The correct operation of gas heating equipment largely depends on the system that removes the combustion products. Before equipping a chimney for a gas boiler in a private house, you need to have an idea of the types of equipment, the principles of its operation and the regulatory documents according to which it is installed. Regardless of who will carry out the work, the choice of the device and installation should be taken with full responsibility.

Before choosing the type of chimney for a gas boiler, it is necessary to carefully study the information: existing options for chimneys, requirements for their installation, expediency of use

Content

- 1 Types of chimney systems: which chimney to choose

- 2 Chimney for a gas boiler in a private house: basic requirements of SNiP 2.04.05-91

- 3 The procedure for arranging a gas boiler chimney in a private house

- 4 Chimneys for gas boilers from stainless steel

- 5 Rules for installing a chimney for a gas column

- 6 How to check the draft in the chimney of a gas boiler

- 7 Coaxial chimney for a gas boiler: installation rules, advantages, installation

- 8 DIY brick chimney

- 9 Chimneys for gas boilers: prices for various types of pipes

Types of chimney systems: which chimney to choose

Installation of a combustion products disposal system on a gas boiler contributes to the efficient operation of the equipment and the entire heating system, safe and comfortable heating, as well as trouble-free operation of the boiler. Before buying a chimney for a gas boiler, it would be useful to get expert advice on the existing options for chimneys and the expediency of their use.

Types of smoke ducts for gas boilers:

- brick chimney - its construction is planned at the stage of building a house and a foundation is being arranged under it. A prerequisite is a smooth surface of the inner walls of the chimney. It should be noted that the structure must be resistant to the action of acid, which is formed due to condensation of steam. Otherwise, there will be a rapid destruction of the brick chimney pipe. Used in combination with ceramic or steel liners. Brick chimneys for gas boilers are distinguished by a complex structure, duration of construction and costly cost. In terms of technical indicators, they are in many ways inferior to the emerging modern chimney systems;

- stainless pipe construction - this version of the chimney is highly resistant to the action of a chemical environment and mechanical damage. The system is designed as a sandwich structure: when a pipe with a smaller diameter is inserted into the outer pipe. A fire-resistant material - basalt wool - is placed in the free space between them. Manufacturers offer a wide range of chimney models;

- coaxial chimney - the structure is assembled according to the "pipe in pipe" principle: air is taken in for combustion through one pipe, and combustion products are removed through the other. Such a system has high technical characteristics that contribute to the safety and efficiency of all gas equipment. And due to the fact that the combustion cycle takes place outside the room, a boiler with a coaxial chimney is an environmentally friendly equipment;

- chimney made of ceramic pipes - these are ceramic blocks with thermal insulation, installed in a concrete frame. Such a chimney system is resistant to temperature fluctuations, watertight, fireproof and has high mechanical strength. The main requirement for installation is high-quality joining of ceramic modules.

Which pipe for the chimney is better to use - everyone decides based on their specific situation. The main thing is to highlight the strengths and weaknesses of any option. Regardless of which type of chimney you prefer, its design and installation must comply with SNiP 2.04.05-91 "Heating, ventilation and air conditioning". Having studied these standards, you can find out how to properly install a chimney on a gas boiler.

Chimney for a gas boiler in a private house: basic requirements of SNiP 2.04.05-91

Measures for the arrangement of a chimney for a gas boiler, from the design stage to the installation of the system itself, must comply with the requirements of the current regulatory framework, since improper installation and operation of gas equipment calls into question the safety of people using gas installations.

The main structural elements of the chimney:

- gas duct - the channel leaving the boiler into the chimney pipe is connected by an adapter;

- chimney pipes;

- revision - attached to the bottom of the chimney shaft and serves to clean the channel from combustion products and remove excess moisture;

- fasteners (brackets, clamps) - are used for fastening to the wall;

- other accessories for the system device.

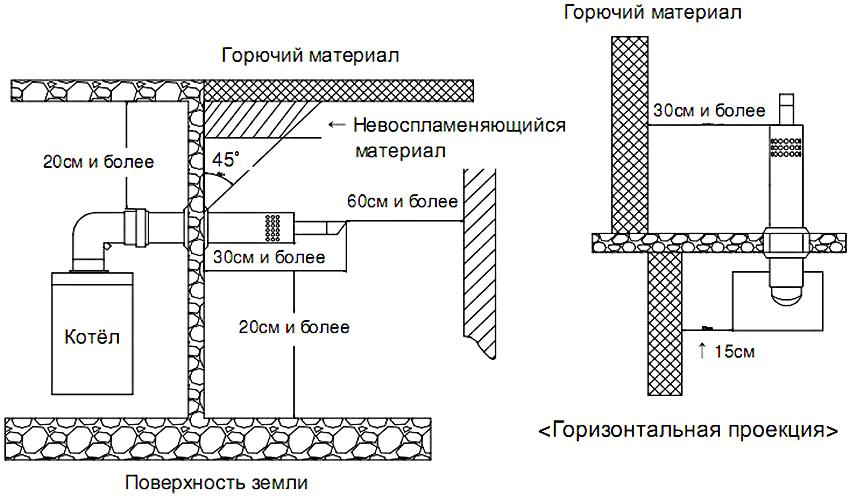

As a rule, the location of a gas boiler in a private house is planned on the lower floor in a separate room (boiler room). All elements of the heating system must be connected to each other strictly tightly. The basic rules for installing chimneys for gas boilers, regulating the technological procedure, are presented in the normative acts SNiP 2.04.05-91 and contain the following requirements:

- proper draft - ensures complete removal of exhaust gases;

- resistance to high temperatures;

- tightness of docking places - all components along the entire length of the chimney system must fit tightly to each other;

- the pipe in the place where it passes through the ceiling must be solid, without joints;

- condensate trap - the design of this element must ensure the collection and removal of liquid;

- if there are turns in the structure, revision hatches are arranged in these places to diagnose the condition of the chimney, clean it and drain condensate;

- the length of the branch pipe to the side should not exceed 1 m;

- possible permissible number of turns on chimneys - no more than 3;

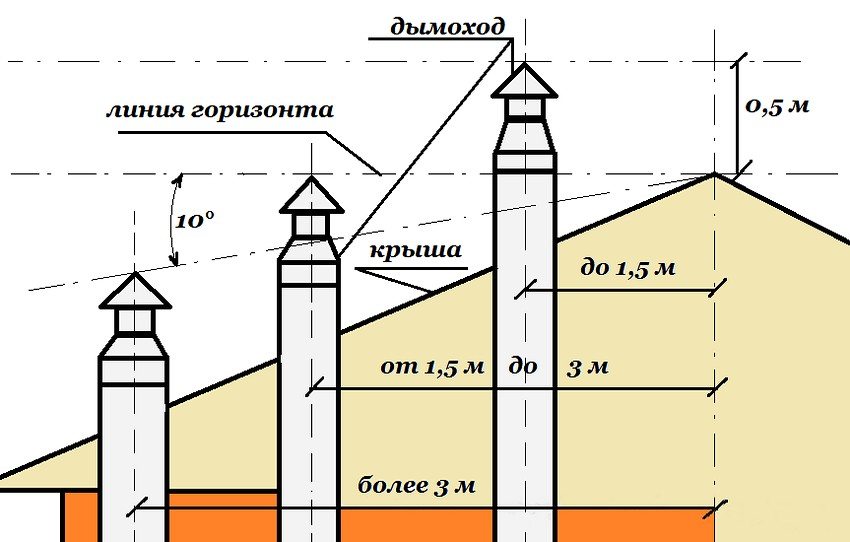

- the height of the chimney pipe must exceed the height of the roof (at the highest point) so that good draft is provided and no reverse occurs;

- the distance between the chimney pipes and the surface, which is made of non-combustible materials, can be at least 5 cm, and if the surface material is combustible, at least 25 cm.

Useful advice! Complete tightness of the chimney sections will not allow hot combustion products to escape from the system.

The procedure for arranging a gas boiler chimney in a private house

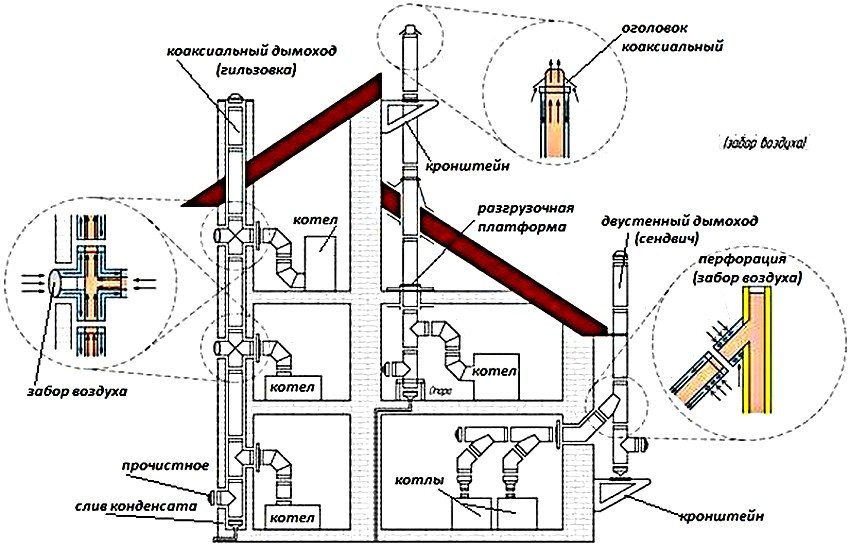

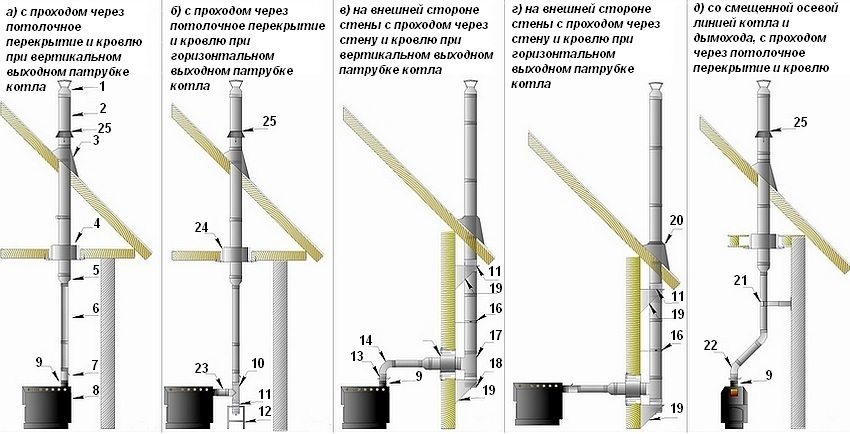

Depending on at what stage it is planned to install a chimney for a gas boiler, the exhaust system can be internal or external (remote). In cottages under construction, where the use of gas boilers is provided, internal chimneys are used, the placement of which is taken into account by the project. In houses of old buildings, when switching to heating by means of a gas boiler, the chimney is taken out.

You can compare the strengths and weaknesses of external and remote chimneys by looking at the table:

| Chimney type | |

| Remote | Interior |

| Complete thermal insulation of the chimney is required | Thermal insulation is only needed in the area that goes out |

| Safe operation is guaranteed subject to standards | The possibility of penetration of combustion products into the room is not excluded, high fire hazard |

| The chimney device is made of the same type of elements and is simple to perform | It is distinguished by a complex installation, since there is a need for a large number of components and components of the chimney |

| Availability in carrying out any kind of repair work and maintenance | Difficulty in carrying out maintenance and repair of the chimney |

The installation of the chimney of an internal-type gas boiler is associated with the construction of a foundation and a protective channel made of brick. Then the safety of operation will be ensured. Such systems are more efficient and the formation of condensation in them is minimal. In some cases, chimneys can be attached to the wall of the house behind which the boiler is installed.

The device of a remote chimney requires high-quality fastening and mandatory maximum insulation, since condensate in such structures is formed in large quantities.

The main stages of installing a chimney for an internal gas boiler:

- marking of places for the device of holes in the ceiling and roof of the house;

- chimney opening device;

- connection of the boiler branch pipe with the gas duct;

- installation of revision, tee;

The main types of assembly of double-walled vertical chimneys. Their device: 1 - head; 2 - sandwich pipe; 3 - steel roof passage; 4 - decorative ceiling throughput unit; 5 - start sandwich; 6 - modular pipe; 7 - rotary gate; 8 - boiler with vertical chimney; 9 - adapter; 10 - modular 90 degree tee; 11 - assembly site; 12 - floor support for the mounting platform; 13 - gate valve; 14 - modular 90 degree bend; 15 - wall passage; 16 - wall bracket; 17 - sandwich tee 90 degrees; 18 - plug with condensate drain; 19 - wall support for the mounting platform; 20 - passage roofing Master Flash; 21 - telescopic bracket; 22 - modular elbow 135 degrees; 23 - pipe 0.25 m (1.0 mm); 24 - minerite box (10 mm basalt cardboard); 25 - flange

- chimney pipe extension;

- reinforcement of joints with clamps;

- fastening the structure with brackets;

- thermal insulation of the outer part.

Useful advice! The location of the chimney system must be strictly vertical, without narrowing or widening the duct.

Chimneys for gas boilers from stainless steel

Chimneys made of steel can have a single-walled or double-walled design. Single-layer chimneys can be installed in heated rooms and used for casing brick chimneys. In three-layer systems, there is an insulating layer between the two pipes, which makes it possible to use them for both indoor and outdoor installation.

Due to the fact that the gas fuel contains impurities of sulfur, when removing waste products, its vapors have an aggressive effect, corroding the walls of the flue ducts. Therefore, in the production of stainless steel chimneys for gas boilers, heat-resistant and acid-resistant material of the AISI 316L brand is used. Its application greatly increases the service life of chimney systems.

Chimneys made of stainless steel have many advantages, such as low weight, resistance to fire and aggressive chemical attack

Of the weaknesses of the stainless steel chimney pipe for a gas boiler, a not entirely aesthetic appearance can be noted. The benefits include:

- resistance to corrosion and aggressive chemical composition;

- light weight, no need for a base device;

- incombustibility of the material - stainless steel does not melt even at a temperature of 500 ºС;

- modular design - factory production of a large number of tees, adapters and elbows allows you to build a chimney into any house;

- factory production of all elements of the steel chimney allows you to assemble and remove it at any convenient angle;

- absolutely smooth round inner surface - provides a minimum of obstacles on the way to the removal of combustion products;

- the possibility of installation in an already built house;

- quite affordable chimney price for a gas boiler.

When installing an external steel chimney, the probability of a dew point is high: if the outside temperature is low, the discharged vapors form condensation and a water lock is created. It clogs the channel, preventing the products from leaving, and thereby blocks the combustion process. This can be avoided by placing the pipe in the lined chimney channel made of brickwork. This technique will also solve the aesthetic side of the building.

Another option to avoid the formation of a water plug is to use a sandwich structure of two pipes, one of which is protected by a layer of basalt wool. Such a remote chimney system no longer needs additional insulation. The diameter of the chimney for a gas boiler is selected so that it matches the section of the outlet of the equipment.

Useful advice! Stainless steel chimneys are easy to maintain, however, it is necessary to have the system inspected by a specialist once every 3 years.

Rules for installing a chimney for a gas column

The key to the safe operation of a gas water heater is a correct exhaust system. For the column, chimneys are used that remove the combustion products into the flue duct or directly into the atmosphere. The following types of pipes are used to remove exhaust gases:

- corrugated pipe - easy to install, material flexibility allows

stretch it up to 2-3 m in length, and also lengthen it by connecting several sections of the corrugation; - aluminum pipe - easy to install, resistant to condensation, needs additional thermal insulation;

- coaxial chimneys - the price of such systems can be reduced due to the possibility of leading the pipe through the wall. This saves material and installation costs. The main advantage of such a chimney is that air from the room does not participate in the operation of all equipment.

Basic requirements for the installation of chimney pipes for gas water heaters:

- the operation of devices is prohibited without a chimney securely fixed in it;

- the draft inside the chimney system must be constant;

- the pipe material must be non-combustible, resistant to corrosion, condensation and high temperatures;

- the outer section of the chimney must be vertical;

- the structure must be sealed to avoid the ingress of carbon monoxide into the room;

- the chimney must be installed in an open area for quick troubleshooting if necessary;

- the chimney must be at least 0.5 m above the roof level;

- It is strictly forbidden to use ventilation systems, the space between floors, attics for the removal of combustion products.

How to check the draft in the chimney of a gas boiler

Draft is one of the main indicators of the correct functioning of the chimney. Its effectiveness depends on the following parameters:

- chimney cross section - heated gases are removed faster with a smaller cross section, but if it is too small, there is a threat of combustion products entering the room. If the chimney cross-section is unreasonably large, a reverse draft effect may be created;

- accumulation of a large amount of soot on the walls of the barrel - due to this, the working section is reduced, which leads to a decrease in the rate of carbon monoxide removal;

- a large number of turns in the system - any of the turns of the pipe slows down the movement of exhaust gases;

- insufficient tightness of the chimney - the presence of small cracks, gaps promotes the penetration of cold air into the system, which prevents the rapid removal of smoke;

- Weather - High humidity and low atmospheric pressure can reduce thrust.

There are several methods to check the condition of traction. If the diagnostics is carried out by professionals, they use an anemometer - a device for measuring the speed of gas movement. In everyday life, they use the so-called folk methods:

- visual inspection - if there is smoke in the room, then there is a reverse draft;

- using a thin sheet of paper - it is brought to the viewing window: the stronger the paper is attracted, the better the thrust;

- candle flame - a lit candle is brought to the channel and the flame is blown out. The direction of the smoke from an extinguished candle towards the chimney indicates good draft.

Important! The draft in gas boilers should be checked with the equipment turned off.

Depending on the reason for which there is weak traction, measures are taken to improve it. Cleaning the channel from soot is carried out using a special device consisting of a ruff, a sinker and a rope. The device is lowered into the canal and with forward movements is cleaned along its entire length. To achieve complete sealing of the brick chimney, it is necessary to eliminate all cracks resulting from the destruction of the masonry.

Coaxial chimney for a gas boiler: installation rules, advantages, installation

The main advantage of installing a coaxial chimney for a gas boiler is that such a chimney not only removes exhaust gases outside, but also provides the combustion chamber with air from the street. Thanks to this, the room does not need additional ventilation, and the air in the house remains capable of maintaining the health and efficiency of the people there. Equipment with such a discharge of combustion products is called a gas boiler without a chimney.

Coaxial chimney design

The design of the coaxial chimney is based on two pipes of different diameters, one of which is located inside the other. The inner pipe is designed to remove waste materials to the outside. Through the outer pipe, or rather, through the space between the inner and outer pipes, air is taken from the outside, which is used for gas combustion. Thus, the chimney copes with several functions at once:

- increased safety of the chimney - the incoming air from the street heats up, and the outgoing combustion products cool down;

- increase in boiler performance - the efficiency of the equipment increases due to the fact that the air enters the combustion chamber already heated;

- maximum gas combustion - due to the fact that the boiler efficiency increases, complete fuel combustion is achieved;

- environmental friendliness of the heating system - the entire working cycle of gas equipment takes place outside, which ensures the comfort and safety of heating.

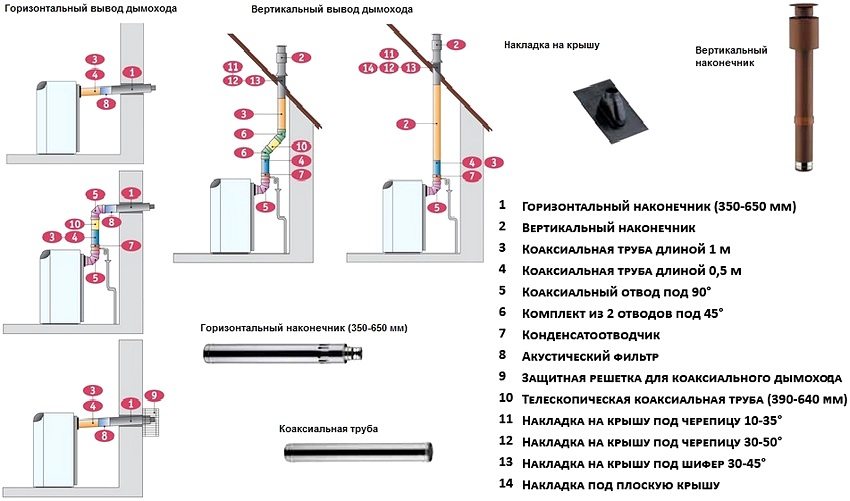

For the manufacture of a chimney, round pipes are used: the outer pipe with a diameter of 100 mm is made of steel with a thickness of 1-2 mm, the inner one is made of an aluminum alloy. The diameter of the latter is 60 mm. Pipes with such a ratio of diameters are used in coaxial chimneys for wall-mounted gas boilers and floor-standing devices with a closed-type combustion chamber. To avoid contact of pipes with each other, jumpers are installed along their entire length.

According to the installation method, coaxial type chimneys can be horizontal and vertical. The horizontal version is more popular due to its easy installation. In the case when it is technically impossible to mount the system horizontally or the distance from the boiler to the outer wall exceeds 4 m, they resort to installing a vertical coaxial chimney. It should be noted that its installation is more complicated.

Advantages of coaxial flue gas systems

Coaxial chimneys are used for various gas equipment in which the combustion chamber has a closed design. These are floor and wall gas boilers, gas flow heaters (columns), convectors and other devices.

It is worth noting the main advantages of using coaxial chimneys over other types of gas exhaust systems:

- natural heat exchange - heating of the incoming air and cooling of the outgoing gases occurs due to the design of the pipe, which, in turn, prevents the wall from heating up much;

- increasing the productivity of the gas equipment itself;

- compactness - the chimney is neatly mounted and does not take up much space, which allows it to be used not only in private cottages, but also in high-rise apartments;

- safety of operation - there is no lack of oxygen in the air of the room where the boiler is installed, since the contact of air from the room with excreted substances is completely excluded;

- ease of installation - allows you to reduce the cost of installing a coaxial chimney.

Useful advice! If you have purchased a wall-mounted gas boiler for autonomous heating of an apartment, using a coaxial chimney for it is the safest, since combustion products are removed not into the ventilation channel, but directly into the atmosphere.

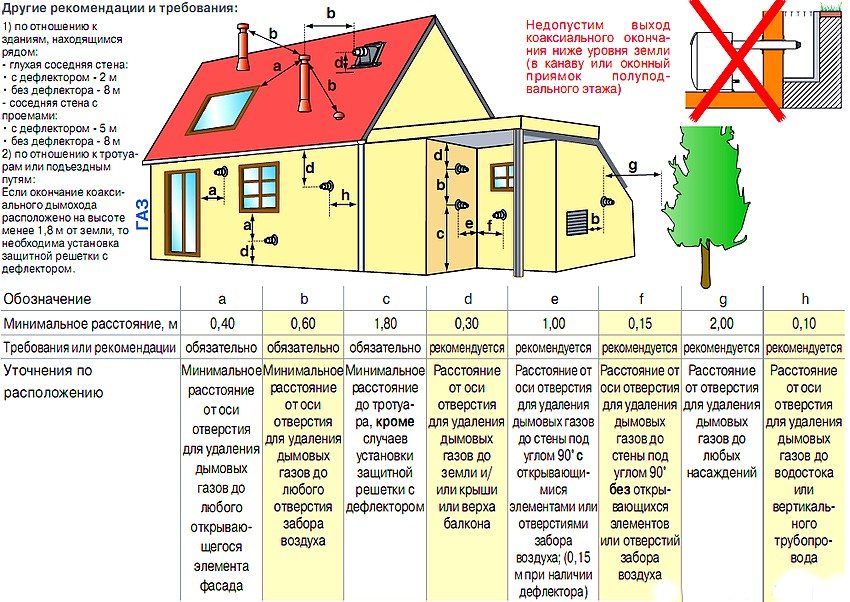

Requirements for installing a coaxial chimney

As with any gas equipment, specific requirements of SNiP 2.04.05-91, section 3 "Heating" are imposed on the installation of coaxial chimneys; 2.04.08–87, as well as the prescriptions regulated by the Safety Rules in the Gas Industry. They can be different depending on the installation method of the coaxial chimney: horizontal or vertical.

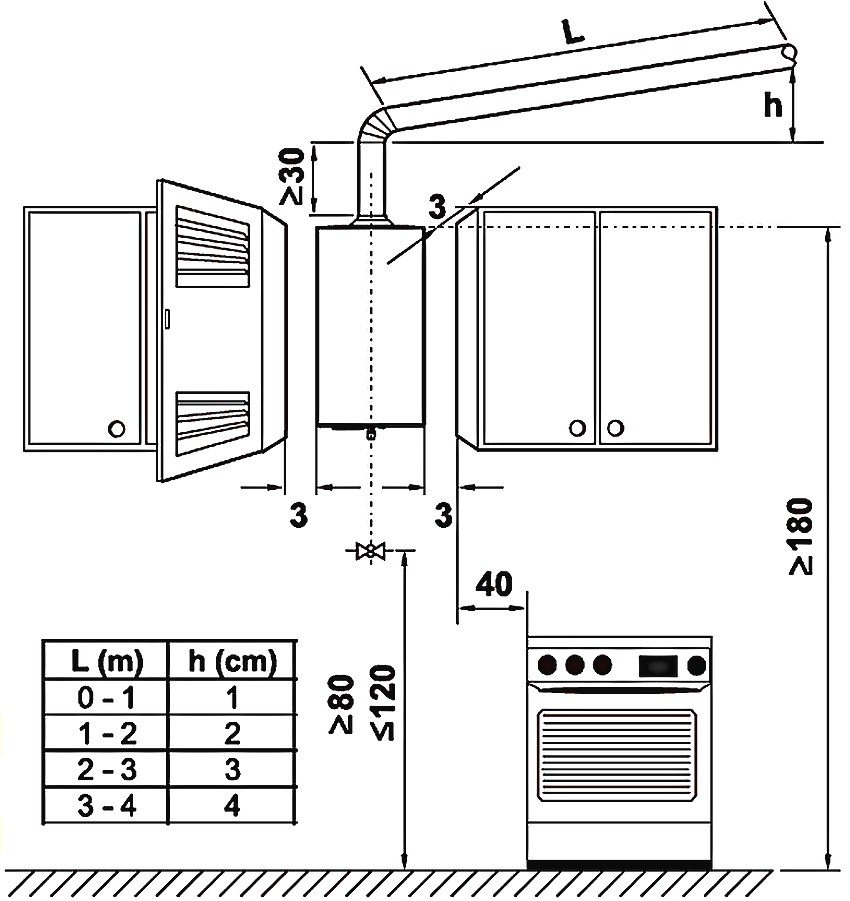

For any type of installation, there is a general requirement for the maximum length of the coaxial chimney for a gas boiler: it cannot exceed 4 m.When it is required to conduct the chimney system at a considerable distance, special coaxial models with dimensional standards are used.

Recommendations and requirements for the installation of a coaxial chimney for gas boilers with a capacity of less than 70 kW

When a vertical coaxial chimney for a gas boiler passes through the ceiling and the roof, an adapter is used, the design of which is provided by the manufacturer specifically for this system. This also applies to coaxial flue extensions when it is required to install a system of the required length. Tightness in places where pipes pass through the ceiling is provided by a special head - terminal. It also prevents precipitation from entering the system.

The horizontal method of installing a coaxial chimney is used, as a rule, for wall-mounted gas equipment.To avoid the ingress of condensate, it is necessary to maintain a downward slope of the chimney from the boiler of 3 to 5%. There are standards for the location in the outer wall of the smoke ducts for the chimney. So, if the hole is supposed to be in the wall next to the window, the distance to the window should not be less than 0.5 m, if above the window - not less than 0.25 m.

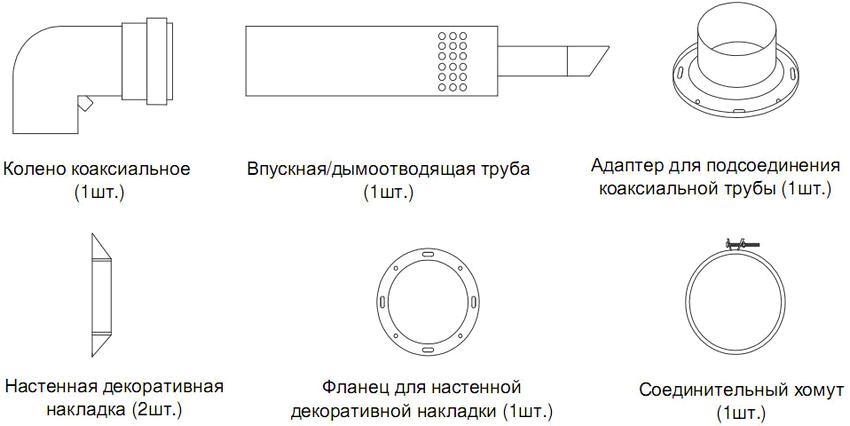

Many manufacturers of gas equipment include in the delivery a pipe for removing combustion products. If you bought a coaxial chimney for a gas boiler together with the equipment, you need to check that the kit contains a horizontal part of the pipe (usually about 1 m long), a branch, a terminal (head), a set of gaskets, a membrane. If, when installing the pipe through the wall, it is necessary to bypass any protrusions or fittings, bends and bends are used.

Useful advice! It is necessary to provide protection of all leads and inlets on the coaxial chimney from the ingress of foreign objects.

Coaxial chimney for a gas boiler in a private house: how to do it yourself

Before installing a coaxial chimney with your own hands, you must familiarize yourself with the installation and operation manual of the purchased gas equipment. Due to the specific design of the coaxial pipe, the installation of a chimney for a wall-mounted gas boiler must be done with extreme caution. Avoid the formation of dents or other damage on the pipes, leading to the depressurization of the system.

To complete the installation work, you will need the following system elements:

- pipe with flange;

- crimping clamps;

- coaxial knee;

- adapter for connection to the boiler;

- an extension with sealing cuffs (if required);

- decorative overlays.

According to the requirements for the installation of the chimney, a hole of the required diameter is arranged in the outer wall. If there is a window opening in the wall, place the opening no closer than 0.5 m from the window. When connecting the chimney to a gas boiler, first connect the adapter, and then all the links assembled into a single structure.

The pipe is led out through a hole in the wall, observing a slope from the boiler. If it is necessary to bring the chimney to the wall, the structure is fixed with clamps. The gaps between the wall hole and the inserted pipe are blown out with foam or sealed with mineral wool. After that, these places are closed with decorative rings.

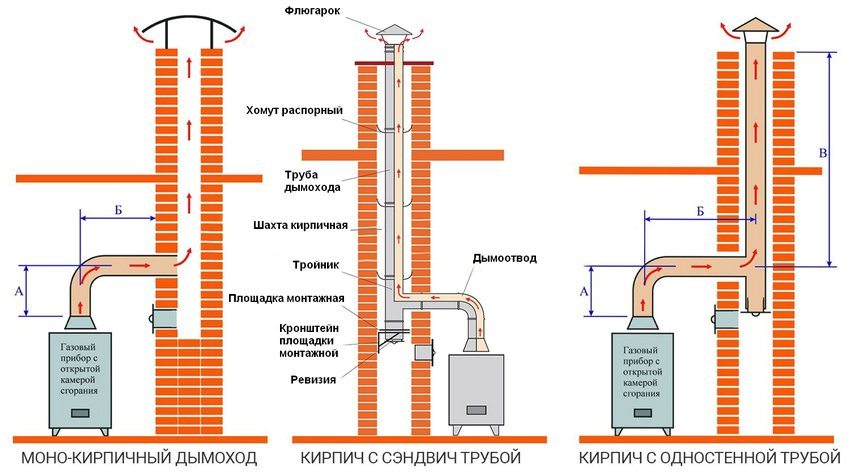

DIY brick chimney

The construction of the brick chimney is an exclusively vertical channel with a square or rectangular section. For laying a brick chimney, a solid ceramic brick is used, which is laid on a mortar. The outer section of the canal is laid out with ordinary bricks corresponding to the style of housing construction, which can be seen in numerous photos of brick chimneys. If the house is tiled with stone or plastered, you can arrange the chimney in the same way.

Brick chimneys for gas boilers: installation requirements

Before laying out a brick chimney for a boiler, it is necessary to erect a foundation, the height of which should be at least 0.3 m.The dimensions of the base along the perimeter should protrude beyond the contour of the channel itself by at least 0.15 m.If the chimney is located in part of the outer wall, its foundation should be flush with its base. Do-it-yourself bricklaying of a chimney made of bricks (video instructions confirm this) begins at the stage of building the walls of the house.

Requirements for brick chimneys:

- the smoke channel should be vertical, without ledges, narrowed and widened sections;

- the thickness of the brickwork for the chimney is taken taking into account the exclusion of freezing;

- the minimum allowable cross-section of the chimney ducts is 14 x 14 cm, which corresponds to the size of half a brick, taking into account the seam;

- the size of a brick chimney, the height of which is less than 5 m, should be increased to a channel section of 14 x 20 cm;

- the construction of the chimney is carried out in the walls between the heated rooms, which will prevent its cooling and reduce the draft;

- tightness - the laying of a brick chimney is carried out with a dressing so that the vertical seam of the previous row is overlapped by the brick of the next one;

- the inner surface of the channel should be smooth;

Useful advice! To achieve a flat and smooth inner surface of the channel, use special templates when building a brick chimney with your own hands.

- the distance between adjacent chimney ducts should not be less than 5 average external pipe diameters;

- if ventilation ducts are located next to the chimney, their height should be equal to the height of the chimneys.

To reduce construction costs, as many channels as possible should be placed in the common chimney. In this case, the nearby chimney and ventilation ducts will heat each other, which will generally improve the functioning of the chimney.

Preparation of mortar for laying a brick chimney

The composition of the mortar for laying a brick chimney is selected taking into account which section of the pipe is laid out: external or internal. For the construction of the external channel, the same mortar is used as for the masonry of the bearing walls of the housing construction. It is prepared from cement, sand, water and can harden in air and water. The mixture is prepared in such a volume that it was worked out within an hour, as it quickly sets.

In order for the mixture not to collapse under the influence of an aggressive environment, it is recommended to add special additives to it, which increase its plasticity, strength and acid resistance. Thanks to these additives, it is possible to improve the quality of the masonry itself, to increase the speed of construction and the durability of the work performed.

The preparation of a mortar for a brick chimney passing inside a house is based on the use of refractory clay and chamotte in a 1: 1 ratio in its composition. Such mixtures do an excellent job with high temperatures, they are durable and do not emit harmful substances. To give the clay mixture strength, you can add table salt to its composition (about 120-150 g per bucket).

Useful advice! The strength of the chimney mortar can be increased by adding Portland cement in a proportion of 1 kg per bucket.

When laying a brick chimney with your own hands, you can purchase ready-made mixtures that are heat-resistant and acid-resistant. Preparing the solution yourself can reduce the cost of erecting a chimney.

It is quite possible to build a brick chimney with your own hands - the video below will help you get acquainted in detail with the stages of building a structure, taking into account all the basic requirements.

The feasibility of using a brick chimney for a gas boiler

Taking into account the advantages and disadvantages of brick chimneys, it is possible to draw conclusions regarding their use in combination with gas boilers. Their advantages include:

- the likelihood of using an already existing chimney, which reduces chimney costs;

- the ability to operate in conjunction with gas equipment with an open combustion chamber;

- acceptable cost of materials for the construction and decoration of the structure.

The durability of brick channels is observed only when they are used for fireplaces or stoves.If they are used for gas boilers, due to the low temperature of the combustion products, condensation will form on the channel walls, and the harsh operating conditions in an aggressive environment will lead to the gradual destruction of brickwork and deterioration of performance.

In addition, the requirements for such chimneys are more stringent:

- impeccable masonry - if the skills are not enough, it will be necessary to invite a qualified bricklayer to work, which will cost a lump sum. Prices for work: rough brick chimney masonry from 6000 rubles per 1 m³, facing masonry - 2500 rubles. for 1 m²;

- impossibility to perform a complex configuration of the channel (if you need to bypass, for example, a beam in the floor);

- the use of the old channel should be carried out using a sleeve;

- the need for thermal insulation.

The disadvantages of such a system include a decrease in traction during the heating of the brick. Thus, the correct chimney for a gas boiler will be a brick channel together with a steel or ceramic liner. The photo of brick chimneys shows that the liners are equipped in the process of laying the channel. In this case, it is necessary to leave a gap between the liner tube and the brick surface. This is necessary so that the pipe can move inside the channel.

Chimneys for gas boilers: prices for various types of pipes

When planning your budget when purchasing chimneys, you should take into account the length and diameter of the channel, the presence and number of turns, as well as the material from which the pipes are made. There are no fundamental differences in the design and cost of chimneys for floor-standing gas boilers and wall-mounted appliances. A stainless steel chimney will cost more than a brick chimney, but a steel chimney is easier to install, making installation costs affordable.

When soot accumulates on the inner walls of the chimney, it becomes difficult to remove carbon monoxide from the room

You can buy a chimney for a gas boiler at specialized sales points and in online stores that sell these products. A large assortment of fittings, fittings, tees, adapters, plugs and other necessary construction details is also offered for sale. Given the convenient sorting of products by category and model, you can quickly find and order the desired product.

The cost of 1 m of a single-loop stainless steel pipe with diameters of 100, 110, 115, 120 mm is 650 rubles, the same pipe with a diameter of 140-150 mm will cost 750 rubles. The price of a stainless steel elbow with a 90 ° rotation angle for a pipe with a diameter of 110-120 mm is 550 rubles. with a metal thickness of 0.6 mm. You can buy 1 m of stainless steel sandwich pipe with a diameter of 140-230 mm for 1900 rubles.

Useful advice! You can save on the purchase of high-quality and durable chimney pipes if you place an order during the discount period.

The price of a coaxial chimney for a gas boiler with a diameter of 60-100 mm and a length of 1 m, sold in a horizontal set, is 3500 rubles. The purchase of a Baxi coaxial chimney - a world manufacturer of modern heating systems - will cost 4200 rubles. The complete chimney kit for a wall-mounted gas boiler includes a 75 cm pipe with a diameter of 60-100 mm, a 90 ° bend and a tip. All products are guaranteed.

Competent installation of any household appliances is the key to its safe and long-term operation. Especially when it comes to gas equipment. The installation of a combustion products removal system for gas boilers requires preliminary engineering calculations and qualified implementation.