Since ancient times, natural stone has served as one of the main materials for construction. However, everything changed with the advent of modern building material - brick. A person was able to independently give the finished product the desired characteristics. Every day you can see the use of this building material in a variety of variations. Today it is not a problem to purchase a standard brick yourself: you can find out the dimensions and selection criteria in this article.

Content

Where standard brick is used: sizes and varieties

Brick is a versatile material that is used in many areas of construction. There are several types and standards for the size of bricks. The correct choice of material is the key to a successful result of your work.

Depending on the material of manufacture, as well as on the characteristics of the product, bricks can be divided into four main groups:

- Ordinary red brick.

- White silicate brick.

- Ceramic bricks.

- Facing brick.

The main areas of use of bricks:

- erection of walls (including bearing ones);

- laying the foundation;

- construction of basement floors;

- arrangement of basements;

- facing of facades;

- construction of stairs;

- erection of brick partitions in houses;

- laying of fireplaces and stoves.

The most common use is the familiar red brick. Its technical characteristics are excellent for performing a wide variety of jobs. Including the construction of elevator shafts, columns, vaults of buildings. Often, ordinary red brick is used to lay the foundation of low-rise buildings.

If we talk about the construction of stairs, then in this case it is better to use a ceramic product. It is more resistant to moisture, temperature changes and other environmental influences. In addition, ceramics are relatively easy to mechanical stress, which allows bricks to be cut if necessary.

Brick size standard

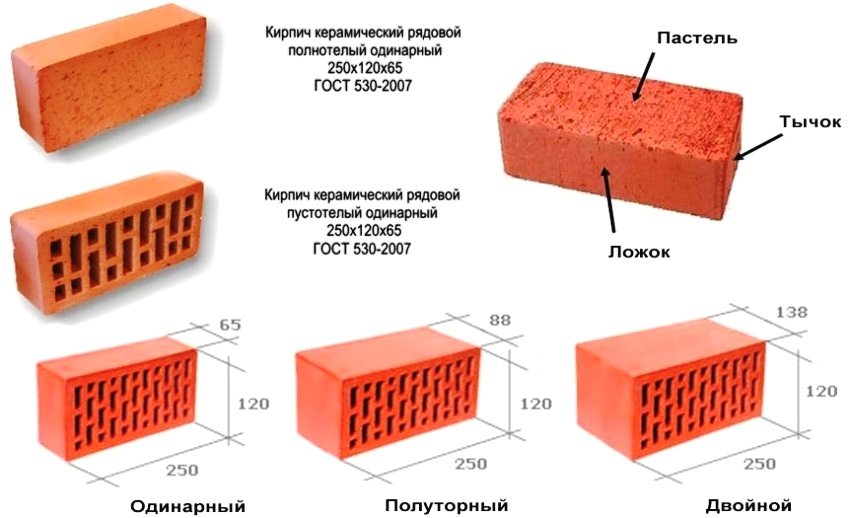

There are single, double and one-and-a-half bricks, we will consider the sizes of each type below.

In the process of development of the construction craft, certain standards have been developed that the material must meet. Single brick size: 120 mm wide, 250 mm long and 65 mm high. It is this size of bricks that is considered ideal for masonry with alternating longitudinal and transverse placement.

Related article:

The size of the silicate brick, its features and installation. Scope of application. Advantages and disadvantages of the material. Types and features of styling. General advice for working with sand-lime bricks.

With the passage of time and the development of construction, more and more diverse materials were required. So new, non-standard bricks of one and a half size appeared. Their parameters are 120 mm wide, 250 mm long and 88 mm high.

The use of such bricks requires knowledge of a special masonry technique designed to lighten the total weight of the building. So, it is necessary to alternate solid bricks with porous, perforated or hollow.

Double brick has impressive dimensions, as a result of which it is never made full-bodied. The size of the brick is 120 mm wide, 250 mm long and 103 mm high. They are used only for lightweight masonry.

Red ordinary brick: size, weight, marking

Red brick is a versatile material that is produced by firing pressed clay briquettes. Most often it is used for the construction of foundations, walls, partitions. It is also used for laying stoves and fences.

Avoid purchasing burnt bricks. They can be seen with the naked eye along the black, scorched middle and scorched edges. For most construction work, such material cannot be used, but it is suitable for laying the foundation.

The weight of solid bricks ranges from 3.5 to 3.8 kg. One cubic meter of red bricks weighs about 1700 kg and holds about 480 pieces. On the packaging, the manufacturer must indicate the pressure that this particular material can withstand in compression in kg / cm², for example, 76, 100, 125, 200, etc.

Helpful advice! A well-fired brick will produce a clear, sonorous sound upon impact.

White brick: sizes and applications

White or silicate bricks are made on the basis of silicate, which is why it got its name. A durable and lightweight material that is mainly used for the construction of walls and partitions. Such bricks are never used for laying foundations, stoves, pipes, fireplaces or plinths. White brick size standard: 250x120x88 mm.

Helpful advice! Knowing the modular size of the brick, you can design the future structure and calculate the required amount of material.

Ceramic brick, dimensions and characteristics

The material familiar to all of us, which, in turn, is divided into building and facing. Stove brick is distinguished as a separate type. The size and convenient shape allow for even, smooth laying without excessive seams. The standard size of the brick is 250x125x65 mm.

Since this material is used for masonry in very critical places, it is unacceptable to use bricks, even with small defects. It is not difficult to check the quality of bricks - when tapping, refractory bricks should make a metallic sound. When splitting, it should crumble into large pieces. Poor quality, unburned material will accumulate moisture, which can lead to the destruction of the structure. Kiln bricks are more expensive than ordinary bricks, but they are refractory and retain heat well. The size of the refractory bricks is always the same.

Helpful advice! Instead of stove, it is quite acceptable to use fireclay bricks. The dimensions and characteristics of this material meet all the requirements.

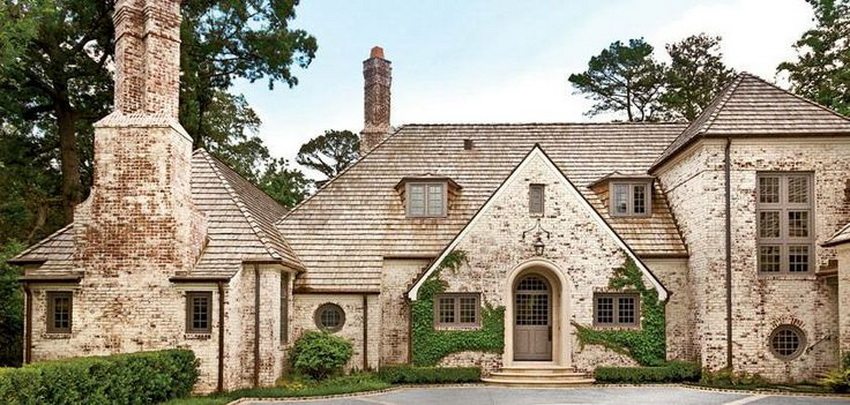

Facing brick: dimensions and application features

Decorative bricks are used for masonry walls, while providing a flat, smooth surface. Its correct shape allows the product to be used as a final wall decoration both inside the house and outside. At the same time, the glossy surface of the outer walls of the brick gives the surface a special chic.

It is for these qualities that decorative brick is often called "front" or "front". There are no difficulties in working with this type of material, except for the need to pay special attention to cutting the seams. The size of the facing brick can be different depending on the type: single, one-and-a-half or double.

The standard for the size of the facing brick is no different from the usual counterpart. Handicrafts are an exception. Non-standard dimensions of a single facing brick can be 210x100x50 mm, 240x115x52 mm or 210x100x65 mm.

These sizes of single facing bricks are not produced in factories, and they are an order of magnitude higher. Always produced in limited series. They are used for the restoration of old buildings or for the implementation of original building ideas.

The size of hand-made one-and-a-half facing bricks can also be very different, for example, 240x115x71 mm. Using bricks of this size is extremely beneficial.

Double facing bricks of non-standard sizes are available in the format 240x115x113 or 190x90x90 mm.

Whether to use standard-size facing bricks for decorating your home, or to purchase more expensive handmade materials - it's up to you. However, before buying, it is better to consult with a specialist who can explain all the nuances of working with a specific type of bricks.

How to choose a standard brick. Dimensions and specifications

Before buying a brick, you must clearly understand the purpose of purchasing it. It is she who will determine the required properties of the material.

The color of a brick depends on the clay from which it is made. The most common option is a red-burning clay mass. It gives the finished product the red color we are used to. Less commonly, you can find clay bricks of white, apricot or yellowish color, for the manufacture of which white-burning clay is used. It happens that a special pigment is added to the original material to obtain the desired color or shade.

Ordinary brick is great for building walls and building structures of any complexity. Standard dimensions of ordinary bricks: 250x120x56 mm.

In the future, it requires additional finishing, for example, plastering. The facing material has such flat and smooth surfaces that it does not need additional finishing. However, the prices and sizes of facing bricks are much more diverse.

Helpful advice! Bricks can have a relief pattern on the surface, designed for better adhesion to the plaster.

An important criterion for choosing a brick is strength, that is, the ability of the material not to collapse under the influence of external loads. For the construction of a low-rise house, it is quite enough that a brick can withstand a load of 100 kg per 1 cm. If we are talking about the construction of a multi-storey house, then the indicator should be at least 150. The strength of each specific batch is always indicated by the manufacturer on the packaging.

For the construction of multi-storey buildings, it is necessary to choose bricks with very high strength indicators.

Another important indicator of brick quality is frost resistance. This value is measured in cycles and is determined by tests for each brick grade separately. The finished product is first placed in water and then in the freezer.The length of stay on each Wednesday is 8 hours. This is one cycle, which is repeated until the material begins to visually change its characteristics.

Multi-storey buildings and industrial buildings, according to the norms, are built of bricks with frost resistance of at least 35 cycles. However, the market offers products with a wide variety of indicators. You can easily find 25 and 15 cycles. The cost of material with a low indicator will be significantly lower, but will you not regret it over time? If you are not sure which option to choose, it is better to contact a specialist who will help you choose a brick that is suitable for your climate and type of building.

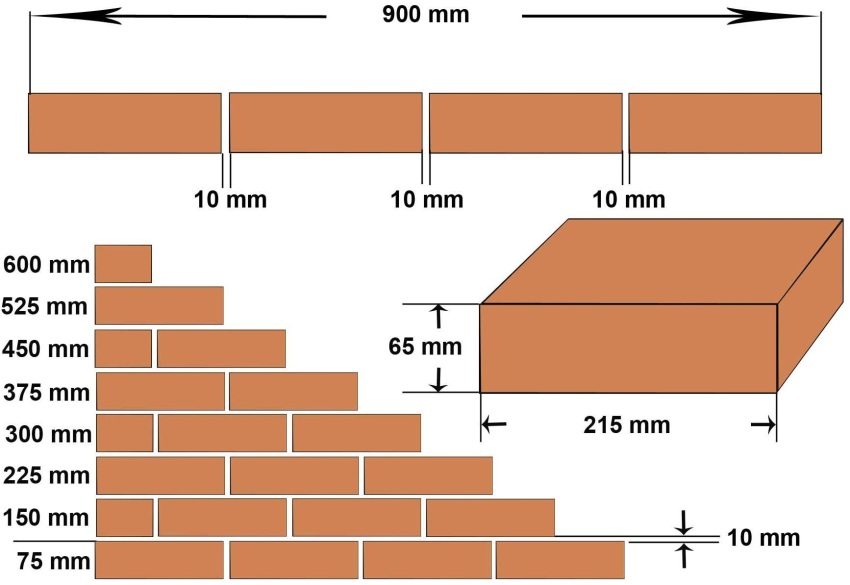

The appearance of bricks

Today there are two options for brick sizes: standard and non-standard. As previously mentioned, the standard length is 250mm, width is 120mm, and height is 65mm. Such parameters are associated not only with the fact that such a brick is as convenient as possible in work and fits well in the hand. The fact is that during the construction process, the bricks are located perpendicular to each other, while alternating the longitudinal and transverse sides.

Take a closer look at the numbers and you will notice that the standard indicators are almost multiples of each other. And this facilitates any calculations, work with such material and minimizes the need for sawing bricks.

You can often find bricks of non-standard sizes. They have the same length and width as the standard ones, and differ only in the height of the stone. For example, the thickness of a one-and-a-half product is 88 mm, and a double product is 138 mm. Such materials are mainly used for decorative purposes. They are good for decorating houses, roofs and facades.

For example, a good choice of color and size of facing bricks: yellow one-and-a-half or double brown.

Brick weight

Another characteristic of a brick is its weight. For different types of products, this indicator is completely different. So, the weight of a standard ceramic or sand-lime brick is 3.8-4 kg. Moreover, if the brick has a cavity inside, then it will weigh less. Therefore, during the design, the weight of each brick is not taken into account, but only the specific masonry, that is, the weight of 1 cubic meter of building material plus the weight of the required amount of cement mortar.

When designing a building, it is necessary to take into account such a parameter as the total specific weight of the masonry

The specific weight of masonry can range from 600 kg / m³ to 1800 kg / m³ and directly depends on the weight of each brick. Having calculated the weight of the future building at the design stage, you can make adjustments to the laying of the foundation, thus making the structure more durable and reliable.

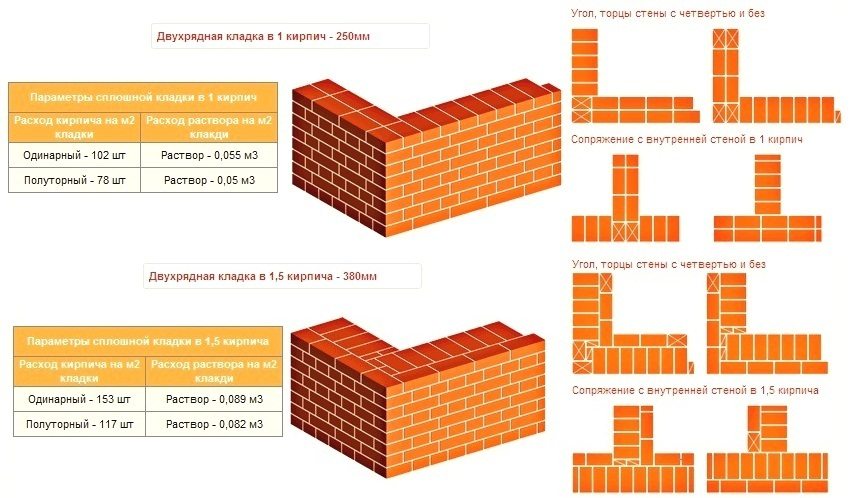

The size of brick structures

The size of the structure will always be a multiple of the brick width. If we talk about the standard size of facing bricks, then this value will be 120 mm. Depending on the number of layers, the width of the wall can be 120, 250, 380, 510 mm, etc. In this calculation, a 10 mm joint between the bricks must be taken into account.

The only exception to the rule can be considered only thin partitions, which are laid from ceramic bricks placed on the edge. Accordingly, in this case, the width of the partition corresponds to the brick width - 65 mm.

Openings and short walls are always designed to be multiples of the brick size. Otherwise, it becomes necessary to cut bricks of the required size, which significantly increases the complexity of the process.

Brick has always been and will be a popular building material. This product is difficult to replace with anything in modern construction, due to its high technical characteristics.So if you are thinking of building your own home, you should definitely consider bricks as the main material for work. Despite their simplicity, bricks are very diverse, which makes it possible to embody unusual design ideas and the most original ideas.