GVL is one of the most popular building materials today. The name stands for gypsum fiber sheet. The product itself is a board made from a mixture of gypsum and cellulose fibers. So that the repair does not take up extra money, it is necessary to correctly calculate the material consumption. To do this, you need to know the size of the GVL sheet. It is important to consider that different surfaces have their own parameters.

Content

- 1 GVL: what is it, decoding, the main features of the panels

- 2 The main options for using sheets: what affects the thickness of GVL sheets

- 3 Dimensions of GVL sheets for floor and ceiling decoration

- 4 GVL sheet size: how to work with the material correctly

- 5 Step-by-step instructions for installing GVL for walls: basic mistakes

- 6 An important question regarding the safety of the use of the material

- 7 Sizes and prices of GVL boards: moisture resistant, wall and other types

GVL: what is it, decoding, the main features of the panels

GVL and GKL sheets are deservedly considered the most demanded materials for construction and repair. If many people have known gypsum plasterboard (gypsum plasterboard) for a long time, then gypsum fiber appeared relatively recently and almost immediately conquered most of the building materials market. All thanks to the versatility and increased strength of the gypsum fiber board.

Information! Gypsum fiber sheets are produced by combining gypsum and cellulose fibers, which are obtained from recycled paper.

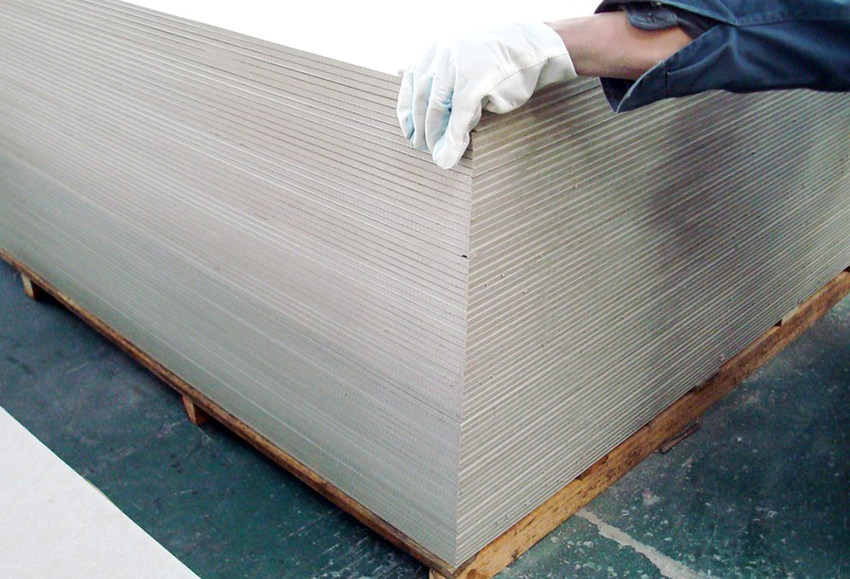

After mixing the key components, the sheets are shaped using a press, where the components are compressed under high pressure. The output is a sheet of gypsum fiber. This homogeneous structure is the main difference from drywall, which consists of several separate parts. Thanks to the integrity of the panel, GVL is stronger and more reliable. It is for this reason that they are considered more in demand in the construction of false walls and other partitions.

Depending on the features, the products are divided into 2 types:

- standard, which are marked by GVL;

- GVLV - slabs with increased moisture resistance characteristics.

Sheets are also classified by type of edge:

- "PC" - straight line;

- "FC" - folded;

- "K" - sheets with no edge.

Panels with a longitudinal straight edge are used for cladding frame structures (for walls and ceilings). To make the joints less visible, a reinforcement technique is used.Material marked "FK" has a corner edge, which is obtained by gluing two sheets together with a slight offset. The side clearance usually does not exceed 30-50 mm.

The main advantages of gypsum fiber sheets: moisture resistant and conventional

One of the main advantages of GVL is fire resistance, which reduces the likelihood of fire spreading during a fire. The material belongs to the G-1 type, which means it is hardly combustible. Other benefits of sheets:

- Ecological cleanliness. Gypsum fiber is considered environmentally friendly, since only natural materials are used in the manufacture. This allows you to mount the sheets in children's rooms and medical institutions.

- Resistance to temperature extremes. Thanks to this characteristic, the material can be used in any residential and unheated technical premises (in basements, garages).

- Simple installation. The gypsum fiber board can be cut in any way without worrying about crumbling or cracking, which allows it to be used for finishing even the most difficult surface. Moreover, the number of joints does not reduce the strength of the structure.

- Good soundproofing. The material is suitable for creating screens that reflect extraneous noise, and the characteristics of noise insulation increase depending on the thickness of the gypsum fiber board.

- Additional insulation. The panels, due to their low thermal conductivity, are able to retain heat in the room for a long time.

The sheets are characterized by reliability, environmental friendliness and resistance to temperature changes

All the listed advantages are provided by the technical characteristics of GVL:

- density - up to 1250, kg / m3;

- surface water absorption - less than 1 kg / m2h;

- bending strength - 4.5-5.5, MPa;

- thermal conductivity - up to 6.2 W / (m*FROM);

- vapor permeation resistance - m2h Pa / mg;

- hardness - more than 20 MPa;

- humidity - less than 1.5%.

Despite the huge number of advantages, blocks also have certain disadvantages. The main thing is the weight of the sheet of gypsum plasterboard, which is much more than the mass of ordinary drywall. The minimum weight of a small-format panel is 18 kg, and the average figure for standard panels is 36-45 kg. Another negative point is that the boards do not bend as well as drywall, and the cost of GVL sheets is 2 times higher than the price of gypsum boards.

Various sizes of sheets of gypsum fiber board for walls and other surfaces

The standard dimensions of GVL sheets are regulated by the standards of GOST and SNiP, which determine the parameters of the panels in terms of length, thickness and width. The minimum thickness of the GVL sheet is 10 mm, but there are other options:

- 12.5 mm;

- 18 mm;

- 20 mm.

As for the length, there are 3 main sizes: 50, 100 and 120 cm.At the same time, the following length options are available (in centimeters):

- 150;

- 200;

- 250;

- 270;

You can also purchase a non-standard version of the size of sheets of GVLV and GVL: length - 120 cm, width - 60 cm and thickness - 1.2 or 2 cm.

Expert advice! If many custom sheets are required, experienced builders prefer to contact the manufacturer directly. It is often very difficult to find large quantities of goods on trading floors.

Speaking of dimensions, we should definitely mention Knauf, which is the main supplier of gypsum board and gypsum fiber products on the market. The manufacturer produces special sheets used for making dry screed on the base.

The panels are usually sold under the “super floor” label. In this case, Knauf gypsum fiber sheet is realized with a size of 120 × 120 cm and differs in increased thickness (up to 2 centimeters). Such blocks are two sheets glued together with an offset, so they have a folded edge, which helps to avoid visible joints.

When buying, it should be borne in mind that the increased thickness of gypsum fiber board for the ceiling makes the sheets less durable when bent.This is important not only during installation, but also during material transportation. Nevertheless, such panels are quite suitable for making arched entrances.

To make it easier to understand the choice of material in retail outlets, manufacturers use markings that are applied to the back of the panels. It indicates the number of GOST used in the manufacture, the main parameters and characteristics of the GVL sheets. If the fabric is impregnated with hydrophobic substances during production, then the product becomes moisture resistant, in which case the abbreviation becomes GVLV.

The main options for using sheets: what affects the thickness of GVL sheets

When compared with drywall, GVL has a greater weight, therefore, for the installation of large sheets, it is imperative to first perform a metal or wooden crate. In this case, it is permissible to install the panels on glue, but only if they are small in size and will not exert additional stress on the wall. In addition to being used for finishing horizontal and vertical surfaces, it is also suitable for creating partitions, false walls, boxes and other decorative elements.

Depending on the field of application, gypsum fiber sheets are divided into the following types:

- wall;

- outdoor;

- ceiling.

As in the case with other materials, the purpose of the panels is determined primarily based on the thickness, therefore, this indicator is different for each type. The thickness of the wall partitions is 1.25 cm. This is enough to provide a solid cladding that will withstand mechanical loads well, including point impacts.

If you need to make a partition, it is better to use thickened super sheets, the thickness of which is at least 1.5 cm, because the frame of the structure must be different in rigidity. Some believe that panels of 1.25 cm are also suitable for work. It is permissible to purchase moisture-resistant or ordinary GVL for partitions - everything will depend on the type and characteristics of the operation of the room. The size of the wall sheets is set by the GOST R51829-2001 standard. The following parameters are considered standard (in millimeters):

- 1200×1500;

- 1200x2500;

- 1200x3600.

Dimensions of GVL sheets for floor and ceiling decoration

GVL sheets for the ceiling practically do not differ from wall panels. The standard size is also considered to be 1200 × 1500 mm, but the main difference is the thickness, which is usually 1 cm. The slabs are thinner, because the ceiling does not have a significant load, as on the walls. The reduced weight of the sheet GVL allows you to simplify the installation process.

it interesting! Due to the fact that drywall panels are easier to bend, this material is used more often than gypsum fiber to create unusual multi-level or curved ceiling structures. But the moisture-resistant gypsum fiber board for the ceiling will help protect housing from flooding by neighbors from above.

Floor sheets are used to create dry screed. In this case, the organization of the lathing is mandatory, under which the material is poured (most often expanded clay acts as it), and the panels are already laid up. Obviously, the floor is subject to much more stress than the walls or ceiling. It is for this reason that the material is characterized by increased thickness. The minimum indicator here is 18 cm, the maximum is 25 cm, and the average thickness is 20 cm. The sizes and prices of GVL sheets for walls are somewhat different from those of floor panels. Plates of the following dimensions are often laid on the floor:

- 1200 × 600 mm;

- 1500 × 500 mm.

The standard dimensions of GVL for the ceiling are 120x150 cm, but more dimensional sheets can be found on sale

Sometimes on trading floors, sheets of this size are sold under the label "small". For proper installation, it is preliminarily recommended to mark the floor and lay out a layer of waterproofing.The advantage is that GVL can be used in conjunction with the installation of a floor heating system. Tiles, laminate, tiles and other floor coverings can be placed on top of the laid sheets. Only in the case when it is planned to lay thin linoleum, it is recommended to fill the gypsum fiber with a layer of a leveling mixture. There are also other options for using the material:

- Finishing of elevator shafts and emergency exits. Fire resistance and good sound insulation of the sheets allows their use in special premises.

- Facade cladding. For these purposes, moisture-resistant GVL sheets of suitable size are selected, characterized by an increased degree of frost and moisture resistance.

GVL sheet size: how to work with the material correctly

Every renovation or construction is not complete without the need to cut sheets. In order to carefully cut the slab, you can use an ordinary knife. In this case, in order to give the material the required size, you should perform the following actions:

- Place the panel on a comfortable surface. In this case, it is important to ensure that the sheet does not sag much.

- Using a level or flat rail, mark out.

- Draw several times along the drawn line with a knife (at least 6-8) to leave a deep cut.

- Make a break. At the same time, most experienced builders argue that the break should be done not down, but up.

This method is considered the most elementary and time consuming. If you want to speed up the process and have some skills in the field of construction, it is better to use a jigsaw, but you need to take into account that in this case the work will be accompanied by the formation of dust.

Before installing the sheets on the floor, you should prepare the base well:

- eliminate the old cover;

- close up cracks and other irregularities;

- remove all garbage;

- perform waterproofing (if necessary).

Related article:

Chipboard: sheet size, thickness and cost of material from leading manufacturers

Features of laminated chipboard boards, their advantages, disadvantages and applications. Basic sizes and prices from leading manufacturers.

The progress of laying sheets on the floor will look like this:

- First of all, a damper tape is glued to the surface, and then the panels themselves are laid.

- Fastening can be done in two ways - with glue or self-tapping screws for GLV.

- During installation, regardless of the size of the sheets, the recommended distance between fasteners must be observed, which is at least 20 cm.

- In order for the joints to be less noticeable, they should be repaired with glue or putty.

After finishing the work, you can immediately start laying the selected topcoat.

Helpful information! The course of actions for laying gypsum plasterboard does not differ from the process of installing ordinary drywall. In this case, the material is also fixed with self-tapping screws, after which all joints are reinforced, and then the previously primed surface is putty.

Step-by-step instructions for installing GVL for walls: basic mistakes

Wall panels are fastened in two ways:

- frameless;

- wireframe.

The frameless method involves the use of a special glue, the type and quantity of which is determined depending on the quality of the wall and the presence of irregularities. If there are no significant defects on the surface, plaster glue is applied to the material, after which the sheet is pressed against the wall.

In the event that it is planned to work with surfaces on which there are significant irregularities, it will be necessary to apply a strong adhesive mixture to the entire base of the sheet. For better adhesion, you will additionally need to perform spot application - every 30-40 cm.You should also increase the amount of glue applied if it is then supposed to fix hangers or shelves on the walls, which exert additional stress.

The presence of a frame will help increase the strength of any surface and increase the wall's ability to withstand increased loads. The advantage of making the frame is also considered the fact that a layer of insulation or soundproofing material can be neatly laid between the sheet and the wall.

With the help of GVL panels, many also make boxes in which you can neatly place electrical wiring, plumbing pipes and other communication systems. Fastening of sheets to the frame is carried out by means of special self-tapping screws, characterized by two-row threads.

List of recommendations to avoid major mistakes:

- no need to chamfer before applying the putty;

- you should not use anything other than screws for GVL with two-row thread for fastening;

- it is better to leave gaps between the sheets, the thickness of which is half the thickness of the slab;

- all gaps are filled with gypsum mixture or special glue;

- before working with the surface, it is necessary to carry out thorough processing, eliminate all irregularities and prime the base.

An important question regarding the safety of the use of the material

In some sources there is information that sheets of GVL are harmful and hazardous to the health of others, therefore they are categorically not recommended for use in rooms for children and even for internal work in general. Similar information can be found about other panel products from different manufacturers.

The overwhelming majority of experts categorically do not support such a statement. To understand whether the material is harmful, first of all, you should pay attention to the manufacturing features, as well as the substances used.

As noted earlier, the main constituents of the material are gypsum and cellulose fiber, which are bonded to each other using a bonding element. In this case, this component is harmless latex, which additionally endows the material with moisture resistance. Thus, it becomes clear that even with high heating, for example, in a fire, the material will not release toxic substances. Accordingly, there is no possibility of vapor poisoning.

Fact! GVL sheets, unlike other types of floors, are able to withstand high temperature effects for 1.5 hours, while the panels do not change their structure.

Sizes and prices of GVL boards: moisture resistant, wall and other types

When buying gypsum fiber sheets, it is important to pay attention to the manufacturer and product reviews available online. The leader in sales is the German company Knauf, which supplies about 70% of sheet products to the domestic market. The most popular are the so-called "superlists", which are distinguished by increased performance characteristics. In addition, there are also analogues of domestic firms that have a more democratic price, but may be inferior in quality.

Among the main representatives are the following firms:

- AMK-Group. Russian company producing good quality panels. The main advantage is more affordable cost (compared to Knauf products).

- One of the largest manufacturers of gypsum mixtures for construction and gypsum-based boards. All the company's products meet the required standards and are recommended for use in children's educational and medical institutions.

Chinese sheets of gypsum fiber board are often found on the market.Whatever material is chosen, the seller must be sure to ask the accompanying documentation for the goods and certificates, so as not to accidentally purchase low-quality panels. It is also important to familiarize yourself with the labeling in order to choose the size and type of products that you need. When buying, you should not take into account only the appearance of the blocks.

When choosing materials for repairs, cost should not be the determining criterion. If you buy cheap and low-quality products, there is a possibility that you will have to completely redo everything. To navigate, you need to know that a good moisture-resistant sheet of Knauf will cost 400-500 rubles.

The approximate range of sizes and prices of GVL sheets from this manufacturer looks like this:

- "Super floor" 1200x600x20 mm - 300 rubles;

- gypsum fiber board with a folded edge 2500x1200x10 mm - 445 rubles;

- moisture-resistant folded panels 2500x1200x10 mm - 465 rubles;

- moisture resistant GVL 2500x1200x12.5 mm - 520 rubles;

- sheet GVL 2500х1200х12.5 mm - 510 rubles.

From the information provided, it is clear that the main criteria affecting the price of moisture-resistant GVL sheets are the size and type of edge. It can also be seen that the cost of GVL and GVLV differs minimally, therefore, one should not save money during repairs: in places where the surface is likely to get wet, it is better to use only moisture-resistant plates.

GVL sheets, regardless of size, are high-quality and easy-to-process materials. The thicker the sheet, the greater the weight of the gypsum board, and this is important to consider during installation. Frost and moisture resistance of the panels allows them to be used even in unheated rooms. When choosing the correct sheet size, you need to take into account which surface you plan to work with, and you must first calculate the working area. Do not be afraid to cut sheets, because the number of joints does not impair the strength of the surface.