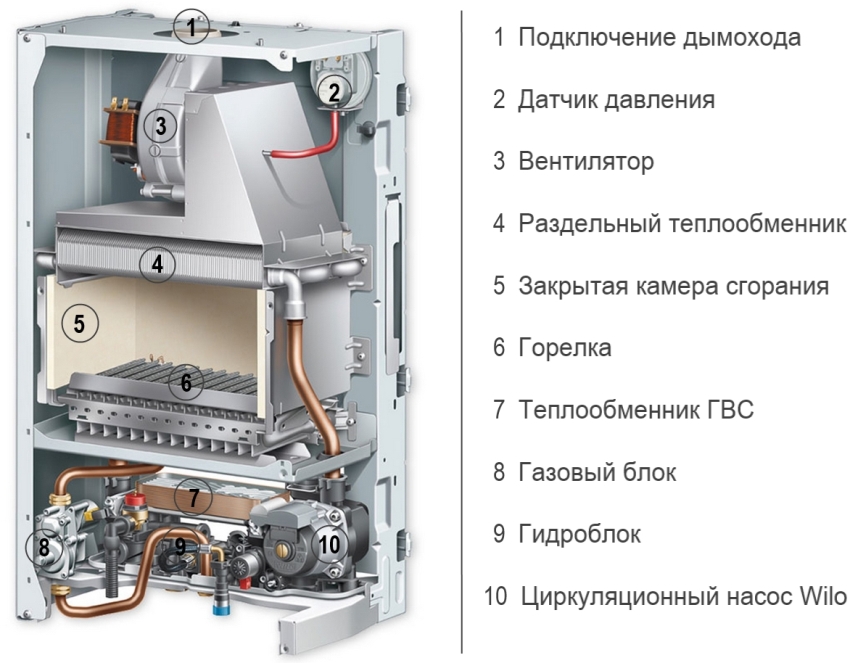

Other elements that make up gas boilers for private houses:

- Circular pump. Required for forced ventilation, with which the operating cycle of the machine begins.

- Three-way valve. A part that starts gas and allows the device to switch to heating or water supply mode.

- Ignition elements. The best gas boilers for home heating are those that are equipped with automatic ignition.

- The combustion chamber. Open or closed space for installing the burner.

- Burner. A thermal energy source that heats the chilled liquid and generates heat for the heating system and hot water. The operation of the burner is controlled by the automation.

- Heat exchanger. Equipment for heat exchange along the boiler circuits, according to the type of structure, heat exchangers are divided into primary, secondary and combined.

Other important details to pay attention to before installing a gas boiler

An important element of any gas boiler in a private house is considered to be a coolant, which is a liquid medium that evenly distributes heat inside the heating system. In most cases, the substance is a water-based antifreeze with ethylene glycol and specific chemical additives. The heating medium is designed in such a way that the components of the system are not damaged and there is no negative impact on the health of residents.

In addition, a properly filled composition protects radiators from the negative effects of corrosive processes taking place inside. High-quality refrigerant provides a high heating temperature - up to 110 ° C, but the substance is not considered flammable and can withstand temperatures from 0 to -65 ° C. Due to these properties, the unit can be operated in harsh climatic conditions and directly on the street.

The correct and well-coordinated operation of the device is also influenced by the automation system, which consists of sensors responsible for smooth operation. They are responsible for stability, efficiency and safety of use. The first group of sensors activates and stops the burner as needed. The second - deactivates the system in the event of unsafe situations. For example, when fuel begins to flow into the system and the ignition does not work, the system automatically shuts off the gas supply and sends a signal that there is a malfunction.

Before connecting the boiler to gas communications, you must first obtain a permit from the gas service

Many are interested in the question of how to properly conduct heating in a private house. You should start by organizing a comfortable and safe boiler room. It is also important to pay attention to the laying of pipelines, some of which can be used as underfloor heating elements, and the installation of convectors in the right places.

The principle of operation of gas boilers for heating residential premises

Before choosing a gas boiler for a private house, you need to familiarize yourself with the general principle of operation of the device and understand some important options. The first thing to remember is that gas boilers are designed to generate heat energy used for heating, hot water supply, or both.

The fuel is exclusively gas: most often methane or a mixture of propane and butane. The choice of this heating method is entirely justified, especially on the territory of Russia.Gas cannot be called too cheap fuel, but nevertheless it is easy to transport, so its use for district heating is more profitable, especially when compared with fuel for wood burning or other solid fuel appliances.

In addition to the fact that for such boilers it will be necessary to calculate the required amount of fuel in advance, they must be constantly fed manually. If you forget to do this, it can get cold in the house.

Modern gas boilers for houses are automated, which makes them even more profitable in the eyes of users, because the heating process requires minimal human intervention. All gas boilers for home heating, regardless of type and purpose, work according to the same principle. When fuel begins to flow into the boiler, piezoelectric or electronic ignition is turned on, after which a wick is ignited from the resulting spark.

After turning on the main burner, the boiler heats up the water to the required temperature. When the programmed temperature is reached, the main burner goes out. If water cooling begins, this change is cut off by the thermocouple sensor that opens the gas supply valve. After that, the burner lights up again, the water starts to heat up automatically. This procedure is automatically duplicated as many times as is required to maintain the desired temperature in the system. According to reviews, gas boilers are characterized by the following main advantages:

- automated work that does not need constant monitoring;

- lower cost of energy carrier;

- the ability to use at any time;

- high performance;

- lack of the need for frequent maintenance;

- simple and safe operation.

What are the boilers for heating a private house, depending on the principle of operation

The type of fuel is not the only criterion that distinguishes various heaters. Boilers are classified based on efficiency, thrust, ignition method and operating characteristics. The efficiency will depend on the quality of the fuel used and the type of construction. There are two main types of boilers:

- Convection. These are the most traditional devices, some experts classify them as less efficient, because they use only the heat of combustion of the gas. Convection boilers are designed to prevent the formation of condensation. In addition, the supply and return temperatures differ slightly - by only 15-25 ° С.

- Condensing. Their efficiency is higher due to the fact that not only the heat of combustion affects the heating of the room, but also a small amount of condensate. The energy that the device uses to generate condensate also works for heating and does not go out through the ventilation system to the street.

It is interesting! Depending on the method of ignition of gas heating boilers, electronic devices with auto start and piezoelectric models with manual start, which require human intervention in work, are distinguished.

In traditional heating boilers for a private house, using a convection system, the heat from the combusted methane enters the heating system through a heat exchanger. In this case, spent fuel escapes into the chimney due to convection, removing part of the heat. When choosing a gas boiler of this type, it must be borne in mind that the efficiency is at the level of 80-90%, although some manufacturers in the instructions for the devices call an indicator equal to 105-110%.

The main advantage of the condensing type of gas boiler for heating a private house is that the exhaust first of all enters the regulator, in which the combustion products are cooled and give useful heat to the water in the system before leaving the chimney. This heat is not enough for full heating of the coolant, but this amount is enough for heating the return water. As a result of this work, the coolant cooled down in the radiator, before entering the boiler, warms up a little in the recuperator. Thus, the efficiency of the device exceeds 100%.

When buying, it should be borne in mind that, despite the greater efficiency of a condensing gas boiler, boiler repair of this type will have to be carried out more often. This is explained as follows: the more complex the system, the faster it will fail. It is also important to know that the resulting condensate is a weak acid, which is strictly not recommended to be drained into a septic tank, because this will lead to the death of all microflora in it.

Types of gas boilers: double-circuit and single-circuit

How to choose a gas boiler? First of all, you need to know the main types of devices due to the fact that there is a big difference between them. So, a single-circuit boiler is a one-line device with one heat exchanger. Initially, the devices were intended only for heating living quarters and organizing a warm floor. They are not suitable for providing residents with hot water.

A double-circuit gas boiler for heating a private house is already equipped with two heat exchangers and two independent highways:

- one for hot water;

- the second is for heating.

The water is heated either by the boiler heater or by the tank built into the device. Some models also differ in the presence of a free-standing boiler. When choosing a double-circuit or single-circuit gas boiler for heating, you should focus on several factors:

- the number of people living in the house;

- housing area;

- the frequency of use of heating and hot water.

The main disadvantage of a double-circuit boiler with a flow-through heating system is that the heating and hot water systems are turned on in turn, and do not work simultaneously. Therefore, while someone is taking a shower, the batteries in the house begin to cool down a little, especially if a gas boiler of 24 kW (or less) is not designed to maintain a sufficiently high temperature at two points of water intake.

The main problem is that if a person takes a shower, and the second person starts to wash the dishes, then the water in the bathroom will not be warm enough or contrasting enough. Often this problem cannot be solved even with the purchase of a more powerful unit, because with a standard connection diameter (½ inch), the water flow capacity will not be enough.

Features of single-circuit and double-circuit gas boilers for heating a private house

In the event that the tap is at a distance of more than five meters from the heater, to warm up the water, you will need to drain the cool stream for 10-15 minutes. To avoid such a problem, experts recommend choosing a double-circuit gas boiler with a built-in water storage tank for heating a private house. In some models, the volume of the tank reaches 40 liters, which is enough for a quick shower for two people. Of course, you won't be able to take a bath with that much water.

If you need constant hot water supply, for more comfortable use, you should purchase a single-circuit gas boiler for heating a private house with additional components, for example, with an indirect heating tank.The container stands separately and is used in a situation when it is required to prepare a large volume of water - 100-200 liters. The boiler resembles a standard household appliance, consisting of a metal container with thermal insulation.

Inside the system, there is a coil connected to the heating system of the house, through which heated water or antifreeze moves, as a result of which the water in the tank is heated. For a standard family of three to four people, a 100 liter capacity is enough. After turning off the device, the water in the tank cools down very slowly, which allows it to be used for a long period.

Related article:

Air heating system: efficient heating and air conditioning

Types of equipment used. Gas and solid fuel boilers. Calculation of the efficiency of air heating. DIY installation.

This combination of equipment provides hot water recirculation. Thus, when you open any tap, quite hot water will flow in the house. However, it is important to understand that in this case, fuel and electricity consumption will increase.

Useful advice! Experienced owners recommend additionally connecting a heated floor system and a heated towel rail to the wiring, which will automatically warm up when the heater is turned on.

In addition to the advantages, some disadvantages of using a system consisting of a single-circuit boiler and a boiler stand out:

- higher cost of the system even in comparison with a double-circuit gas boiler for heating;

- the need to allocate most of the utility room for installation.

Equipment sales specialists also pay attention to the fact that the purchase of a double-circuit boiler in the presence of too hard water in the pipeline may lead to the fact that soon it will be necessary to replace the heat exchanger. In some cases, repairs will cost half the cost of a gas boiler. Therefore, in order to avoid unnecessary expenses, it is better to think over this moment in advance and install high-quality filters that need to be changed from time to time.

By and large, double-circuit gas boilers are considered the best solution for small private houses or apartments, because they do not take up much space. In some cases, especially if the bathroom is far from the heater, it is recommended to combine a double-circuit boiler with an electric boiler, which is installed directly in the bathroom. As a result, it will be possible to protect yourself from changes in water temperature while taking a shower and to have an alternative option for obtaining hot water in case of failure of one of the devices.

Types of single-circuit and double-circuit gas boilers: wall and floor devices

Depending on the installation method, floor-standing and wall-mounted gas boilers for heating are distinguished. Due to the fact that the second option provides for fastening to a vertical surface, it is distinguished by a smaller mass, which in rare cases exceeds 80 kg, although the power in this case can reach 35 kW, but not more. Wall-mounted models are often equipped with a built-in boiler with a volume of about 40 liters. Such devices can be considered an excellent solution for small apartments and houses - up to 120-130 m².

According to reviews, this type of gas boilers has the following advantages:

- There is no need for allocation for the installation of a separate room, because the unit is conveniently placed in the bathroom or in the kitchen.

- The presence of a closed combustion chamber allows the chimney for a gas boiler to be brought out directly into the ventilation system or outside through a small hole in the wall.

The mass of floor-standing gas boilers for heating usually exceeds 100 kg. According to the requirements of SNiPs, it is necessary to allocate a separate boiler room for them, observing the rules of fire and technical safety. In this case, you will need to pay attention to such parameters as:

- ceiling height;

- the size of the base for the boiler equipment;

- air exchange rate in the room.

An open combustion chamber is mainly found in floor-standing gas boilers for heating a private house, therefore, for normal operation of the device, it will be necessary to ensure a constant flow of air. The most important advantage of this type of heater is its high power compared to wall-mounted equipment.

You need to carefully select the model of a floor-standing gas boiler, having familiarized yourself with the type of equipment and the recommendations of specialists

When choosing a wall-mounted or floor-standing option, it should be borne in mind that wall-mounted boilers are often cheaper, because they are additionally equipped with an expansion tank and a circulation pump. At the same time, for the floor structure, these elements will need to be purchased separately, which will lead to additional costs.

Another distinguishing feature of floor-standing boilers is the possibility of using antifreeze, which is not suitable for wall-mounted appliances, where the substance causes deformations and leaks, causing serious environmental problems. This fact must be taken into account when buying equipment for temporary operation in the cold season in a country house or summer cottage.

Gas boiler for heating a private house: types and features of different types of heat exchangers

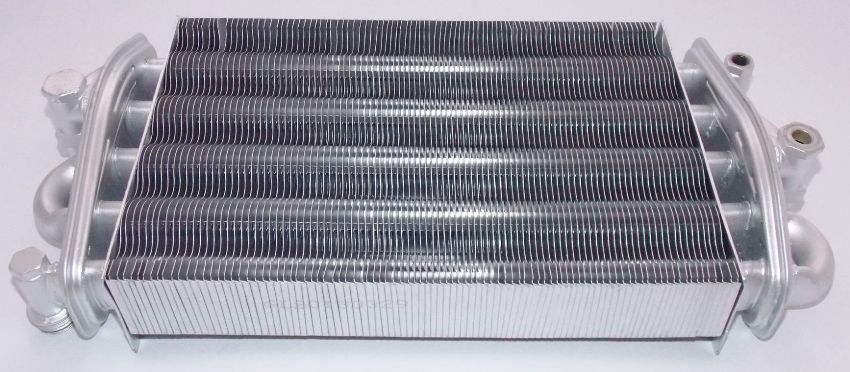

Wall-mounted gas boilers for heating a private house, as well as structures installed on the floor, have one weak point - heat exchangers, which differ in two parameters: design characteristics and material of manufacture. The device is a system of primary and secondary elements. Primary ones are intended for heating the coolant in the heating system. Auxiliary are responsible for heating floors and heated towel rails.

There are two types of heat exchangers, depending on the design:

- Since the heating circuit needs to be heated to higher temperatures, the main heat exchanger is located directly above the heat source, which is a gas burner.

- The secondary heat exchanger is usually installed behind the primary and is heated not from the heat of the burner, but from the previous heat exchanger. Such an arrangement is justified not only economically, but also in terms of efficiency, because the same amount of water is not required for secondary purposes as for the main water supply.

The main element is curved metal pipes with edges, in the upper and lower corners of which two nozzles are located at an angle: one for the entrance and the second for the exit. The secondary heat exchanger is usually more compact and has the form of an oversized plate structure.

Instruments have also been developed with four nozzles attached to all corners of the top plate. This design resembles a heat exchanger with a radiator. Despite the fact that thanks to it, heat is efficiently distributed, many do not recommend purchasing such a heater. There are heat exchangers with a metal jacket through which pipes filled with coolant are laid.

Before choosing a gas boiler, you need to know the advantages and disadvantages of all types of heat exchangers, because this particular part is considered the most valuable. Separately located elements have the following advantages:

- Longer service life compared to combined models.This is due to the fact that the cross-section of the pipes has a larger diameter and is less prone to clogging.

- The ability to repair a contour part separately. There is no need to completely change the entire heat exchanger, because the problem can be solved locally, which will help save time and money.

- Optimum coolant temperature in the circuits. In a closed heating system, the temperature is elevated, and in the water supply system it is most suitable for use, which eliminates the possibility of getting burned when opening the hot tap in the bathroom or kitchen.

- Slow build-up of scale on the inside of the pipes. This is due to the fact that the liquid is constantly circulating in the circuits, so there is no chance of stagnation.

The efficiency of the boiler operation largely depends on the condition of the heat exchanger installed in it.

It is interesting! The main disadvantages of gas boilers with a separate heat exchanger include their large size and weak three-way valve.

The main types of materials used for the production of heat exchangers for boilers

An alternative heat exchanger is considered to be bithermal. The element is characterized by the fact that the heating and hot water circuits are combined into one unit. The choice of a gas boiler for a private house with such a heat exchanger is justified due to the maximum compactness and high performance. The main disadvantage can be considered the fact that when one element fails, the entire heat exchanger becomes unusable. In this case, safety is also required, because very hot water can come from the tap.

Both types of heat exchangers are made of metal, because this material is durable, efficient and good at giving off thermal energy to the coolant. The following metals are most often used for production:

- cast iron;

- copper;

- stainless steel.

The materials used vary in terms of weight, cost, strength, corrosion resistance, durability and heat transfer efficiency.

The most weighty is cast iron, which is several times heavier than steel and copper. This criterion is especially important to consider when choosing the location of the boiler. It is necessary to pay attention to the fact that if the base for a cast-iron boiler is not properly prepared, it may overturn. Another disadvantage of such units is considered to be low efficiency.

But if you need to purchase a simple, cheap and economical gas boiler for heating a private house, then this option will be optimal, but it should be borne in mind that its installation will be more expensive than installing steel or copper devices. The device is installed only on the floor, and at least two assistants are required to move a heavy structure from place to place.

Important! Care should be taken when fixing, because cast iron elements do not tolerate the formation of condensation and the effects of cold water, which often gets into the heating elements due to poor ventilation. An important advantage of cast iron heat exchangers is that they are collapsible. It is in this form that the devices are preferable to install and repair.

As strange as it may sound, cast-iron heat exchangers are considered very fragile. They are prone to erosion processes. The boilers are easily damaged during transportation and are also afraid of thermal shock. This means that if cold water reaches the cast iron heat exchanger, it is likely that it will deform or crack.

When operating a cast iron heat exchanger, it is important to know that the material is heated and cooled not instantly, but gradually.Therefore, the pipeline will continue to heat up for some time after the system is turned off. With careful use, the service life of a cast iron boiler reaches 50 years.

Characteristics of gas boilers with steel elements

Many people think about which gas boiler is better - cast iron or steel. The choice of specialists falls exactly on the second option, even despite the higher price of the product. Steel is significantly lighter and is used for the production of boilers of any capacity. Such devices can be placed both on the floor and on the wall. In general, structures with steel elements are distinguished by an optimal ratio of price and quality.

Steel itself is very resistant to combustion, not afraid of mechanical damage and thermal shock. The weak points of steel boilers include the fact that frequent temperature changes cause wear on the body at the seams where poor welding takes place. According to the ratings of gas boilers for heating a private house and user reviews, among the advantages of appliances with steel filling are:

- Easy installation. Due to their low weight, the heaters are easier to install, even though the structure is not demountable. If repairs are necessary, you will need to remove the unit and repair the entire element.

- No corrosion. All parts that come into contact with water undergo chemical reactions, but stainless steel heat exchangers with such a problem are not typical.

- Heat transfer. A boiler with a steel interior heats up quickly and cools down quickly, but it is distinguished by its high heat exchange efficiency.

In terms of service life, steel is several times inferior to cast iron. Most manufacturers give a warranty for devices for only 10-15 years, and in some cases even no more than 5 years.

Features of the operation of copper and aluminum heat exchangers

Copper heat exchangers are among the lightest and most compact, but the price of gas boilers for a house of this type will be much higher than the rest. For this reason, copper is only used in European products. Despite this, the copper coil and its ribs are very thin. They are susceptible to combustion and wear due to chemical reactions with the liquid.

Important! Elements made of soft copper are the least resistant to mechanical damage. This indicates that the device must be handled with care and attention.

Main characteristics of copper-filled boilers:

- Installation. The small weight of the devices allows you to carry out the installation yourself, without outside help

- Life time. Copper has the shortest lifespan. It is very rare that a manufacturer's warranty exceeds 10 years.

- Corrosion. Copper products do not corrode, but oxidize over time, which reduces heat transfer efficiency and shortens shelf life.

- Heat transfer. Copper heats up and cools faster than other materials.

Aluminum heat exchangers are mainly installed in modern, expensive condensing boilers. It is aluminum that is considered the optimal material for the manufacture of a heat exchanger, because this metal is not afraid of corrosion and oxidation. In some models of gas boilers, aluminum is combined with steel plates to increase stability and strength.

Classification of gas boilers: boilers with different types of burners and combustion chambers

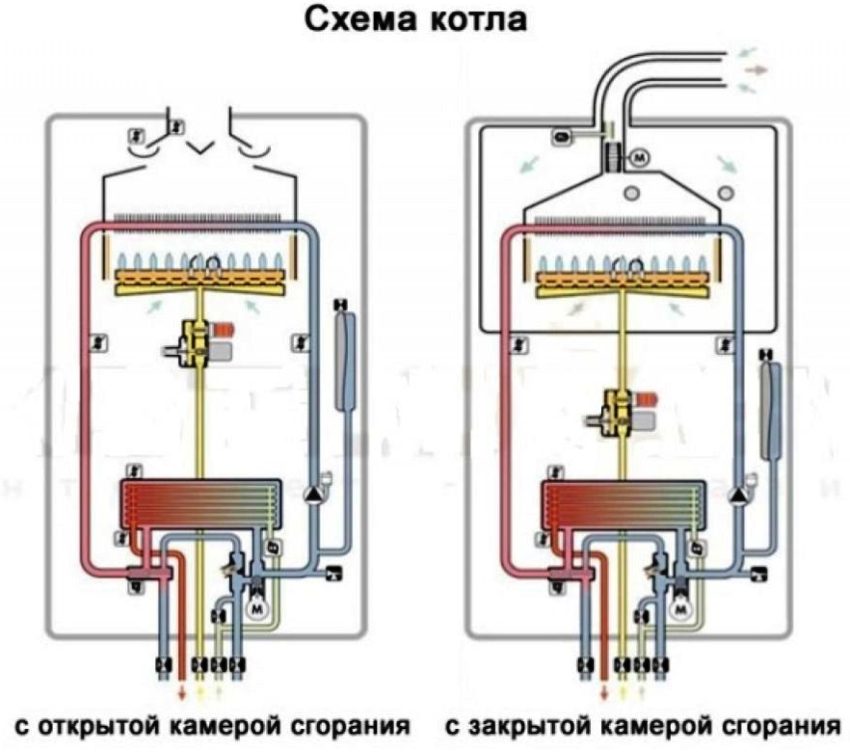

In order to maintain the combustion process of gas in the device, a constant supply of oxygen is required, which enters the furnace in two ways - from the street or from the room.If the main volume comes from the street, the boiler is supplemented with an atmospheric burner, into which air flows naturally. If the main amount of oxygen is taken from the room, a closed burner is built into the device, forcing the flow.

Thus, gas boilers for domestic use have an open or closed combustion chamber. Open chamber appliances use the natural flow of air, where the oxygen required for the combustion reaction comes from the room and the combustion products return in the same direction. Therefore, for such heaters, a powerful ventilation system is required, which must constantly work and clean the air from contamination.

Sometimes even with sophisticated forced ventilation, carbon monoxide is not completely removed from the room. A lack of oxygen is formed, which can negatively affect the health of the residents of the house. To avoid the accumulation of harmful substances, it is recommended to install boilers with open systems in separate rooms specially equipped in accordance with safety requirements.

According to the rules, it is strictly forbidden to mount such boilers in residential premises. In case of unauthorized installation, for example, in the living room, a large fine may be imposed in the event of an inspection by the gas services. However, these units also have advantages. The price of gas heating boilers of this type is many times less than the cost of closed wall installations, and they also work quietly and often do not depend on electricity.

Important! Before buying equipment, many are wondering how many square meters should be in a boiler room in a private house. According to the rules, the premises allocated for boiler rooms must differ in an area of at least 4 m² and a volume of 8 m³. It is imperative that an efficient exhaust hood be installed here and a forced ventilation system is thought out.

Boilers with a closed chamber use air coming from the street, and the combustion products are returned there. Devices of this type are equipped with a ventilation and smoke exhaust system. A fan always runs inside the system, which makes the structure not completely stable. The advantage of closed heating devices is their compactness, high efficiency, attractive design and fire safety. Boilers do not take oxygen from the room and cannot cause suffocation.

What are burners, in what parameters they differ

In any models, even the old AGV gas boilers for private houses, there is an element such as a gas burner, which conducts natural gas through the combustion chamber. This is where oxygen interacts with the fuel and then ignites as it exits the mixer. Each burner is equipped with nozzles that distribute gas throughout the system, contributing to uniform heating of the carrier.

It is thanks to this detail that the presence of a constant flame is ensured. Combustion plants vary according to the type of fuel used. In general, burners are divided into the following types:

- Household. Can be used in a private house or apartment.

- Industrial. Installed only in production facilities.

Heating burner types are classified according to several parameters, such as the type of fuel used:

- Oil burners. Designed to operate on liquefied gas, gasoline or kerosene. Most often, liquefied gas is suitable for stationary installed models, and other types of fuel liquids are used in mobile burners.

- Solid fuel devices. They are often installed in country houses.It is important to use a solid type of fuel when the boiler has a decorative body that imitates a stove or fireplace. Coal is suitable as a solid fuel.

- Gas-burners. Usually they run on natural gas: propane, methane, methylbutane. It is these fuels that are used in a large number of gas boilers.

- Universal devices. They are suitable for several types of fuel at the same time, but such burner options are extremely rare.

By the type of oxygen supply, the following burners are distinguished:

- Injection. The gas is oxygenated before entering the chamber.

- Atmospheric. The same principle of operation, based on the injection system, but the amount of oxygen that enriches the chamber is less.

- Regenerative. The gas is mixed with oxygen in a heated state, and the process of fuel heating itself is carried out before being fed into the combustion chamber due to the operation of the generator.

- Diffuse. The gas mixes with oxygen directly during combustion.

- With a supercharger. The air is supplied to the burner by means of a fan.

A separate group can be divided into gas burners, in which complete or partial mixing of gas with oxygen takes place. This type of device works on the basis of the torch principle when butane is used as the natural gas. In this case, the mixing of fuel and oxygen occurs precisely at the stage of exiting the injector. In this case, the fuel mass burns with an optimal intensity.

Overview of gas boilers for private heating at home: manufacturers and models

It is virtually impossible to say exactly which gas boiler for a private house is the best, because many manufacturers offer a wide range of devices that differ in equipment, internal filling, as well as quality and type. Each company tries to provide the buyer with products that meet specific needs and are complemented by a large number of useful functions.

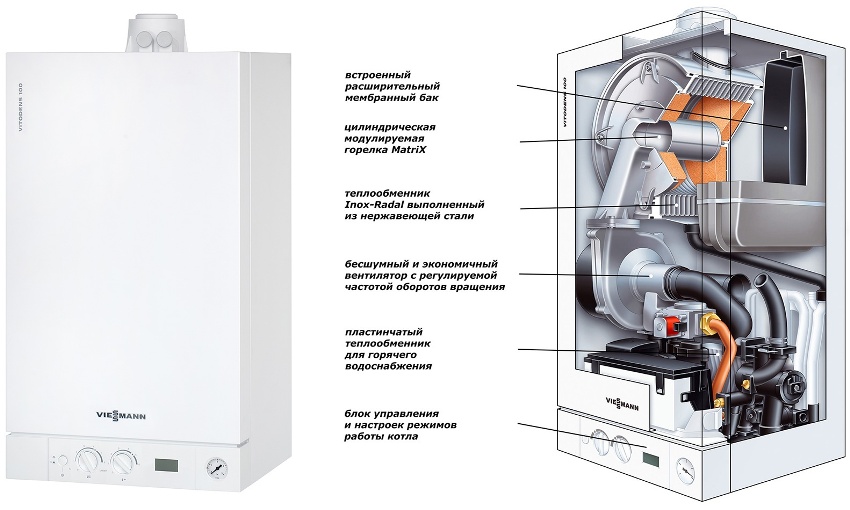

Viessmann offers the Vitopend 100 A1HB model range, represented by mounted gas boilers for heating a private house of various capacities - 24, 30 and 34 kW, which is quite enough to warm up a 250 m² housing. Each device is compact, which allows you to easily find the ideal installation location in any room. Due to the fact that the devices are assembled on a single modular platform, this greatly simplifies their installation and maintenance.

Helpful information! The design features of Viessmann boilers allow you to install devices close to other furniture and at the same time not leave additional space nearby. This makes it possible to carry out installation close to kitchen furniture, which will create an integral picture in the interior of the room.

The main advantages of single-circuit models of the company are considered to be low gas consumption, a high level of efficiency - 93%, a self-diagnostic function with intelligent control, as well as the presence of auto-tuning of power, which is regulated depending on the ambient temperature. Safety of use is ensured by the new frost protection coaxial flue system. All models of this line of the brand are distinguished by their attractive appearance and compact dimensions.

The only disadvantage is the absence of a remote control panel for the device. The cost of gas boilers for heating a private house starts at 43,500 rubles.

Characteristics and prices of gas boilers for heating a private house of the company "Baksi"

Gas boilers "Baksi" are presented in a large assortment.The Eco Four model range consists of wall-hung double-circuit boilers operating on liquefied or mains gas, which differ in power of 14 or 24 kW. The devices have gained wide popularity in the Russian market due to their performance, compact size and high build quality. The price of double-circuit gas boilers for heating starts at 39 thousand rubles.

Double-circuit devices heat water in a flow-through mode, and for single-circuit models, an indirect heating tank is connected to provide hot water supply. The main characteristics of the units:

- primary copper heat exchanger;

- gas burner and heat exchanger for hot water from high quality stainless steel;

- availability of protection against freezing and blocking;

- a circulation pump equipped with an air vent, operating automatically;

- automatic bypass;

- electronic ignition and flame control;

- the minimum gas pressure in the system is 5 mbar.

Ease of use is ensured by the presence of a liquid crystal screen that displays information about the status of the system. The devices have built-in electronic self-diagnostics, transmitting a blocking signal to the dispatching console. Optionally, an outdoor temperature sensor can be connected to the device, because weather-dependent automation is built into the system. The temperature in the system is automatically controlled.

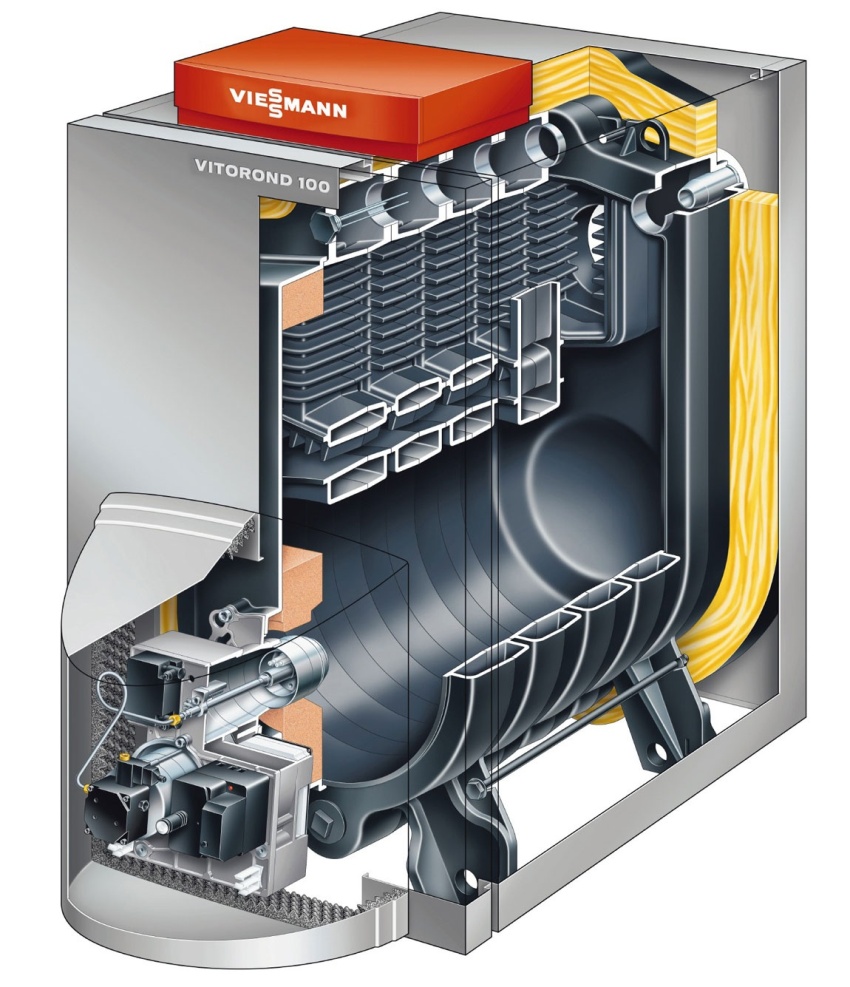

The Baxi Slim range is represented by floor standing gas boilers for heating a private house. The Italian manufacturer offers 10 models with power from 22 to 62 kW, which operate on main gas. Long-term use of the device is guaranteed thanks to the built-in cast iron heat exchanger.

Double-circuit boilers have a built-in boiler to provide hot water supply, while in other models it is possible to connect an additional storage boiler. The devices have two temperature control ranges: one for radiators, the second for the underfloor heating system. The models are equipped with protection systems that protect:

- from freezing;

- overheating;

- blocking.

Italian boilers are characterized by compact dimensions, attractive modern design, weather-dependent automation, pressure gauge and safety valves. Additionally, there is the possibility of connecting a programmable valve. The price of gas boilers starts from 55 thousand rubles.

The best gas boilers for heating private houses Russian-made Proterm

Protherm "Medved" 40 KLOM is the best boiler of Russian origin, distinguished by premium quality. The model has a built-in cast iron heat exchanger, which ensures reliability and high performance of the device. The power of the unit is 35 kW, and the maximum gas consumption does not exceed 4.1 m³ / h.

Helpful information! When used correctly, the cast iron heat exchanger installed inside the appliance is virtually permanent.

An important advantage of Proterm gas boilers is that all imported electronic filling is included in the kit, this includes protection and control automation. All operating parameters are displayed on a conveniently located LCD display, which displays media temperature and system pressure. Another advantage of Protherm "Bear" devices is the fact that they belong to non-volatile gas boilers for heating a private house with an open combustion chamber. The advantages of the heater are also:

- long warranty period - 25 years;

- easy maintenance;

- the ability to work from LNG cylinders;

- compact dimensions with high power and performance;

- built-in pump for the hot water supply circuit;

- control mode "winter-summer".

As for the disadvantages, this can be attributed to the rather thin metal used to make the case. This characteristic does not affect the quality of the device's operation, but it must be handled very carefully. In general, we can say that in the rating of gas boilers in the low-cost segment, these models occupy high positions due to their high reliability and affordable prices - from 56 thousand rubles.

Other popular companies that produce gas boilers for the Russian market

Gas boilers "Ariston" on the market are mainly represented by the following series: Egis, Clas and Genus. Each of the models is distinguished by a certain set of characteristics, but all of them are double-circuit devices designed for heating premises and providing hot water.

The price of gas boilers for heating a private house "Ariston" of the Egis series starts from 32 thousand rubles. All devices have small dimensions that fit into the interior of small rooms. Each model is characterized by the presence of an intelligent control system, a high level of efficiency. The bithermal heat exchanger ensures smooth operation, and the ergonomic LED control panel makes it easy to monitor the system status.

Ariston gas boilers of the Clas series have a decorative casing for connecting the pipeline. The products in this series are equipped with an oversized pump and an expansion tank for water. For safe use, the model has a hole for the analysis of combustion products. All operating errors are displayed on a digital display. Other advantages are the function of pumping air from the heating circuit and a built-in filter for mechanical cleaning of the coolant.

The model range of the Genus series is represented by two-circuit boilers equipped with a fan with continuously variable speed control and a copper heat exchanger. The benefits are also:

- semi-automatic make-up;

- air evacuation;

- protection against freezing and scale formation;

- blocking of the circulation pump.

The best gas boilers of Korean origin are considered to be Navien devices, which, after the rise in price of European goods, became their excellent alternative. The cost of the models is 30-40% lower, and in terms of build quality and reliability they are in no way inferior to the “Europeans”.

Gas boilers "Navien" are constantly being modified and improved, while each new model of the brand is supplemented with necessary and useful functions. Special modulating burners ensure quiet operation and maintain a comfortable room temperature. The presence of voice prompts simplifies operation and settings, especially for consumers who do not know how to use the device correctly.

It is interesting! An important advantage of most Navien models is the ability to control the gas boiler via a smartphone using iOS and Android systems and connect the device to the smart home system.

All boilers of the Korean brand are perfectly adapted to Russian realities and tolerate voltage surges in the power grid, pressure drops in the main gas supply, and also continue to work in case of fuel supply when the pressure drops. The device itself detects possible malfunctions and displays an error code.

A gas boiler is an expensive and important device used in a private house or apartment with autonomous heating. You should not make a purchase spontaneously, focusing only on a suitable cost.A poor-quality device can quickly fail, especially if the features of the supplied fuel and the installation location were not taken into account. Only a competent approach to buying will allow for a long time not to think about how to change a gas boiler in a private house and what needs to be prepared for this. If you make your choice deliberately, the device will serve for more than a dozen years.