Installation of a metal-plastic system is not the final stage of the window replacement process. To prevent freezing and the formation of condensation, the walls of the window opening are finished. To date, sandwich panels for slopes, which are characterized by excellent technical, operational qualities and ease of installation, have proven themselves from the best side. You can learn more about this building material from the article.

Content

- 1 What are window slopes: the purpose of a structural element

- 2 What are the requirements for the material for the slopes

- 3 Sandwich panels: a modern versatile material

- 4 Sizes and versions of sandwich panels for windows

- 5 Sandwich panels for slopes: advantages and disadvantages of the material

- 6 Comparison of sandwich panels and insulating glass: which is better

- 7 How to install sandwich panel slopes

- 8 How to choose slopes: the best finishing option

- 9 Features of plasterboard slopes for window openings

- 10 Features of slopes for gypsum fiber windows

- 11 Plastic panels for window slopes: material features

What are window slopes: the purpose of a structural element

The first step is to figure out what the slopes are and what is their main purpose. This structural element of the window opening is the inner wall of the niche surrounding the window frame on both sides. The installation of the window profile is not the final stage. For a presentable view of the window system, it is necessary to install good fittings for the PVC window. It includes not only handles, mechanisms and hinges. The assortment of elements also includes window slopes for profile decoration.

Important! It is imperative to finish the slopes to exclude the occurrence of many negative factors that will negatively affect the appearance, service life of the window system and the microclimate of the room.

Finishing the niche will eliminate the accumulation of condensate and freezing of the window frame. It is able to protect the seams between the frame and the window opening from destruction, therefore it is important to carry out both internal and external facing of the slopes. The protection of niches can improve the thermal insulation properties of the premises, preventing the penetration of cold masses into the street and the exit of heat energy outside.

Important! Window slopes are also the decorative design of the window system.

As a finishing of slopes, you can perform plastering, plastering the surface with plasterboard, plastic panels. The most popular and not laborious way today is the use of sandwich panels for slopes. This material not only gives the window a finished appearance, but also, due to the presence of internal insulation, provides a warm temperature regime in the room.

When covering slopes with plasterboard, a large consumption of material will be required, which is due to its fragility. Plastering the side elements is a laborious and time-consuming process that requires certain skills in order to ultimately obtain a smooth surface. In addition, such work is associated with significant pollution of the surrounding space.

Useful advice! The most harmonious is the combination of a window and slopes made of the same material.

What are the requirements for the material for the slopes

Regardless of the technology of protective and decorative finishing of the window opening, the finished slopes must meet certain requirements. The design is obliged to resist different mechanical influences without loss of performance and aesthetic characteristics. It is necessary that the slopes are moisture resistant. This is especially true for outdoor structures. The material should be characterized by durability, immunity to ultraviolet rays and high humidity, temperature extremes.

Important! For waterproofing the frame, an ebb for a PVC window is attached from the outside.

The protective structure of the window should not deform over time. It must be distinguished by a long period of operation without losing its original properties. Due to the fact that the sloping panel covers the installation gap, this is the main source of heat loss. It is necessary that the material is characterized by low thermal conductivity, which will provide a good level of heat and sound insulation in the room.

The selected slope finishes must be aesthetically pleasing. A neat appearance is characteristic of a high-quality cladding. It is necessary that the finish is in harmony with the window profile and fits into the interior design of the room. The fittings for Maco windows have proven themselves on the best side in this matter.

Sandwich panels: a modern versatile material

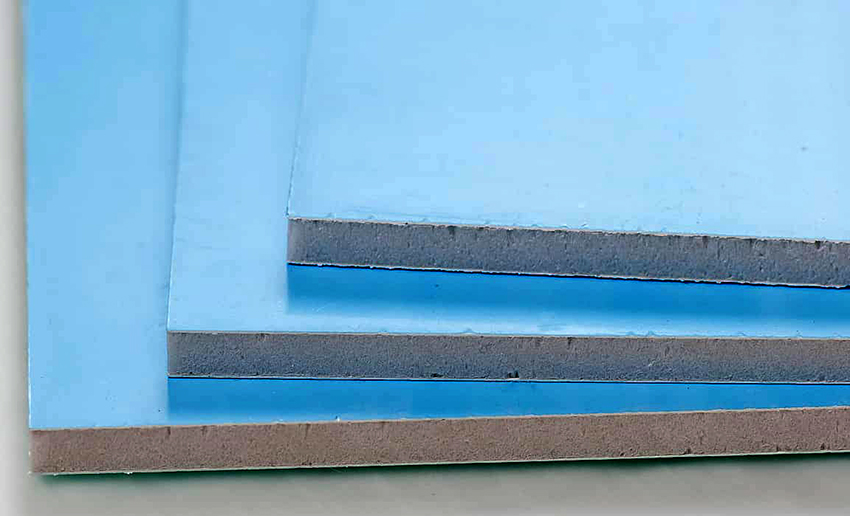

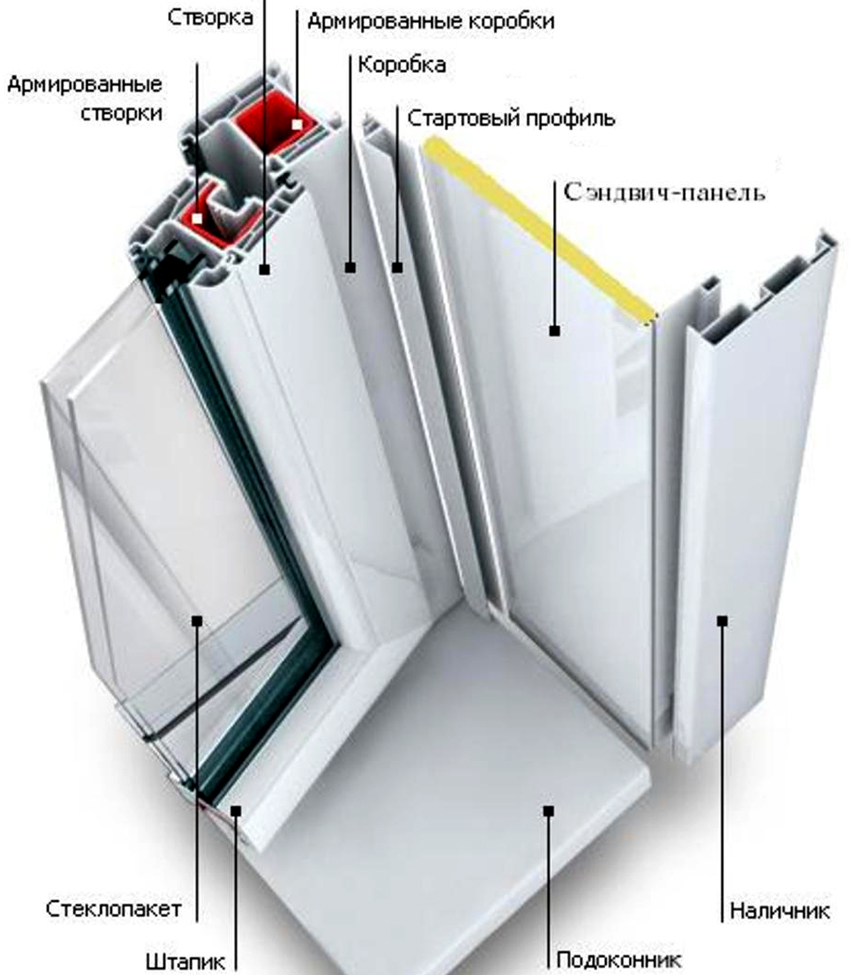

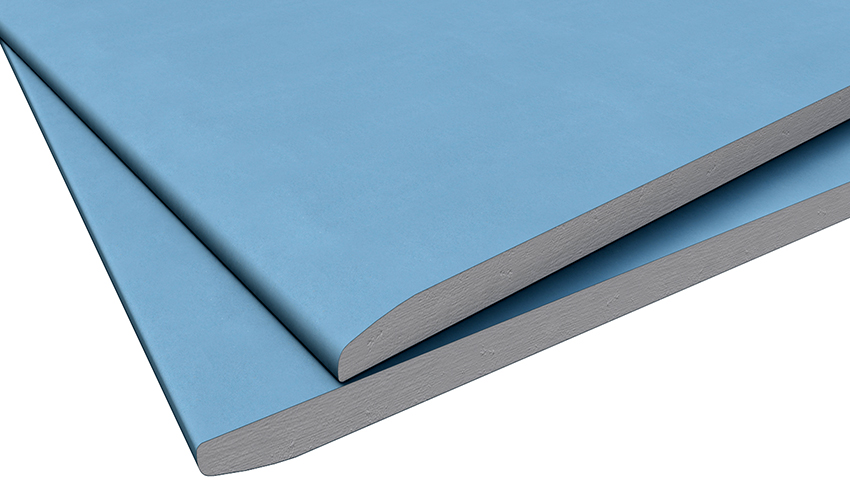

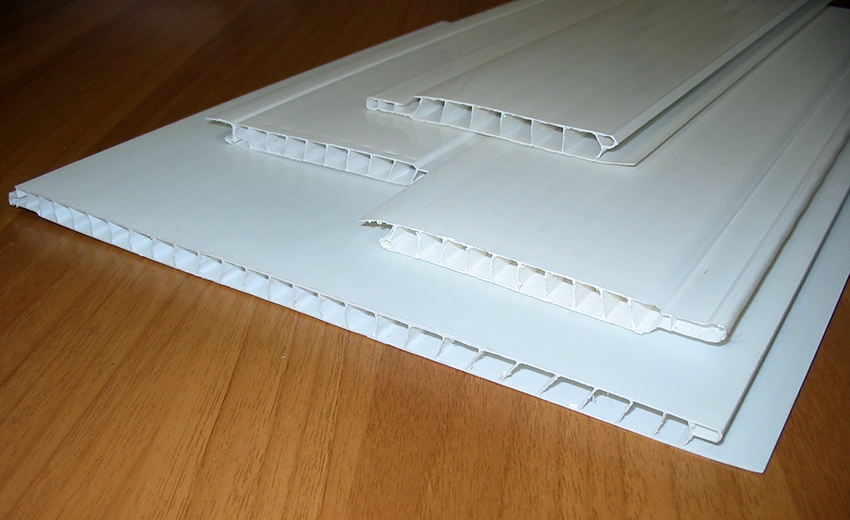

Plastic sandwich panels are sheets of extruded polystyrene foam. The thickness of the products is 9 mm. Canvases can be finished on both sides with polyvinyl chloride film 1-1.5 mm thick. The internal structure of sandwich panels is represented by the following elements: a J- and C-shaped profile for fixing the inner border of the slope, a directing wooden beam, an insulating material and an upper decorative panel.

As a heater in the composition of sandwich panels, polyurethane foam, free-foam plastic, extruded polystyrene are used, with which all cavities are filled. The last option is characterized by the best thermal resistance. Insulation blocks the flow of cold air masses from the street into the room.

The top decorative panel can be made of laminated plastic, rigid or foamed PVC sheet. The first type of coating is made by resin impregnation of a multi-layer material in the form of pressed decorative or kraft paper.

Rigid PVC sheet is represented by a white sheet covering, the thickness of which is within 0.8-2 mm. The special coating can be glossy or matte. The density of such a panel reaches 1.4 g / m³.The internal structure of a foamed PVC sheet has a porous composition, therefore such a coating is less dense and has good thermal insulation.

The outer layer can be painted in any color, which makes it possible to choose a shade that suits the window and room design. The most popular is the white PVC sandwich panel for slopes. A yellow shade of panels can often be found. Products made in a natural style, imitating wood, fit harmoniously into the interior.

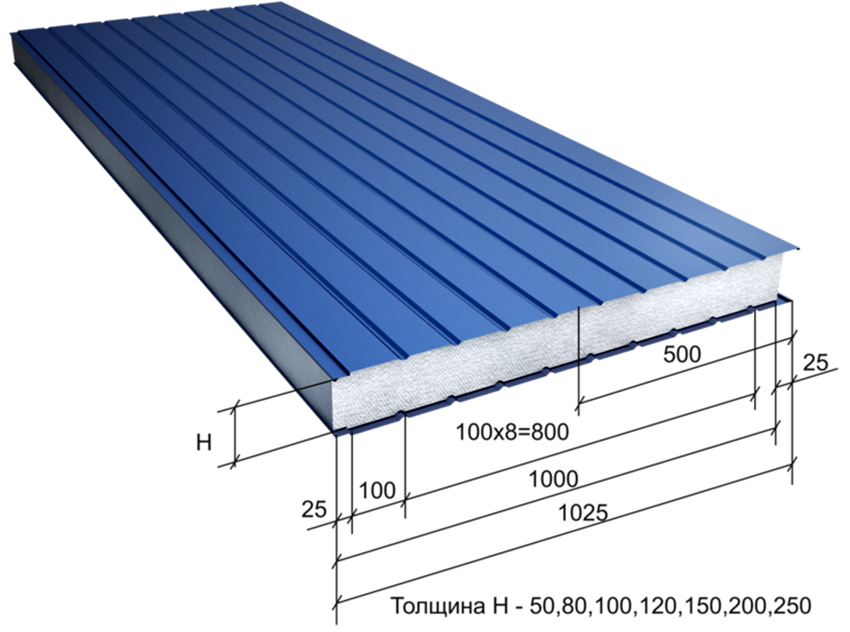

Sizes and versions of sandwich panels for windows

Sandwich panels are produced in two variations: ready-made, where the material does not require assembly and is intended to be fixed with an adhesive, and disassembled, when it needs preliminary fixing of the component elements by using self-tapping screws.

Plastic window sandwich panels can be made in one-sided and double-sided form. In the first case, one side of the product is rough, in the other - the front, which has a large thickness. For a double-sided product, both sides are front.

Important! Sandwich panels can be used for both plastic and wooden windows.

The dimensions of the sandwich panels for slopes are determined by the equipment on which the material is manufactured. Despite this, there are standardized parameters. Products have a maximum length of 12-16 m. Greater value can lead to damage to the structure of the element under its own weight during installation. In addition, long products are difficult to transport. The width of the sandwich panels reaches 100, 115, 199 and 120 cm. The thickness is in the range of 5-35 cm. The most popular are white sandwich panels for slopes 3000x1500x10 mm.

Products are often made to individual sizes. Some options for sandwich panels can be used for finishing the slopes of not only windows, but also doors. In this case, their length is 3 m, width - 115, 130 and 150 cm. The thickness of the products is 10, 24, 32 and 40 mm. Sandwich panels of 3000x1500x10 mm used for slopes are in great demand, the cost of which starts at 900 rubles / piece.

Sandwich panels for slopes: advantages and disadvantages of the material

Slope sandwich panels have many advantages. This finish contributes to the creation of good thermal and noise insulation. Sound absorption index is 21 dB. The material has a high level of vapor permeability. Such a coating will not get wet from moisture, will not deform or crack. Sandwich panels show increased resistance to mechanical damage, negative effects of sunlight, resistance to mold and mildew formation.

Important! For a reliable connection of the material with the slope, polyurethane foam is used, which is also an additional insulation.

The design is characterized by a low weight, which is only 4 kg with a product thickness of 24 mm, so it does not have a significant effect on the elements of the window opening and does not require the use of reinforced fasteners.

Sandwich-paneled slopes do not need constant maintenance. Any contamination can be easily removed with a sponge and soap solution, which will not damage the structure of the structure. The material is absolutely harmless to human health. During operation, no harmful components are released into the atmosphere.

Sandwich panel slopes do not need additional design, since they have a pleasant texture, which is similar to the surface of a plastic window.The demand for the material is also associated with the reasonable price of sandwich panels for window slopes, which can be bought at any hardware store.

However, such sandwich slope panels have their drawbacks. The material is susceptible to high temperatures, which can lead to deformation changes and yellowing of the product surface. Sandwich paneling is not performed if there is a small gap between the wall and the hinge. This will cause the structure to fit loosely against the niche. Incorrect installation can lead to cracks and gaps.

Comparison of sandwich panels and insulating glass: which is better

The design of a balcony or loggia is often accompanied by the joint installation of metal-plastic glazing and plastic sandwich panels. The latter are often used for cladding blind sections, which can be located at the bottom of the balcony door frame, reaching the floor, or for finishing the side sections. This is done to limit light transmission in specific locations. In addition, due to their good strength properties, sandwich panels are considered the best option in comparison with a glass unit in terms of safety.

Installation of sandwich panels instead of a glass unit allows you to make the side sections of a balcony or loggia deaf, which is necessary for installing cabinets or other items that should not be visible from the outside. This design can subsequently be used as a ventilation outlet, since a number of holes can be made in it.

However, using panels instead of insulating glass has other advantages. The material is resistant to various negative influences. It is immune to ultraviolet radiation, moisture, chemicals, mechanical and shock loads. The panels are durable, reliable and durable. They do not need much maintenance, which is not the case with traditional glazing. You can also choose a different color design of the material, which is clearly shown in the photo of the sandwich panels.

Important! The "Salamander" window profile is very popular today, and it is possible to order sandwich panels with a protective film, which not only improves the decorative qualities of the material, but also increases its strength characteristics.

Since the plastic sandwich panel is represented by a multilayer material, inside which there is a layer of insulation, such a sheathing is characterized by good heat-insulating and sound-absorbing properties.

How to install sandwich panel slopes

The process of finishing window slopes with sandwich panels consists of several stages. To complete the work, you will need the following tools and materials: PVC profile, tilting and starting profiles, liquid nails, sealant, concrete primer, plaster, antifungal agent, building level, tape measure, mounting knife, screwdriver, self-tapping screws, brush, spatula, sandpaper ...

Installation of slopes from sandwich panels is carried out in three ways: liquid nails, polyurethane foam or a frame made of wooden blocks can be used. Panels, in turn, come in two and three layers. The last option is PVC coated on both sides. Such panels are installed exclusively on a wooden frame, since they are characterized by increased rigidity. It is pointless to fix them with liquid nails to the wall, since the PVC back side has a low adhesion rate.

Related article:

Do-it-yourself slopes on installed plastic windows: video and installation instructions

Comparative characteristics of various options for finishing window blocks, installation of drywall.

Installation of sandwich panels in a window on wooden slats consists of the following algorithm of actions. The slopes are measured first. The obtained data is transferred to the panels, after which blanks are made using a sharp knife. Panels can also be cut with a circular saw with a small tooth pitch, which eliminates the possibility of delamination or cracking of the product.

Important! The sandwich panel can be cut at a temperature not lower than 5 ºC, lower values lead to fragility of the material.

Further installation of sandwich panel slopes into the window

From the outside of the window frame, along the edge, fasten the mounting rails, which form a complete contour. The correctness of installation is controlled by the building level. Wooden elements must be made from dry wood. Otherwise, if there is excess moisture, the slats will dry out, which will lead to deformation of the structure. Before fastening, they must be treated with special moisture-repellent compounds.

The next step is to attach the starter profile to the plastic frame. The gap that has formed must be filled with polyurethane foam or mineral wool. Sandwich panels used for finishing slopes are inserted into the grooves of the profile. They are not glued with liquid nails or foam, but are nailed down with a construction stapler. The staples are capable of piercing the outside of the products, therefore, with this installation option, only three-layer products are used.

Helpful advice! It is necessary to purchase a starter profile from the same manufacturer that made the sandwich panels.

If the starting element is not used, the finishing of the slopes with sandwich panels is carried out by fixing the material with an adhesive. In this case, the inner corner is treated with a sealant in order to hide possible defects.

The sequence of installation of PVC sandwich panels on liquid nails

Consider the technology of installing slopes from sandwich panels on liquid nails. The first step is a thorough cleaning of the slopes with the removal of the old coating, dirt, and the remains of polyurethane foam. The base must be perfectly flat, therefore, all defects should be eliminated with a plaster mixture. All cracks, crevices are sealed with this material, the surface is smoothed. The process is controlled by the building level.

After the plastered surface has completely set, it should be treated with a primer, which is intended for porous coatings. The procedure is carried out for further reliable adhesion of the panels to the base. After drying, the surface is treated with a special antifungal compound. The dried base is ready for sandwich paneling.

Before the installation of sandwich panels, measurements are taken of each slope in order to prepare products of appropriate dimensions. The trimming of the trim is made with a cutting object in the form of a mounting knife. The panel should be laid on the floor, then marked with a tape measure and a pencil. With a sharp knife blade, you need to go through the marks several times. After trimming, the edges of the finished workpiece are processed with sandpaper to remove burrs.

The first step is to install side slopes from sandwich panels with your own hands. The starting profile is fixed in the wall near the window using self-tapping screws with a pitch of 15 cm. A strip of liquid nails in a zigzag design is applied to the prepared panel in the center and in straight stripes along the perimeter of the product. The workpiece is inserted into the starting profile with one edge and firmly pressed against the slope. The installation of the second side and top panels is carried out in the same way.Components must be installed with minimum gaps between them.

Important! If the starter profile is not used when finishing the slopes from PVC panels, the sandwich element is mounted close to the window. It is brought in 1 cm deep, fixing it with polyurethane foam.

To make the window opening look more aesthetically pleasing, it can be trimmed with an edging profile along the entire perimeter. To achieve a neat appearance, the joints in the corners must be trimmed at a 45 ° angle. To mask butt joints, you can use liquid plastic or white sealant.

Do-it-yourself installation of sandwich panels on foam

Slopes from sandwich panels for plastic windows can be mounted using polyurethane foam. For this, a multi-layer type of material with two stiffeners is selected. At the first stage, measurements are taken. The final look of finishing the window opening depends on the accuracy of this process. Based on the results obtained, the products are marked, in accordance with which the panels are cut with a sharp object.

A starting profile is mounted to the joining section between the wall and the window frame using self-tapping screws with a pitch of 10-15 cm. Finishing of the slopes with sandwich panels starts from the upper bar. It is inserted into the groove of the starting profile. The resulting gap between the wall and the PVC element is filled with polyurethane foam. The material should be applied very carefully, since the foam can double in the process of drying.

Helpful advice! It is better to choose a professional type of polyurethane foam, applied to the surface in a small layer.

The installation of a plastic sandwich panel is carried out, which is carried out using masking tape. Next, the side slopes are clad in the same way. After the polyurethane foam has completely dried, the excess material is cut off, the structure is ready for further use.

How to choose slopes: the best finishing option

There are several options for finishing slopes. For this, materials such as plaster, drywall, gypsum fiber, plastic panels and sandwich panels can be used. The price for window slopes of the latter type of material is the highest compared to other options.

The traditional way of finishing the slopes is to plaster the side and upper niches of the window frame. The technology consists in leveling the surface by applying several layers of plaster, followed by priming and painting the surface. This method has a number of distinctive advantages. First of all, it is versatile. You can plaster the slope in a room with any humidity and temperature conditions. The mixture itself is an inexpensive material.

Plaster slopes are characterized by resistance to mechanical stress, ultraviolet radiation and moisture. This finish does not contain seams or joints. The surface is perfectly flat and smooth. In case of a decrease in aesthetics, such slopes can be easily updated or repaired.

Despite its many advantages, this method of finishing slopes has its drawbacks. Plastering the side niches is a time-consuming and laborious process that requires interruptions in work to dry each new layer. In addition, to get a good result, you need to have the appropriate skills. Plaster slopes are characterized by low thermal insulation properties. They are prone to freezing and condensation.

Important! To perform plastering work, you will need to trim the foam inward by 1-2 cm, which will weaken the heat-insulating joint.

The plaster and plastic frame do not interact well enough with each other, which will soon lead to the formation of cracks. You can fill them with a sealant. However, there is no universal compound that adheres equally well to plaster and PVC window block.

Features of plasterboard slopes for window openings

Many people prefer drywall slopes. The method is based on gluing or screwing sheets of material of the required size to the side niches, followed by priming, puttying and painting. This option attracts with simple and quick installation, which even a novice master can handle. The material is also characterized by an acceptable cost.

With the help of plasterboard strips, you can create perfectly flat sides of the window. The space between the drywall and the wall is filled with foam, which serves as a window seal. Such a surface is suitable for multiple colors.

However, this method is not without its drawbacks. The material is susceptible to moisture, so it can only be used for finishing interior slopes. Condensation forms on the surface, which will soon lead to swelling and destruction of the structure. You can eliminate such defects by completely reworking the slopes.

Drywall, like plaster slopes, is not able to firmly interact with the plastic frame. This promotes the formation of cracks at the mating points. The material is quite fragile, which does not exclude the possibility of its punching and deflection during installation.

After installing drywall, you will need priming, puttying and painting the surface to give it a complete appearance, which is not required in the case of using sandwich panels for window slopes. It will take a few more days to complete all the work.

Helpful advice! In order not to carry out a fine finish, you can use laminated drywall, which is mounted using special corners that cover the ends of the sheet.

The sequence of installation of plasterboard slopes

Installation of drywall slopes can be carried out in two ways: frame and frameless.

With the frame installation method, at the initial stage, the starting profile should be screwed with self-tapping screws, as is the case with the use of sandwich panels for window slopes. It is fixed on the line of joining the plasterboard sheet and the window frame in the groove. A kind of frame is ready, after which you can proceed with installation.

A feature of plasterboard slopes is that the strips of material do not fit tightly to the window frame. A gap is formed, which negatively affects the thermal insulation properties of the opening. This space should be filled with polyurethane foam or mineral wool.

Important! Filling the gap with polyurethane foam is done very carefully, as the material increases in volume, which can lead to damage to the drywall.

Perforated corners are installed at the junction of the gypsum plasterboard panels. The finished surface is primed and putty. After the composition has completely dried, the coating is rubbed with sandpaper to obtain an even base, which is painted in any color with water-based paint.

The frameless method involves the installation of plasterboard panels to the window opening using liquid nails or other suitable composition. The surface is thoroughly cleaned and primed beforehand. Each element of the slope with the applied glue is tightly pressed against the niche.To fix the elements, you can either use a wooden bar, which will give the structure evenness, or install spacers to the windowsill. After complete drying, the slopes are puttyed with their subsequent staining.

Features of slopes for gypsum fiber windows

Gypsum fiber is often used for finishing slopes. The installation technology of the material is similar to the principle of decorating niches with plasterboard. However, gypsum fiber has distinctive advantages over its analogue. The material has good strength and rigidity. There is a variety of products that are characterized by excellent moisture-proof properties. This feature makes it possible to use the material for finishing the external slopes of windows.

Gypsum fiber slopes are characterized by ease of installation and high speed of work. The material is distinguished by excellent technical and operational qualities. It firmly resists mechanical stress, adverse environmental factors. Due to the presence of fibers in the structure of the material, it is an additional insulation for the window, which increases its thermal insulation properties, which makes it similar to PVC sandwich panels for slopes.

Due to the good strength and rigidity of the material, it is possible to obtain the ideal geometry of the structure, which will be distinguished by a long period of operation. Such slopes are characterized by maintainability. The damaged area can be filled and tinted.

The disadvantages of the material include a higher cost in comparison with conventional drywall. However, it is lower than the price of slope sandwich panels. Cutting such material is also much more difficult. The surface needs a finishing, which is carried out by priming, puttying and painting.

Helpful advice! When painting gypsum fiber slopes with high-quality latex paint, it is possible to obtain a durable moisture-resistant surface that can be washed.

Plastic panels for window slopes: material features

You can create reliable and aesthetic slopes using plastic panels. They are characterized by a sufficient level of rigidity, wear resistance, moisture resistance. As a result of using the material, it will be possible to create a flat, smooth surface that does not need finishing.

Important! For slopes, you should choose panels made of primary plastic that are resistant to ultraviolet radiation, which will not lead to yellowing over time.

Installation of panels is carried out using liquid nails, which provides a reliable, strong and durable fixation. The installation of the material is easy and quick, with a minimum amount of dust and dirt during the work. Due to the fact that the slope and the window frame are made of the same material, it is possible to achieve the absence of cracks at the points of contact of the elements.

Important! For additional tightness, excluding the negative effects of temperature extremes, the butt joint is treated with a sealant.

PVC panels for slopes are completely moisture resistant, so they can be used for outdoor decoration. The presence of an edge profile allows to give the window a more aesthetic appearance. The element is applied to the joint between the wall finish and the window opening. The cost of the material is an order of magnitude lower than the price of sandwich panels for the slopes of plastic windows.

The disadvantages include the lack of strength of the material, which is why it is prone to mechanical damage. In the event of a defect, a complete strip replacement is performed.Complementary elements are often of poor quality, as a result of which they turn yellow, standing out ugly against the snow-white background of the slopes. In addition, unlike sandwich panels for slopes, plastic elements do not contain insulation, which reduces the thermal insulation properties of the window.

Sandwich panels are very popular today for finishing window slopes. This is due to the strength, reliability, moisture resistance and good thermal insulation properties. The material is assembled easily and easily. Also pleasing is the democratic price per m2 of sandwich panels for slopes, which averages 150-200 rubles.