In order for the house to be durable and warm, pre-fabricated and inexpensive, it is necessary to choose the right material for its construction. The construction services market offers innovative construction methods that allow you to build houses quickly, efficiently and cheaply. One of these technologies is the construction of houses from vulture panels. SIP panels: what is it? Turnkey houses from SIP panels, prices for construction services confirm the feasibility of this method.

Content

- 1 SIP panels: what is it? Turnkey SIP-panel houses, prices, advantages

- 2 SIP panels, what is it?

- 3 Sizes and prices of SIP panels

- 4 Where to buy SIP panels

- 5 Pros and cons of SIP panels. Residents reviews

- 6 Making SIP panels with your own hands at home

- 7 How the price of a house from SIP panels is formed

- 8 Construction of houses from turnkey SIP panels. Project prices from various companies

- 9 House kits from SIP panels from the factory

- 10 The price of house kits made of SIP panels from different manufacturers

- 11 Methods of exterior decoration of houses from SIP panels

- 12 Finishing options for a house from SIP panels inside

- 13 Houses from SIP panels: reviews of living

SIP panels: what is it? Turnkey SIP-panel houses, prices, advantages

SIP panels are a durable building material that has been used for the construction of residential and industrial buildings for more than half a century. The technology of building houses from SIP panels can be distinguished from other methods due to a number of advantages:

- quick erection - a construction team of 3-4 people can erect a structure according to a standard design within 3 months;

- stability, strength - the monolithic construction of SIP panels contributes to the fact that the walls of structures made of this material can withstand a load of up to 10 tons vertically. Such buildings can be operated even in seismically unsettled areas;

- environmental friendliness - the technology for the production of SIP panels is based on the use of safe and high-quality natural and polymer materials, in addition, the construction of houses from these panels is not associated with the formation of a large amount of construction waste and garbage;

- the duration of operation - the expanded polystyrene with which the SIP panels are filled is not subject to decay and deformation;

- low thermal conductivity - houses made of such material are several times warmer than brick buildings, they are warm in winter and cool in the hot season;

- excellent sound insulation - sandwich panels filled with polyurethane foam are able to absorb sound vibrations over 70 decibels;

Another important advantage is efficiency: the price of a brick cottage will cost 1.5-2 times more than the cost of a house made of SIP panels of the same area. The reduction in price also occurs due to the fact that the device of an expensive foundation for the construction of a house from vulture panels is not required. The video of the construction stages clearly confirms that it is enough to install such an object on a lightweight foundation, the cost of which is four times cheaper than the base for a brick house.

The cost is also affected by the speed of construction of the object, since less labor is required. The construction of a house from turnkey vulture panels will take about 3-4 months, while the construction of a brick cottage can take up to 1.5 years. And all this time, the team of workers needs to be paid wages. Thus, by building a house from vulture panels, you get not only an object with excellent performance characteristics, but also at a relatively affordable price.

SIP panels, what is it?

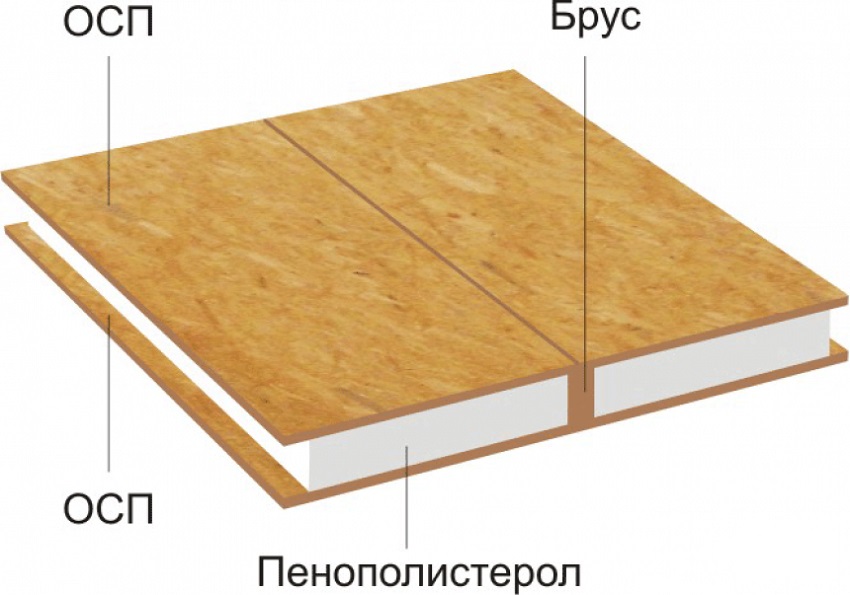

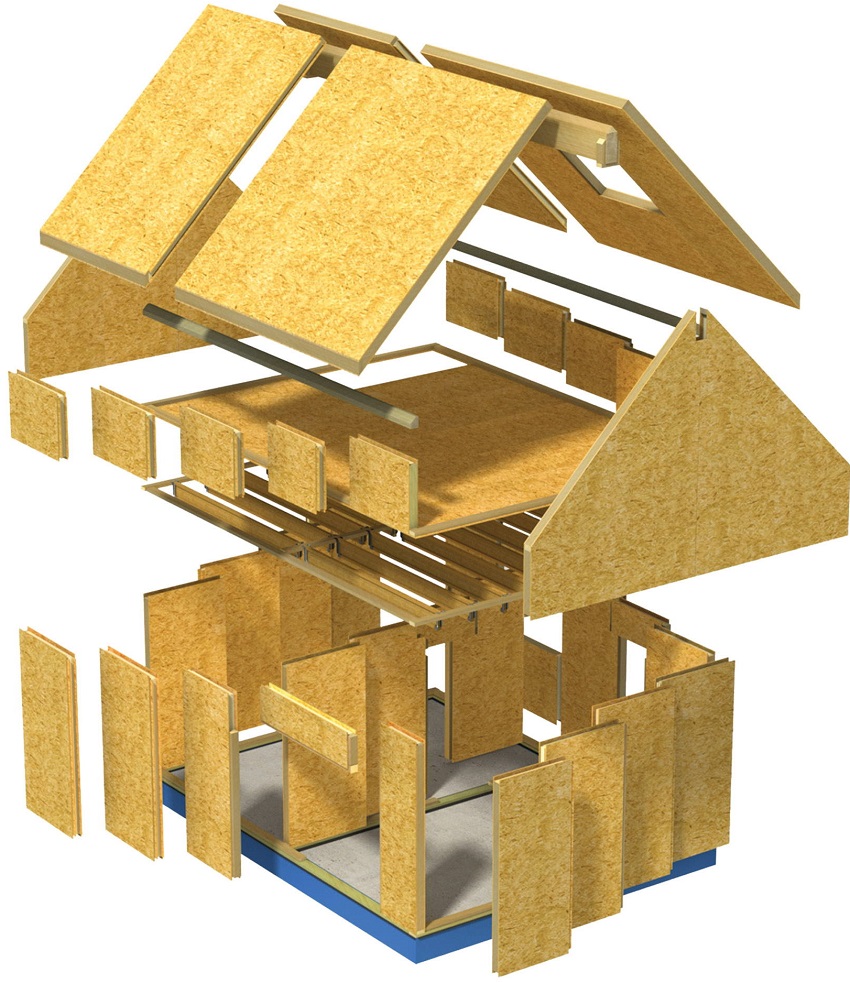

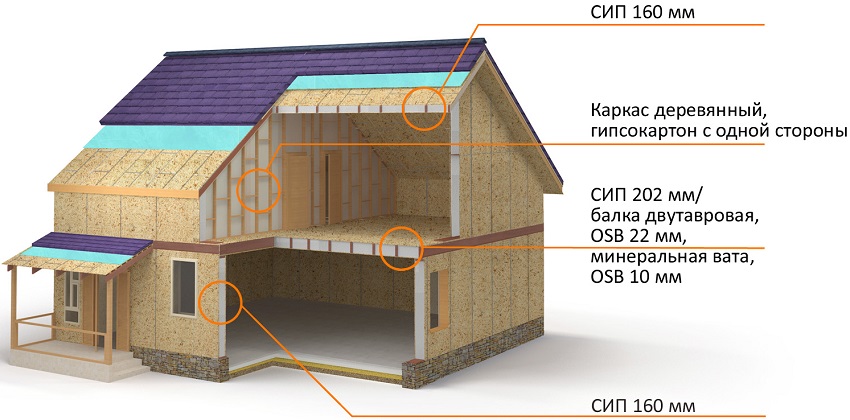

The structure of the classical SIP-panel is a three-layer sandwich board, where the function of the filler is performed by a polymer enclosed between two OSB sheets. It is worth noting that there are two ways to fill SIP panels. In one case, it is solid polystyrene foam, which is glued to OSB boards under high pressure. In the other, liquid polyurethane foam is pumped under pressure into the space between the plates.

Due to its porous structure, expanded polystyrene perfectly retains heat, does not absorb moisture, but at the same time is a vapor-permeable material. The values of water and vapor permeability of polystyrene foam depend on the density of the material. In addition, it is not susceptible to the formation of mold and mildew, and insects do not start in it. It is non-flammable and has sufficient sound insulation performance.

As for the outer layer of SIP panels, it must be durable and moisture resistant, since it is he who perceives the main load. In order not to make the sandwich construction heavier, this layer should be made of lightweight material. These are the characteristics that OSB sheets have. Thanks to special presses and gluing, wood chips are transformed into a multi-layer board with high strength characteristics.

To protect the filling of the SIP panel from unwanted environmental influences, access to it is closed. To do this, the ends of the sandwich are tightly fastened with a wooden bar. In high-quality structures, glued laminated timber is used, which has a certificate of conformity. The structure of the finished sandwich can be seen in the photo of SIP panels.

Puseful advice! The ability of a SIP panel to take high loads depends on the strength of the adhesive bond of the inner and outer layers of the structure.

The main stage in the production of SIP panels is the application of glue, since the strength of the finished structure depends on the quality of the connection of the materials used in the sandwich. There are standards for the use of glue in SIP panels, according to which 115-140 g of glue should fall on 1 m². Such clarity can be achieved using special equipment for the production of SIP panels, which is why a high-quality sandwich can be obtained only under production conditions.

Sizes and prices of SIP panels

The thickness of the panels and their dimensions can be different, since they are produced not only for external walls, but also for internal partitions, ceilings and floor coverings. In addition, it can be observed that the dimensions of the panels differ slightly in size from different manufacturers. As a rule, in the production of SIP panels, two standard sizes are used, 2500x1250 mm and 2800x1250 mm.

The thickness of the panels is also selected depending on their application.To use the material for the outer walls, the thickness must correspond to 160 mm, the inner walls can be made of panels with a thickness of 120 mm. In the ceilings between floors, SIP panels with a thickness of 200 mm are used; for the construction of roofs, it is recommended to use structures with a thickness of over 240 mm. It should be noted that when using SIP panels for floors, it is necessary to cut it lengthwise in order to comply with the prescription for deflection.

The cost of a SIP panel depends on the quality and price of materials and glue used for its production. Therefore, if you are offered a product at a clearly reduced price, there is a possibility of purchasing a SIP panel made by handicraft. A building made of such a material has a huge risk of collapse under load. And this will happen not at the stage of construction work, but during operation, when there will already be no one to make a claim.

Helpful advice! The purchase of cheap SIP panels does not justify the decrease in the strength of the structure made from them.

When the price of SIP-panels is formed, it also matters how high-quality equipment was used for their production. This fact explains some fragmentation in prices for panels of one manufacturer or another. Comparative table of the cost of SIP panels in 2016 prices from different companies.

| SIP-panel name | Manufacturer | Panel dimensions, mm | Price, rub / pc |

| Egger (an OSB-3 plate of the German company Egger is used as the outer layer) | PSK "Dom Stroy" | 2500х1250х124 | 3000 |

| TekoDom company | 3100 | ||

| DK "Fansip" | 3080 | ||

| EcoEuroDom company | 2700 | ||

| Egger (an OSB-3 plate of the German company Egger is used as the outer layer) | PSK "Dom Stroy" | 2500х1250х174 | 3315 |

| TekoDom company | 3500 | ||

| DK "Fansip" | 3395 | ||

| EcoEuroDom company | 3000 | ||

| Kalevala (OSB-3 slab of Kalevala DOK, Russia is used as the outer layer) | PSK "Dom Stroy" | 2800х1250х224 | 3850 |

| TekoDom company | 3700 | ||

| DK "Fansip" | 3780 | ||

| EcoEuroDom company | 3710 |

Where to buy SIP panels

If, after weighing all the pros and cons, you opted for frame technology, you will need to buy SIP panels for building a house. Prices for the material can be different, and the question of its quality is very serious. The market abounds in inexpensive handcrafted SIP panels. The danger of cheap panels from dubious manufacturers consists in the use of low-quality components and manual application of glue, which leads to a decrease in the strength of the material.

All companies involved in the development of projects of houses from SIP panels and their construction, as a rule, have their own factories for the production of panels. The material is made on high-tech equipment using only high-quality cladding, insulation and glue. All products of the companies are confirmed by test certificates for compliance with GOST and TU. The buyer is provided with product certificates.

In addition, by purchasing SIP panels from the manufacturer, you will exclude the payment of intermediary services from their cost. In addition to panels, companies are engaged in the sale of related products. If you plan to build a house from SIP panels with your own hands, it is possible to order the cutting of panels according to the existing drawings. The service will include cutting a part, cutting a groove, marking all elements.

Before buying SIP panels, you should visit the manufacturers' websites. Perhaps this will help to find products at the best price. The sites contain all the necessary information about the manufacturer, panels, their components, sizes and costs. Here you can also familiarize yourself with catalogs of finished projects of houses from SIP panels with descriptions and prices.

Helpful advice! When purchasing SIP panels, ask the seller for certificates and documents confirming the production of products.

Pros and cons of SIP panels. Residents reviews

The use of SIP panels for the construction of houses, garages and other structures is associated with the excellent strength characteristics of this material and the fast erection of the structure. And yet, the flagship in the list of advantages is the low price of a finished house made of SIP panels with high quality construction. Houses built according to the Canadian method are always warm and can be used for many years.

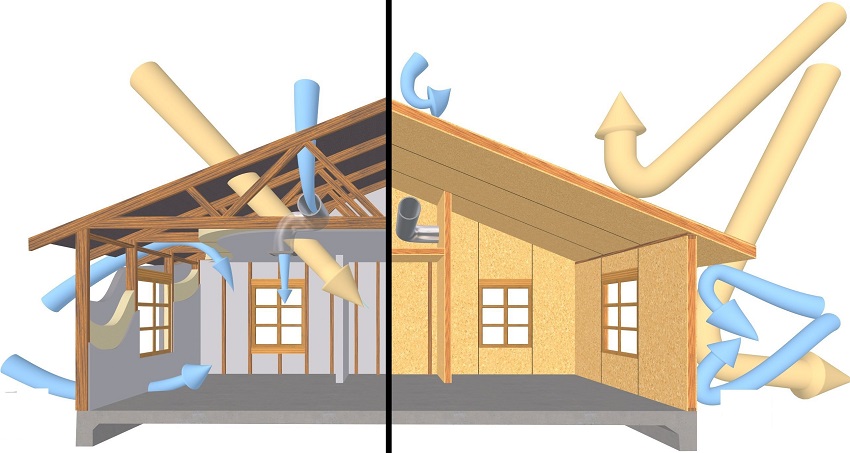

The advantages of sandwich panels include low thermal conductivity, which is much less in comparison with other materials used in the classical construction of houses. This is achieved due to the use of expanded polystyrene in SIP panels, in which the still air inside the bubbles serves as a heat-insulating layer. The cost of heating in a house made of SIP panels can be up to 5 times lower than it would be required to heat a brick house.

The undoubted advantages include the light weight of the sandwich structure, the ability to carry out construction work at any time of the year. Ease of installation allows you to assemble a house from vulture panels with your own hands. It is possible to complete a project of any complexity, whether it is the construction of a house or a garage from SIP panels, with a minimum set of tools and small construction skills.

The disadvantages of SIP panels include a certain degree of flammability, given that the outer layers are made of wood chips. However, treating OSB with flame retardants minimizes the risk of ignition. The negative aspects include the fact that the top layer of the slab can be damaged by rodents, but the core of the panel is absolutely not of interest to them.

Helpful advice! Compliance with fire safety rules, high-quality electrical wiring, correct placement of electrical outlets is the key to the safe operation of houses from SIP panels.

SIP panels, what is it? Reviews of the building material

For those who have not come across Canadian technology for building houses, you should read the reviews. What it is, SIP panels, you can learn from the opinions of those who already live in such a house. Many note that the positive point is that when building a house from SIP panels, there is no need to lay a strong foundation. In addition, a lightweight sandwich is much easier and more economical to transport and unload, and the work does not require the involvement of expensive construction equipment.

Among the recommendations of the tenants, you can find advice on the need to pay special attention to the ventilation device in the house from SIP panels. Negative reviews indicate that such material is poorly permeable to moisture and air. Some conclude that it is more expedient to use such a building as a country house, since it does not freeze through, even if there is no heating in it.

A positive effect on the popularity of the use of SIP panels is that the structure can be erected on any soil, construction work can be carried out in any season of the year, as well as the fact that the construction of the box is relatively cheap. Many consider the negative factors that communication is possible only in an open way.

There are frequent cases when they arrange the decoration of the facade of a house from SIP panels. Many people note that with such an application, drafts appear on the joining line of the panels, condensation forms in these places and they freeze. However, you can find tips on how to avoid this effect on forums and in tenant reviews. It is enough to process SIP panels at the joints with mounting tape to eliminate this disadvantage.

The reviews of residents and their experience in operation available on the network will help you better understand the pros and cons of SIP panels when using them in the construction of a house for permanent residence.

Making SIP panels with your own hands at home

In an effort to save money, many practice their own production of SIP panels. Considering the average price of component materials (OSB boards, filler, glue), the cost of the finished SIP panel will be about 1300-1400 rubles, which is much cheaper than the factory product. The process of making SIP panels with your own hands is not complicated, but it is important to observe some features here.

Related article:

Facade panels for exterior decoration of the house: types and installation. Facade panels for exterior decoration can significantly improve the exterior of the building. At the same time, facing work allows you to insulate the structure.

For work you will need:

- OSB-boards - for the outer layers of SIP-panels;

- expanded polystyrene - other materials can be used as a filler;

- polyurethane glue - for connecting layers into a single structure;

- wooden beam;

- device for pressing assembled SIP panels - you can use a powerful vacuum pump or press installation;

- thermal knife - with it you can cut panels;

- notched trowel, roller, brush, spray - for applying glue.

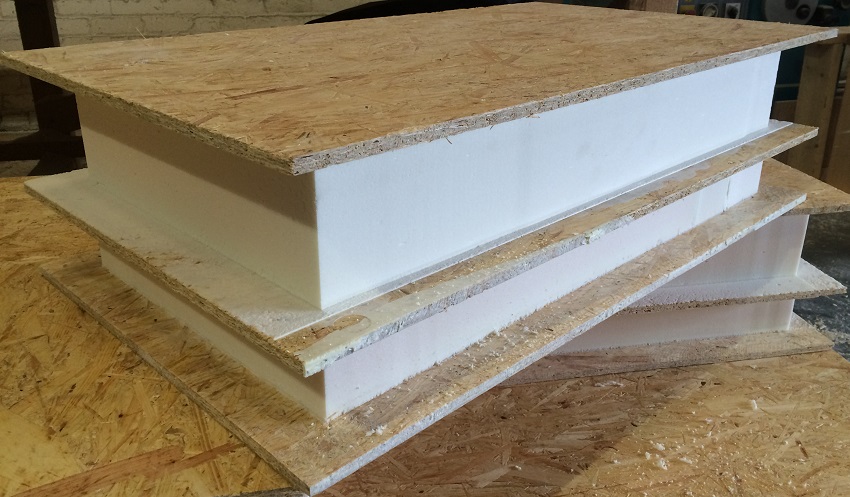

Work begins by placing the first OSB board on the table surface. It should be noted that the surface area of the desktop should be larger than the dimensions of the SIP panel itself. Glue is applied to the laid plate at the rate of 160-200 g per square meter of surface. Having withstood the glue for 9-10 minutes, expanded polystyrene is laid on it. At this stage, it is important not to overexpose the glue in order to prevent it from polymerizing.

Further, the layer of insulation must be carefully leveled, a layer of glue must be applied on top of it and the next OSB board must be laid. Thus, at least five SIP panels are assembled at once and stacked exactly one on top of the other. After that, all panels are covered with a special sealed cover and the air is pumped out from the inside using a vacuum pump. As a result, the assembled structures are subjected to a pressure of about 1 ton per 1 m². The pressure duration is at least 1 hour.

After the manufacture of the first batch of SIP panels of 5 pieces, they begin to manufacture the following ones. It is recommended to stand the finished panels for 24 hours, stacking them.

Helpful advice! When self-manufacturing, you should adhere to safety rules: work must be done in work clothes and protective gloves. In addition, the room should be bright and well ventilated.

How the price of a house from SIP panels is formed

Before ordering construction, everyone will be interested in the cost of a house made of turnkey SIP panels. The fact is that many companies in their catalogs indicate the approximate price of 1 m². But in reality, it may turn out that the price of one square meter of a small one-storey house will be much higher than the cost of a two-storey cottage. It follows from this that the materials required for construction, the volume of construction work and the cost of construction in general do not depend only on the total area of the building.

In addition, each customer has their own preferences and different financial capabilities. Those for whom quality and reliability are important choose organizations that carry out their own production of SIP panels and in which the construction process, in their opinion, is well-established. The cost of 1 m² for such companies is more expensive, but this does not mean that they cannot satisfy those whose goal is to purchase an inexpensive house from SIP panels.

There are a number of parameters that affect the cost of a finished house made of SIP panels. In addition to the total area, the number of storeys, the number and layout of rooms, the complexity of the roof structure, the presence of balconies, loggias and other factors matter.Some rules will help you to find your way around the average price of one square meter:

- the arrangement of the foundation, attic and roof will affect the cost of 1 m² of a one-story building to a greater extent than in a two-story building;

- the construction of 1 m² of a small house is always more expensive than the construction of a large cottage. The price per square meter is 1.5-1.8 times higher. Therefore, for those whose budget is limited, it is better to opt for a two-story building;

- the cost of 1 m² reflects the complexity of the house project. For buildings that are simple in architectural design and layout, the price per square is always lower. If you do not have a sufficient budget, you can limit yourself to a two-story box with a simple roof structure;

- the price includes the cost of materials used in construction. The type of foundation, the type of the supporting structure, the material of the roof matter here. The designers of the company can advise on how to reduce the cost of construction, but what is not worth saving on.

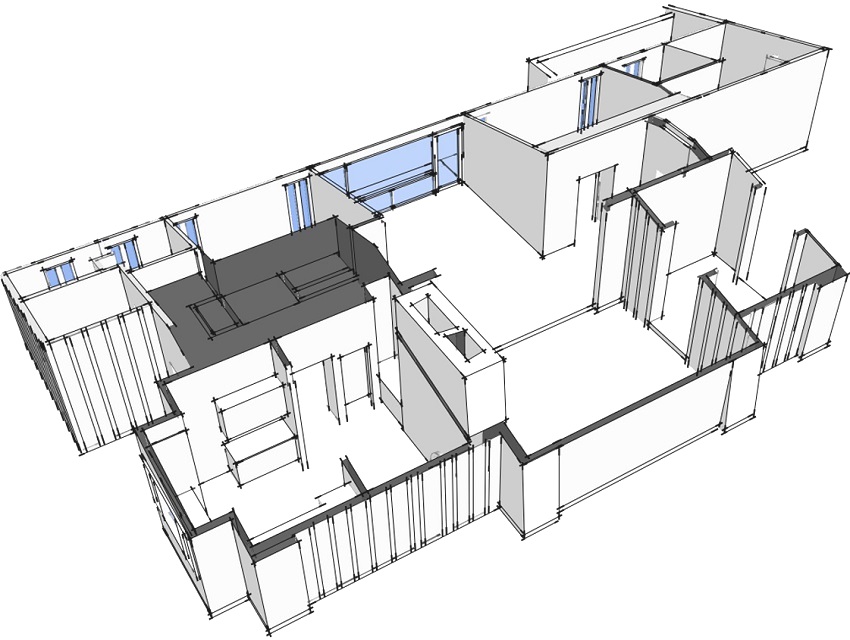

Construction of houses from turnkey SIP panels. Project prices from various companies

Any self-respecting developer company has an official website, which contains full information about the technology for the production of SIP panels, the quality of the materials used, the certificates available, the construction time and other information useful to the customer. Project catalogs are accompanied by photos of houses made of SIP panels with price indication and a full description of the construction stages. Thus, before you buy a house from SIP panels, you should familiarize yourself with offers from different companies.

Projects of one-story houses from vulture panels

The advantage of using ready-made standard projects of one-story houses from SIP panels is that focusing on ready-made developments can significantly reduce the construction time of the facility and reduce the cost of construction in general. The priority direction of any one-story house project is the rational use of the usable area. Well-thought-out planning solutions allow everyone to become the owner of the most comfortable house built from SIP panels. In projects, both prices and the amount of materials are indicated approximately: they must be specified when ordering.

For the convenience of choosing a suitable project, catalogs on the websites of developer companies are divided into subgroups based on the area of the house and its number of storeys. Thanks to the convenient search, you can easily find an option that will directly satisfy your requirements. Having decided on the project and contacting a specialist of the company, you can get qualified advice not only on the construction of the structure itself from SIP panels, but also with regards to all communications and systems.

The company "EcoEuroDom" offers for sale panels of its own production and presents options for one-story houses from turnkey SIP panels. The price of a set 71-501 of a small house 6.5x5.5 m is 841,450 rubles. The package of services includes assembly of a house at the customer's site, installation of a foundation made of screw piles, installation of PVC windows with double glazing and mosquito nets, installation of roofing from flexible tiles.

An inexpensive house made of turnkey SIP panels with a size of 6x9 m is offered by PSK "Dom Stroy". Project 20-C includes the installation of a pile-screw foundation, the construction of a house box made of Kalevala SIP panels, a metal roofing, double-glazed windows Rehau and a small cozy terrace. Additional advantages of the project are free delivery (up to 100 km) and unloading of building materials at the customer's site. The cost of construction is 760,100 rubles.

Helpful advice! Before choosing and ordering a suitable house project from SIP panels, ask the site manager about the current discounts and bonuses that can significantly affect the final cost of construction.

DomaIzSip LLC is implementing a project of a compact one-storey house with an area of 65 sq.m. called "Guest". The price includes a foundation made of piles, construction of external and internal walls, floors, roofs. The project implements the ability to choose the color of the roofing. PVC windows are installed, an insulated metal entrance door. At the request of the customer, interior and exterior decoration of the house is possible. The final calculation of costs is made in the case of ordering a project.

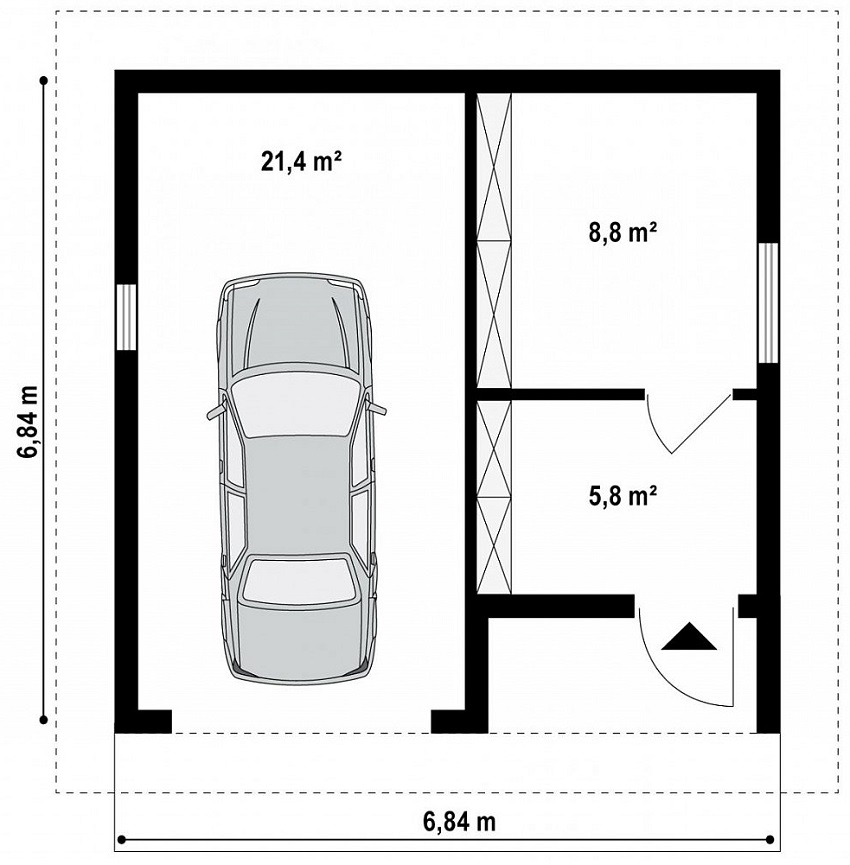

SIP-panel houses with a garage: projects and prices

Those for whom the main requirements for housing are practicality and comfort, among the many options will choose a house project with a garage from turnkey SIP panels. Prices for such buildings differ slightly from the cost of building an ordinary house, since the garage attached to the house is with it on the same foundation and under the same roof, has a common internal wall and a single communications system. Thus, the project of a house from SIP panels with a garage is an economical option among other solutions.

In such projects, as a rule, two entrances to the garage are provided: from the side of the gate and directly from the house. This is quite convenient as it allows you to get to the car without leaving the street. Interesting solutions for houses with a garage are offered by the "House Stroy" company. The cost of building a "turnkey" one-story house with a spacious terrace and a garage with a total area of 252 m² is 2,900,000 rubles. The layout includes a hall, a living room, two bedrooms, an office, a bathroom, a utility block, a garage room of 48 m² and a terrace of 43 m².

House project with garage from SIP panels

Cultural center "Fansip" presents a project of a one-storey house "Rhodes" with a compact garage of 15 m². The project includes three rooms: a spacious living room, two small bedrooms, a kitchen of 10 m², a bathroom, a bathroom, a storage room. The garage has three entrances: you can get into it from the street, from the hallway or through the utility block. The project includes a cozy veranda and a fireplace. The cost of the finished construction is 1,520,000 rubles.

The InterCity company develops interesting modern house designs from SIP panels. One of the stylish architectural solutions is the project of a two-story house with a garage "Toronto". The total area of the cottage is 280 m². The layout of the first floor includes a kitchen, living room, gym, garage. On the second floor there are three bedrooms, a bathroom and a large comfortable 55 m² terrace. Turnkey construction will cost 3,700,000 rubles.

Turnkey garages from SIP panels. Construction prices

If the layout of the site does not allow building a house with an attached garage, you can order the construction of a detached garage from SIP panels. The advantages of a detached garage are the availability of erecting it on the site independently of other buildings and the main house, as well as the possibility of organizing minor repair work or small production in the garage.

The company "SIP Group" provides services for the design, construction and exterior decoration of garages from SIP panels. Projects of garages for one and two cars are offered. The average cost of building a garage is from 5850 rubles. per square meter, facade decoration - from 990 rubles. for 1 m². For those who decide to build a garage with their own hands, the company implements ready-made projects at a price of 160 rubles. for 1 m².

A detached garage in a European style for two cars with an area of 39 square meters from the company "Russip" will cost 215,100 rubles. The standard kit includes a foundation, walls, attic floor and roof truss system. In the catalogs of the company "SipDomik" you can find a project of a two-storey garage "Comfort" with an area of 4x6 m, the construction of which will cost 350,100 rubles. The cost of building a one-story garage from this company with the same dimensions will be 190,100 rubles.

The cost of building a garage depends not only on the overall dimensions of the structure, but also on the thickness of the insulation in the SIP panels. The rather cold climate of the region where the construction is being carried out requires the use of a sandwich with an insulation layer thickness of at least 20 mm.

Helpful advice! Many companies provide the opportunity to order a ready-made kit for self-assembly of the garage, which is accompanied by detailed instructions for the construction and the necessary tools.

Baths from vulture panels. Projects and prices

Almost every owner of a private cottage or country house thinks about building a solid bath on his site. Due to the insulating properties of SIP panels, as well as their resistance to the formation of mold and mildew, this material is excellent for construction of baths... Along with projects of houses for permanent residence, developer companies present in their catalogs inexpensive baths from turnkey SIP panels.

The construction company "DomStroyProekt" offers modern projects of spacious and small baths. The price of a bath from SIP panels on a turnkey basis "Kungur-49" with a total area of 36 sq. M is 304,000 rubles. The layout includes all the necessary premises: a steam room, a washing room, a relaxation room and a terrace. The basic kit includes base, walls and roof. External and internal design of the building is carried out at the request of the customer, based on his preferences.

The company "Viva Haus" is implementing a project of a bath with an area of 36 square meters in several configuration options: house panels, house kit, fine finishing. The construction of a turnkey bath will cost 598,100 rubles. The price includes the manufacture and installation of a house kit, a pile-screw foundation, a roof made of flexible tiles, windows and internal doors from a PVC profile, entrance metal doors.

You can buy an inexpensive bath by contacting the SIP Group company. The company's specialists can build a building within a week. There are projects of free-standing baths and attached to the existing house. The cost of 1 square meter of construction is about 7000 rubles. If you take into account the price together with the finishing of the facade, you should add another 1000 rubles to the cost of 1 square meter.

Since the construction technology is relatively new, many are wary of SIP-panel baths. Owner reviews indicate that such baths heat up quickly and retain heat for a long time. Some advise the corner of the wall where the stove will be located to be laid out with bricks. According to others, it is better to additionally cover the walls of the steam room with a layer of insulation in order to avoid excessive heating of the SIP panels.

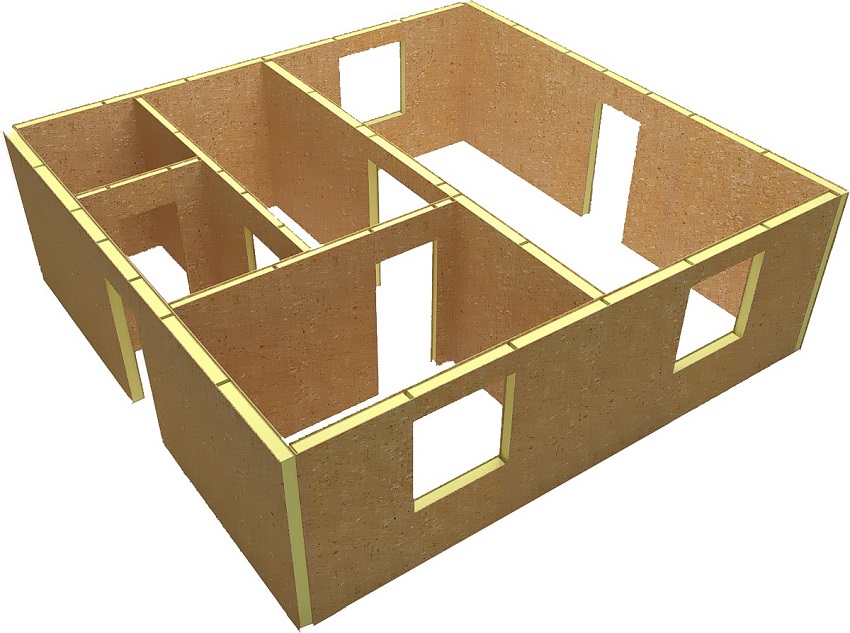

House kits from SIP panels from the factory

For those who can assemble a house using Canadian technology on their own and at the same time save on construction, manufacturers offer to purchase house kits from SIP panels. As a rule, companies offer several configurations. In the first version, the house kit includes external and internal walls, floor slabs, interfloor ceilings, and a roof. All structural details from SIP panels are cut according to the house project.

The second set of the house kit includes all the elements included in the first set, as well as a bar and a board for attaching the panels to each other, a bar for tying the foundation and roofing felt under it, bituminous mastic used to waterproof the floor of the first floor, the entire package of fasteners, including galvanized self-tapping screws, polyurethane foam to fill the empty space in SIP panels.

It is possible to order a house kit with assembly on your territory. In this case, it is necessary to have a foundation on the site. A house set of SIP panels from the manufacturer is accompanied by assembly drawings and assembly instructions.At the request of the client, developer companies can provide services for the registration of permits for gas, water and electricity supply.

Helpful advice! If you decide to assemble the house yourself, check out the construction technology from the numerous Internet stories about building houses from self-supporting insulated panels with your own hands. The video contains information about the assembly stages and the nuances of installation.

The main advantage of home kits is that most of the construction work was carried out in the factory. On site, you only have to assemble the structure, which will save about 25% of the cost of the house kit. It is worth noting that you can buy home kits from SIP panels at the best prices from companies that have their own production. Thanks to factory production and customization of the panels, the cost is significantly reduced.

The price of house kits made of SIP panels from different manufacturers

The cost and composition of house kits from different companies may differ, therefore, before purchasing, it is necessary to analyze the price on the websites of developer companies. The approximate cost of 1 sq. M of a house set made of SIP panels from the company "EcoEuroDom" is: basic set, which includes SIP panels cut according to the project - 4500 rubles, a house set consisting of SIP panels and sawn timber - 5850 rubles, house set with installation - 7350 rubles.

The company "Canadian House" offers a basic house kit at a price of 8530 per sq. M, the cost of the Basic Plus set is 9580 rubles. for 1 m². House set for finishing "Standard" will cost 16146 per square meter. The last set includes electrical wiring, as well as wiring for water and sewer pipes.

House kits from the SIP Group company include panels of walls, ceilings, partitions, boards and beams, roofing, consumables (screws, foam), project documentation. The cost of the house kit is 6050 rubles. per 1 m² The customer can choose any project he likes and order a house kit for it. The company can include installation work, external and internal finishing of the house from SIP panels, engineering networks in agreement with the client.

Helpful advice! Many developers provide the customer with the opportunity to make individual adjustments to the layout of the house. To do this, you must contact the designers in advance so that they make changes to the standard project.

The production and construction company "MIS Dom" sells ready-made house kits at the most favorable price. The cost of the "Standard" set is 5910 rubles. for 1 m². The package includes not only SIP panels for walls, partitions and ceilings, but also a strapping and foundation beam. The project documentation is attached to the housecomplete. Transportation to the assembly site and unloading are not included in the kit price.

Methods of exterior decoration of houses from SIP panels

To protect a house made of SIP panels from external influences of natural factors and to give the house a more attractive look, various types of facade decoration are used. It is worth noting that for the exterior decoration of a house from SIP panels, you can use almost all finishing materials intended for facing facades. However, when finishing, it should be borne in mind that the wooden elements with which the panels are connected can slightly deform under the influence of temperature and humidity.

There are frequent cases of use for finishing the facades of houses from SIP panels of various types of siding. This material is easy to install, has a lot of colors and gives the house an attractive appearance.Facades made in a combination of siding of several colors look exceptionally. Contrast cladding can highlight and emphasize various elements of the house: terrace, balcony, bay windows.

The exterior decoration of the house with a block house is noteworthy. Thanks to the natural composition, decorative paneling gives the building the look of a country house. This material is practical, durable and easy to assemble. The block house is positioned horizontally, which skillfully imitates the surface of rounded logs. The lining is not subject to cracking and maintains a perfectly flat facade surface for a long time.

As an exterior decoration of houses made of SIP panels, you can use natural and artificial stone, clinker tiles, corrugated board with imitation of stone, brick, wood. The option of plastering external walls from SIP panels is not excluded. Considering the richness of colors and textures, as well as the physical properties of the plaster, the facade is flawlessly even, smooth and protected from external influences.

Finishing options for a house from SIP panels inside

A wide variety of materials can be used to decorate walls and ceilings. There are a lot of options, as evidenced by a photo of the interior decoration of houses from SIP panels. Most often, before the finishing coating, the walls are sheathed with plasterboard, which can be screwed directly to the surface of OSB boards. Electrical wiring is usually hidden in the joints between drywall sheets.

Helpful advice! In damp rooms, such as a kitchen, a bath, a bathroom, moisture-resistant drywall is used.

Drywall is also used for sheathing the ceilings of a house from SIP panels. They can be done in one or several levels. Depending on preferences, wallpaper, paint, decorative plaster or ceramic tiles are applied to the plasterboard base. Quite often, a stretch ceiling is used in houses made of SIP panels. This method of finishing the ceiling is the most practical and gives the interior space sophistication.

Interior decoration is selected taking into account the style of the interior. For country houses, wall decoration with clapboard is suitable, which will make the room more natural and aesthetic. Plastic lining is very popular as a finishing material. It can be used for wet rooms as well as for the hallway. The material has excellent characteristics, it is easy to care for it.

For finishing the floors, use linoleum, laminate, ceramic tiles, carpet, floorboards. If the floor is finished on the second floor, a cork backing is used for additional sound insulation. The option is not excluded when the interior decoration is performed directly on the slab, applying a primer and putty to it. Thus, the choice of finishing materials directly depends on your preferences and financial capabilities.

Houses from SIP panels: reviews of living

Since Canadian technology is a relatively new type of construction, many are interested in the main pros and cons of houses made of SIP panels. According to those who have been living in such a house for some time, it is always warm inside, there are no drafts. Residents claim that the temperature of the walls in the corners and on flat areas is the same. As for heating, many people note significant fuel savings, since the house heats up quickly and retains heat for a long time.

Significant advantages include the fact that in summer there is no need to purchase an air conditioner in a house made of SIP panels: it is cool inside. The positive aspects include the fact that such a house is being built rather quickly, it is easy to make interior decoration in it - the walls are smooth, without any deviations. Another plus: many testify that during the entire period of residence they never noticed mice in the house.

Due to the structure of SIP panels, the house is not afraid of strong gusts of wind and hot sun rays

Of the minuses of houses made of SIP panels, those living in them note that without good ventilation, the house has to be constantly ventilated. In addition, some note that there is little vibration when opening or closing window sashes and doors. But this may be one of those cases when the construction technology was not followed during construction. In any case, there are much more positive reviews about houses from SIP panels.

Thus, modern, pre-fabricated, practical and magnificent SIP-panel houses are the best option for those who dream of their own cottage.