The weight of pipes is a parameter that determines the mass of 1 running meter of a steel part. There are several ways in which this indicator can be calculated. These methods have some differences depending on the types of pipes that differ in the shape of the section. Determining the mass of pipes is a serious measure required to calculate transportation costs and construction nuances.

Calculation of the mass of a steel pipe is used in construction to determine the strength of a future structure

Content

- 1 For what purposes is the mass of steel pipes determined

- 2 How to correctly calculate the weight of the pipe yourself: recommendations

- 3 Advantages and disadvantages of steel pipe

- 4 Steel pipe weight calculation rules

- 5 Pipe weight: how to calculate the mass when purchasing

- 6 How to calculate the weight of a profile pipe (square and rectangular)

- 7 Methods for determining the weight of steel electrowelded pipes

- 8 Calculation of the weight of a stainless pipe: sequence of actions and features

- 9 Formula for calculating the weight of pipes with a non-standard section

- 10 Steel pipe weight chart: tips for use

- 11 Using the Online Pipe Weight Calculator

For what purposes is the mass of steel pipes determined

Steel pipes are widely used in the construction industry. In any project, you can find information about the mass of the water supply system laid in the building. The same applies to other piping systems and structures made of shaped steel. The weight of water and gas supply steel pipes is calculated in several ways. What else is required to calculate this parameter?

The theoretical mass is necessary for the sale, since the pipes are sold based on mass, not length. Thus, the determination of this indicator makes it possible to calculate the cost of a single batch.

The calculation of the mass of these products is used in construction to determine the strength of the future structure. This parameter allows you to find out what loads the frame made of pipes can carry.

Note! Finding the specific gravity helps to increase the accuracy of calculations, since real values often do not coincide with GOSTs.

And finally, the calculation of the weight of the metal pipes is done before the transportation of the products. Transportation must be carried out on special cargo equipment, taking into account the possible load.When concluding a contract specifying the number of products and their weight, you should be sure that the transportation will be carried out in one trip.

It is necessary to know the weight of the pipes for sale, since the material is sold taking into account the mass, not the length

Thus, knowing the mass of steel pipes is a prerequisite when purchasing them. Of course, when buying these parts one by one, there is no need for such a calculation. Determination of weight in such a situation may be required only in order to calculate the real cost of products.

How to correctly calculate the weight of the pipe yourself: recommendations

The calculation of the mass of a steel part of this type can be performed independently (without applying state standards). First of all, it will be necessary to determine the basic physical and geometric characteristics of rolled metal. The calculation of the weight of round parts is somewhat different from the calculation of this parameter for shaped pipes (rectangular and square).

To determine the weight of a meter of a pipe with a circular cross-section, it is necessary to measure its inner and outer diameters. For shaped pipes, the required step is to determine the width and height. If necessary, you can use the regulatory documentation that is publicly available on the Internet. The corresponding GOSTs contain all the necessary information about pipes of any type. It is important to remember that there is a corresponding document for each type of these parts.

In order to determine the mass of a meter of circular pipe, you need to measure its inner and outer diameters

Many indicators (for example, length) can be determined independently using a construction tape. In order for the calculation to be as accurate as possible, it is recommended to find out the type of material, its brand.

You can find out how much a pipe weighs without performing complex calculations. GOSTs regulating metal pipe-rolling products contain special tables. They indicate the main indicators characterizing the part (including weight). You can also use the online calculator, which contains the algorithm for calculating the mass.

Advantages and disadvantages of steel pipe

Steel products have many advantages that are worth considering. First of all, it should be noted that parts made of this alloy are distinguished by high strength characteristics. It is this fact that determines their widespread use in the construction industry, where the strength of products is one of the main indicators. A wide range of parts is also considered an important advantage, as it allows you to expand their operational scope. In the construction market, you can easily choose parts that are suitable in shape and technical characteristics.

Note! These products are manufactured and sold in running meters. The weight of the pipes is the main characteristic that affects the cost.

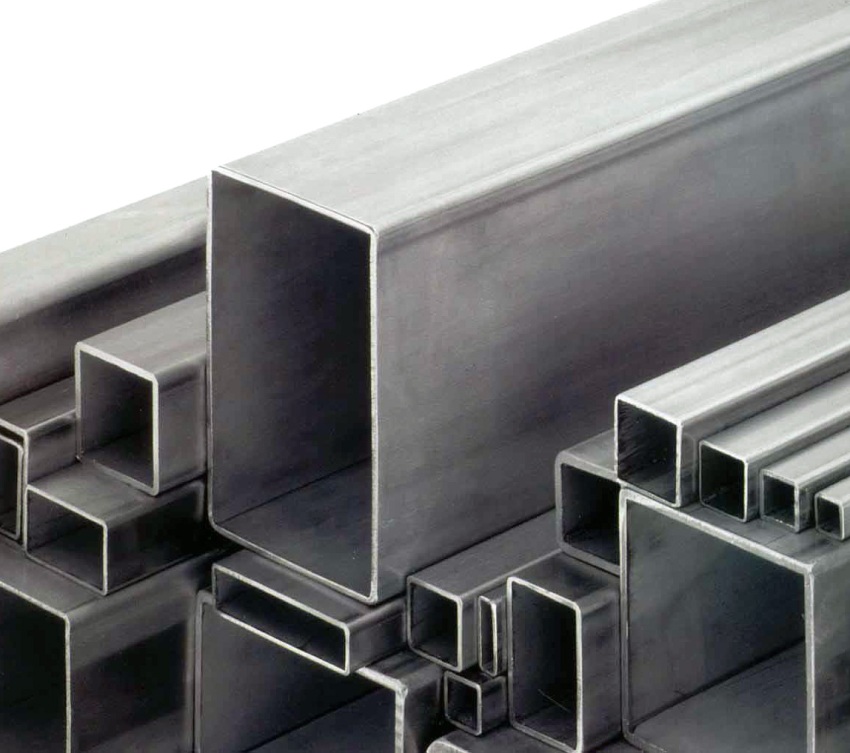

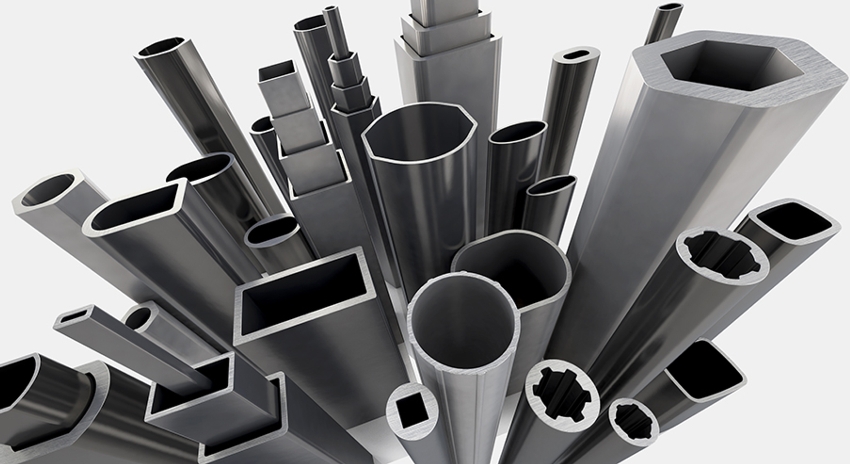

All steel pipes can be divided into three categories:

- round;

- profiled (square and rectangular);

- non-standard (multifaceted).

A serious advantage inherent in these products is that they are highly resistant to mechanical stress. Steel pipes withstand pressure and shock very well. It should be noted that they have an acceptable cost and belong to the middle price segment.

A wide variety of types of parts allows them to be used in various fields: construction, household, etc. Steel products have a small index of linear expansion. This is a very important advantage, since many pipes expand when heated, and if they are placed in a screed, this can lead to cracks.

In order to answer the question of how to calculate the weight of a pipe, you need to get to know more closely all the methods that allow you to make this calculation. Knowledge of the mass of steel products is required at all stages, from their acquisition to installation.

Steel pipe weight calculation rules

It may seem to many people that determining the mass of pipes is a simple matter. However, such a calculation has many nuances that you need to pay attention to. First of all, it is important to remember that when purchasing a batch of steel pipes, it is imperative to check the weight. Any discrepancies in the calculations may lead to the fact that there is simply not enough material.

Excess weight can affect the building characteristics of the future structure. The load on the structure must be within the limits calculated earlier and indicated in the corresponding drawing. The weight of 1 meter of pipe is calculated taking into account the grade of steel from which the product is made.

It often happens that the actual weight of the pipe does not correspond to the specific gravity prescribed in the regulatory documentation. This is due to the nature of production. A product that perfectly matches the documentation is almost impossible to execute. Therefore, GOSTs indicate the permissible deviations in size.

When determining the weight of a meter of steel pipe, it is recommended to use several methods at once. This will keep design errors to a minimum. If a formula is used to determine the mass, then it is recommended to double-check the reliability of the final results several times.

Pipe weight: how to calculate the mass when purchasing

Most often, manufacturers who manufacture metal pipes of various types sell their products in bulk. The sale of individual parts is also carried out, but its percentage is much lower compared to large orders, which are issued by developers and individuals.

Helpful information! Measuring the length of products that make up one batch is not a convenient solution. In order to simplify implementation, the cost is calculated taking into account the mass of the batch, which is determined based on the mass of the part. To calculate it, you need to know the weight of 1 meter of the pipe. This is the fastest method of calculation, but it is not the best for the customer. This is due to the fact that after using steel pipes, as a rule, some percentage of surplus remains.

To determine the mass of a batch in production, two methods are used. The first one takes into account the use of an online calculator. This program allows you to quickly calculate the weight of steel parts. Often, an online calculator is posted on the website of a company that manufactures steel products. Thus, each customer can determine the required batch weight in a matter of minutes and immediately place an order.

The second method to calculate the weight of the steel pipe for procurement is weighing. It is produced using special cargo equipment. This operation is performed in 2 stages. First of all, the machine (or trailer) is located on the scales, which allows you to determine its mass. Then a batch of metal parts is loaded into it. The original weight of the vehicle is subtracted from the resulting figure - the total mass of the batch is obtained.

Each buyer can come to the production, if it is required to determine other characteristics of the batch. For example, you may need to calculate the number of pipes in one order. And also very often you need to know the length of the products.As a result, such calculations will make it possible to place an order not by weight, but by the number of packages.

Calculation of steel pipes: the weight of round products and features of its determination

Round pipes made of steel are very popular when laying various communications. It is important to remember that such products have their own characteristics for calculating mass. To determine this indicator, you need to know some physical and geometric characteristics. Before starting the calculation, the following data is required:

- wall thickness;

- outside diameter;

- sectional shape;

- steel grade (for accuracy of calculations).

The easiest way to calculate in this case is to use a special online calculator. Calculating the weight of a steel round pipe using a special program, which contains a formula that allows you to quickly determine the mass, is very simple. All that is needed for this is to enter the necessary parameters of the part in the appropriate cells.

Note! It is important to remember that when calculating the weight of a product with a circular cross-section, the main indicator is the grade of the alloy. Experts do not recommend performing a calculation without taking this characteristic into account.

To find the desired value, the following action is performed: the volume of the material is multiplied by the density of the steel. The density index for steel is a fixed unit and is 7850 kg / m³. With this calculation, you can determine the mass of any round part (for example, the weight of a pipe is 76 mm).

Today, there are two methods for calculating the volume of a steel round product or a part made of another material. The first of them involves the calculation of a preliminary blank (sheet), from which the pipe is made. In the second case, it is necessary to find the difference between the volumes of the outer and inner cylinders.

Related article:

Assortment of corners in regulatory documents: GOSTs, product characteristics

Varieties of steel corners: equal and unequal. Popular product sizes. Steel angle weight.

Formulas for determining the mass of steel round pipes

The calculation of the mass is carried out using special formulas. In order to understand them, it is recommended to study the calculation stages and the values used in this in more detail. The first formula requires knowledge of the diameter of the steel product and its wall thickness. As an example, the calculation of the pipe weight is 219x8 mm. First, the surface area of 1 meter of the part is determined. This equation is as follows:

S = π x D, where:

S is the sectional area of 1 m of the part;

D is the diameter;

π is a mathematical constant, which is 3.14.

In its finished form (with substituted values), this formula looks like this:

S = 3.14 x 0.219 = 0.68 m

After determining the area of 1 m of a round product, it is necessary to calculate the volume of steel spent on the production of the steel part. To do this, you need to multiply the area indicator obtained earlier by the pipe wall thickness. To determine the weight of 1 meter of 2019x8 pipe, you must strictly follow the calculations. Let's see how this is done with an example:

V = S x t, where:

V is the volume of consumed steel;

S is the sectional area of the part;

t is the wall thickness.

After entering the required values, the equation takes the following form:

V = 0.68 x 0.008 = 0.00544 m³

To determine the weight of 1 meter of a metal pipe, you must strictly follow the calculations of the formula V = S x t

The last step in determining the mass of a steel round product is to multiply the volume by the density of the material. This parameter is contained in special density tables.For steel, as mentioned above, the fixed value is 7850 kg / m³. So, the final stage of calculating the mass of a steel pipe:

m (1 m) = V x ρ, where:

m (1 m) - weight of 1 m of the product;

V is the volume of consumed steel;

ρ is the density of the material.

The calculation using this formula looks like this:

m (1 m) = 7850 x 0.00544 = 42.7 kg

Using this method, you can determine the mass of a part of any width (for example, the weight of 1 meter of a pipe is 219x10 mm). The figure obtained as a result of calculations may not correspond to the table. The schemes indicate the theoretical value of 1 running meter. There are tables that contain the mass of products with a certain standard size in tons.

Note! Calculation of this type allows you to obtain the mass of 1 running meter of the part. To find the total mass of the pipe, multiply the weight of 1 m by the length of the product.

The final step in determining the mass of a metal pipe is to multiply the volume by the density of the material

The second way to calculate the mass of steel round pipes

There is another formula by which you can calculate the mass of products with a circular cross section. This method involves determining the volumes of the outer and inner cylinders. The first step in such a calculation is to find the area of the outer and inner surfaces of a round steel part. This method allows you to calculate the mass of a product of any standard size, for example, the weight of a pipe 159 or 219 mm. The formula by which this calculation is performed:

S (outer) = π x D, where:

S (outer) - the area of the outer surface of the part;

π - 3.14;

D - diameter.

After entering the necessary values, the formula takes on a more understandable form:

3.14 x 0.219 = 0.68766 m2

Next, you need to calculate the second indicator of the area - internal. To do this, subtract the thickness of the part, multiplied by 2, and converted to the desired shape from the outer section previously defined. The equation will look like this:

S (internal) = S (external) - t x 2; (t is the thickness of the part).

The first step in calculating the mass is to find the area of the outer and inner surfaces of a round pipe

The finished formula looks like this:

0.219 - 0.016 = 0.203 m2

Then it is necessary to multiply the number Pi by the figure obtained as a result of the previous calculation. This will determine the inner diameter required to calculate the pipe weight of 219 mm. Ready formula:

0.203 x 3.14 = 0.63742 m2

The next step involves subtracting from the outer diameter a similar indicator corresponding to the inner side of the part. As a result, we get the finished difference, which is 0.05024. It must be multiplied by 1 m, which will convert the number into cubic form (m³). The final step in this series of calculations is to determine the weight of the product. To do this, it is necessary to multiply the difference in cylinder volumes by the density of the material, which will allow you to calculate the weight of 1 meter of the product. The final calculation looks like this:

0.05024 x 785 = 39.4 kg

It should be remembered that the difference between the results obtained using two different formulas is not a critical factor. Both values also differ from the tabular weight of 1 meter of a round steel pipe with such dimensions. This can be explained quite simply. The calculation of this indicator, as a rule, takes into account the permissible errors in the dimensions, which are prescribed in the corresponding GOSTs, while standard values were substituted in the formulas discussed above.

How to calculate the weight of a profile pipe (square and rectangular)

The formulas that are used to find the mass of round pipes are not suitable for determining the weight of shaped products. The round type of rolled metal is more common, as it is more often used in the construction and economic fields. Profile pipes differ in that they have a different sectional shape.On sale you can find the following options for these products:

- square;

- rectangular;

- diamond-shaped;

- oval;

- trapezoidal.

Specific gravity shaped pipe can be determined independently using special formulas

There are several ways to find the weight of steel profile pipes, as is the case with round parts. Such products are used in construction, most often for the organization of interfloor floors. With the help of them, frame structures (both simple and complex) are mounted.

Helpful information! The simplest frame options are used in the construction of greenhouses in summer cottages, as well as to create garage structures.

The use of rectangular or square rolled metal in construction requires precision. The mass of products is calculated in advance and is indicated in the design documentation. The specific gravity of a profile pipe can be determined independently using special formulas. To calculate the mass of square products, the following equation is applied:

m = (ρ) x 0.0157 x t x (A x 2 - 2.86 x t) x L, where:

ρ is the density of the metal;

0.0157 is a constant value for calculating the specific gravity;

A - side length;

t is the wall thickness of the product;

The formulas that are used to find the mass of round pipes are not suitable for determining the weight of shaped products

2.86 is a constant value;

L is the length of the pipe.

The above formula allows you to determine the mass of one part with a square sectional shape. The batch weight in this case is calculated very simply. To do this, multiply the mass of one product by the number of pipes. For rectangular parts, there is its own formula, with which the mass is determined (for example, the weight of a profile pipe is 40x20x2). A similar equation looks like this:

m = (ρ / 7850) x 0.0157 x t x (A + B - 2.86 x t) x L

Values A and B correspond to the lengths of the sides of a rectangular metal piece. It is worth noting that the data obtained as a result of using these formulas may differ from the tabular numbers. However, this difference is quite normal.

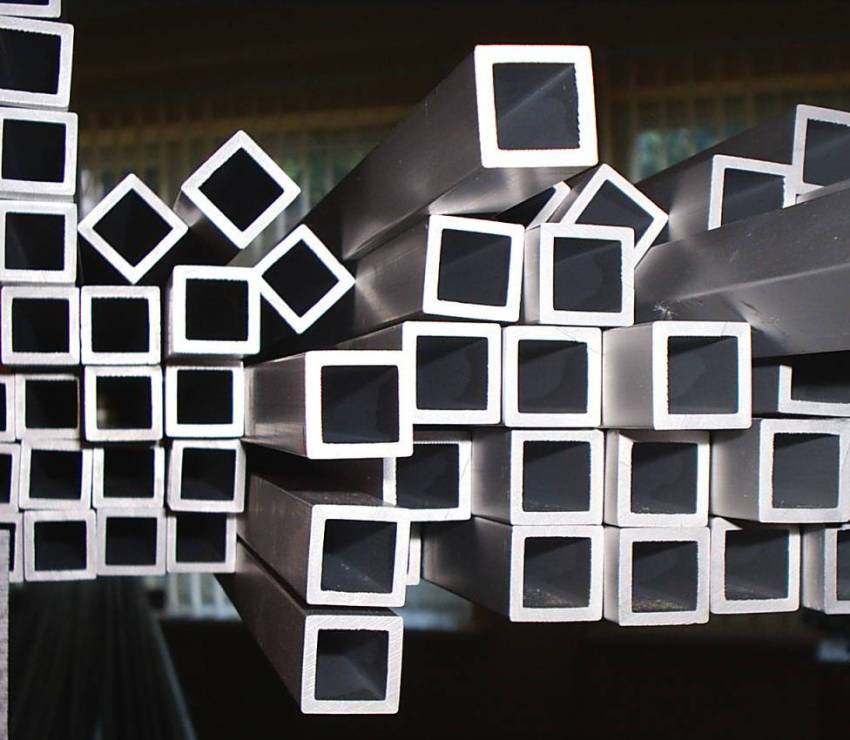

Methods for calculating the weight of a square pipe: popular options

The mass of products made of steel and having a square section can be determined using different formulas. When carrying out geometric calculations, there are certain nuances that you need to know. Most often, the weight of a steel part with a square section is found using a formula that multiplies the volume of the walls of the product by its density.

The specific gravity of all steel products is a fixed parameter, which is 7850 kg / m³. The application of the method, taking into account the use of the volume of the sides and the density, makes it possible to determine the weight of a running meter of a shaped pipe quite accurately.

To find the mass of a meter of a part, a formula is most often used, in which it is necessary to multiply the thickness of the product by the wall area. The area is determined by multiplying the length of the part by its width (for a rectangle). The resulting figure must be multiplied by 4 (the number of walls in a square pipe). After calculating the weight of 1 m of the part, it is necessary to enter the resulting value into the final equation, which allows you to calculate the mass of the entire product. Consider this formula:

m = 7850 x t x 4 x A x 1, where:

A - product dimensions;

t is the wall thickness of the part.

The mass of a meter of a steel profile pipe can be found using the table, which contains all the necessary information

Note! To determine the mass of 1 m, the easiest way is to use the weight table for steel square pipes.

Another popular method by which the mass of a square steel pipe is determined involves the application of a formula that has a constant:

m = (A - t) x t x 0.0316, where:

A - product dimensions;

t is the thickness of the part.

As an example, using this formula, you can determine the weight of 1 meter of 80x80x4 pipe. The finished equation containing the substituted values will look like this:

m = (80 - 4) x 4 x 0.0316 = 9.6 kg

However, the method that takes into account the use of these formulas is still not the simplest and fastest. If necessary, you can determine the mass per meter of the product using tables containing all the necessary information about rolled steel. Such tables are located in GOSTs that regulate one or another type of rolled metal.

To find the mass of a meter of a profile pipe, a formula is used in which it is necessary to multiply the thickness of the product by the wall area

How to calculate the weight of a profile pipe: table

Various techniques can be used to calculate the specific gravity of a profile. The most popular of these is the tabular method. The use of special tables, which can be found without much difficulty in regulatory documents, saves the time required for the calculation. The diagrams contain all the necessary geometric parameters, as well as physical data, which include weight.

Weight tables for 1 meter of steel pipes include already calculated data, which is easy to determine based on the dimensions of the part. With the help of such tables, you can quickly calculate the total mass of the shaped product. To do this, multiply the value corresponding to the weight of 1 meter by the length of the pipe.

Table 1. Weight per meter of steel square profiled pipe:

| Dimensions, mm | Weight 1 rm. m, kg |

| 100x100x8 | 22,25 |

| 20x20x2 | 1,08 |

| 50x50x3 | 4,31 |

| 80x80x5 | 11,44 |

| 40x40x4 | 4,3 |

| 100x100x4 | 11,84 |

| 25x25x2 | 1,39 |

| 60x60x4 | 6,82 |

| 15x15x1 | 0,479 |

| 80x80x3 | 7,133 |

| 50x50x4 | 5,56 |

| 30x30x2 | 1,7 |

| 60x60x2 | 3,59 |

| 40x40x3 | 3,36 |

Table 2. Weight per meter of rectangular steel profiled pipe:

| Dimensions, mm | Weight 1 rm. m, kg |

| 150x100x5 | 18,5 |

| 80x40x2 | 3,59 |

| 50x40x2 | 2,65 |

| 20x10x1.5 | 0,6 |

| 120x60x3 | 8,07 |

| 80x40x4 | 6,82 |

| 100x50x4 | 8,7 |

| 40x25x2 | 1,86 |

| 120x80x4 | 11,84 |

| 30x20x2 | 1,39 |

| 40x20x2 | 1,7 |

| 20x10x1.2 | 0,5 |

It is worth noting that there are special tables that indicate the number of meters in 1 ton of products. It is very easy to use the steel profile pipe weight tables. The data from these tables can be used not only to determine the mass of 1 meter, but also for other, more complex construction calculations.

Methods for determining the weight of steel electrowelded pipes

The weight of the electrofusion piece depends on several factors. First of all, it is worth noting such an indicator as the specific density of the material. Of course, the geometric parameters of the part also play an important role. The most important ones are:

- diameter (for round parts);

- width and height (for profiled steel);

- thickness;

- length.

Note! To carry out calculations, it is necessary to understand that the length of the part when determining the specific or (as it is also called) theoretical weight will be equal to 1 m.

The density of this material is a constant value corresponding to the number 7850 m³. To determine the weight of electrowelded pipes, the following methods are used:

- formulas;

- tables;

- online calculators.

Each of the above methods involves obtaining a value that is not ideal. The final result, which is approximate, is influenced by several factors. For example, a fixed density value (7850 m³) is used to calculate the specific gravity of all types of steel pipes. However, different steel grades are used for each type of part. Thus, the fixed value affects the final result, which differs from the actual one.

The difference in density of different grades of steel is not very noticeable when calculating if the batch size is not large enough. In the electric welded steel pipe tables, the weight is also approximate.In addition, the totals in the tables are often rounded off (for convenience).

Another reason for the approximate calculations is that ideal dimensions are used to carry out the calculations. As a rule, they differ from the actual ones, since they do not take into account the roundings in the corners of the pipes. Rounding as a parameter can be present in profile pipes. How much does such a product weigh? The best way to answer this question is to use a spreadsheet or online calculator. This will save time.

The real part is distinguished by the neatness of the welds. Such seams can have different beads of metal. Another factor that contributes to inaccurate calculations is manufacturing tolerances. A universal method for determining mass is using formulas. But more often than not, this option does not justify itself, since not every person will be able to carry out a complex calculation that takes into account the use of many auxiliary geometric and physical parameters.

Calculation of the weight of a stainless pipe: sequence of actions and features

Stainless steel pipes differ from conventional steel products in that they are more resistant to adverse operating conditions. For example, they are highly resistant to rusting, unlike conventional steel pipes.

Helpful information! It is worth noting the increased strength of these products, which is reflected in the shelf life.

How to calculate the mass of a stainless steel part? This operation is not very difficult. To determine the specific gravity, it is necessary to multiply parameters such as material density and volume. In turn, in order to calculate the volume of the product, you will need to multiply the surface area of the part by the wall thickness.

Let's consider how to determine the weight of a stainless steel pipe 57x57x3 mm, for example. The calculation in this case includes 3 stages. The first formula will look like this:

S = B x L x 4

Stainless steel pipes are distinguished by the fact that they are more resistant to adverse operating conditions

S - area;

B - width of 1 wall;

L - product length;

4 - the number of walls.

The completed equation with substituted values looks like this:

S = 57 x 6 x 4 = 1.368 m²

With this method, weights of different sizes can be determined (for example, pipe weights 108, 120 or 150 mm). After calculating the area of the stainless part, you can proceed to the next step. The second step takes into account the determination of the pipe volume. To do this, as mentioned above, it is necessary to multiply the surface area and wall thickness:

V = S x t

V = 1.368 x 3 = 4, 104 m³

To determine the specific gravity of a stainless steel pipe, it is necessary to multiply parameters such as material density and volume

And finally, after calculating the volume of the product, you can find its specific gravity. To do this, you need to multiply the fixed density of steel, equal to 7850 m³, by the volume of the part. Consider the equation:

m = V x 7850

m = 4.104 x 7850 = 3.2 kg

To determine the mass of a pipe made of stainless steel, there is another, simpler method. It is suitable for round parts. To carry out the calculation, you will need to subtract the wall thickness from the outer diameter. Then the resulting difference is multiplied by the thickness and a fixed number, which is 0.025 kg.

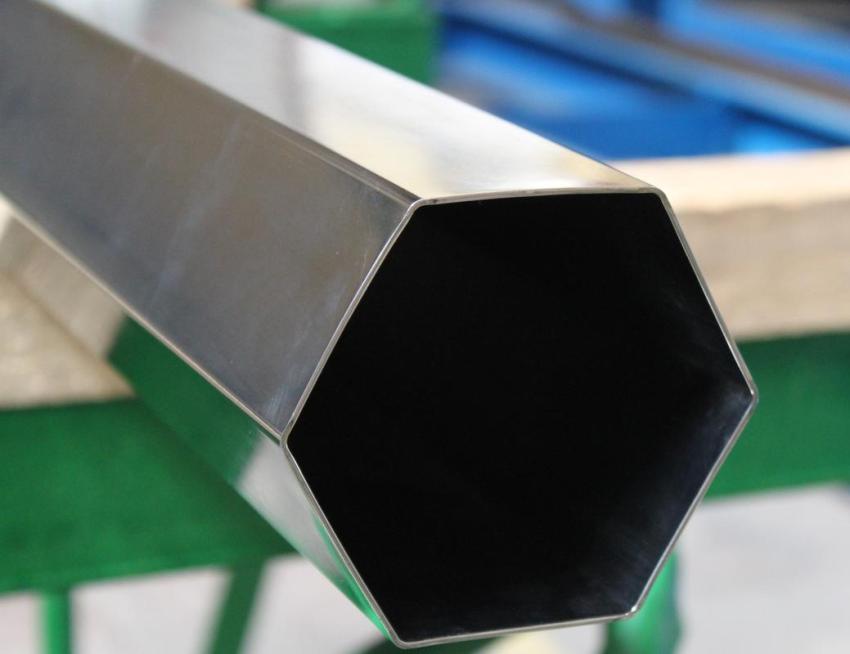

The formula for calculating the weight of pipes with a non-standard section

In addition to round and shaped products, there is another common type - pipes with a non-standard section. Many people wonder how to find tons of such details. In the modern steel pipe market, the most common options for unconventional cross-sections are:

- oval;

In addition to round and shaped products, there is another common type - pipes with a non-standard section

- trapezoidal;

- diamond-shaped;

- pentahedron;

- hexagon.

On the Internet, you can find tables of the weight of pipes with a non-standard section. In addition, there are special formulas that allow you to independently calculate this parameter. The operational scope of such products is quite extensive. They are used for the installation of fences and other all kinds of fences, as well as railings. In production, these parts are included in a variety of designs. To determine the specific gravity of pipes with a non-standard section, the formula is applied:

m = ρ x S x L, where:

ρ is an indicator of material density;

S - cross-sectional area;

L is the length of the product.

This formula is universal. Therefore, using it, you can calculate the specific gravity of parts with different sectional shapes. The equation allows you to answer the question of how to find out the weight of a pipe with a non-standard section.

Note! In order to determine how the products from the same batch meet the requirements stated by the manufacturer, it is recommended to perform a simple check. To do this, you will need to select 3-4 arbitrary parts from a batch and calculate the mass of each of them. Comparison of the data obtained will provide a range of tolerances.

If the weight of the pipes is already known, then it becomes possible to calculate the total length of the batch. There is a special formula for this:

L = m / ρ x S

For the final result to be as accurate as possible, a number of other factors must be considered. Among them are the following: alloy composition, uniformity of wall thickness of the part, corrosion rate. And also the mass is influenced by air humidity and its temperature.

Steel pipe weight table: tips for use

In this case, a special table can serve as a data source. Its choice is carried out depending on the type of product. In addition to GOSTs, diagrams can be found on many specialized sites. Today on the Internet you can easily find tables for determining the mass of parts from different materials (for example, the weight of a cast-iron pipe is 100 mm).

Finding mass in a tabular way requires compliance with two basic rules. First of all, it is very important not to be mistaken when choosing a table. To do this, you need to check whether the name of the state standard corresponds to the material of the product, the mass of which you want to determine.

The second rule is that you should not completely rely on data defined using a table. As a rule, the specific gravity of the pipe does not correspond to the actual one. Thus, any calculation will only be approximate. For small batches, this distinction is not a major problem.

As an example, you can take a steel part with dimensions of 60x60x3. The weight of 1 meter of this type of pipe is 5.25 kg, if you follow the table calculation. This product belongs to the profile group and has walls equal in width. The actual weight of a product with such dimensions may differ. The maximum allowance in this case is 10% of the total mass (52.5 g).

The tabular method is very good in the case when you do not have time to perform long, complex calculations. However, it is always worth remembering about the error that is present in this case.

Using the Online Pipe Weight Calculator

The online calculator is a very simple way to quickly determine the mass of steel pipes. It is worth saying that there are programs that allow you to calculate the weight of products made from other materials. The online calculator works according to the prescribed algorithm.The formula in this program takes into account the following characteristics:

- density;

- width and height (for shaped pipes);

- diameter (for round products);

- wall thickness;

- length.

The steel pipe weight calculator is very easy to use. All that is needed for this is to know the required values and enter them in the appropriate cells. Many online calculators require knowledge of the steel grade. This makes it possible to carry out more accurate calculations.

Note! Using calculators, you can calculate parts made of copper, galvanized steel, stainless steel and cast iron.

It is worth noting that the calculation is efficient and can be performed even for large products (for example, the weight of 1 meter of pipe is 530x8 mm). Care must be taken when using the calculator. If the cells are filled incorrectly, the result will be incorrect.

Using an online calculator, you can quickly determine the mass steel pipes

The mass of 1 meter of rolled metal is determined in three ways: formulas, tables, calculator. Each of these methods is good in its own way, but they all have one thing in common - the approximate calculation. Receiving the mass of 1 meter of rolled metal allows you to calculate the weight of the entire batch.