The production of reinforced steel, like the production of goods in other industries, is unified. To determine the quality of products, requirements for products specially developed by the State Standard for various parameters are used. In this type of production, standards are set for the diameter, weight and section of the rods. All these characteristics are united by one term - rebar range. This article will tell you more about the set of requirements.

Content

- 1 Scope of application, features of reinforcement: diameter, classes, marking, compliance with GOST

- 2 Rebar assortment table: designations and characteristics of various classes

- 3 Reinforcement range: additional marking options

- 4 How to determine the area of reinforcement: calculation table

- 5 How much does a meter of reinforcement weigh and how many meters of reinforcement in a ton: examples of calculations

- 6 Rebar price per ton and per meter: cost components

Scope of application, features of reinforcement: diameter, classes, marking, compliance with GOST

Reinforcement is an important component in the general list of building materials. It is characterized by a wide range of applications at various stages of building construction. Not a single reinforced concrete structure can do without it, serving as reinforcement and support both in the foundation of a small house, and in the construction of a large-scale railway bridge or overpass. Reinforcement technology is even used to strengthen glass structures.

Even at the initial stage of the development of design and estimate documentation, every self-respecting engineer and architect has at hand a special table of the ratio of the weight and footage of the reinforcement, as well as the sections of reinforcing rods in accordance with the established state standards. The main one among them is GOST 5781-82. Also, products must comply with GOST 52544-2006, STO ASChM 7-93, TU 14-1-5254-94. The norms regulate the requirements for a specific type of reinforced products. Their combination corresponds to the term - a range of reinforcement.

The fittings are round metal rods with a smooth or corrugated surface. They are made from several types of steel. The diameter of the rods ranges from 4 to 80 mm. The product range is divided into classes A1 - A6.

Diameter, that is, the size of the cross-section of a rebar or wire, is the main indicator underlying the product mix.Hence the corresponding terms: reinforcement of 8 mm or weight of 1 m of reinforcement 12. These products are also classified according to other properties, including strength, durability, specific gravity and other characteristics, which will be discussed below.

Reinforcement classes: product range in terms of strength and mechanical parameters

The word assortment (or assortment), in French, sounds like assortir and means "to choose", that is, to sort by varieties in accordance with typical characteristics. These parameters include:

The fittings differ in different parameters, such as dimensions, profile and material for production

- material used to manufacture products;

- reinforcement dimensions, such as size, diameter, surface type;

- profile.

Helpful advice! Products are packed according to their diameter classification. Reinforcing metal products up to 10 mm are released in coils, and above this parameter they are packed with rods of a certain length.

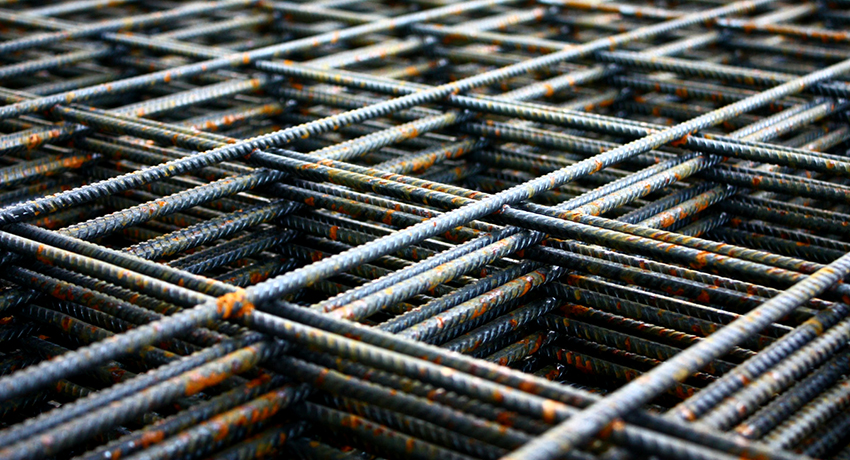

Armature used in construction work in the form of rods, mesh, wire or frame. Based on its purpose, it is divided into structural, anchor, assembly or working. This takes into account the presence or absence of tension, as well as the need to strengthen the structure in a certain area. The reinforcement can be longitudinal or transverse.

Reinforcement is also labeled and classified according to other characteristic features, but first of all, the diameter of the reinforcement, as well as the degree of strength, flexibility and mechanical characteristics, are taken into account. Capital letters A (less often B) with a specific index, which indicates the conformity of the reinforcement to a separate class, serve as a symbol in the assortment marking. We will consider the main and most popular classes of reinforcement in construction in this article.

Rebar assortment table: designations and characteristics of various classes

Even professionals are sometimes confused in construction terminology and marking. Different types of materials, including fittings, have their own classification, which makes it possible to simplify and unify many processes as much as possible.

A special table of reinforcement classes will help you navigate the classification and labeling. It has a fairly simple and understandable structure, consists of several columns, where the first is the main marking, and then the corresponding characteristics:

- weight;

- section size or diameter;

- resistance to loads;

- embedding in stressed reinforced concrete structures;

- the relative amount of elongation after rupture;

- rod length;

- steel grade.

The table can also contain more advanced information, for example, allowing you to calculate the weight of a running meter of reinforcement or, conversely, calculate how many meters there are in a ton of reinforcement 12 mm. For novice builders, a simplified version with a minimum of reference information is suitable.

The reinforcement class includes several numerical and letter designations that determine its strength, size and purpose. Moreover, according to the table of the assortment of fittings, GOST 5781 82 regulates the old and new markings. The old one includes products belonging to classes from AI to AVI. Accordingly, the new one is designated as follows: А240, А300, А400, А500, А600, 800 and А1000.

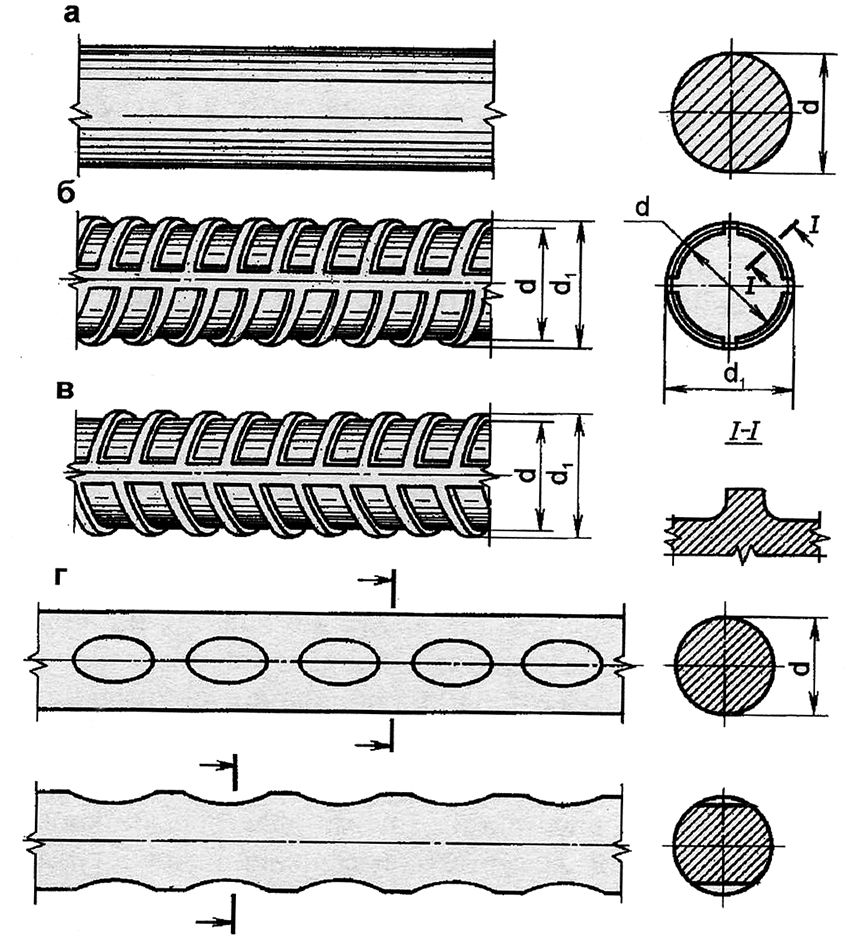

Armature of class А240С has a smooth outer structure, and products marked А300С, А400С, А500С, as well as А600, А600К, А800, А800К and А1000 have a corrugated surface.

Helpful advice! There is a certain coding of the fittings, which looks like this: fittings A-400-C Ø12. Where the letter A denotes the marking of the material, the number 400 is the class of reinforcement, 12 is the diameter of the bar.

Explanation of the valve table with the characteristics of each class

Each class of reinforcement has its own characteristics, while many of the data may be the same for different types or radically differ. Their main parameters are given below.

АI or А240 - reinforcement, which is a smooth-bore rod with a cross-section from 6 to 40 mm. It is used in the manufacture of reinforced concrete products, for the construction of monolithic and support structures. Reinforcement bars of any diameter are produced in rods, packed in packages. It is allowed to manufacture products with a cross-section of up to 12 mm in coils.

АII or А300 is a profile with a corrugated surface and a diameter of 10 to 80 mm. Belongs to materials that hold strong pressure. They serve as the base of the supporting structure, which is subject to the main load. They are used in the construction of low-rise buildings, monolithic buildings and during repairs.

АIII or А400, А500 - reinforcing bars having a periodic profile with a section from 6 to 40 mm. The most popular class of fittings for a wide range of applications in both residential and industrial or commercial construction. Also used in the production of concrete products, in the construction of roads and sidewalks. Products with a diameter of up to 10 mm are produced in coils, over this size - in rods.

a - rod smooth, class A240; b - rod periodic profile of class A300; c - class A400 and higher; g - wire class B600

АIV or А600 - rods with a diameter of 10-32 mm. They are used in the construction of stressed elements. The products are similar to those of class AIII, but have a lower rib frequency.

AV or A800 is a rare range of reinforcement with a high degree of strength. They are used in the construction of especially large and super-heavy objects, such as bridges, piers, metro, hydroelectric power plants.

А6 (А1000) - made of heat-resistant steel. Has an increased level of resistance to various types of deformation. It is used in multi-storey construction.

A500S fittings: GOST, key parameters and characteristics

Since the third category is the most common, then what class of reinforcement (A400 or A500) to choose is up to the designers, who take into account all the nuances of construction work. Speaking about the structural features of this type, you should pay attention to GOST A500 fittings. It regulates the production of a circular profile with two ribs along the rod and parallel rows of crescent-shaped protrusions across. Moreover, they do not intersect with paired edges along the body of the bar.

The profile has high ductility and strength characteristics during rolling. A500 reinforcement rods have a minimum length of 6 m, and a maximum length of 25 m. The optimal length of rods is 12 m. According to the assortment table, A500S reinforcement is made from high-quality marked steel St3SP, St3PS and St3GPS. The material has excellent weldability, but this is not its only advantage.

Helpful advice! It is possible to connect A500C reinforcement elements using electric arc welding machines. This advantage is indicated by the letter C in the profile marking. The quality of the welding reduces the minimum presence of alloying elements.

The positive properties of such reinforcement are as follows:

- increased degree of strength and flexibility, absence of weak points that can lead to the destruction of reinforcement;

- relatively low production cost and, as a consequence, affordable cost of valves per ton;

- the specific gravity of A500 reinforcement implies significant savings in steel volumes in the manufacturing process.

GOST requirements: reinforcement B500, features of its manufacture

The A500C reinforcement is successfully used in compressed elements. At the same time, the quality of concreting is improved due to the reduction in the number of metal structures in the columns.Profiles can be used in projects where sections of classes АІ and АІІІ are specified. An analogue of the universal fittings А500С can be В500 fittings.

According to the chemical and technological characteristics of raw materials and structures, B500C valves comply with European standards. The main advantage is flexibility. The high degree of plasticity of reinforcement structures prevents the destruction of buildings. Reinforcement products of this class in the Russian Federation are produced in accordance with GOST R 52554. They are intended for the construction of structures from lightweight and weighted concrete.

Such structures are used in aggressive environments. Reinforcement bars are used both in the form of independent rods and in frames and welded products. According to its characteristics, B500C is an effective substitute for valves marked A400, A400C, A240. The B500C fittings have the following basic parameters:

- produced in accordance with European Union standards, which makes it possible to use it on European equipment;

- does not curl due to the absence of stripes;

- lengthens by 1.4%, withstanding a load of over 3%;

- characterized by excellent weldability.

As for the pricing policy, it is different and depends on the characteristics of the fittings and the volume of required products.

Related article:

Reinforcement: weight and length, ratio and calculations in construction work

Examples and the need for calculations, reference tables. The ratio of the length, weight and diameter of the rods. Application of the online calculator.

Reinforcement range: additional marking options

To determine more specific characteristics of the reinforcement, a special additional marking system has been created. For example, the abbreviation A5K means that these are A5 class profiles, and the letter K indicates the presence of additional protection against corrosion. For this, the material is treated with special means that ensure its durability.

The presence of the letter C in the marking indicates that the fittings can be welded. It should be borne in mind that not all products belonging to different classes can be welded to each other, especially if there is no C mark in the designation.

If the marking contains the letter K, this means that the valve has additional protection against corrosion.

Speaking about the range of fittings, mention should be made of such a term as shut-off (or pipeline) fittings. These types of profiles are used in plumbing work. Accordingly, as a separate subtype of material, this reinforcement has its own classes and markings. In this case, the main parameter of choice is tightness. This criterion indicates the quality of the assembly in the pipeline, without which it is impossible to assemble it. The tightness index is indicated in the characteristics on the packaging of the material.

Helpful advice! It is better to interconnect reinforcing bars with different markings and in the absence of the letter C in the designation using special couplings and wire.

How to determine the area of reinforcement: calculation table

The cross-sectional area of reinforcement is one of the most important parameters that determine strength. The higher the expected load, the larger the area should be. To find out these data, you need to contact the sales consultant or read the product passport. If the product is purchased second-hand, then you will have to make the calculation yourself. To do this, you must follow these instructions:

- Measure the diameter. A caliper will help. It is necessary to take into account that the result can be a non-circular unit, therefore it is rounded, guided by mathematical rules.

- Determine the cross-sectional area of the reinforcement by its diameter using a special table. With its help, you can calculate how much 1 meter of reinforcement weighs and how many meters per ton of reinforcement.

Rebar assortment table, weight 1 meter and diameter.

| Cross section, area, cm² | Rebar diameter, mm | Linear weight of reinforcement, g | How many rebar in a ton, m |

| 0,283 | 6 | 222 | 4505 |

| 0,503 | 8 | 395 | 2532 |

| 0,785 | 10 | 617 | 1620 |

| 1,131 | 12 | 888 | 1126 |

| 1,54 | 14 | 1210 | 826 |

| 2,01 | 16 | 1580 | 633 |

| 2,64 | 18 | 2000 | 500 |

| 3,14 | 20 | 2470 | 405 |

| 3,8 | 22 | 2980 | 336 |

| 4,91 | 25 | 3850 | 260 |

| 6,16 | 28 | 4830 | 207 |

| 8,04 | 32 | 6310 | 158 |

| 10,18 | 36 | 7990 | 125 |

| 12,58 | 40 | 9870 | 101 |

| 15,48 | 45 | 12480 | 80 |

Thanks to the table, you can easily determine other data, for example, how many meters in a ton of reinforcement 12 mm. We look for the exponent 12 in the diameter graph and find the corresponding value in the length graph. This parameter is equal to 1126 m.

Self-calculation of reinforcement area, online calculator

If there is no table, you need to measure the diameter yourself. Let's say it is 6 mm, this figure is divided by 2 to find out the radius. We get the result - 3 mm, square it - 9 mm. The resulting number must be multiplied by the constant value of the area of the circle Pi, equal to 3.14. The result of calculations is 28.26 mm² or 0.2826 cm². This self-calculation indicator corresponds to the data in the table.

This method of determining the cross-sectional area is ideal if the rebars are smooth. For rods with a corrugated surface, the calculations look somewhat more complicated. Such products have a larger area and have the highest degree of adhesion to concrete, which makes them indispensable in the construction of reinforced concrete frames. The calculation process includes the following steps:

If there is no assortment table, then you can use the online calculator to calculate the reinforcement area

- Calculation of the overall indicator of the diameter. For this, two measurements are made - on a ribbed surface and in a narrow recessed part. To make the result more accurate, it is better to carry out measurements in addition in several different places.

- Determination of the arithmetic mean by adding the indicators and dividing the resulting sum by 2.

- After calculating the diameter, the cross-sectional area of the reinforcement is determined as described above, according to the formula: S = π * r², where S is the area; π - constant value 3.14; r is the radius.

Helpful advice! If the table is not available, then the weight is determined using special calculations.

Computer programs and Internet technologies greatly simplify the process of calculating the cross-sectional area of reinforcement. The online calculator allows you to do this in a matter of minutes. It is enough to enter the indicators in the required cells to instantly get the finished result.

How much does a meter of reinforcement weigh and how many meters of reinforcement in a ton: examples of calculations

Skills in calculating the diameter of the bars will also be needed when calculating the weight of the reinforcement. Such knowledge is necessary when drawing up projects and construction estimates. An accurate determination of the weight of the reinforcement will help save on the purchase of materials. It is important to note the fact that large manufacturers sell fittings at a price of 1 ton, and not per meter. However, the cost of production in this case will be several times cheaper.

As an example, we can consider how to calculate the mass of the required material for the construction of a reinforced concrete foundation with a total length of 100 m. The diameter of the reinforcement is 10 mm. We look for the necessary data in the table, they correspond to 617 g. We multiply this number by 100 and get 61 kg 700 g. The weight of 1 meter of reinforcement can be calculated in other ways (there are three in total):

- according to the normative table;

- using data on the specific gravity of the reinforcement;

- using the rebar weight calculator.

Thanks to accurate calculations of the required weight of the reinforcement, you can save on the purchase of material

The required number of rods according to the standard weight is calculated using the above weight table in relation to the running meter. This is the simplest calculation option (apart from the online calculator).

For example, 2300 m of reinforcement 14 will be used for construction. The weight of 1 meter of rods is 1.21 kg. We make calculations: 2300 * 1.21 = 2783 kg. Thus, to complete this volume of work, 2 tons of 783 kg of steel rods will be required. Similarly, the number of rods in one ton of the corresponding diameter is calculated. The data is taken from the table.

Rebar price per ton and per meter: cost components

Several factors influence the price formation of any product.This also applies to fittings. Smooth and corrugated rods have different costs, because the production of the latter involves a more laborious and time-consuming process. The more complex the technology, the higher the price of the finished product.

The value formation is also influenced by the strength and ductility of the material. To increase these indicators, silicon or chromium is added to the alloy, and manganese for flexibility. Steel fluidity also matters.

In addition, the pricing depends on the qualities indicated in the labeling. For example, you will have to pay additionally for reinforcement with a T mark for heat hardening, or K, which indicates resistance to corrosion.

Helpful advice! An important indicator of cost is the volume of production. Reinforcement bars purchased in large quantities (tons) are much cheaper.

Manufacturers act on this principle: the higher the sales, the better. That is why the volume of purchased products significantly affects its cost. Accordingly, the price of reinforcement per 1 meter will be much higher than the goods purchased in tons.

The fact how much a meter of reinforcement costs is also influenced by the seasonality of the work, since any construction site depends on weather conditions. Therefore, in the autumn-winter period, the price of rebar, like other types of building materials, drops significantly. It is this period that is considered the most optimal for the acquisition of goods, but at the same time, you should worry about its appropriate storage.

Reinforcement is an important material in modern capital construction. it type of rolled metal has a number of serious quality characteristics and operational requirements, regulated by GOST. They are displayed in special tables and standards called rebar gauge. Knowledge of its main indicators and the ability to carry out correct calculations will help not only to purchase a quality product, but also significantly reduce the cost of purchasing it.