In home improvement, high-quality and beautiful flooring is of great importance. It largely determines the appearance of the room and at the same time must withstand serious loads. Let's consider what the floorboard should be: sizes, types, wood species, as well as some features of working with different types of material. This will allow you to deal with all the subtleties and purchase a suitable option in the future.

Content

- 1 Floorboards: types of material used as flooring

- 2 Floorboard: dimensions and recommendations for selection

- 3 How to know which flooring is good

- 4 Varieties of floorboards depending on the wood

- 5 How many cubes are in a floorboard and how to understand how much it is: 1 cube of material

- 6 Wet and dry flooring: the required moisture content of the lumber

- 7 Choice of material: floorboard grooved and non-grooved

- 8 Installation of a floorboard: features and secrets of technology

Floorboards: types of material used as flooring

Several types of wood flooring are used for flooring. And each of them has its own characteristics, advantages and disadvantages.

A beautiful and high-quality floor covering not only determines the appearance of the room, but also withstands heavy loads

Classic flooring: properties and characteristics

This type of material can be used as not only a rough, but also a finishing version of the coating. It is made from solid wood or by gluing several elements together. Visually, this material looks like a milled board. To make a floor from a floorboard, you can use ordinary material or made according to European standards, the so-called Euroboard. For its manufacture, special technologies and special European equipment are used.

The quality of the second type of floor covering is usually noticeably higher. On the one hand, it has a lower moisture content, and on the other, high standards do not allow the presence of even small defects, such as holes, knots, stains, etc. Such a surface is smoother, perfectly sanded, but this material is much more expensive.

Obviously, it is better to purchase Euro-plank if you plan to use it for a finished floor.But the usual material is often used just as a rough coating, on top of which laminate or linoleum will be laid. Whether it is worth spending money on the purchase of Euro boards, each buyer decides for himself. It is recommended that you familiarize yourself with both material options in order to find the most suitable one.

Solid wood flooring has a beautiful appearance

Laying a floorboard of this type implies joining with a lock joint: the groove and the ridge converge. This ensures high coating strength and an attractive appearance. Even if a little drying occurs over time, the floor will still look good.

Helpful advice! If you have to work with a large board, for example, 5-6 m long, it is best to give preference to material with cone-shaped ridges. This makes styling much easier and faster.

Fastening a floorboard of this type is always done in a groove, so the only question is how to make the installation procedure as simple as possible. Rectangular spikes are common, but it is difficult to fit them into the grooves, especially if there is even a slight curvature. In this case, stacking is a complicated procedure. Sometimes, in order to facilitate the task, the boards are sawn into pieces. Here are just the appearance of the flooring is greatly deteriorated.

Quarters are a good fixation option. In this case, one of the boards is cut half the width at the top, and the other is cut in the same way at the bottom. This is a very simple fixing method and it looks really nice.

You need to understand that the solid wood board has slightly different standards: it is allowed to have knots, resin, small bluish spots. So it is often used as a roughing coating, simply laying end to end and securing with nails.

Glued floorboard: high cost, increased durability

A glued board is made of several elements, glued together in such a way as to provide additional strength. At the same time, the fibers are arranged so that during the entire period of use, each element does not lose its original appearance and characteristics.

Drying of such boards is almost completely excluded, which allows the floor to remain level. Laying such a coating is a rather laborious procedure. In addition, glued timber has a high cost due to its complex manufacturing technology.

The main advantage of the glued board is its high resistance to heavy loads. That is, in rooms where there is heavy furniture or high traffic of people, this option will be simply irreplaceable. In addition, this material is quite often used for decorating children's rooms in order to provide the floor with an attractive appearance and the necessary endurance.

Due to its structure, the glued board tolerates moisture well. And although you shouldn't put it in a bathroom or a bath, where the humidity is too high and almost constant, for ordinary living spaces, even for the kitchen, it is perfect.

Decking: a great option for rooms with high humidity

The decking is characterized by a special wavy surface. This is ideal for furnishing rooms with high humidity, for example, a bathroom, a bath. In addition to being highly resistant to moisture, the rough surface reduces the risk of slipping and falling on wet floors.

As the name implies, decking is also used for arranging terraces, that is, places that are partially in contact with both the street and the house. This material is also called garden parquet, since it can really be laid in the garden, in the open air.It does not lose its characteristics under the influence of various atmospheric phenomena.

Among the features of these boards, it is worth noting the presence of special compensation grooves, which are small in size (only a few millimeters), but perfectly relieve excess stress. This is necessary due to the effects of rainfall and sun.

Important! Installation of decking is almost never done end-to-end, since space is needed for the free expansion of the elements. Usually, small gaps are left between the boards, which over time, depending on external factors, can disappear and reappear.

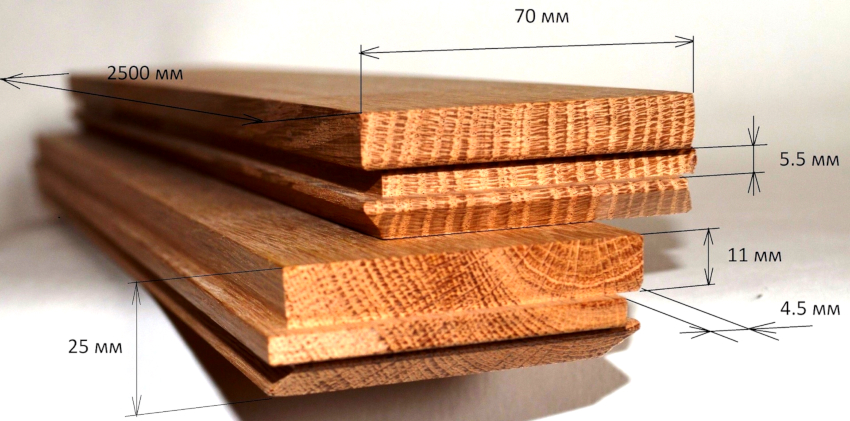

Floorboard: dimensions and recommendations for selection

The first criterion for choosing a floorboard is the specifics of its further use (for rough or final flooring). Before you go shopping, you need to decide where and for what the material will be used. In addition, the length and width of the floorboard are of great importance. Indeed, the service life of the coating and its endurance to loads depend on how correctly the size is selected.

How to choose the size of the board depending on the length of the room:

| Room length (m) | Board thickness (mm) | Distance between lags (mm) | Section of a bar for lags (mm) |

| 2 | 20 | 300 | 110x60 |

| 3 | 25 | 400 | 150x80 |

| 4 | 30 | 500 | 180x100 |

| 5 | 35 | 600 | 200x150 |

| 6 | 40 | 700 | 220x180 |

The length of the board should be adjusted to ensure the minimum number of joints and to minimize the need to trim the boards. The less waste the better.

When it comes to arranging a country house, the thickness of the material used should be at least 35-50 mm. 35mm floorboard is considered standard and is often used in homes. In the case of flooring with increased stress, for example, in a gym or where many people pass every day, it is recommended to use a 50 or 70 mm floorboard.

The width of the board should be selected with a small margin. This allows the floor to be sanded periodically to restore the surface to its original appearance. But the required length of the board should be determined as accurately as possible.

Important! The wider the board, the faster it will lose its original shape. Narrow products are more durable and practical in this respect. That is why a wide floorboard is not always preferable to a narrow one.

How to know which flooring is good

For the convenience of buyers, there is a special classification of wood by types and classes, which makes it easy to select the required material.

Wood classification table by types and classes:

| Class | Quality |

| Extra | The most smooth surface without knots and any defects |

| AND | Smooth surface without cracks or chips. A slight presence of knots is allowed, not more often than 150 cm.There may be small blue spots, no more than two surface cracks, resin |

| IN | No more than 4 knots per 150 cm, no more than 2 superficial cracks, light defects and damage, resin |

| FROM | The lowest class, as a result of which the presence of surface cracks, 2 knots, stripes contrasting in color, blueness and even some mechanical damage are allowed |

Understanding what kind of boards there are, you can easily choose an option suitable for a specific type of housing. After all, it is completely pointless to overpay for an extra-class if a rough finish of the floor is planned, and it is also not recommended to make a finish coating of poor quality material. The table will help determine the required class of material, reasonably approach its choice and planning costs.

Varieties of floorboards depending on the wood

Floor decking can be made from a wide variety of woods. Before giving preference to one or another option, you need to familiarize yourself with the differences and characteristics of different options. Only then will the choice made be optimal.

Coniferous trees. The most popular and demanded option, the price and quality of which are considered optimal. For spruce and pine, these types of flooring contain a large amount of resin, which prevents it from degrading under the influence of moisture and prevents the formation of mold.

Fir is also used for the manufacture of boards, but it contains significantly less resin, therefore, it additionally requires treatment with antiseptic agents.

Softwood smells good - and many people like it. In addition, this material has excellent vapor permeability, thereby maintaining an optimal level of humidity in the room.

Oak. Oak floorboards have long been renowned for their strength and durability. Even a serious exposure to moisture practically does not affect this material in any way, and rot, fungi and mold do not occur. In addition, wood perfectly retains heat and insulates against noise. Therefore, despite the high cost, such an investment is fully justified.

Alder and aspen are not very strong and durable options. However, it is a material that is safe for health, therefore it is often used in children's rooms, home saunas and baths. Where the floor is exposed to severe stress, it is better not to use such wood.

Linden. It is extremely often prone to rotting and the formation of fungi, so it will definitely not be possible to do without antiseptic treatment. But this material is inexpensive and has good thermal insulation properties, a beautiful structure and a light pleasant smell.

Siberian larch. An extremely varied material that comes in 12 shades. Strong and durable larch is resistant to moisture, does not rot or mold. The pleasant aroma it gives off is a natural antiseptic, which helps maintain a healthy microclimate in the room.

Cedar wood is characterized not only by its strength and stability, but also by an unusually beautiful structure. The essential oils contained in its composition maintain a healthy microclimate in the room. The high cost of this material quickly pays off due to its unique characteristics.

Laying the floorboard largely determines not only the appearance of the room, but also the features of the microclimate in it, because the thermal insulation of the floor and the ability of the material to pass air are the most important selection criteria. In addition, the durability of the wood allows you not to worry about the safety of the coating.

How many cubes are in a floorboard and how to understand how much it is: 1 cube of material

Flooring, like all other lumber, is measured in cubes. However, not all buyers understand how many boards are contained in 1 cube and how to determine how much material is needed for a particular room. Let's see how to deal with these questions using a simple calculation example.

To calculate the amount of material in 1 m³, you need to know the volume of one board. Determining this is quite simple: the thickness of the board is multiplied by its width and length. As an example, consider a product with parameters 35x100x6000 mm. For convenience, all indicators must be converted into meters and multiplied: 0.035 * 0.1 * 6 = 0.021 m³ - as a result of performing arithmetic operations, we found out that the volume of one board is 0.021 m³.

Then, by simple calculations, we determine how many units of material of this size are contained in one cube of a floorboard: 1 / 0.021 = 47.62 pcs.

For the convenience of buyers, there is also a special table of standard indicators, which shows how many boards 6 meters long are in one cubic meter.

| Board size (mm) | Volume (m³) | Quantity in 1 m³ (pcs.) |

| 25x100 | 0,015 | 66,6 |

| 25x150 | 0,0225 | 44,4 |

| 25x200 | 0,03 | 33,3 |

| 40x100 | 0,024 | 41,6 |

| 40x150 | 0,036 | 27,7 |

| 40x200 | 0,048 | 20,8 |

| 50x50 | 0,015 | 66,6 |

Note! For convenience, the number of boards in one cubic meter is usually rounded, and downwards. When deciding how to calculate the number of boards on the floor, you should definitely take into account that it is necessary to purchase products with a margin of 15 to 30%. This will avoid unpleasant moments associated with a lack of material, especially since some of it is usually discarded, and this is quite normal.

Wet and dry flooring: the required moisture content of the lumber

When it comes to living quarters, it is enough for the moisture content of the floorboard to be from 12 to 14%. If it is necessary to equip a bath or sauna, then this value should be greater - 20-25%. This is due to the fact that well-dried lumber under the influence of moisture will warp and deform, swell.

It is a serious mistake to buy lumber that is wetter than necessary, expecting that it will dry out by the time it is laid. Attempts to dry the boards yourself may deform them. In order to properly dry the material, it is necessary to use special chambers in which a certain temperature is maintained. And the time of such drying should be strictly limited.

Related article:

Engineered floorboard: a great way to decorate your home without over-spending

What is it and how is it different from parquet. The main characteristics of the flooring, advantages and disadvantages. Leading manufacturers.

It is almost impossible to check the moisture level in the wood yourself. To do this, you must have a special device - a moisture meter for wood.

Higher quality material is considered to be collected between autumn and winter. This is due to the high content of resins and tannins. They reduce the likelihood of deformation and allow products to retain their original appearance and size.

Choice of material: floorboard grooved and non-grooved

In order to choose the right material, regardless of the features of its further installation, you need to pay special attention to several main aspects:

- It is necessary to check the compliance of all geometric parameters: the width, length and thickness of all boards must be the same. It is worth inspecting the edges - they must also be even and smooth, not have defects in the places of further joints.

- When it comes to tongue-and-groove material, it is important to carefully study the places of the tool joints. The groove needs to be deeper than the height of the ridge. This is a prerequisite, because if the flange is larger than the groove, gaps will form during joining.

When buying a lot of material, checking each board is simply impossible. In this case, you can limit yourself to inspecting randomly selected samples, and it is also worth requesting documentation and certificates confirming the appropriate quality of the material. In addition, you can only make a purchase from trusted sellers who have a decent reputation and provide really high-quality products.

Installation of a floorboard: features and secrets of technology

Regardless of whether the laying of the flooring will be carried out by a specialist or the work is carried out independently, it is worth getting acquainted with the technology and features of this process in any case.

If the installation of the floorboard will be carried out independently, you must first study the technology and features of this process

Selection of the optimal thickness of the floorboard and the base for laying

Floorboards are a fairly versatile material that works great with substrates such as:

- concrete floor;

- plywood;

- lags;

- old wood or parquet floor.

The main thing that is necessary for a high-quality installation of a wooden floor is filling the free space between the new coating and the base. Usually, mineral wool is used for this purpose, which additionally insulates and soundproof. In addition, cotton wool does not allow excess moisture and cold to pass through. This is very convenient, especially since you can even put it directly on concrete.

It is important to understand that the thinner the board is, the more it will bend under load. This means that the base for thin material must be made securely, since floorboard 36 requires more frequent lags than floorboard 40. Products of any thickness can be used as flooring (a wide range of boards allows this).

Self-laying flooring technology

The design of the floorboard is easy to install. Usually, special grooves are provided for this. If not, you can use floorboard screws to secure the flooring.

Important! The main laying rule, which must be adhered to: the boards should be located strictly across the movement. This will reduce stress while walking and extend the life of the floor.

If you constantly walk on one long board, then over time it will become unusable in the place where there was the greatest load. If the products are located across, then the load will be distributed on different boards. Due to this, the service life of the coating will increase.

Installation of the first element should be done near the far wall. In this case, the floorboard, the tongue of which will be inside (near the wall), will easily connect to the next one. To fasten the first element, self-tapping screws are also used, which are directed at an angle of 45 degrees. Thanks to a curly screwdriver, the self-tapping screw can be deepened into the wood.

The second board usually fits easily into the groove of the first. A rubber mallet is most often used to ensure a firm and even attachment. The surface will eventually be perfect if each subsequent board is aligned with the previous one. Use a level to check. If necessary, you can put pieces of bars under the bottom.

After fixing the last board, its extra groove can be removed with a jigsaw, and then cleaned up the cut. Then it remains only to process the floor with a grinder and cover it with varnish, stain or mastic.

Useful advice! For a more reliable fixing of the boards to the floor, they can be fastened with self-tapping screws. The caps are then covered with a sealant and, like the rest of the surface, varnished.

Features of laying floorboards on logs

Installation, which involves the use of lags, is more complicated and requires high precision in all work. First of all, it must be said that logs are wooden blocks that are located horizontally. The floorboard itself is mounted across them. Often, not a special beam is used as lags, but ordinary beams, which are used to overlap between the first and second floors.

The first thing you need to pay attention to is the distance between the floor joists. The table given a little earlier will help you choose the best option, taking into account the size of the existing board. Floor joists, the size and distance between which are selected correctly, can provide additional strength, thermal insulation and evenness of the final coating.

For fastening the lags, ordinary dowels are used, so it is not necessary to buy special anchor bolts. If the fastening is carried out on a concrete floor, the logs are drilled through. Plastic tips are driven into concrete, into which self-tapping screws are then screwed.

Sometimes logs are fixed with mortar (although this option is unacceptable for plywood). Lags are poured directly on the ground with a small amount of the mixture. This allows you to achieve the necessary solidity of the coating, while not having a negative effect on the beam itself.

Fixing the floorboard with construction adhesive

The floorboard can be placed on a special construction adhesive. Usually, an epoxy is used for this. When this glue hardens, it becomes very hard and durable. Sometimes, instead of an epoxy composition, a dispersed or polyurethane solution is used. At the same time, the technology of mounting the board itself remains the same as in the case of a lock connection.

How to fix the floorboard, you need to decide on the basis of the available data and taking into account the characteristics of the base. For example, sometimes it is better to give preference to a floorboard that is less than the length of the room. This allows you to smooth out height differences in the room, which is impossible when installing very long products.

The selection of a suitable floorboard and adherence to the rules of the technology for their installation allow you to make a beautiful and high-quality floor covering. In the bedroom, in the children's room, in the kitchen and even in the bathroom, such a floor will look great and fully fulfill all its tasks for many years.