A fountain or waterfall is a real decoration of any landscape. Such a building completely changes the microclimate of the adjacent territory, revives and decorates the exterior. To be able to admire and enjoy the flowing water, a fountain pump is needed. This unit is able to create the required pressure, due to which the water rises to the surface and smoothly falls down.

Content

- 1 Fountain pump: purpose and principle of operation of the device

- 2 The principle of operation of a submersible pump for a fountain in the country

- 3 Surface pumps for fountains and waterfalls

- 4 Which filter to install with a fountain pump

- 5 Criteria for choosing a pump for a waterfall and fountain

- 6 Useful tips when buying a water pump for a fountain

- 7 Popular decorative fountain pump manufacturers

- 8 Features of installation of pumps for waterfalls and fountains

- 9 How to make a pump with your own hands for a small fountain

Fountain pump: purpose and principle of operation of the device

The pump is a special device that cyclically distills water along a set circuit. Often this equipment is used to decorate decorative hydraulic structures on country estates and summer cottages.

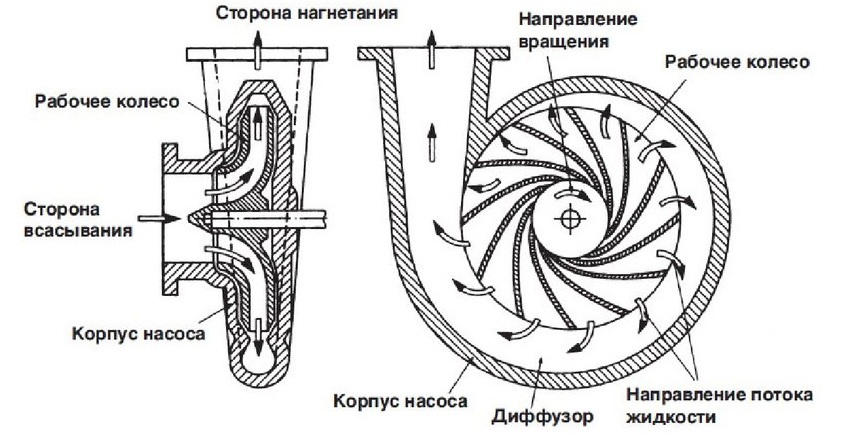

The principle of the pump is that the device creates a positive pressure that expels water with a certain force

The principle of operation of a fountain with a pump is based on the creation of positive pressure, which pushes water with a certain force. The power of the unit determines the height of the propelling jet. The pumping equipment for a fountain may include a different list of constituent elements, which depends on the type of device and its manufacturer. But any set consists of a rotating motor and an impeller, which affect the flow force.

A garden pump for a fountain has approximately the following configuration:

- motor;

- motor housing;

- nozzle;

- retractable pipe;

- fluid flow regulator;

- faucet for connecting a waterfall or fountain;

- pump impeller;

- fountain head;

- spray;

- grid.

The pump for summer cottages is distinguished by its mobility and compact design. The unit is used seasonally. He does not need additional communications and copes with the movement of water without the need to connect a water supply.

Almost all pumping equipment consists of similar parts: a rotating motor and an impeller that affects the flow force

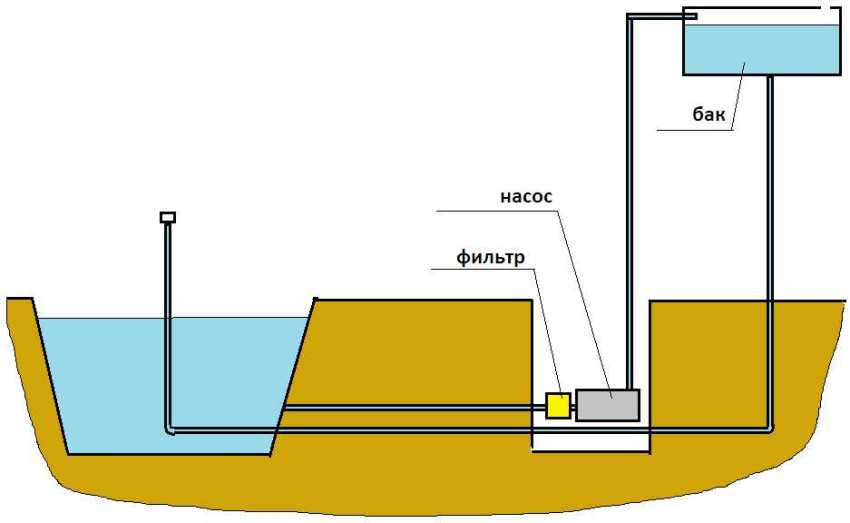

For a country house or summer cottage, circulating devices are installed that work in a closed mode. Their water receiver is located below the bowl with the fountain. With the help of a pump, water is pumped into the pipe through different nozzles, moves up and is sprayed at a certain height. For the waterfall to work, the liquid rises from the tank, falls onto the indentations and returns to the tank. Such a closed water system cannot be provided without an electric pump.

The principle of operation of a submersible pump for a fountain in the country

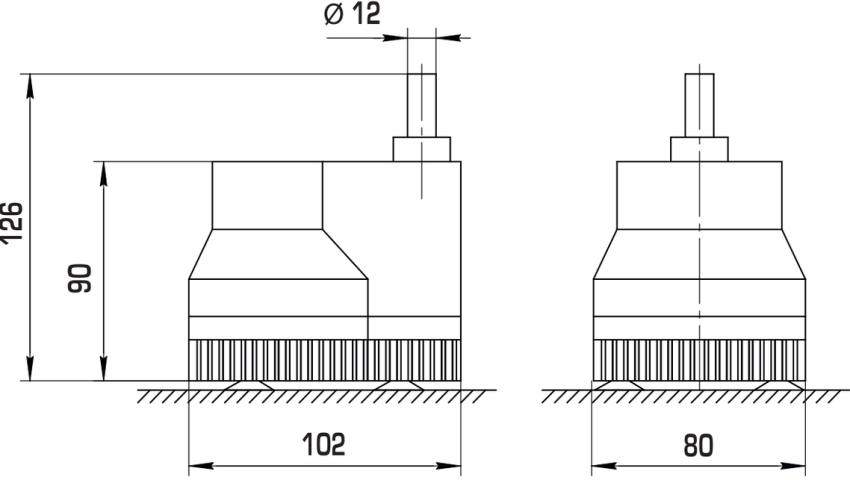

The submersible device belongs to the wet type of centrifugal pumping equipment. The housing is made of durable plastic or stainless steel, depending on the conditions of its operation. The motor power can be in the range of 6-100 W.

This type of pump is used for small fountains no more than 2 m deep, floating and submersible tanks, stationary and wall structures. The pump is installed on the bottom of the tank by means of special suction cups that prevent the unit from moving during its operation. If the device is used for ponds, it is placed on a small concrete or brick plinth to prevent silt from entering the system. In addition, this arrangement is preferable for fountains, as the wear of the cleaning elements is reduced.

The pump body is completely submerged in water. The upper element, made in the form of a special nozzle, plays the role of a sprinkler, rising above the water surface at a certain distance. Suction takes place through the barred bottom of the unit, where the filter is installed. Submersible pumps are characterized by light weight and compact dimensions. The pressure in the system largely depends on the cross-section of the pipes and supply hoses. The smaller they are, the more intense the jet will be and the greater the density of the water flow.

The scheme of the submersible pump for fountain

Helpful advice! It is recommended to periodically remove the filter from the housing and clean it. If it fails, it is necessary to immediately replace it with a new one, since the condition of the filter is directly related to the period of operation of the pump.

Design features of a submersible pump for a pond and a fountain

The submersible device draws water from the lower layers of the reservoir or an external source, followed by its release through the nozzles. In the first variant, the pump must be equipped with a filtration system to avoid clogging the system. A jet of water is sprayed over the unit. If the system is supplemented with a hose of a certain length, the flow can be brought to a certain place, which is set by the idea of landscape design. The pipes are connected and lengthened according to the telescopic principle using rubber or plastic connections.

Submersible pumps operate almost silently with low power consumption (it is required 30% less than for a surface unit). This is due to the fact that the attachment is located close to the motor, and this contributes to minimal power loss.

The pump operates from the mains, therefore, when installing the system, it must be grounded without fail. For normal operation of the pump, a voltage of 24 V. is sufficient. Such devices belong to low-voltage units, for which a simple transformer can be a power source.

When choosing equipment, first of all, it is necessary to compare the power of the device with the size of the bowl of an artificial reservoir

The longer the tube length and the number of additional structural elements, the more electricity will be consumed. This requires a high-powered device. It will be connected to the electrical network using a cable that must be covered with a waterproof material.

Submersible pumps are designed to handle virtually clean, contamination-free water.The presence of impurities in the water at a concentration of 50 g / m is allowed3, the size of which does not exceed 0.2 mm. To avoid breakdowns, all pumps are equipped with fine mesh stainless steel mesh filters located in the pump suction element. They trap mechanical impurities, protecting the internal parts of the pump from premature abrasion and wear.

Strengths and weaknesses of submersible fountain pumps

The advantages of submersible fountain pumps include the following criteria:

- low cost, which is affordable for any summer resident;

- ease and simplicity in installation, allowing you to install yourself;

- high efficiency;

- minimum power consumption;

- quiet operation, which allows you to enjoy the sound of pouring water;

- invisibility, which is associated with the installation of the device at the bottom of the tank, eliminating the need to find a suitable place and subsequent masking of the unit;

- compactness of models, which is suitable even for small fountains.

Among the disadvantages of submersible fountain pumps are:

- the complexity of repair and maintenance, this requires draining the tank;

- needs strict adherence to electrical safety;

- the need to dismantle the equipment in the winter.

Surface pumps for fountains and waterfalls

Surface pumping units are dry equipment. They are mainly used for complex multi-level high structures. This device is chosen when it becomes necessary to connect several objects to one pump. In this case, you should focus on the pressure for different elements and set the correct flow power level. When connecting two circuits, a tee must be installed.

The surface pump is large and expensive. It should be located in a dry place in the immediate vicinity of the reservoir, on which the power of the unit will depend. When connecting long hoses and a large number of all kinds of attachments, the efficiency of the device decreases. The maximum permissible distance for normal operation of the unit should not exceed 2 m, which is indicated in the instructions.

After installation, the unit should be masked so that it does not spoil the appearance of the landscape. Such devices are convenient in operation and maintenance, do not need to be dismantled during the winter period.

Surface aggregates are less sensitive to dirt and organic matter in the water. They can pump water from any source. For this, the device hose is lowered into it, which is connected to the inlet pipe of the pump. The power cables do not need additional protection, which ensures safe pump operation.

Since the structure is located in the open air, it should be adequately protected from moisture and direct sunlight. To do this, the pump is covered with a protective casing, which to some extent reduces the noise that the unit emits. Also, a separate box or pavilion can be equipped for the device, protecting it from precipitation.

Helpful advice! If the water contains coarse solids, it is recommended to install a foot valve with a fine filter mesh on the suction hose.

Among the disadvantages of the device, a high level of pump noise can be distinguished, which requires the installation of sound insulation. For this, the pavilion or protective casing for the pump is sheathed from the inside with noise-absorbing material.

Which filter to install with a fountain pump

When building a pond fountain, be sure to use a filter. It can be simple, external, pond, ultraviolet.The first option is presented in the form of a small block made of porous material. The product is installed near the mesh of the submersible pump unit. It provides mechanical and biological water purification during continuous operation of the device.

An external filter is a multi-layer unit that is connected to the pump through a perforated inlet pipe. Water seeps through a mesh or porous filter, where mechanical water purification takes place. The next filter layer is made of porous material. There is a perforated base at the bottom of the block. With continuous operation of the pump, biological water purification is provided in all layers of the filter.

The filter, which is located at the bottom of the reservoir, is a block filled with fine gravel and porous material for mechanical cleaning.

For polluted natural ponds, the most rational solution is to install a UV purifier powered by electricity. This is a unit with a special chamber with lamps, falling into which water is exposed to ultraviolet radiation. The cleaned liquid enters the pump suction line. The main disadvantage of such a filter is its high cost.

Criteria for choosing a pump for a waterfall and fountain

When choosing pumping equipment for a fountain, one should focus on performance, operating voltage, power and water rise, which are indicated in the device's passport. The pump should run at medium speed while reaching the required power level. If the unit is constantly given all the best, its working resource will very quickly be exhausted, which will require replacing the device with a more productive one.

When choosing a pump, compare the power of the unit and the size of the artificial reservoir. The height of the jet of the device should not exceed one third of the width of the reservoir. In order to obtain a height of 1.3 m, it is necessary to purchase a pump with a flow rate of at least 800 l / h. To create a jet with a height of 2 m, the unit must be designed for a capacity of 3000 l / h.

Electrical power and voltage determine the power source. Powerful units operate from an electrical network of 220 V. They are powered by a cable through an RCD and a circuit breaker. Low-voltage units can operate from 12 and 24 V mains, power supplies are used for them.

Helpful advice! For spray fountains, it is recommended to give preference to units with high pressure and low productivity, and for waterfalls - low-voltage pumps with high productivity.

An important criterion is the location of the reservoir. For indoor fountains, it is enough to use 5-8 W low-voltage units. These are small, quiet devices that do not generate vibration waves. They are mostly not equipped with a filter because they deal with clean water. These units have a short and thin power cord without grounding. Pumps for outdoor fountains and ponds must be fitted with filters. The power cord must be thick and grounded.

Related article:

Sand filter for the pool: to keep the water always clean

The principle of operation, operation and maintenance of sand filters. Installation of equipment. Self-made filter.

Useful tips when buying a water pump for a fountain

When buying a pump for a fountain, you should choose a unit with a complete set of additional elements, which include hoses, nozzles, spray heads, and water flow control systems. It will be expensive and troublesome to buy them separately.The pump must be made of a material that is resistant to corrosion, which will directly affect the period of operation of the device.

The price of a pump for a submersible fountain will be higher than for a surface one. This is due to the fact that in its manufacture, special materials are used that exhibit increased resistance to underwater pressure and constant contact with an aqueous medium. The cost of the device is also influenced by the type and number of components, the presence of ultraviolet radiation and illumination.

Garden pump fountain are selected according to two main parameters: productivity (flow rate) and pressure

When choosing a pump for a fountain, it is better to prefer models equipped with the following elements:

- a tee with a valve, with which the water flow can be distributed to two points;

- transition pipe for increasing the outlet pressure;

- head with LEDs, used to illuminate the fountain, which occurs when it is installed on a special threaded extension.

Helpful advice! All of the above items can be purchased separately, depending on their need.

Popular decorative fountain pump manufacturers

The leading position among the manufacturers of pumps for fountains belongs to the American company Pondtech. It specializes in the production of units for water structures for various purposes. The HP series includes high capacity pumps up to 70,000 l / h with a power of 230-900 watts. The pumping speed of liquid can be 45-70 m³ / hour. The height of the jet lift is 6.5-85 m.

The AR category is represented by small-sized units with an extended configuration, with a maximum productivity of 4500 l / h and a power of 6-145 W. The CQP series includes illuminated fountain pumps. They are used to create decorative waterfall and fountain compositions.

An important advantage of Messnerce Pumps is that they are all made of stainless steel and have an attractive design.

The German company Messner produces energy-saving pumping units with a power range of 48-650 W. The lifting height of the jet is 3.1-5.5 m. All models of the units are equipped with an overheating protection function and have a reinforced bearing, which contributes to a long service life of the device. Many models of this brand can pump liquid with a suspension size of up to 8 mm.

Another German brand OASE offers pumping equipment of any price category, ranging from economy class with a delivery of 1000 l / h and ending with an extra-class with a capacity of 41000 l / h. The main feature of the devices is the presence of such additional functions as frost protection, individual regulation of the water supply, electronic control and a system of auxiliary filters.

Features of installation of pumps for waterfalls and fountains

A submersible pump for a summer cottage fountain is installed at the bottom of the reservoir. It is usually mounted on a brick pillow or plastic pedestal. It is not recommended to arrange a metal substrate, since the material is not resistant to oxidation, which will lead to the destruction of the structure.

The top of the pump should be connected to the pump using a plastic or rubber tube. To avoid deformation, you can use a corrugated hose. When installing a submersible pump, be careful to observe the water level in the tank. Excessive draining can lead to damage to the unit, which is associated with an insufficient water level in the tank. Running the unit idle can lead to irreversible consequences.

Important! When organizing power supply, you should worry about the correct connection of all power harnesses and the implementation of grounding.

A surface pump is installed next to a water reservoir in a box or pavilion, where it is necessary to provide for its insulation and grounding of cable lines. Often the casing of the unit is additionally covered with a waterproof casing.

How to make a pump with your own hands for a small fountain

To organize a garden fountain, you can use a pump from a washing machine. It connects to the water supply and power supply. It is important here to ensure proper insulation of the unit, not allowing it to come into contact with water.

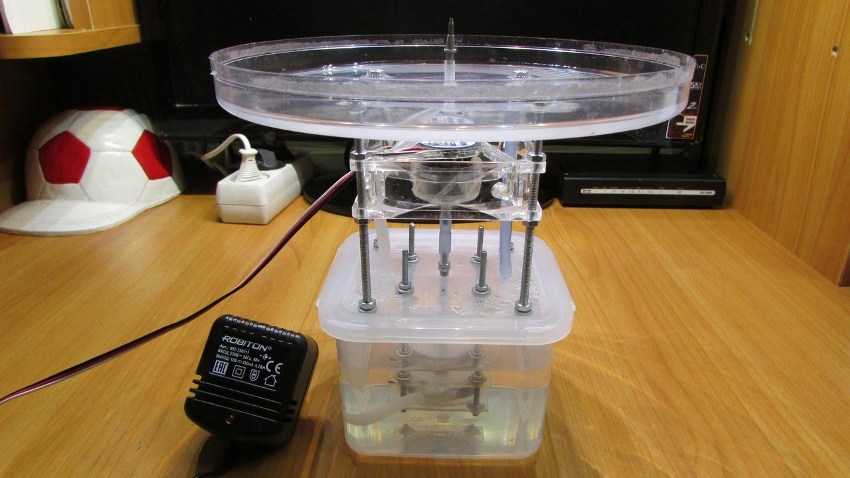

A pump for a room fountain can be made independently on the basis of an illuminated fan. Such a device will work from a 12 V DC network and connect through a power supply to a household network. The portable fountain can be charged from a car battery.

To make a pump for a home fountain, you will need the following list of materials:

- computer fan;

- plastic container with a lid;

- 12 V power supply;

- plastic bowl;

- aquarium hose;

- studs М3 and М4 with nuts and washers for them;

- plexiglass 1.5 mm thick;

- screw M3;

- gel pen;

- Janet's syringe, 150 ml;

- aluminum sheet 0.2 mm thick.

DIY water pump making process

The main element of the pump is the water pump. To create it, templates are executed. Parts must be accurate to align easily when assembling the pump. All elements are made of aluminum sheet in an amount of 2 pieces. of each kind. Four squares of 50x50 mm are cut out. For the bottom plate, holes with a diameter of 10 mm are made, for the top plate - 4.5 mm. In the corners of the templates, holes are made symmetrically for studs with a diameter of 3 mm. The distance from the edges of the products to the center of the holes should be 12 mm.

Holes with a diameter of 3 mm are made in plexiglass using a drill heated over a flame. The glass is clamped between two identical aluminum templates and secured with bolts and nuts. The templates are aligned, and then holes are drilled in opposite corners in the same way. The bottom plate is made in the same way. The edges of the plexiglass are cut using a heated stationery knife according to the template. If necessary, they should be cleaned with fine sandpaper.

By means of a template, holes are also made in the lid of the plastic container, which is the water reservoir. In the central hole of the upper plate it is necessary to insert a small segment 40-50 cm long from the rod of the gel pen, which will act as an oil seal and a bearing at the same time.

Janet's syringe is used to complete the body. A ring 13 mm high and 40 mm in diameter should be cut from it. In order to make an even cut, it is necessary to use a device: using two bolts and nuts on an even piece of board, you need to attach the blade from the clerical knife, stepping back 13 mm from its beginning. The blade is heated with a soldering iron, and a risk is applied to the syringe around the entire circumference, along which a cut is made with a clerical knife.

Next, with a knife, it is necessary to cut the rod from the gel pen at an angle, according to the size of which the hole in the syringe body is made. The next step is to connect all the parts with a hot melt gun.

Making a pump impeller for a small fountain

To manufacture the impeller, blanks are cut from an aluminum sheet: two discs with a diameter of 38.5 mm and two strips with a width of 6 mm. In the central part of the circles, holes with a diameter of 4.5 mm and 10 mm must be made. The aluminum strips are bent slightly and applied to the discs to form the blades. There can be 5-6 of them. The length of the blades is determined locally. They are glued to the disc with super glue.Glue is applied to the upper edges of the blades, and a plastic body is put on. Place the top disc on top. The assembly is placed under the load and kept in this position for 30 minutes.

Useful advice! After the glue has completely dried, all edges are filed to remove burrs and irregularities.

Next, studs are cut with a length exceeding the height of the container. Nuts are screwed on them and washers are put on. It is most convenient to assemble the knot upside down. The top plate made of plexiglass with a bearing made of a gel pen is put on the studs. It is fixed at a distance of 60 mm from the edge of the stud and fixed with nuts and washers. Then the impeller is installed with a large opening upwards. A screw is inserted into its small hole, which is secured with a nut from the bearing side.

DIY assembly of all pump parts for a fountain

The sealant is applied to the lower end of the plastic housing, which is put on the impeller and firmly pressed against the plate. After the glue hardens, the performance of the impeller is checked, which, when rotating, should not touch the walls of the housing.

A sealant is applied to the end of the plastic case, where the lower plate is installed, which is threaded through the holes of the stud. Parts are secured with nuts and washers. The fan must be checked for operability by connecting it to the computer.

It is possible to build a small pump for a fountain with your own hands at home without using expensive materials.

A square of 12x12 mm is cut out of plexiglass. A hole with a diameter of 3 mm is drilled in its center, where the screw is inserted so that its head is flush with the glass plane. The shaft is mounted on the fan, centered and fixed with a nut. It is fixed using a heat gun with glue, which is applied in an even layer to avoid destruction during operation.

A piece of the rod from the handle should be put on the bolt and fixed with superglue. You need to attach a homemade pump to the container lid on the studs. Also, an impeller bolt with a screwed nut is threaded into the hole in the cover, on which the rod from the handle is fixed with glue.

To fasten the fan, you must cut off the M4 studs, which are inserted into its holes and fixed with nuts and washers. The motor shaft is connected to the pump shaft by means of an aquarium hose.

Testing a homemade mini fountain pump

The initial test of the small water pump is done with no load. To do this, the fan is connected to the computer's power supply, and then the pump is turned on. The absence of noise, beating, grinding is checked, and the rotation speed of the impeller is also monitored.

Next, a check is performed on the operability of the device with water. For this, the pump is installed in the working position on a container with liquid. The hose coming out of the pump rises to the required height and is secured. The pump starts up. The height of the water column is determined by the water level in the hose, which characterizes the capabilities of the pump. For this device, it will be 0.5 m.

The next step is to check the pump performance. For this, the amount of water flowing out of it into another container is measured when the device is operating for 1 minute. Liquid volume is measured in liters and multiplied by 60.

Important! To create a mini-waterfall with your own hands, you should use a larger container and ensure the constant operation of the pump with a continuous supply of water to it.

Making a bowl for an indoor fountain

A bowl for a indoor fountain with your own hands without a pump can be made from any container of the required size.Holes are made in it for pins, nozzles and water draining into a container. For the last holes, glands are provided from the segments of the gel pen rod. Before attaching the studs, it is necessary to liberally grease with colorless silicone sealant. A bowl is put on them, which is fixed with nuts. Fixed with sealant.

A fountain nozzle is made from the tip of the gel pen with the stylus removed. A hose from the pump is connected to the element. A hose should be attached to the drain by lowering it into a container. To avoid gurgling when draining water, a tee is put on the lower end of the hose. The tubes are bent in different directions, but as close as possible to the walls of the plastic container.

The container is filled with water through the bowl. The tightness of the installation is checked. An ordinary syringe removes air bubbles from the pump. An engine is connected to the power supply. For this, the red fan wire is connected to the plus of the unit, and the black wire to the minus. The signal white wire is insulated. The pump is put into operation and its performance is checked. During the test, attention should be paid to the absence of runout and leakage. The light is turned on and the backlight is tested.

For an indoor fountain, of course, you can make a pump yourself. And for a pond or waterfall, it is better to use ready-made units from well-known manufacturers. The instructions for the pumping equipment prescribe all the technical characteristics of the device, according to which it is necessary to select a unit for a specific task.