The bed is the main element of the bedroom. The level of comfort, the functionality of the bed and the quality of sleep depend on the model variant. The choice of a bed should be approached with special responsibility, especially when it comes to a child's sleeping place. A high-quality, strong, durable design with an aesthetic appearance will be expensive. A do-it-yourself children's bed will cost much less, and the result will exceed all expectations.

Content

- 1 DIY children's bed: basic design requirements

- 2 DIY bed: dimensions, projects and diagrams, sketches and drawings

- 3 Crib dimensions depending on the type of construction

- 4 Materials for making a classic baby bed from 5 years old

- 5 How to make your own baby bed for a newborn

- 6 Making a single wooden crib from 3 years old

- 7 Manufacturing of a structure from 3 years old with sides: children's loft bed

- 8 How to make a transforming bed yourself: a sequence of actions

DIY children's bed: basic design requirements

A self-made crib for children must meet the following requirements:

- this piece of furniture should be made exclusively from natural and environmentally friendly materials;

- the bed must have a reliable, strong and stable structure;

- the product should not contain sharp corners, protrusions;

- the surface of all components of the structure must be smooth, without chips and roughness;

- it is necessary that the size of the bed corresponds to the height and build of the child (with a margin of 25-30 cm in length);

- the structure must contain fencing elements and other devices that exclude the possibility of falling;

- bed for a child should have high functionality, which is expressed in the presence of drawers, shelves and niches.

A self-made children's bed made of wood has a number of advantages:

- you can be sure of the quality of the materials used for its manufacture, since many store products do not have information about the design parameters;

- a bed project is created according to individual parameters, taking into account personal requirements and desires;

- during the manufacture of a product, it is possible to check the structure for strength and stability;

- large financial costs are not required;

- handmade furniture gives incomparable pleasure and aesthetic pleasure.

First bought mattress, corresponding to the parameters of the child, the exact size of the bed will depend on it

DIY bed: dimensions, projects and diagrams, sketches and drawings

Today children's beds are presented in a wide variety of species. They differ in the type of construction, dimensions, the number of constituent elements, the presence of additional furniture devices and the material of manufacture. However, not every model can be done at home.

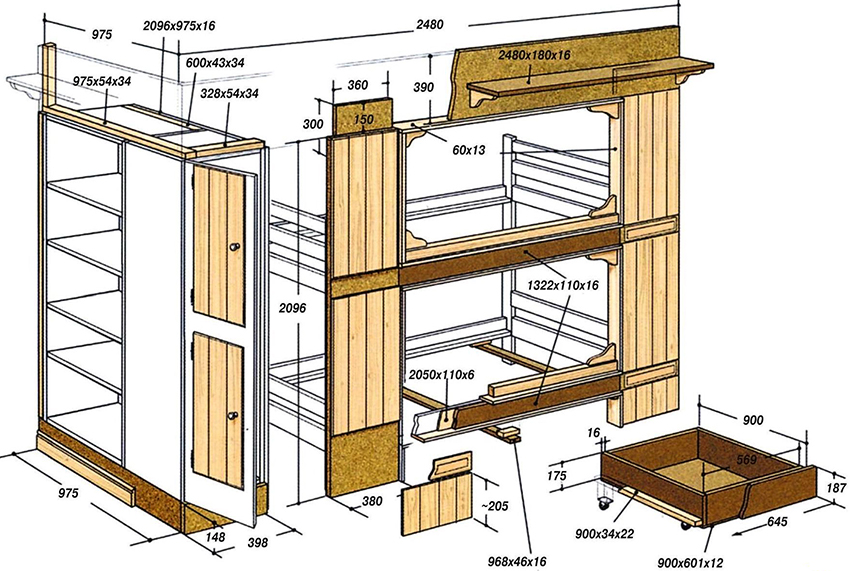

The most popular models that you can make yourself are classic wooden beds with your own hands. The photos clearly show the options for products with and without a side, loft beds and bunk structures. On specialized sites on the Internet, you can find a variety of do-it-yourself drawings of children's beds and the dimensions of each individual structural element.

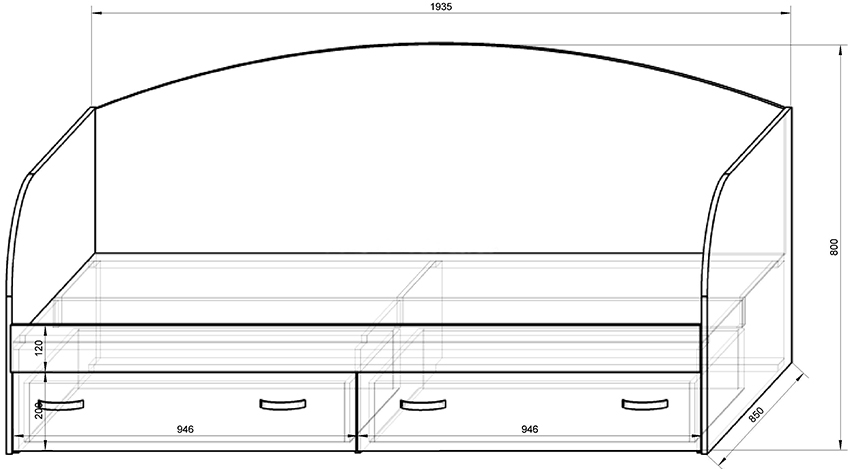

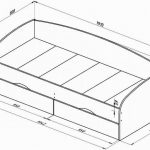

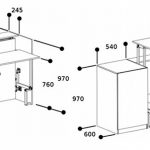

The classic single bed for children is the easiest to make. It carries a minimal functional load, since it can only be equipped with a laundry drawer. The design consists of a frame, headboard, footboard, base, sidewalls and legs, which are clearly displayed by the drawings of the baby bed. The size of the frame, for the manufacture of which a wooden beam is used, depends on the dimensions of the berth, which is determined by the parameters of the mattress.

The base can be solid (from a chipboard sheet) or lattice in the form of lamellas with ventilation holes. The second option is preferable. The footboard and headboard are usually made of solid wood, plywood or chipboard. Structures can have a variety of shapes.

Important! The height of the headboard should be greater than the size of the footboard.

For fencing a berth, the front and rear sidewalls are used in the form of a solid or lattice wall. Bed legs are custom made or purchased from a store. In the first case, they can be separately attached or are a continuation of a one-piece main structure.

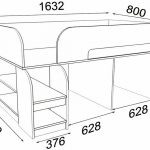

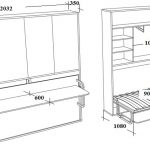

The loft bed is considered more functional. The sleeping place is located upstairs. Under it, you can organize a full-fledged storage system by placing a chest of drawers, wardrobe or shelving. The creation of such a structure requires skills and abilities in furniture production. For two children, you can make a two-tier structure, the creation of which also requires certain experience from the master.

Crib dimensions depending on the type of construction

Each type of baby bed has its own standard dimensions. Infants up to 6 months old can sleep in a compact crib, which resembles a stroller. The dimensions of the bed are 80x40 cm. Small deviations are provided for different design models.

The size of the bed for a newborn of a standard design is 60x120 cm. The side walls can be removable. The height of the bed relative to the floor can be changed, which allows it to adapt to the age of the child. Do-it-yourself single-bed crib has a width of 70 cm and a length of 130 cm.The design is carried out with protective fences, which are removable. The dimensions of sliding beds, the device of which allows you to change their size with the growth of the child, can reach a length of 160-170 cm.

Helpful advice! For a child who is spinning in a dream, it is recommended to choose a product with a width of at least 80 cm.

The requirements for a sleeping place for a teenage child differ significantly from the requirements for a bed for a younger student. The child's style and rhythm of life changes. Him room becomes a place for receiving guests.The standard size of a teenage bed is 90x180 cm. However, many parents refuse such an acquisition, since the structure will be small in a couple of years. The best option are beds with a size of 90x200 cm. Such an adult bed will be not only comfortable, but also durable.

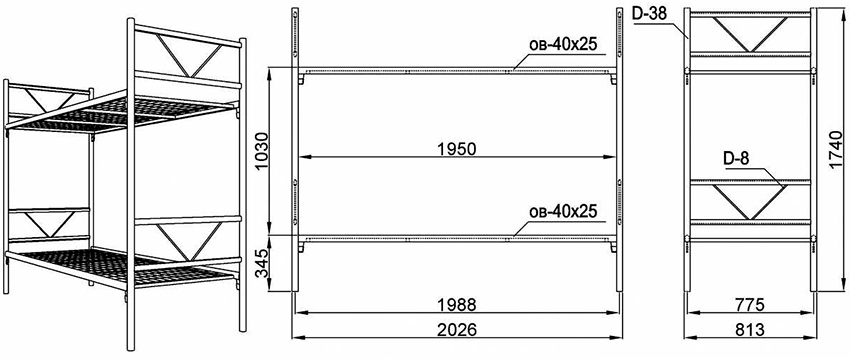

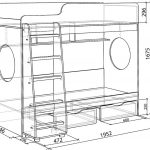

For two children, the best option is bunk beds... The height of the structure reaches 1.5-1.8 m, which depends on the height of the ceiling in the room. The outer dimensions of sleeping places may be different. The beds, which are located on the second tier, have dimensions of 80x200 or 90x200 cm. The berths on the lower floor can be shorter by 20-30 cm.

Materials for making a classic baby bed from 5 years old

For the manufacture of the frame, solid wood should be used. So do-it-yourself wooden bed characterized by safety, strength, reliability, environmental friendliness and durability, but it is distinguished by its high cost. Edged board is more affordable. The furniture board in the form of a solid wooden plate, created from glued bars of natural wood, has proven itself well. Lightweight MDF is also suitable.

Useful advice! Heavy solid wood should not be used as the material will make the structure heavy and uncomfortable to move.

For lamellas, you should choose an elastic material. Plywood is a good solution. Chipboard can be used for beds for children from 2 years old. The headboard and footboard are often made of MDF or chipboard. This material can also be used for the manufacture of drawers, shelves, decorative panels. For the production of a crib made of wood, a minimum set of tools is required, consisting of an electric jigsaw, a drill and a grinder.

In addition to the main material, you will need additional elements:

- fasteners of different diameters;

- joiner's glue;

- special furniture metal corners;

- guide panels for drawers;

- fittings;

- sandpaper;

Related article:

Diy bunk bed: assembly steps for different design options

Varieties of construction. Optimal dimensions. Manufacturing material. The sequence of assembling a bed made of wood, chipboard and metal.

- paper tape;

- stain;

- paint;

- varnish.

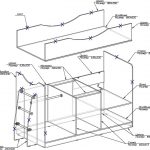

How to make your own baby bed for a newborn

Making a classic baby crib is a simple process. Dimensional drawings of a traditional wooden structure can be obtained from the Internet. The first step is to purchase a mattress, the size of which will determine the parameters of the bed.

The standard size of the product is 60x120 cm.The height of the sides of the structure, starting from the floor, reaches 90 cm.The backrests will have a larger size equal to 110 cm.It is best if the berth is located at a height of 30-35 cm, which will allow the baby 2-3 years to climb it without hindrance. The distance between the vertical bars on the headboards and sides of the bed should be 10-12 cm.

For the manufacture of the strapping of the side elements and sides of the bed for the baby, boards with a section of 35x70 mm are used. The bed on which the mattress will fit is made of six beams with a section of 30x50 mm. Holes with a depth of 25 mm are made in long beams for strapping the frame with a blind spike. The length of the cross members is equal to the width of the mattress minus twice the width of the beams. To the resulting value, add a value equal to the sum of the two nest depths.

Useful advice! In order to eliminate errors and speed up the process, marks are made at once on all identical parts.

How to make a baby bed for a newborn: sequence of actions

On both edges of the wooden beams, thorns are made (a through thorn is used to connect them). Such holes are made with a circular saw, which is adjustable in the height of the entrance. The spike should be the same thickness as the socket. This procedure is the same for all identical parts. The excess wood is removed with a saw.

Next, the parts of the lounger are glued. It is important here to monitor the evenness of all corners, which should have a value equal to 90 °. For the manufacture of bed rods, slats with a section of 20x20 mm are used. They must be attached to the crossbars of the backs and sides by using a single blind tenon. After the back frame is assembled, the length of the rods is calculated, to which you need to add double the length of the spike.

After making all the elements of the bed, the surface of each part must be carefully sanded. The rasp rounds off all sharp edges and corners. The next step is gluing all the details of the backrest on the hem. It is required to closely monitor the rectangularity of the structure.

The sides of the bed are made, the sizes of which are different. The lower transverse crossbars of the backs are docked with these elements. The length of the tailgate is equal to the length of the lounger with an allowance of 1 cm. To obtain the height of the side, it is necessary to subtract the height of the lower transverse slats of the back from 90.

To get a strip that can be removed on the front side, the length of its perches should be 15 cm shorter than the length of these elements of the second side. The spikes on them are made using the same algorithm that is used for their manufacture on the backs.

The side is glued on the hem in such a way that all its elements are perpendicular to each other. The next step is the assembly of the sides and back of the structure using self-tapping screws for fixing. Then do-it-yourself removable limiter for a baby bed is installed. It is attached to the outer board with an elastic band. Upon completion of the assembly, the bed is covered with plywood 3-4 mm thick, which is fixed with small studs.

Making a single wooden crib from 3 years old

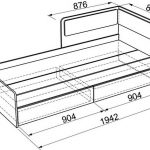

The structure of the structure for the child includes a base and backrests, which is clearly shown in the drawing of the bed. The width and length of the product is determined mattress dimensions... The bottom of the bed should be no more than 35 cm from the floor, so that the child can easily climb onto it.

The frame is made of two beams, which are made of edged boards measuring 50x100 mm. The required length of the product is measured with a tape measure, which is indicated with a pencil. According to the label, using a jigsaw, a board of a given size is sawn off in an amount of two pieces. Glue is applied to the side of each bar. By means of self-tapping screws, strips of 25x50 mm are fixed in these places for attaching the lamellas, and they should be 10 cm shorter than the crossbar.

How is the preparation of the base for the mattress of a baby bed from 2 years old? For this, boards are cut from slats (20x20 mm), the length of which corresponds to the width of the mattress. Their number is determined based on the complete filling of the base space. Products with an emphasis are fastened parallel to each other with the help of self-tapping screws to the strips of the crossbeams. The step between them should be no more than 10 cm.

Important! The self-tapping screw's head must completely go into the wooden crossbar, leaving a small depression, which is filled with a putty mixture.

Then you need to grind all holes for fasteners.In the extreme slats, cutouts are made for the legs of the bed, which are made from a bar of 50x50 mm in the amount of 8 pcs. The four pieces under the headboard should be longer than the pieces under the footboard. The workpieces are glued in pairs and fixed with self-tapping screws.

Creation of side elements of the bed for children from 3 years old

The next step is to make holes for the dowels in the boards with a groove 25 mm wide using an electric drill, which are used to make the foot and head of the structure. They are drilled at the ends of the strips. You should be extremely careful when making holes, which should be at the same level on all planks. It is necessary that they have the same depth, which is equal to ½ the length of the board.

The headboard and footboard of the bed can be made from solid pieces of chipboard or MDF. The first element is longer than the second. The width of the parts is determined based on the value of this parameter of the mattress, to which is added the double wall thickness of the longitudinal crossbars of the bed frame. Products can have a different shape of the end part, which is round or wavy. If the side elements of the bed are made with railings, then another 25 mm should be added to the width of the product.

Useful advice! Having cut out products from chipboard or MDF, their surface should be pasted over with paper tape, which will prevent the formation of chips.

If wooden boards are used to make the side elements of the bed for children from 2 years old, then the following sequence of actions is required. Parts of equal length are cut from bars with a size of 25x50 mm. They are inserted into vertical plank grooves filled with glue. Holes for dowels are made in the legs. They accommodate side structural elements. The parts should be pressed tightly, excluding distortions and cracks.

Having made the vertical supports of the side elements, they should be tied with a frame around the perimeter to create a wooden roof. The last step is to attach the ridge beam, which will connect the base of the bed-house structure with your own hands. After all the details of the product are prepared, the moment comes for their assembly. Beforehand, each element is checked for chips and grooves, which are sealed with a putty mixture, and the surface is sanded to a smooth state. Further, all parts are treated with a primer or stain. After they have completely dried, the surface of the products is covered with paint.

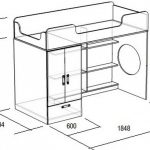

Manufacturing of a structure from 3 years old with sides: children's loft bed

There are several types of loft beds. The structure can be located on four supports, attached to a wall or ceiling. The first option is the easiest to manufacture. The stock is made of solid wood. For its production, you will need a glued or calibrated board with a section of 40 mm, a bar of 50x50 mm, planed strips 35 mm wide and 10 mm thick.

From the board, the frame of a do-it-yourself loft-bed is knocked off, which in each direction has internal dimensions larger by 20 cm than the dimensions of the mattress. The frame from the bar is screwed to the bottom end of the box flush from the inside. A rack base is made from thin strips. Elements should be 20 mm shorter than the inner dimensions of the box. The strips are located at a distance of 50-65 mm from each other and are screwed to the frame with self-tapping screws.

The height of the fence of a child's bed from 3 years old with their own hands is determined based on the thickness of the mattress. The sideboard should rise 15-20 cm above it. At the location of the stairs in the fence, a gap of about 80 cm wide is made. For the manufacture of the sides, it is advisable to use a decorative panel made of MDF or chipboard. You can also enclose the sleeping bed with a frame made of wooden beams with a section of 25x25 mm.Its racks will abut against the timber on which the rack base of the berth is located. They are fastened with through ties to the box enclosing them.

Useful advice! To prevent the sharp edges of the bars from pressing into the mattress and not damaging its mattress cover, they must be chamfered.

The stock is fixed by means of screw connections or metal corners to the uprights. For reliability, the supports are fixed with rails from the ends.

Organization of the lower zone of a child's bed from 3 years old with sides

In the free space formed under the do-it-yourself loft bed, you can fit a spacious wardrobe. Its doors are best placed on the side of the structure. The second wall in this case will be an additional fulcrum. In the remaining free space, you can install a rack with open shelves or a desk. Children's beds with drawers are very popular, which fill the lower space under the berth.

You can also place a longitudinal cabinet in a free space. The side support panels will experience minimal stress, and the sleeping area will not interfere with free access to the cabinet. Its walls are attached in the same way for both options. One outer side is sewn up with laminated chipboard, to which shelves must be attached using confirmations. Then a straight panel is fixed, which is used for hanging the doors.

The resulting rectangular bedside space can be divided by means of horizontal and vertical partitions into any zones with drawers and open shelves. Here it is desirable to set desk, table top which is made of laminated chipboard. This is only possible with a sufficient berth height. One of the side panels of the structure will serve as a fulcrum. Different options are shown in the photo of do-it-yourself children's beds made of wood.

Useful advice! For additional space saving, the laminated chipboard tabletop can be retractable or folding.

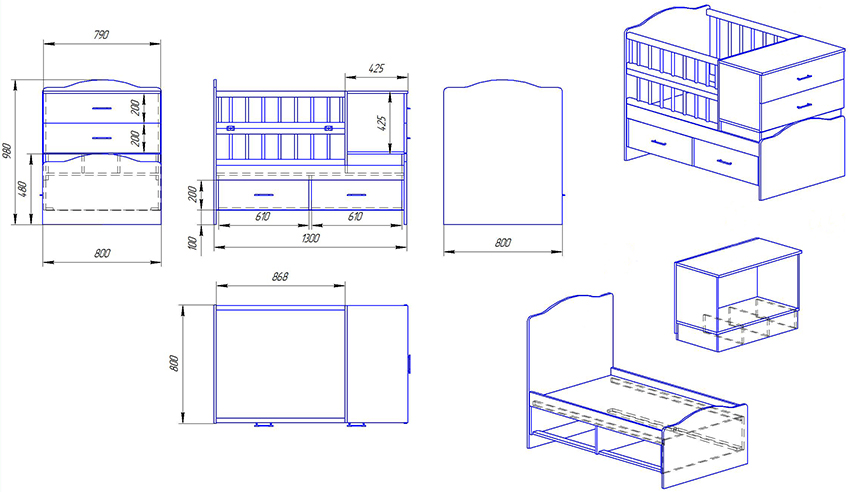

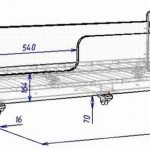

How to make a transforming bed yourself: a sequence of actions

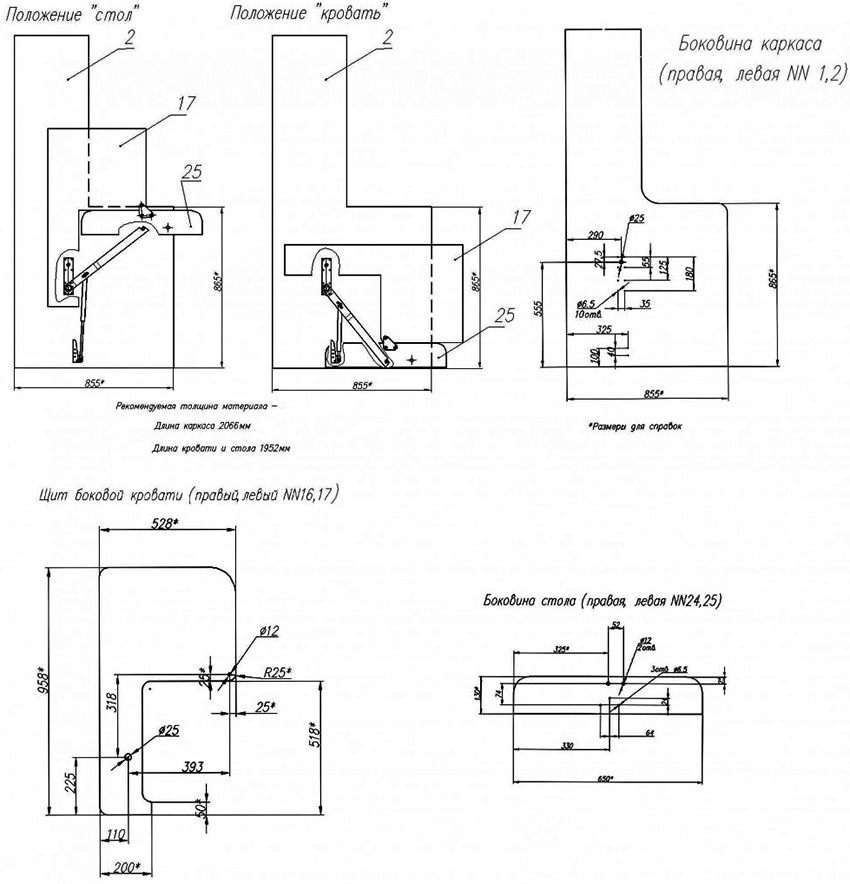

The convertible folding bed consists of three main elements: a bed, a box and a lifting mechanism. Bed dimensions are based on age. However, it is necessary to provide a large margin, taking into account the growing up of the child. As a material for making a crib with your own hands, you can use natural wood, MDF or chipboard. The latter option is the cheapest, providing the structure with low weight.

The box must be strong enough to withstand the load of the moving bed and the lifting mechanism. It consists of a skirting board, a back panel and a stop strip. The size of the box is calculated based on the size of the mattress and the height of the headboards. All parts are assembled on the floor and fixed with self-tapping screws. The box is installed on the floor or base and is screwed to the wall with metal corners.

The mattress bed should be easily lifted and fixed in an upright position. A factory-made orthopedic frame is ideal as a moving part. It is equipped with legs, the height of which is adjusted to the required dimensions. To prevent the mattress from shifting in different directions around the perimeter of the frame, it is required to create sides from a high-quality wooden board.

Useful advice! Additionally, it is recommended to install a counterbalance system or gas shock absorbers.

The lifting mechanism can be made independently from trunnions with bearings or from garage curtains. A more reliable option is to purchase a factory kit. The mechanism must be fixed to the box and the sleeping place.The front of the bed in an upright position can be decorated under a wardrobe with imitation doors with handles or create a monolithic mirror surface.

Today, on the Internet, there are detailed drawings with the dimensions of various designs for children's beds. Having minimal skills and having a great desire to please your child, you can create a unique sleeping bed with your own hands.