Sliding wardrobe is the most demanded type of furniture for the home. Such designs are ideal for storing various things, accessories, clothes and shoes, as well as other items. To save space in the room, this type of furniture is equipped with sliding systems. The functioning of such doors is provided by the guides for the wardrobe. This article will help you understand the features and technical characteristics of such products.

Content

Guides for the wardrobe: general information about fittings

As part of the furniture fittings, the guides have an essential function. Thanks to these elements, the sliding system, together with the sashes, works easily, freely and quietly. The principle of operation of this design is quite simple: the door leaves move along the rails for the wardrobe by means of rollers or balls.

Versailles is the most common and demanded type of sliding system, which is found in compartment-type wardrobes. Such popularity is due to the availability of durable, reliable and high-quality components, as well as easy-to-use internal filling elements. Sliding systems are additionally equipped with stoppers, seals and rollers for sliding wardrobes. Guides with such a complex design exclude the possibility of skewing the door leaves and arbitrary closing.

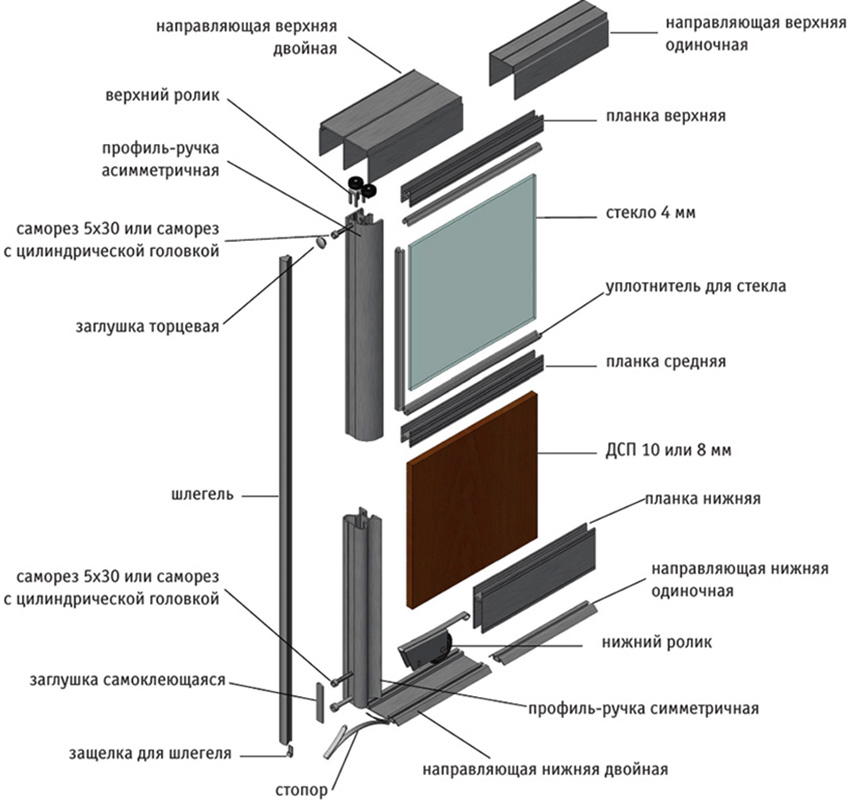

Components of a sliding system and requirements for runners for sliding doors

The width of the guides for the wardrobe and other parameters of the fittings should be selected taking into account the characteristics of the door leaf. In this case, the weight and dimensions of each sash, as well as the material from which they are made, are taken into account. Sliding rails are usually supplied with furniture, so there is no need to purchase these items separately. However, they may be needed in the event that the fittings fail and a complete or partial replacement is required.

Useful advice! If you choose guides that meet the basic quality requirements, then such products can be used for a long time.

If the installation of the guides for the doors of the wardrobe is done correctly, then the opening and closing of the curtain will occur in the same plane. Together with other fittings, this type of product is part of a sliding system. Guideline requirements:

- High level of strength - good strength characteristics ensure a long service life of the sliding system, even if it is used regularly.

- Aesthetics - the guides must necessarily correspond to the style of the room where the cabinet is located, as well as the design of the furniture itself.

- Convenience - the sliding system should be so simple and easy to use that any user can easily open and close the cabinet doors.

The standard equipment of the sliding system is the same in all coupé designs. But the list of additional fittings may vary depending on the cabinet model and its internal content.

The sliding system includes the following elements:

- upper and lower guides for the wardrobe, along which the door leaf moves;

- profiles with vertical and horizontal installation type for reliable fixation of all elements of the internal filling;

- door closers for the smooth running of the shutters;

- silicone sealant;

- a system consisting of lower and upper rollers for sliding doors of wardrobes, due to which their free and quiet movement is ensured;

- screws as fasteners;

- stops for fixing the door leaf in a certain area (in the form of spring brackets);

- brushes.

Types of guide profiles for sliding doors: classification by material type

When choosing guides for a wardrobe, you must definitely pay attention to the material of their manufacture. The following raw materials are used for the production of these products:

- plastic;

- aluminum;

- steel.

Plastic guide profiles have the lowest price. Such products do not have a long service life and high reliability. They can be operated without problems for 5-7 years. For this reason, many consumers choose to avoid buying furniture with plastic components.

Useful advice! To extend the life of the sliding system, it is advisable to use plastic rails for the sliding wardrobe only in combination with parts made of metal.

Steel is used for the manufacture of sufficiently strong and reliable products. However, the size of the guides for the wardrobe, including their thickness, must be selected taking into account the parameters of the door leaf. If the fittings are chosen correctly, the service life of the sliding system will be long. The price of such profiles is considered affordable for most buyers and, as a rule, it corresponds to the quality level of these products. Sometimes there are options that are not as durable and easy to install as we would like.

The highest quality parts are made from aluminum. These profiles are usually found in high-end and high-end models. Aluminum rails are designed for cabinets with a height of 4 m or more. Such products are distinguished by an extensive palette of colors and a large selection of decorative design options.

Furniture rails as part of sliding systems

Sliding systems of different types are used in wardrobes, so the door leaf can be opened and fixed in several ways. Varieties of sliding structures designed to open door leaves:

- Support system with bottom guide for sliding doors of wardrobes. Installation of the structure is carried out directly on the floor, or the lower furniture shelf can be used for this purpose. The sash is kept upright by rollers installed in the top profile. The main disadvantage of such systems is that the open bar can become dirty and clogged.

- Hinged system with top guide. This profile is used for hanging the sash. In the lower part of the canvas, special rollers are installed that do not damage the floor covering.

- Combined system. It is considered the most reliable and efficient. Sash movement is carried out by means of furniture ball guides.

- Coplanar system. It has a special structure, due to which the canvases are in the same plane when closed.

Note! In most models, double systems are installed, in which not only the upper, but also the lower guide profile is involved. Such designs exclude the possibility of sash skewing and its oscillations during the movement.

Features of suspended sliding doors without a bottom guide

Suspended sliding system consists of upper slats with rails and a movement mechanism. This device includes a stop for securing the sash and two carriages with rollers. One carriage usually has a pair of wheels. In some cases, their number can be increased to 4 pcs. The carriages themselves are made of metal (steel) or plastic with a high strength index. Due to the presence of ball bearings, the wheels move very smoothly.

The dimensions of the upper rail for the wardrobe can be different, and they depend on the dimensions of the door leaf. This type of furniture is usually made to order, so the parameters of the structures are individual. However, there are a number of recommendations regarding the dimensions, thanks to which the operation of the cabinet becomes comfortable.

The optimal sash width is 0.6-0.9 m. There are also narrower options, but their width should not be less than 0.5 m. Otherwise, a skew may occur and the door leaf will jump out of the guides. The maximum permissible width is 1.1 m, but moving such a heavy sash will require significant effort, so it is better to stick to average values. The upper rail has a U-shaped configuration. It is equipped with two wide shelves that act as stops for the carriage, which moves until it reaches a stop.

Advantages of suspended-type sliding systems:

- The suspension mechanism is capable of withstanding serious loads, which makes it possible to use this system in cabinets with massive door leaves.

- Even with a heavy door leaf weight, the suspension system works silently.

- There is no need to install reinforcement frames on each sash, which simplifies not only the cabinet design itself, but also the assembly process. Such furniture looks more aesthetically pleasing and is much cheaper.

The harness also has disadvantages. Even with the availability of high-quality fittings, over time, the door leaf begins to loosen.

Helpful advice! To exclude a breakdown of the mechanism, you need to equip the suspension system with a special stabilizer. Thanks to this, the door leaf will remain in place.

Support system with bottom guide for sliding doors of wardrobes

In support-type sliding systems, the load from the door leaves falls on the rails that are installed in the lower part of the cabinet. The upper profile acts as a holder.It fixes the canvas in a vertical position and looks like an M-shaped bar.

When installing roller guides in the support system, steel reinforcement frames are necessarily mounted on the sashes. The profile itself looks like a flat bar with two rails for wheels. The leaves in such runners are staggered. There are two ways to install the bottom rail: cut-in and overhead. The first option looks more neat and aesthetically pleasing. But the installation of a profile in an overhead way is much easier and cheaper.

The lower casters are made of hard and very durable plastic. If heavy massive doors are to be installed in the cabinet, these rollers must be supplemented with steel bushings.

The main advantage of a supporting sliding system is its low cost, as well as the ability to adjust the height of the flaps. The disadvantages include a high risk of contamination. If the runners are clogged with debris and dust, the doors will be difficult to move, and high loads on the wheels will cause them to wear out prematurely.

Helpful advice! If belt brushes are installed, most of the dirt will be swept off the runners when the door is opened and closed.

Features of furniture runners with combined and coplanar system

The combined system combines the advantages of supporting and hinged mechanisms. In this case, the sash can be fixed both from above and from below. The cost of sliding rails for cabinet doors with a combined system is very high. However, this drawback is fully compensated for by excellent quality and durability, because during operation the door leaves not only move silently and smoothly, but also do not loosen over time.

The combined sliding system is ideal for sliding wardrobes in which the length of the leaves exceeds 1 m. This version of the mechanism can also be used in conjunction with heavy conventional-sized doors made of solid wood.

In the coplanar sliding system, the closed canvases are arranged in a special way. This mechanism includes a combined set of guide profiles that are attached not only from above, but also on the sash itself. To open the door leaf, pull the handle towards you. As a result of this action, the sash will move slightly forward and be able to move to the right or left. This leaves the adjacent door behind.

Related article:

Fittings for sliding wardrobes as a basis for functional furniture design

The main types and purpose of parts used in the assembly of furniture. Elements of internal filling in cabinets of compartment type.

Advantages of the coplanar sliding system:

- silent, soft and smooth opening of door leaves;

- cabinet doors, due to their even placement, look aesthetically pleasing, like the front of the furniture;

- the system provides savings in the internal area of the cabinet (about 10%).

Technical features of guides for wardrobe doors and prices for products

Slides for sliding wardrobes can have several runners. Their number depends on the number of door leaves. The following types of profiles are distinguished:

- single-rail;

- two-lane;

- three-row.

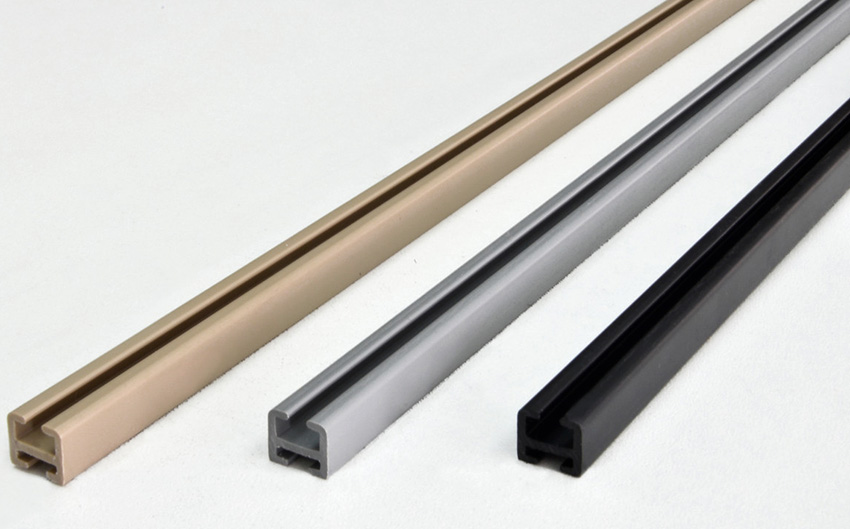

Most modern cabinet models have a two-lane system. The color of the guides depends on the material from which they are made. Steel profiles are available in bronze, silver, gold and champagne. If desired, the buyer will be able to select products that imitate various types of wood.The palette of colors for aluminum profiles is more extensive, as is the choice of textures.

Note! Colored coating on steel profiles is less resistant and less durable. Over time, it cracks and peels off.

There are two types of coatings used on aluminum profiles:

- Anodized coating - chemical methods are used to paint the metal surface. The veneer is very durable as the pigment particles penetrate into the material. As a result, the paint is resistant to mechanical stress, and is also not afraid of exposure to moisture and direct sunlight.

- Colored PVC film - this type of coating is characterized by wear resistance, durability and moisture resistance. The film reduces the noise level that occurs during the opening and closing of the sashes.

Price table for sliding wardrobes:

| Name | price, rub. |

| Bottom rail, 590 cm (single strip) | 660 |

| Bottom rail 600 cm (silver) | 660 |

| Bottom rail, 600 cm (bronze) | 1055 |

| Bottom rail, 600 cm (gold) | 1100 |

| Top rail 590cm (Plank 1-Strip, Silver) | 1200 |

| Top rail 600 cm (2-way, silver) | 2240 |

| Top rail 600 cm (2-lane, bronze / gold / champagne) | 2420 |

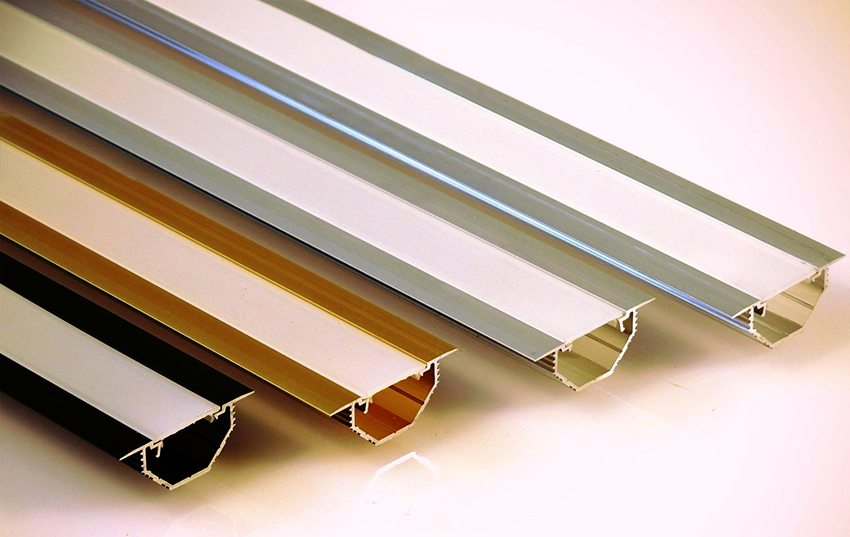

Installation of the lower and upper rails for the wardrobe

The top guide rail is fixed to the top of the cabinet. Self-tapping screws are used to fix this hardware. Press washers and universal screws are suitable as fasteners, but they must necessarily have a countersunk head.

Upper rail mounting diagram:

- Holes of 4 mm should be made in the guide profile, which will be located in 30 cm increments. For this, a drill can be used.

- If you will be using universal screws as fasteners, you will need to make a countersink in each hole.

- The profile must be installed in the appropriate area of the cabinet and aligned.

- After that, the part is fixed with fasteners.

The lower rail of the wardrobe has a similar structure, but it is used as a support part.

Installation diagram of the lower guide profile:

- Holes of the appropriate size are made in the profile.

- You should not immediately fix the fittings, since according to the installation technology, this element should be displaced 2 cm inside the cabinet. In this case, it is imperative to use a level.

- After the exact installation site has been identified and the guide is leveled, you can fix this part with self-tapping screws.

Important! Since the bottom rail is located inside the furniture, you need to make sure that it will not deform the inner filling such as drawers and baskets.

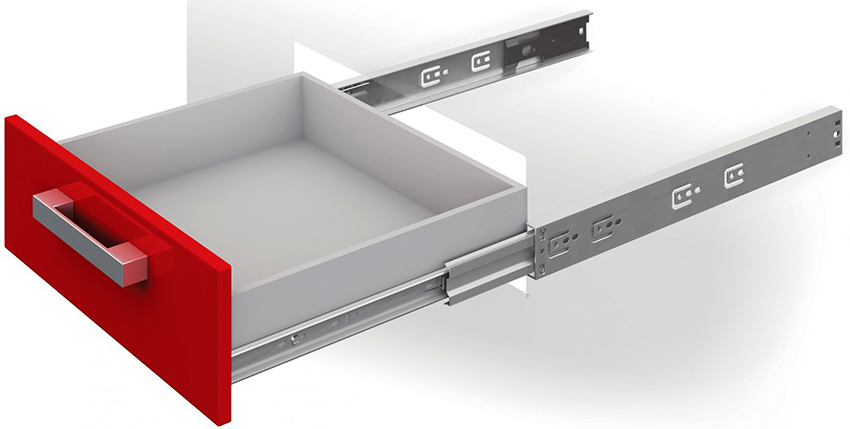

Installation of ball guides for drawers of wardrobe

Modern models of drawer runners have become an optimal replacement for conventional wooden slats, which have been used for quite a long time to move drawers. Telescopic fittings are considered the most practical and functional. It is a fully extendable ball runner.

Advantages of full extension ball guides:

- acceptable cost;

- smooth and soft movement;

- excellent strength characteristics;

- wear resistance;

- simple installation system.

Telescopic guides are characterized by a concealed mounting type. This type of fittings is used not only in dressers, but also in wardrobes, desks, and kitchen furniture. Do not forget about the advantages of concealed rails with a door closer. Such models allow the drawer to be pulled out to its full length, thereby gaining access to all the things that are stored in it. The oil spring ensures smooth closing.

The mechanism of ball guides with a door closer is able to withstand up to 50 thousand openings and closings. The hardware design is designed for weight loads up to 25 kg.

How to mount ball guides: mounting technology

Before installing the ball guides, you must pull out the inside of the hardware. To do this, press the black antennae. The result is two halves, one of which is attached to the inner wall of the cabinet, and the other to the side of the box from the outside.

How to install ball guides? To do this, you should adhere to a certain sequence of actions:

- First, you need to determine the optimal place for mounting the mountings.

- On the side of the box from the outside, markings must be applied. The line of the proposed installation can be located in the lower zone or run strictly in the center.

- Then, using screws, one half of the fittings is fixed in accordance with the marking line.

- The same markings should be applied to the inner wall of the cabinet. The placement of this line will depend on the height of the drawer.

- After that, the second half of the fittings is fixed in place.

To make sure that the installation of the guides with the closer is done correctly, you need to put the box in place and check how freely it opens and closes.

Both parts of the fittings have a large number of holes, each of which has a specific function. Elongated horizontal holes provide the ability to move the profile horizontally while adjusting the guides, and elongated vertical ones - up / down movement. After the hardware is fully configured, it is securely fixed with self-tapping screws or screws. For this, round holes are used.

The bottom rails are usually installed 3 cm from the bottom of the cabinet. The placement of the remaining components depends entirely on the size of the boxes. During operation, the elements should not touch. To avoid this, the distance between the fittings installed on the cabinet walls should be increased by adding 2-3 mm to the height of the front part of the drawer. During the installation process, be sure to ensure that the fixation of all components of the guides is carried out strictly along the marking line.

The guides are the main component of the sliding system in sliding-door wardrobes. For the manufacture of profiles, various materials are used, the highest quality of which is aluminum. The technology for installing fittings for a sliding system is quite simple. If you perform all the calculations correctly and follow the instructions exactly, then the installation can be done independently. For heavily loaded boxes, it is advisable to use a double set of fittings.

Careful maintenance of the sliding system will extend the life of the rails and casters / balls. To do this, it is enough to remove dust and debris 2 times a month with a vacuum cleaner, and then wipe the surface of the rails with a damp sponge.