In our country, for decades, a profile pipe has been produced: sizes (standard and specified by the customer) are presented in a wide range. The process of manufacturing square-section products is more complicated than the method of manufacturing rounded pipes. Their cost is justified by the additional labor costs. The use of special equipment and painstaking work involving the use of the latest technologies are a guarantee of the quality of profiled products.

Content

- 1 Features of hot and cold-deformed pipe products

- 2 Features of the production of shaped metal pipe

- 3 Multifunctionality and basic parameters of pipes with stiffeners

- 4 Profile pipe: dimensions according to GOST, sectional shape

- 5 Profile pipe used in construction: dimensions, tables

- 6 What are the dimensions of the profile pipe, types of rolled products

- 7 Profile pipe: sizes and prices, purpose and functionality

- 8 Pricing Mechanism: Determining the Weight of a Professional Pipe

Features of hot and cold-deformed pipe products

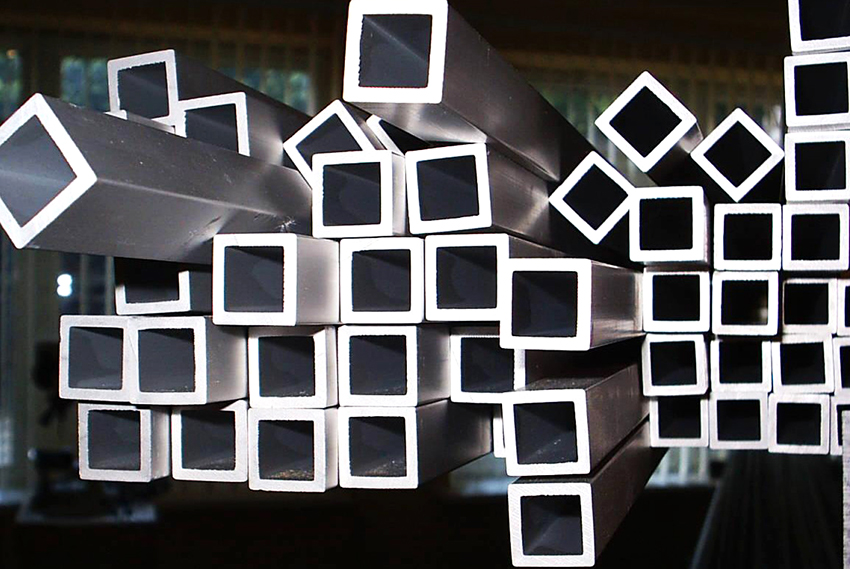

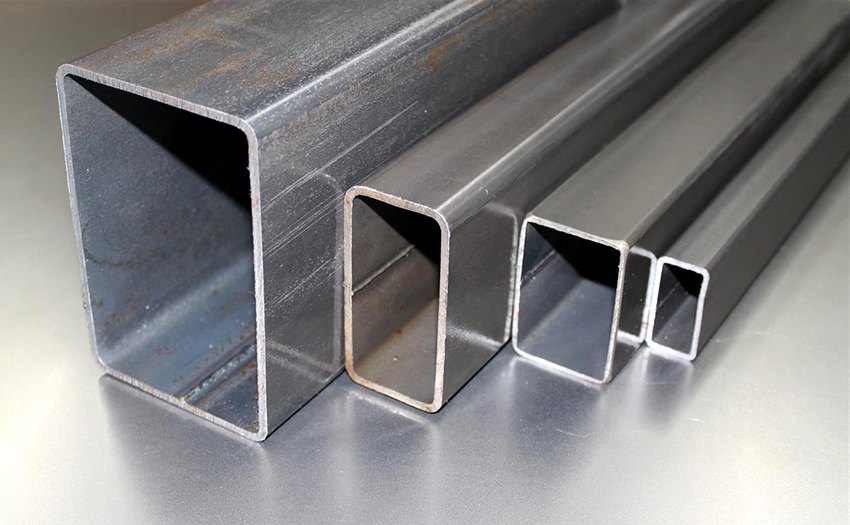

Tubes are called hollow thin-walled and thick-walled metal rods of various formats. Judging by the volumes of production and purchases, the most popular are round and square seamless products. Their consumption increases with the growth of the economy and the needs of the population. The range of products is expanding, different sizes of square shaped tubes are offered.

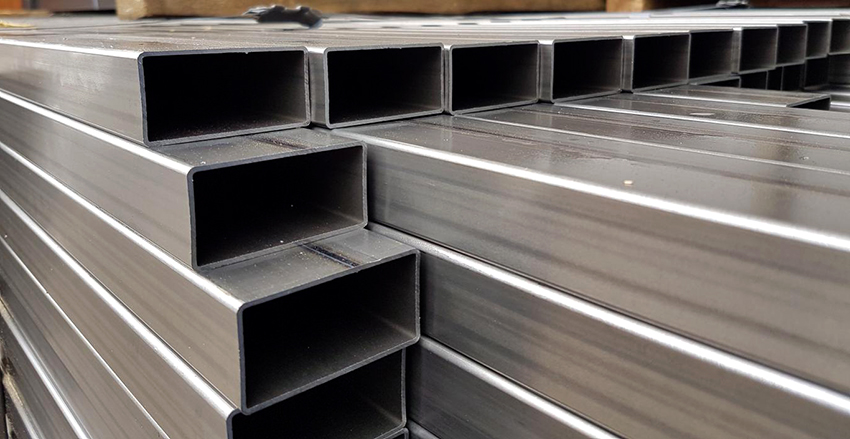

Profile pipes are closed profile products manufactured from rolled steel. Domestic and foreign companies, improving production technologies, offer competitive goods. The main dimensions of rectangular shaped pipes (as well as square and oval) are listed in the tables on the manufacturers' official websites. Deviations are negotiated by managers with a specific buyer.

Helpful advice! The dimensions of the products, their weight and length, specified in the TU, must be checked for compliance with the GOST standards specified in the table before purchasing the batch.

Profiled pipes are molded by sheet metal according to the specified parameters. The process consists of several stages, ends with the processing of products on a sizing mill and seam welding. The maximum dimensions of rectangular pipes were set initially, the standard is 12 m, a short profile is cut from 1 to 9 m in size. Enterprises produce products from available raw materials using special equipment, their assortment is limited by technical conditions (TU).The profile is made from carbon grades of alloyed and high-alloyed (containing chromium, molybdenum, nickel, manganese) steel, resistant to corrosion and high temperature. The brand must meet the standards:

- hot-deformed electric-welded profile - 10ps, St4sp, St4ps, St4kp, St2sp, St2ps, St2kp, 10 and 20;

- hot and cold deformed profile - 10ps, 08kp, 10, 20, 35 and 45.

Profile rolled products are produced according to specified parameters, including wall thickness, in accordance with GOST 1050-88 and 380-94. Mainly steel grades St2, St3, St10, St20 are used for their production.

Features of the production of shaped metal pipe

According to the method of production, profile pipes are hot and cold deformed.

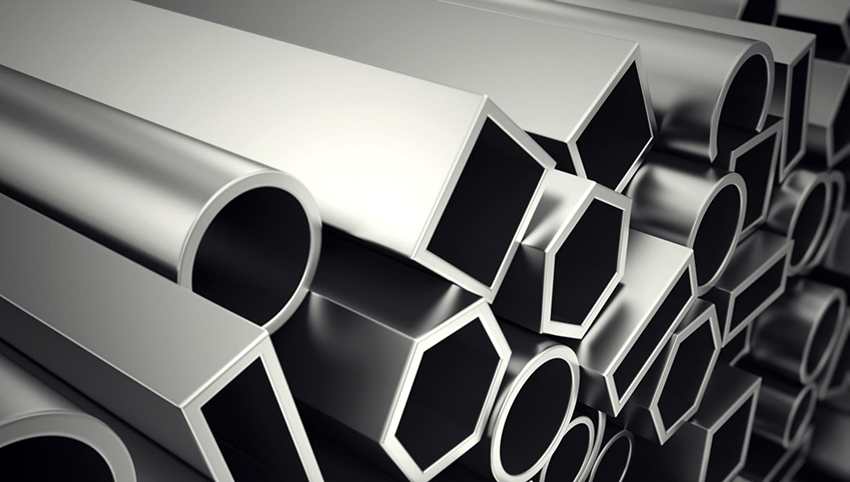

Due to the ductility of metals, the profiling of any steel blank is available under the influence of high temperatures. On the cut (in section), the pipes have the form:

- square;

- rectangle;

- oval.

The flat-oval arched profile (or oval pipes) is no less in demand, and its production is growing. The technology of their forming practically does not differ from the rolling of standard professional pipes. This is, as it were, an intermediate option between round and rectangular structures, and their quality and endurance indicators are an order of magnitude higher than those of these products. The technology for the production of a standard pipe size assumes:

- method of cold forming of rounded products by a press;

- welding of rectangular steel sheets.

Important! The cost of rolled products with a welded seam is lower than the price of solid pipes. There is no need to doubt their quality: the joint is checked by a flaw detector before receiving a certificate and acceptance certificate.

In accordance with GOST, pipes of any size (in inches and mm) are formed using two technologies that are significantly different from each other:

- By welding a sheet or strip profile (a seam can reduce product quality only under significant loads, and the product has a lower price).

- Rounded rods pass the pressing of workpieces of the same shape on a rolling mill (the technology is more expensive, seamless products endure the maximum load in vertical frames).

Pipes are produced by cold forming of rounded products using a press and welding of rectangular sheets

Multifunctionality and basic parameters of pipes with stiffeners

With technological formation steel pipe the dimensions correspond to the given length, the shape when rolling is given rectangular (square) with 4 stiffeners. The output is a pipe profile. Its configuration stands out among ordinary round pipes. Products from cold-worked rolled products are insignificantly different in cost from other varieties. Using cold technology, an aluminum or galvanized profile is produced, it is additionally given anti-corrosion properties.

Helpful advice! It is recommended to look through the prices for finished products in the price lists before buying, taking into account the obvious savings and the cost of delivery to your region.

The increased demand for aluminum profiles is justified by the technical parameters:

- resistance to physical impact;

- low weight with significant dimensions of metal pipes;

- increased strength with sufficient ductility of the metal;

- minor deviations during deformations;

- a wide range of applications;

- affordable prices for the entire aluminum and galvanized assortment, taking into account the standard sizes of pipes.

On the territory of the Russian Federation, more than 400 enterprises specialize in the production of profiled and round steel pipes. They differ in the range of cross-sections and wall thicknesses, and their applications are almost unlimited.

Profile pipe: dimensions according to GOST, sectional shape

All metal components for assembly and installation used in any area must comply with the standards:

- GOST 8639-82 - square section profile;

- GOST 8645-68 - rectangular section profile;

- GOST 8642-68 - arched or oval profile.

Steel pipe size table according to GOST:

| Types of pipe lengths | Length, m | Kind of pipe rolling |

| Measured length | 4,5-11,0 | Used cold-deformed |

| 4,0-12,5 | B / w hot-deformed | |

| 5,0-9,0 | Electrowelded products | |

| Unmeasured length | 1,5-9,0 | Non-woven cold-worked or electrowelded |

| 4,0-12,5 | B / w hot-deformed | |

| Multiple length with 5 mm allowance per cut | 1,5-11,0 | Used cold-deformed |

| 4,0-12,5 | B / w hot-deformed |

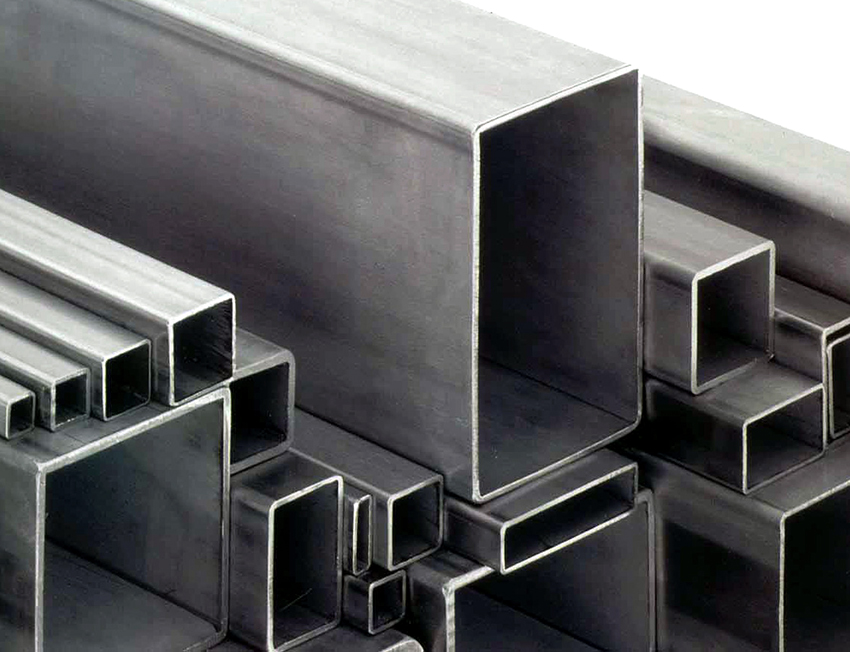

According to GOST, as well as in accordance with tables of profiled pipe sizes, enterprises offer the following products:

- steel pipe profile of rectangular cross-section with dimensions from 15x10 to 180x150 mm with a metal wall thickness of 1-12 mm (special sizes - products from 28x25 to 230x170 mm with a wall thickness of 1.5 to 20 mm);

- square profile with an edge from 10 to 180 mm, wall thickness - from 1 to 14 mm (special sizes - blanks from 32 to 65 mm with a thickness of 4 to 6 mm);

- steel circular oval profile with a format from 6x3 to 90x50 mm and a wall thickness from 0.5 to 2.5 mm (special sizes - blanks from 17x6.6 to 72x22 mm, wall thickness - from 1 to 1.7 mm).

The development of industry and agriculture, oil production and construction areas leads to the expansion of the range of shaped profiles. The production of pipes with a polyhedron cross-section, bent rolled steel and thick-walled supports with an outer diameter of up to 2520 mm (wall up to 75 mm) has been established.

Attention! The enterprises are expanding the production of new shapes of pipes, channels, beams and angles. Before buying, it is important to clarify the assortment; an individual order is also possible.

Profile pipe used in construction: dimensions, tables

Each type of pipes, beams and profiles is designed for a specific purpose. For construction, products with an average wall thickness of 8 to 12 mm are suitable. In the manufacture of such rolled metal, billets from steel grade St3sp / ps5, produced in accordance with GOST 14637-89, are used. Also, high-strength metal of 09G2S grade is used (this is a profile according to GOST 19281-89).

The most popular are professional pipes - universal rolled metal with stiffeners. They are used for construction:

- sports and playgrounds;

- sports complexes and swimming pools;

- fences and fences;

- frame-type metal structures;

- canopies for all kinds of purposes;

- billboards and billboards;

- flagpoles and towers;

- public transport stops, etc.

Each object requires a specific profile. According to standardization, products are classified according to their sectional shape as "rectangle", "square", "oval" and "polygon".

Standard pipe sizes in inches and millimeters, table

Products of rectangular section correspond to the following parameters:

- technical requirements - GOST 13663-86;

- weight 1 linear m - from 0.348 to 55.71 kg;

- section - from 15x10 to 180x150 mm;

- pipe wall thickness - from 0.8 to 12.0 mm.

Square profile:

- technical requirements - GOST 8639-82;

- weight 1 linear m - from 0.22 to 70.33 kg;

- section - from 10x10 to 180x180 mm;

- steel pipe wall thickness - from 0.8 to 14 mm.

Arched profile (oval pipes):

- technical standard - GOST 8642-68;

- weight 1 linear m - from 0.513 to 38.7 kg;

- section - from 6x3 to 72x22 mm;

- wall thickness - from 0.5 to 2.5 mm.

This table will show you the standard sizes and weights of steel pipes:

| Cut shape | Section, mm | Wall, mm | Weight, kg |

| Rectangle | from 10x15 to 1502x180 | from 0.8 to 12.0 | from 0.348 to 55.71 |

| Square | from 10x10 to 180x180 | from 0.8 to 14.0 | from 0.22 to 70.33 |

| Ellipse (oval) | from 6x3 to 72x22 | from 0.5 to 2.5 | from 0.0513 to 3.87 |

The following designations can be found in technical documentation:

- GOST - the state standard for pipes used in gas, oil and heat pipelines;

- DIN / EN - Euro-range of steel pipes in accordance with DIN 2448 and DIN 2458;

- ISO - standard for diameters of plumbing and engineering systems;

- SMS - Swedish standard for pipe diameters and valves;

- ДУ (Dy) - conditional passage.

If the size of the product, presented in millimeters, is required, convert to inches, the value is rounded off with a larger value. There is 25.4 mm per inch (inch), which gives a round-off error for purchase consideration.

Table of pipe diameters in inches and millimeters:

| Pipe diameter, inches | Pipe diameter, mm |

| 1/2 | 15 |

| 3/4 | 20 |

| 1 | 25 |

| 1+1/4 | 32 |

| 1+1/2 | 40 |

| 2 | 50 |

| 2+1/2 | 70 |

| 3 | 80 |

| 4 | 100 |

What are the dimensions of the profile pipe, types of rolled products

The most popular are the following sizes (measured length up to 12 m and in segments of multiple format):

- square pipes - section from 15x15 to 60x60 mm;

- rectangular profile - section from 15x20 to 44x80 mm.

Profile steel pipes (dimensions are regulated by GOST) according to the processing method are mainly divided into the following types:

- seamless cold-worked (cold-drawn and cold-rolled);

- hot-deformed seamless steel pipes (hot-rolled, hot-pressed and hot-forged);

- hot-deformed welded (longitudinal, spiral-seam);

- seamless (centrifugally cast, heat-rolled and heat-drawn) products;

Related article:

Diameters of steel pipes: how to properly plan communications

Why do you need to know the pipe diameter? Varieties of these parameters. Measurement units: inches and millimeters. Tables of diameters of steel pipes.

- longitudinal (electric and welded);

- coiled, brazed and furnace welded pipes;

- cold-worked (drawn and rolled);

- surface-treated steel pipes;

- processed (polished and polished) products with metallic and non-metallic coating;

- nickel plated and with anti-corrosion coating.

Useful advice! It is recommended to specify the length of the products (including the profile pipe), dimensions and weight in the tables.

The following basic parameters of a profile pipe are known:

- profile view (geometric shape on a cut);

- grade of steel or other metal;

- pipe length;

- section diameter (pipe sizes in inches and in millimeters);

- wall thickness;

- the presence of a seam;

- presence of additional processing: galvanizing, grinding, polishing, etc.

Pipes are produced with machined cuts, with threads at one or both ends and with a different type of end finish:

- tapered and expanded metal rods;

- bearing steel pipes;

- products with upset ends and other types of processing.

In addition to rectangular and square structures, according to GOST, the sizes of pipes and their shape can vary within:

- drop-shaped and polygonal rolled products;

- oval and flat oval steel profile.

Important! In difficult operating conditions (at high temperatures), a high pressure profile is used, moreover hardened.

Construction needs: shaped pipes, wall dimensions

Currently, the most demanded are furniture and construction profiles. Pipes of rectangular and square cross-section are produced in accordance with the standards of GOST 30245-2003. It is difficult to imagine industrial, military and civil construction without them. These products are used for the manufacture of such structures:

- frame type buildings;

- stairs and steps;

- overlappings;

- sheds and farms;

- racks and supports;

- bridge columns;

- railway spans;

- warehouses and complexes in the field of logistics.

Useful advice! You should not rush to order a large batch of products without specifics. It is recommended that you first find out all the indicators of the professional pipe in order to determine its suitability for specific tasks.

Furniture blanks are nickel-plated or brushed, oval or square profiles. Most often they are formed from steel strips no more than 1.5 mm thick.This is due to the need for lightweight structures. Such parts are not designed for increased loads, they are subject to destructive mechanical influences. As a rule, furniture blanks are thin-walled products of short length:

- parts of square section with dimensions from 10x10 to 30x30 mm;

- rectangular elements - from 20x10 to 40x25 mm;

- workpieces of oval and flat-oval type within the format of 10x20 mm.

Profiled furniture pipes are manufactured in accordance with the TU enterprises, for example, TU 14-105-737-2004, as well as in accordance with the previously listed GOST standards. High demands are placed on the surface finish and pipe geometry. The oval and flat-oval profiles are aesthetically pleasing and smaller. The price per meter of shaped pipes used for furniture production will be an order of magnitude higher than the cost of other types of pipe products.

Profile pipe: sizes and prices, purpose and functionality

Square pipes are used in various industries, including the production and installation of metal structures for outdoor and indoor use. There are no special requirements for them in terms of surface quality. A general-purpose profile is produced on the basis of hot-rolled steel strips, the thickness varies in the range of 1.5-5 mm. According to functional features or conditions of use, products are classified into the following types:

- metal profiles for general and special purposes;

- products for oil production, gas transportation and geological exploration;

- drilling and casing equipment;

- compressor and pumping equipment;

- water pipes;

- heat-resistant steel products for boiler rooms;

- chemical equipment;

- large highways;

- steel supports with stiffeners for construction;

- durable multi-purpose products.

Important! In order to improve the quality or reduce the cost of products at the request of the customer, you can vary the technology and change the steel grade.

The use of rolled products is widespread in mechanical engineering and construction, agriculture, communication systems and oil refining. All parameters, including pipe length and wall thickness, are regulated by GOST 13663-86.

Prices for pipe products:

- Square profile - from 52 thousand rubles / 1 ton and from 22 rubles. for 1 running. m.

- Rectangular profile - from 51.5 thousand rubles / 1 ton and from 26 rubles. for 1 running. m.

The length of pipe sections, depending on the purpose, varies from 1 to 12 m.

Properties of steel profiles for furniture production

The design properties of the oval and square profiles have been evaluated in the production of furniture. They were used as frames and legs, bases for folding beds and mechanisms for transforming sofas. Profiles are also used as auxiliary elements for forging and its imitation, as well as decorative fragments. The main functions of profiled metal-roll are loads and aesthetics.

Products are classified into 36 standard sizes according to their specific application. Furniture pipes have a small format:

- rectangular section products vary from 20x10 to 40x25 mm;

- parts of a square profile are no more than 30x30 mm in size.

Useful advice! In addition to ordinary pipes, bent blanks are also widely used, which are recommended to be ordered directly from the manufacturer. The plasticity of the metal makes it possible to bend a steel pipe (arbitrary dimensions) at the required angle, forming arched and other complex structures.

Dimension table of profile steel pipes of measured and unmeasured length:

| Type of pipe rolling | Diameter, mm | Wall thickness, mm |

| Electrofusion molding | 10-100 | 1-5 |

| Hot deformation | 60-180 | 4-14 |

| Cold deformation | 10-120 | 1-8 |

Pricing Mechanism: Determining the Weight of a Professional Pipe

The wall thickness of the profile pipe, dimensions and weight (tables reflect these indicators as well) are important for determining the mass of finished products. The majority of enterprises and metal warehouses, offering goods, indicate the price not per running meter, but per ton. The cost of the finished batch includes all labor costs. In warehouses, pipes are not weighed - the theoretical weight of the products indicated in GOST is taken into account.

Due to the large assortment of products, it is difficult to answer the question of how much 1 running meter of a profile pipe weighs. This indicator is influenced by the length and thickness of the wall - the geometry is secondary. There are special computer programs-calculators ("Metal Calculator", "Rolled Metal Assortment") that help to calculate the cost of pipes of a specified size. Various indicators are entered into them, including the thickness of the profile pipe (stainless steel), dimensions - and metal prices are determined based on these data.

Important! GOST allows some deviation of indicators - the difference between theoretical and actual weight, which should not exceed 7-12%.

Calculations are also made according to special formulas that allow you to calculate the weight of the sheet metal from which the profile is released. The length of the sweep of a rectangle or square pipe, dimensions around the perimeter in meters are taken into account. This indicator is multiplied by the wall thickness (in mm) and the specific gravity of the steel (eg 7.85 g / dm³). These are approximate recommendations that help you find out the weight of 1 running meter of the profile of the specified section.

The form of delivery of the profile - packs, bundles, boxes, wagons of different weights, mainly from 1 to 5 tons. The shipment is carried out by a crane and forklift trucks, transportation is carried out by trucks, water and railway transport.

Due to the wide range and size range, profile pipes are used in various fields of construction, furniture production, agriculture, mechanical engineering, as well as in oil refining systems. Due to the versatility of shaped steel pipes, the demand for these products is rapidly increasing. In this regard, the product range, as well as the size range, is constantly expanding.