Keeping warm is not just about saving. First of all, it is health and comfort. Excess moisture, combined with cold air, results in dampness and mold. Being in a room where the fungus has appeared is not only uncomfortable, but also unsafe. In addition, this leads to the inevitable destruction of building structures that are constantly exposed to moisture. A modern reliable vapor barrier for the roof will help to avoid the above problems.

Content

- 1 What is vapor barrier

- 1.1 Types of vapor barrier and their features

- 1.2 Varieties of membrane films

- 1.3 The basics of making the right choice

- 1.4 The sequence of laying a vapor barrier: basic rules

- 1.5 How to properly install a vapor barrier for a roof

- 1.6 Errors made during the installation of a vapor barrier

- 1.7 Steam barrier for a bath

- 1.8 Do you need a vapor barrier when insulating with mineral wool

- 1.9 Prices and manufacturers

- 1.10 Roof vapor barrier: a modern moisture protection solution

What is vapor barrier

The level of dryness, comfort, heat retention in the room largely depends on the condition of the roof. It acts as a barrier between the cold external environment and the internal heat of the building. The use of heaters in the absence of waterproofing for the roof is ineffective. Waterproofing prevents the penetration of steam from the living space into the insulation layers.

In addition to protecting the base from moisture, the material performs an important thermal insulation function, preventing warm air from rising up

For a long time, ordinary polyethylene film was used as a vapor barrier in the construction of roofs. But this material is mechanically vulnerable. In addition, it is characterized by a fairly high level of moisture permeability. The modern vapor barrier film for the roof has a vapor permeability of 0.4 g / m², and ordinary polyethylene - 13-20 g / m². It is used for all types of roofs: flat, pitched, when installing an attic floor. Reliable vapor barrier of the ceiling in a cold attic is especially important.

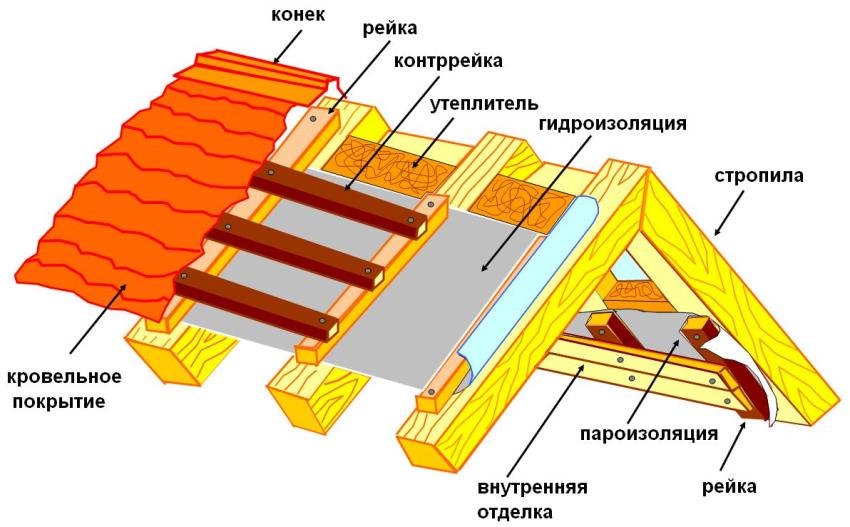

The vapor barrier is one of the components of the "roofing pie", which also includes waterproofing and insulation. If the "pie" is laid correctly and from high-quality materials, then the main functions of vapor barrier can be considered:

- maintaining the microclimate, ensuring air exchange, maintaining the optimal temperature and humidity level in the premises of the building;

- protection of the roof structure from moisture penetration from the outside and steam from the inside, prevention of condensation, damage, fungus, mold;

- reduction of heat loss in the cold season, which helps to save costs for heat carriers;

- increasing the fire resistance of roof structures;

- reducing the cost of repairing the roof and building.

The lack of implementation of at least one of the above functions indicates the poor quality of the film or mistakes made during its installation.

Useful advice! Before purchasing a vapor barrier material, it is necessary (in the absence of knowledge) to consult with an experienced roofer. Incorrect selection can lead to steam damage to the insulation material.

Types of vapor barrier and their features

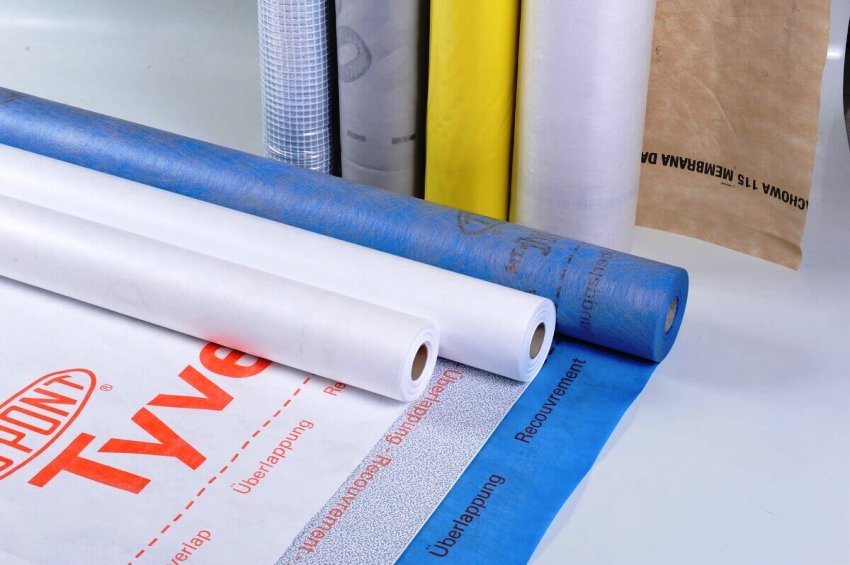

Modern vapor barrier films, actively displacing simple polyethylene, roofing material, glassine, are distinguished by a wide range and purpose. The most common, affordable and affordable types of installation:

- standard vapor barrier film. It prevents condensation from forming on the roof and insulation;

- foil vapor barrier. Unlike a standard layer, it has a reflective function and provides an increased vapor barrier, as well as reflects and returns some of the heat to the room;

- membrane film. Has the effect of isolation and limited vapor permeability, which allows you to control the removal of excess moisture from the room.

The vapor barrier film can be made of polyethylene or polypropylene. Polyethylene is a fragile material, therefore a polyethylene product is reinforced with a special fabric or reinforcing mesh. Polypropylene films are woven fabric laminated on both sides with the finest polypropylene. This type of product is durable, UV-resistant.

There are options when an antioxidant layer is applied to the polypropylene film, which absorbs and retains moisture, and after the cessation of steam supply, the layer dries out through ventilation. A vapor barrier device of this type allows you to lay it in only one way: a rough antioxidant layer is placed at the bottom, a smooth surface at the top.

Films, laminated with a foil layer on one side, are distinguished by the highest vapor barrier properties and are the most suitable type of vapor barrier for the ceiling of rooms with high humidity (baths, saunas, swimming pools, etc.).

Varieties of membrane films

Roofing membranes are a special type of vapor protection. It is a durable, temperature-resistant material. It does not differ in low vapor permeability, but it is effective in the construction of certain types of roofs. It is characterized by a more complex structure than conventional film. The pores of the membrane resemble microscopic funnels. Thanks to this property, it does not let steam through from the outside, but perfectly removes moisture from the inside. Currently, several types of under-roofing membranes are produced:

- Perforated membrane. This is a reinforced film or combination fabric with puncture holes. Used to equip a cold sloped roof. It cannot be used for vapor protection of insulation. In frosty weather, steam can settle on the inner surface of the membrane.

- Porous membrane. Has a lot of interfiber pores for the passage of water vapor between them. The vapor permeability of the material can be different, it depends on the size of the pores and the degree of hydrophilicity of their walls. It is not recommended to use this type of vapor protection in dusty conditions. In dry and windy weather, dust through the gaps can settle on the membrane and close the pores.

- Three-layer superdiffusion membranes. Made from several layers. They have no holes for dust or moisture to enter, which is a significant advantage. Membranes do not lose their high vapor permeability in a dusty environment.Also worth noting is their excellent wind protection.

- Two-layer film membranes. A cheaper version of a multi-layer product. The absence of one of the protective layers significantly impairs reliability.

Vapor barrier materials must be flexible, durable and easy to work with. When fastening with dowels, self-tapping screws, staples, nails, it is necessary that they do not tear, but at the same time fit tightly to the mount.

Useful advice! When choosing a vapor barrier material, special attention must be paid to quality, since this is the bottom layer of the roof structure and its repair is almost impossible.

The basics of making the right choice

When arranging a roof, it is important not only to know how to properly lay a vapor barrier, but also how to decide on the right material. When choosing, it is required, first of all, the type of roofing material.

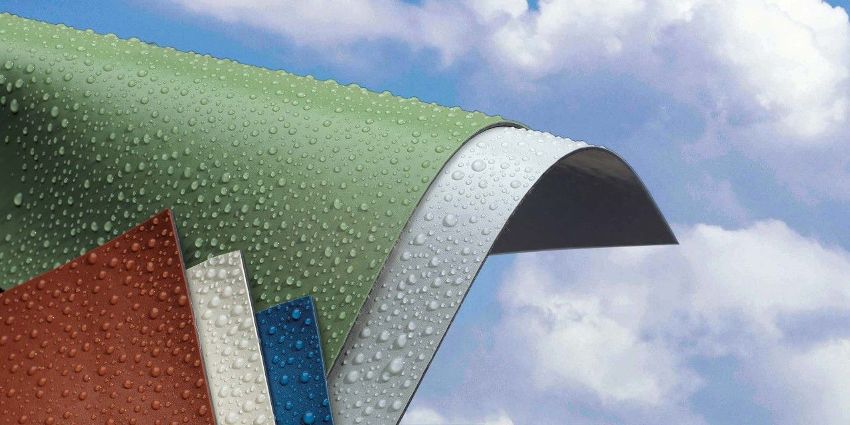

If the roof deck is planned to be made of materials with low thermal conductivity: slate, tiles, ondulin, onduvilla, diffusion vapor barrier membranes should be used.

It is recommended to protect roofs made of metal tiles, corrugated sheeting and with folded roofs (joining sheets with a seam) using a vapor-tight film with an anti-condensation layer.

The material prevents moisture penetration, protects floors from condensation and further destruction

When choosing vapor barrier materials, the following parameters must be considered:

- vapor permeability;

- durability of functioning;

- installation features;

- cost.

The vapor permeability level is measured in g / m2 per day. The less permeability, the more reliably the insulation, decoration, structural elements of the roof are protected from getting wet. To a certain extent, the film must provide air exchange, otherwise a greenhouse effect will be created for the room. Anti-condensation polypropylene films and breathable diffusion membranes ensure optimal vapor protection.

The durability of vapor barrier materials is due to a number of qualities:

- tensile and tear strength;

- resistance to high temperatures;

- immunity to ultraviolet radiation.

Low-cost plastic wrap can tear during installation and break down from temperature changes. Vapor barrier membranes made of non-woven artificial fibers with a protective layer are distinguished by their durability. They are resistant to mechanical damage and temperature.

It is imperative to know the features of installation before purchasing a film, since it is possible to correctly calculate the quantity only if you know the size of the overlaps. Also, the purchase of related materials directly depends on the method of installation. If the adhesion of the vapor barrier material to the mounting tape is low, then this will inevitably subsequently lead to a breach of the vapor barrier layer's tightness. Therefore, a different kind of adhesive tape needs to be purchased.

The price of a vapor barrier for a roof directly depends on its quality. Budget options are short-lived. You must be able to correctly calculate the cost of the material. A low price per roll may not mean optimal cost, but be the result of a small footage. Only a comparison of the price for 1 m² of different types of vapor barrier will help to make the right choice.

Useful advice! The quality of the film must match the quality of the roofing material. If the material is designed for long-term operation, and the period of validity of the vapor barrier is shorter, when replacing it will have to disassemble the entire "roofing pie".

The sequence of laying a vapor barrier: basic rules

There are two types of vapor barrier: roll and sheet.

Installation of roll stacking is performed as follows:

- the material is rolled out;

- measure the required length of the canvases and place them with an overlay (100-200 mm) on adjacent fragments;

- fixed with staples or wooden slats;

- joints and overlaps are fixed with adhesive tape for vapor barrier (or other adhesive tape).

Sheet mounting requires the preliminary creation of a wooden lathing or a frame from a profile, into which the waterproofing will fit. You can fix it with self-tapping screws or a stapler (according to the material).

The smooth side of the vapor barrier must necessarily look outward, that is, towards the rough ceiling

When laying a "roofing cake" the question is: "Which side to lay the vapor barrier?" - arises among the first. The film, which is the same on both sides, does not cause difficulties during installation: which side of the vapor barrier you put - the effect will be the same. The film, which has a two-layer structure, where one side is smooth and the other rough (to retain condensation), is placed with the smooth side outward (adjacent to the insulation), and the rough side - inside the room.

Related article:

Waterproofing the foundation with roll materials

Performing waterproofing work on the foundation with roll materials of various types: detailed instructions.

Which side to lay the foil vapor barrier to the insulation is also easy to determine. Since this type of vapor barrier is intended not only to block moisture vapors, but also to retain heat, the reflective side (foil) should be directed inward, towards the room.

Compliance with simple installation rules and operating standards will significantly extend the service life of the vapor barrier

Membrane vapor barrier can be two-sided, and then for its effectiveness it does not matter which side of the insulation of this type is located to the insulation. If the membrane vapor barrier is one-sided, the manufacturer must indicate the wrong side.

Basic rules for laying a vapor barrier:

- cleaning and drying the coating;

- the vapor barrier film should be installed without sagging, with slight tension;

- a ventilation system is required for proper functioning;

- the tightness of the joints is required.

Helpful advice! When buying waterproofing, you should read the instructions (annotation). Sometimes not one, but two ventilation blows are required.

How to properly install a vapor barrier for a roof

Installation of roof vapor barrier is a process, the complexity of which depends on the type of roof.

The more intricate the rafter structure and, accordingly, the shape of the roof, the more expensive and difficult the task of high-quality insulation becomes. Installation of waterproofing for the roof should be carried out from the inside.

The canvases can be laid vertically and horizontally. If the horizontal method is chosen, then you need to start mounting from the top. Each subsequent sheet is laid on the previous one with an overlap of at least 10 cm. The seams are sealed with adhesive tape. You can use one-sided tape, it is applied on top. Double-sided tape is laid inward.

If the installation of the vapor barrier for the roof is carried out along the rafter legs, that is, vertically, then the overlap of the canvases should be done on wooden rafters. The vapor barrier material is fastened to wooden structural elements with staples or galvanized nails. It is advisable to reinforce the places where the joints are glued with clamping strips, which are especially important to use on roofs with a slope of up to 30 degrees and with a low density of insulation.

It is necessary to lay the vapor barrier as carefully as possible, without leaving gaps or holes between the canvases

Helpful advice! Used wooden planks and blocks must be treated with an antiseptic. This will significantly extend the life of their full service.

If the structure has dormer windows, hatches or other passages through the roof, then a butyl-rubber self-adhesive tape must be glued along their perimeter, which will exclude the passage of moisture and steam, firmly seals the cut-out points in the vapor barrier film, even if they are adjacent to an uneven surface. This type of tape has high water-repellent properties and good resistance to temperature effects. In addition, it easily levels irregularities.

If ventilation pipes pass through the roof, then the film must be wrapped and wrapped tightly around them, firmly fastened with one-sided adhesive tape.

Errors made during the installation of a vapor barrier

In the absence of experience and professional advice when laying a vapor barrier, a number of mistakes are made that will subsequently significantly affect the efficiency of the vapor barrier. The most common ones are:

- loose adhesion of the film to the girders, girders, valley, ridge and ridge beams;

A small gap must be left between the vapor barrier layer and the roofing material to allow moist air to escape

- not knowing which side to put the vapor barrier to the insulation;

- use for sealing narrow adhesive tapes (up to 50 mm);

- when sealing openings, no deformation reserve of the film (20–30 mm) is left;

- the polyethylene product around the skylights is not closed from the inside, as a result of which, after a while, it collapses under the influence of ultraviolet radiation and low temperatures;

- the film goes around the rafter legs. Moisture will penetrate into the gap between the rafters and the vapor barrier;

- no special glue is used in the places where the film adjoins significantly uneven surfaces. Construction tape, butyl and other types of adhesive tapes do not provide complete tightness in such cases.

Helpful advice! When laying a vapor barrier, do not neglect even a seemingly insignificant rule or violate the installation sequence. A good result will be achieved only if all requirements are met.

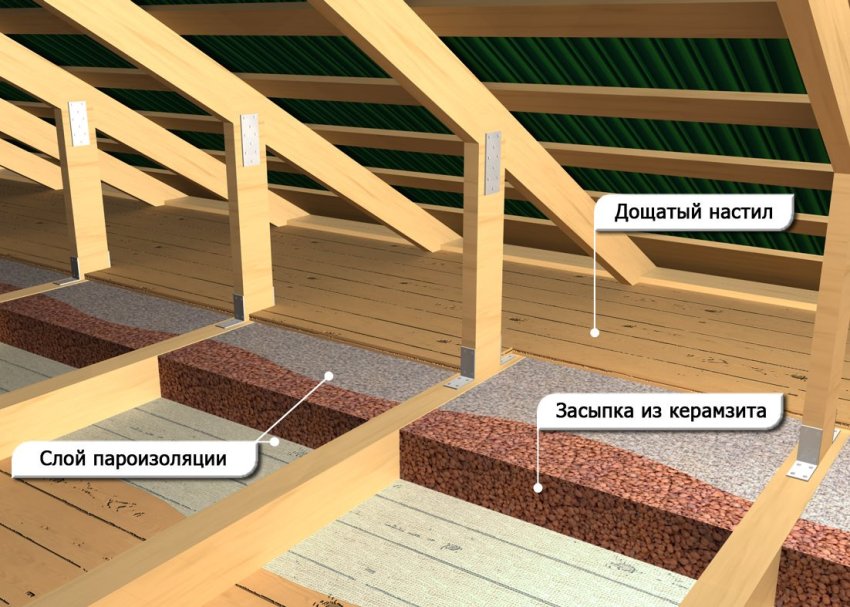

Vapor barrier for a ceiling in a wooden floor

Wood is an organic material, therefore it allows fumes to pass through. But for her too, excessive steam humidification is undesirable, since under its influence the tree expands and can rot. To keep the ceiling under the cold attic in good condition, it is necessary to arrange the correct vapor barrier. It is important to follow the installation sequence here. The component with the minimum vapor barrier is placed first. It should be zero or close to zero. The next layers are with higher permeability than the previous one.

So that wooden ceilings do not deform or rot ahead of time, you should take care of high-quality vapor barrier

From the premises, the vapor barrier should look like this:

- vapor barrier. Polyethylene or polypropylene film, diffusion membrane. Fits on top of the floor;

- thermal insulation. Roll, backfill or tile material. Fills the void between floor beams;

- waterproofing. A layer of diffusion membrane or perforated polyethylene. Fits only in the case of using the attic.

If the attic is not planned to be used, then the waterproofing layer is transferred under the slopes, where it protects the entire roof.

Laying of vapor barrier material on wooden floors is carried out by bending around each beam. The strips are mounted perpendicular to the beams. In this case, the material is not stretched, small sagging is required.

In case of timber paneling, each compartment is wrapped.The material is cut out according to the size of the shield and the height of the walls.

Helpful advice! Do not rewind the roll vapor barrier material, so as not to confuse the side that should contact the ceiling (it is indicated by the manufacturer).

Steam barrier for a bath

Bath - a room that requires a high temperature and is characterized by a high level of humidity. The vapor barrier of this building is used to preserve the insulation, as well as to protect wooden structures from moisture. When choosing vapor barrier materials, it is necessary to take into account that it is advisable to use different insulation for different premises:

- for a steam room, the best option is a foil vapor barrier that reflects heat and creates an additional thermos effect;

- the shower room can be vaporized with polyethylene or polypropylene film;

- in the dressing room and the rest room, a membrane vapor barrier will be appropriate, which will provide the necessary air exchange.

One of the recognized modern vapor barrier materials is Izospan V. It has a fairly broad purpose. The instructions for use of the Izospan V vapor barrier indicate that it can be used for:

- roofing structures;

- floor;

- walls, both outside and inside;

- laminated floors and parquet.

The two-sided structure of this material allows you to actively use it for vapor barrier in bath rooms. How to install the vapor barrier and which side to fasten the Izospan V vapor barrier is prompted by the presence of a different structure of the sides: a rough surface is designed to absorb steam, therefore, it should be directed into the room.

Do you need a vapor barrier when insulating with mineral wool

Mineral wool insulation is an effective type of thermal insulation that is actively used in modern construction. But it has one rather significant drawback: when the mineral wool gets wet, it collapses and loses its heat-insulating properties. That is why the use of a vapor barrier film, along with this insulation, is extremely necessary. It will create a barrier that will protect the thermal insulation layer from the effects of steam and will make it possible to keep the premises warm.

Which side of the vapor barrier should be used if mineral wool insulation is used?

If a double-sided film with a moisture-absorbing layer is used, it must be directed towards the room from which the steam flows rise. The smooth side adjoins the insulation. When using a material with a foil-coated surface, the aluminum coating will become a barrier to moisture penetration into the heat-insulating material. Therefore, it is this surface that should be directed to the room.

Helpful advice! If mineral wool is used to insulate rooms with a high level of humidity, then it is safer to use a vapor barrier with a foil-coated layer, since it has the lowest level of vapor permeability.

When wet, mineral wool almost completely loses its insulating ability, freezes and gradually collapses

Prices and manufacturers

Technonikol is a leading manufacturer of vapor barrier materials in Russia and the CIS. The products are manufactured on a polymer basis. There are the following types of TechnoNIKOL vapor barrier:

- for pitched roofs (has the ability to partially pass steam);

- for flat roofs (has high strength, elasticity);

- reinforced (reinforced three-layer high strength film);

- universal (used for all types of roofs).

The price of TechnoNIKOL vapor barrier per m² is on average 20 rubles. This is a low price level with good quality.

Vapor barrier Yutafol – products of a European manufacturer, which are distinguished by a variety that satisfy various purposes when installing a vapor barrier. For the convenience of the buyer, in order to easily distinguish the material, not to confuse waterproofing, windproofing and vapor barrier, they have the names Yutakon, Yutavek and Yutafol (respectively). In addition to standard types of products, this Czech company produces Yutafol N110 Special film with a self-extinguishing reagent that minimizes the level of flammability. The price of this film for 1 m² is from 17 rubles. Reducing the cost of products due to the simplicity of packaging is a successful decision of the company.

Yutafol vapor barrier is the latest generation of vapor and heat insulation films, they combine environmental friendliness, reliability and durability

Vapor barrier Аxton - products of the French company Leroy Merlin. It has three types: B, C and D. Аxton B - plastic film, budget option. It will last a considerable time if you avoid mechanical damage and fix it correctly, using not a stapler, but special nails with wide heads. This material is used for indoor installation only.

Аxton С is a polypropylene product, more durable and versatile. Has various permeability indicators. This is a two-layer material, it is recommended for insulated and non-insulated types of roofs with a variety of designs. The Аxton D looks like an awning. Used for water and vapor barrier. It is characterized by high strength and ease of installation. The products of this company are distinguished by a high level of environmental friendliness.

Tyvek vapor barrier materials manufactured at a factory in Luxembourg. It is based on high quality polyethylene, non-woven structure. The main difference between the products is environmental friendliness and breathable membranes with controlled vapor permeability created using innovative technologies. The price of Tyvek vapor barrier is 7-10 percent higher than the cost of domestic counterparts.

The price of a vapor barrier for a ceiling depends most of all on the quality of the material, its density and the manufacturer. That is why branded products of foreign companies have a higher cost.

Tyvek - multi-layer insulation, which consists of non-woven polymer fibers with a high level of heat saving and vapor permeability

Roof vapor barrier: modern solution of moisture protection

The roof is a structural element that can withstand a constant double load. From the outside, it is exposed to atmospheric phenomena: precipitation, sunlight, low temperatures, wind. From the inside, it experiences the internal influence of temperature and humidity. In such conditions, it is simply impossible to overestimate the need for a correct vapor barrier, the absence of which can lead to the destruction of the roof and subsequently the building itself.

Modern technologies have made it possible to create films from polymers that are capable of providing vapor barrier of the required level. A wide choice of material allows you to use it in accordance with the conditions and intended purpose. Having carefully studied how to properly lay the vapor barrier, fulfilling all the technical requirements, you can create a healthy microclimate in the premises and provide the structure as a whole for many years of existence without serious repair work, while maintaining an aesthetic appearance.

There is no reason to consider the price of a vapor barrier for a roof per m² high, which makes the material affordable for any developer.

It is important to choose the right vapor barrier membrane to protect the roof from the negative effects of condensation

To carry out a reasonable and rational choice of materials, to correctly install a vapor barrier is the desire of every homeowner. The content of the article is intended to help you install the vapor barrier yourself.But even if such a decision is unacceptable, you need to be aware in order to correctly assess your costs and the quality of the work of hired specialists.