Many people are striving for the original design of the premises today. It is expensive to purchase custom-made products, and it is quite difficult to create an interesting interior from typical models. Affordable manufacturing technology, good performance and the ability to decorate allow the use of polymers when creating interior elements. An epoxy table is the most popular option.

Due to its properties, epoxy resin allows you to create surfaces that do not crack, deform or scratch

Content

- 1 Application of epoxy resin as a table coating

- 2 Wood and epoxy resin countertop for living room

- 3 Making an epoxy table with your own hands

- 4 Epoxy resin table in a modern interior

- 5 Decoration of the local recreation area: table for the street

- 6 A table made of wood and epoxy resin: advantages, disadvantages, prices

- 7 Diy epoxy table: video materials

Application of epoxy resin as a table coating

Certain requirements are imposed on the surface of any table. This is an area that, in the process of use, is subjected to constant mechanical stress: indentations, blows, wiping, and cuts. Therefore, the top layer must be durable. As a piece of furniture, the table must also meet aesthetic requirements.

Among the disadvantages of epoxy resin are the following: high cost, instability to low temperatures, toxicity at high temperatures

Epoxy resin, by virtue of its properties, allows you to create surfaces that cannot be scratched, chipped off, they do not crack or deform. Epoxy pouring tables are easy to decorate. You can give the fill the desired color, shape, supplement with elements of natural material or other object details.

The main operational advantages of the material are the following:

- resistance to mechanical damage;

- moisture resistance;

- non-exposure to ultraviolet radiation;

- immunity to aggressive detergents and cleaning agents, therefore, ease of care;

- high aesthetic qualities.

Of the shortcomings of the material, it is pertinent to note the following:

- high material cost;

- the need to strictly follow the application technology (even with the slightest deviation, the result may be unsatisfactory);

- instability to low temperatures (white flakes appear in the hardened composition);

- toxicity when exposed to high temperatures. (However, the impact of such during operation in home and office conditions is excluded).

The frequent use of epoxy resin for pouring countertops is also due to the fact that it gives a perfectly flat surface.

The active use of epoxy resin for pouring countertops is also explained by the fact that it gives a smooth surface that does not need correction.

Epoxy tables: model varieties

The quantitative use of resin during the manufacture of tables can be different. Some options only require filling the depressions, that is, creating a thin top layer. With large irregularities and the use of untreated wood materials as a frame, the consumption increases significantly. It is possible to use only epoxy for worktops.

The price of epoxy resin tables directly depends on quantitative indicators and shape. In the course of practical manufacturing, three types of products are distinguished:

- Made of resin only, without support. These are small tables that can be used as coffee tables, dressing tables, or decorative ones. These options are not designed for significant mechanical stress.

- Tables with a base, usually wood, where an epoxy layer is used as a topcoat. Such models are easy to decorate. The painting of the base, elements of paper and plastic, coins, stones, shells, etc. are used.

- Combined types. The resin layer alternates with fragments from another material (wood is mainly used).

When making a table only from resin, a form with sides is required. To carry out the top coat, limiters are arranged directly along the edges.

Important! The required amount of epoxy resin and the curing time of the layer depend on the height of the decorative additional parts used.

Combined models can be produced both with the use of restrictive boards, and without them. Their presence is determined by what material is placed along the edges of the countertop.

Resin for pouring countertops: brands and manufacturers

Epoxy resin is a two-component material. Consists of directly resin and hardener. It is on the features of the latter that the operational characteristics of the composition as a whole depend. The quality indicators provided by the manufacturer are also important.

The composition of epoxy resin includes a hardener, the amount and characteristics of which depend on its performance

The most popular brands of epoxy resins for pouring countertops are:

- QTP-1130. The composition of domestic production. More suitable for thin transparent surfaces (glass effect).

- Art-Eco. Domestic material, transparent. In addition to the resin, a color scheme can be purchased from this manufacturer and given the desired color to the composition.

- "ED-20". Differs in a low price. According to user reviews, over time, the layer of this epoxy turns yellow.

- Crystal Glass. A feature of the composition is fluidity. Therefore, this brand is convenient to use when decorating countertops with a large number of object elements.

- PEO-610KE. Material of the middle price segment. A distinctive feature is that it does not turn yellow even with prolonged exposure to heat and ultraviolet radiation.

When buying an epoxy resin, you need to pay attention to the expiration date, study the instructions and features of its use

When buying, you must carefully study the instructions and the specified features of the use of epoxy resin. The table will only be functional and will meet expectations when the properties of the composition correspond to the set goals. The expiration date is also an important point. If it is exceeded, the quality of the material can change significantly.

Interesting options for epoxy kitchen countertops

Epoxy resin is an excellent material for making kitchen countertops. Exposure to moisture and the need for constant care with the use of various detergents are important features of operation. The epoxy surface withstands such loads, and also retains its aesthetics for a long time if the manufacturing technology is followed and the use of high-quality materials.

An interesting option is a tinted glass surface with air bubbles. This table top is a worthy interior decoration and is practical. Gloss gives a feeling of radiant cleanliness, freshness of paints, and the presence of bubbles allows you to hide traces of dirt. The kitchen design looks original and neat.

In the photo of tables made of epoxy resin on the Internet, there are also models that imitate broken glass, natural stone, the seabed, mosaic options. The shapes of countertops can be very diverse: rectangular, square, with roundness and angular cuts in certain areas.

Helpful advice! When choosing a work surface for a kitchen made of epoxy resin, it is better to give preference to products with a decorative decorative addition. In addition to the aesthetic, they also perform a reinforcing function, which improves the performance of the countertop.

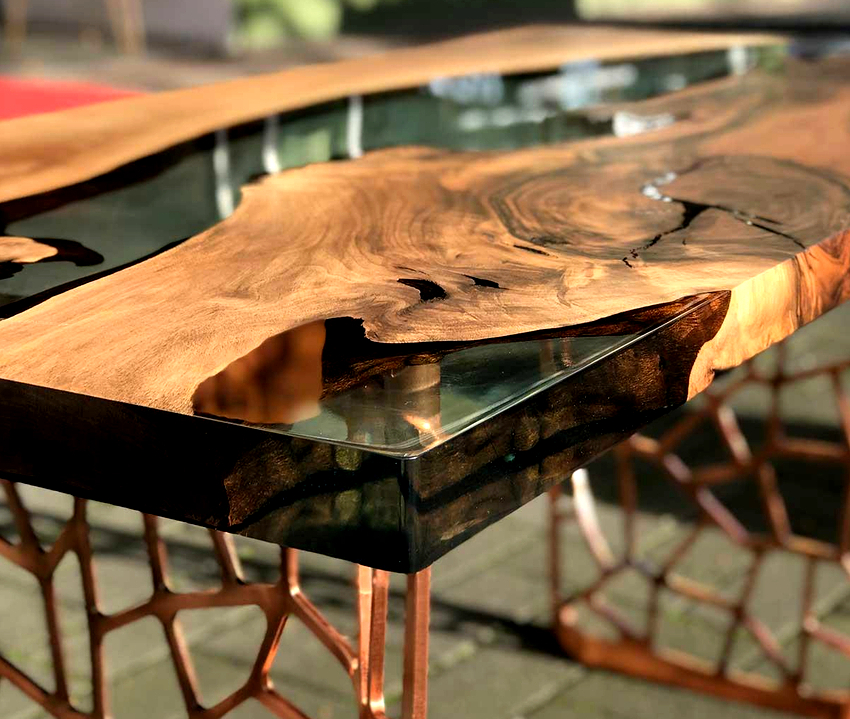

Slab and epoxy table: original and presentable

A slab is a saw cut, a solid wood board, which retains its natural shape and structure. This material allows you to make original tabletops from it, because the cut lines are unique. The epoxy resin fills the pores of the wood, forming a secure bond. The products are durable and beautiful.

Tables made of wood cuts and epoxy resin can have different configurations. It is determined primarily by the method of sawing wood. It can be longitudinal or transverse, that is, executed vertically or horizontally.

Vertical work pieces are suitable for elongated countertops. The definition of "rectangular" is inapplicable in this case, since natural outlines very rarely have straight lines. The cross cut gives a rounded shape. Such tables often have small countertops.

The presence of cracks, voids from knots, irregularities form the basis of the decor. Epoxy fills in cavities, leveling the surface, giving an unusual and aesthetic appearance to the product. The toning of the mixture used provides additional opportunities for creating an original decor.

Epoxy resin slab tables can be either flat or solid. The original shape can be achieved by cutting the wood material horizontally. To fill such models, you need a lot of resin and a high-quality hardener. Costs (both material and physical) are justified by the beautiful appearance of the products.

Wood and epoxy resin countertop for living room

Is an epoxy table appropriate for a living room? Of course, but only if it matches the interior as a whole. And there are some special requirements for the table in the living room. They are as follows:

Epoxy tables are often used in living rooms because their glossy surface contributes to a festive atmosphere.

- Quite large in size. It is supposed to seat at least several people for it.

- Ergonomic shape. The overhangs that maintain their natural lines add originality, but it is uncomfortable to sit in such a part of the table.

- The design of chairs should correspond to the appearance of the table, make up a single composition with it.This requirement is aggravated by the fact that such tables are not covered with tablecloths.

Making tables from epoxy resin for living rooms is also acceptable because it can form a glossy surface that contributes to a festive atmosphere.

It is better if the table in the living room has straight lines around the perimeter. As a decor, it is appropriate to use a blurred pattern of epoxy inserts, as well as a bright solid color, in harmony with other shades in the room, or being an interior accent.

The following requirements are imposed on the table in the living room: large sizes, ergonomic shape, the design must match the interior

Ornaments will decorate the living table in an interesting way. The manufacturing process of such products is somewhat complicated, since the voids should not be arbitrary, but certain sizes and locations.

Helpful advice! When making tables from epoxy resin for a living room (given their size), technology using a support or a combined version should be used, and the wooden parts in the second case should occupy a much larger area.

The highlight of the room design: a table made of epoxy resin with backlight

Epoxy resin without additives is practically amorphous substance. Only additional components make it an excellent creative material. In addition to being able to change colors and shades, epoxy is capable of transforming into a luminous material.

Related article:

Dining table for the kitchen: the role in the interior and the criteria for a successful choice

Material, shape and dimensions of the product. Various options and alternative designs. Compliance of the product design with the interior style.

Illuminated pieces of furniture are appropriate in any interior and premises with various purposes. The living table will become bright and festive, the illuminated dressing table will add intimacy to the burnt environment, the kitchen countertop with luminous end parts will bring lively notes to the everyday functionality of the work area.

Making tables from wood and epoxy resin with backlight does not require complex technologies. In addition to the hardener, you must purchase a luminescent powder. The desired glow intensity can be achieved by changing the proportion of powder and resin: the more luminescent additive, the brighter the glow.

The glowing one should not be in excess, it is annoying. Therefore, countertops with a large illuminated area are appropriate only for infrequent use and for creating a special environment. In the interior of living rooms, small backlights are preferable.

Filled shallow cracks, the outer sides of the countertops, lined with a luminous material, will provide a sufficient decorative effect.

Original and fashion trend: epoxy resin river table

A fairly popular product is an epoxy resin river table. The price of the models depends on the quality of the solid wood used, the amount of epoxy material consumed and the manufacturing technology. There are a lot of design options. It can be a narrow river insert, wide, with islets, complemented by decorative object elements. At the heart of any composition is the same arrangement of parts of the tabletop: wooden inserts along the edges, between which there is an epoxy fill.

The high price often forces you to take up the manufacture of such a table with your own hands.

When creating a model, you should pay attention to the following points:

- The surface of the boards must be perfectly flat. From "helicopters" the product will turn out not only unaesthetic, but also inconvenient in functional terms.

- A test dose should be taken when staining the resin.An unsuccessful color can not only disappoint, but also simply not match the decorative idea.

- When making a table-river from epoxy resin with your own hands using decorative parts, it is necessary to fix light elements, otherwise they will float when pouring.

- The resulting bubbles should be disposed of by piercing them with a needle.

Helpful advice! In order to avoid problems during the pouring process, it is better to heat the resin before use - it will become more plastic.

Making an epoxy table with your own hands

You can make other interesting table options with your own hands. It will not be possible to copy the product from the Internet in full, since it is impossible to pick up absolutely similar wooden blanks, but it is quite possible to use the idea as a whole.

The sequence of actions when performing a table with epoxy resin with your own hands can be as follows:

- Preparation of wooden parts. Material selection, trimming (if necessary), grinding, making molds or sides.

- An approximate calculation of epoxy resin for filling a mold or individual fragments, the acquisition of a composition, including a hardener, colors and other additives.

- Laying out the wooden parts. They must be located strictly horizontally, otherwise sagging may appear on the surface.

- Mixing. Two containers are used: the resin should be poured into one, the hardener should be measured out in the other. The composition must be thoroughly mixed, otherwise it will harden for a long time.

Preparing wooden parts is the first thing to start with making a table with epoxy resin with your own hands

Important! Dry wood before use. Damp parts can deform.

Certain indicators of the environment will also help to make a table made of epoxy resin with your own hands aesthetic. The temperature in the room where the manufacturing process takes place should be maintained at least +22 C °, the humidity should be lowered to the lowest possible values.

Epoxy resin table in a modern interior

The table with epoxy resin is a bright and expressive element. The more original its design, the more thoughtful the interior of the room should be. For a classic style, rectangular or oval baseboards framed with epoxy are suitable. It is better to apply the color brown, possibly to match the wood.

In the photo of tables made of epoxy resin and wood, presented on the Internet, there are many models with bright red, matte gray, white, purple fills. They will be quite appropriate in interiors tending to eclecticism, in modern and high-tech styles.

Illuminated options will brighten up any interior. A lot of illuminated table area is suitable for a teen's room, living room. Unobtrusive small fragments will contribute to relaxation, relaxation. They are applicable for bedrooms and other recreation areas.

Countertops with marble imitation are harmonious for dining tables, work surfaces.

The availability of making do-it-yourself epoxy countertops opens up ample opportunities for the implementation of the most creative design ideas. An IT specialist's desk can be made using computer disks as a decor, the hallway will be originally complemented by a tabletop with attachments of keys and key rings, a tea table can be a picture or a map.

Decoration of the local recreation area: table for the street

Almost every owner of private housing construction tries to equip a place for outdoor recreation. A wooden table is an obligatory element of its filling.Given the strength and aesthetics of the combination of wood and epoxy, it is not difficult to predict the popularity of products from such materials for lounges.

Due to its strength and aesthetics, an epoxy resin table is very often installed in the lounge area.

A positive point in the use of this type of outdoor furniture is that the table can be made from old and seemingly unsuitable wood for these purposes, significantly saving money. When removing the gray top layer from the boards, it is easy to get excellent dry blanks that will not undergo deformation during use.

Perfectly decorate the seating area and tables made of slabs and epoxy resin. A distinctive feature of these products, intended specifically for outdoor use (in living rooms, such decor looks rough), is the use of a cut of wood without removing the bark on the side parts. These countertops contribute to the feeling of being close to nature. The table can be supplemented with chairs with slab backs or benches of a similar type.

Helpful advice! Considering the instability of epoxy resin to low temperatures, it is better to bring furniture into the room for the winter period.

A table made of wood and epoxy resin: advantages, disadvantages, prices

Omitting the operational advantages of epoxy tables, about which a lot has already been said in the article, the following should be noted:

- the ability to create new furniture from old wooden tables by eliminating defects with pouring;

- cheaper products due to the use of wood-based panels instead of solid wood and scrap materials as filling without loss of aesthetics.

The above features diminish the disadvantage of the high cost of epoxy.

It is not difficult to find out how much an epoxy table costs: information on selling sites is available to everyone. It is important to understand the essence of pricing in order to choose a suitable and affordable option. Products can be made of inexpensive wood, but this will not affect the life of the table. The natural non-standard configuration of the countertop does not increase the price, but if the creation of a certain shape is required, the cost will increase significantly.

The cost of a table made of epoxy resin and wood is influenced by the quality of the wood used, its size and shape

The price of tables made of epoxy resin and wood ranges from 12,000 to 80,000 rubles, although you can find cheaper options. Exclusive models, tables with LED strip lights may have a higher price.

Diy epoxy table: video materials

The saying “it's better to see once than hear a hundred times” (in this case, read) is quite relevant in the manufacture of tables from epoxy resin. And it's not about the complexity of the process - it seems quite clear when described. Details and little things are important, scrupulous adherence to technology. Excessive viscosity, slight inaccuracy of proportions, incorrectly exposed elements can significantly spoil the product.

For supporters of visualizing any process, it is better to watch videos to get an idea of exactly how to make an epoxy table.

Helpful advice! When watching the video, it will be useful to pay attention to the brands of the compositions used by the author.

All ingenious is simple. You can really create a masterpiece from wood and epoxy resin. The boring interior will be transformed, the standard will acquire shades of originality, the room will become interesting and comfortable. Photos of products on the Internet will help you choose the basic concept, and the practical advice of this article will tell you how to implement it correctly.