In recent years, the demand for laminated chipboard has increased significantly, which is used not only in the manufacture of furniture, but also in construction and repair work - from rough wall finishing to the installation of decorative flooring. The market offers a huge selection of laminated chipboard: sheet size, colors, texture and types are presented in a wide range. This article will tell you how to determine the optimal ratio of price and quality, and what are the main characteristics worth paying attention to.

Content

Advantages and disadvantages of chipboard

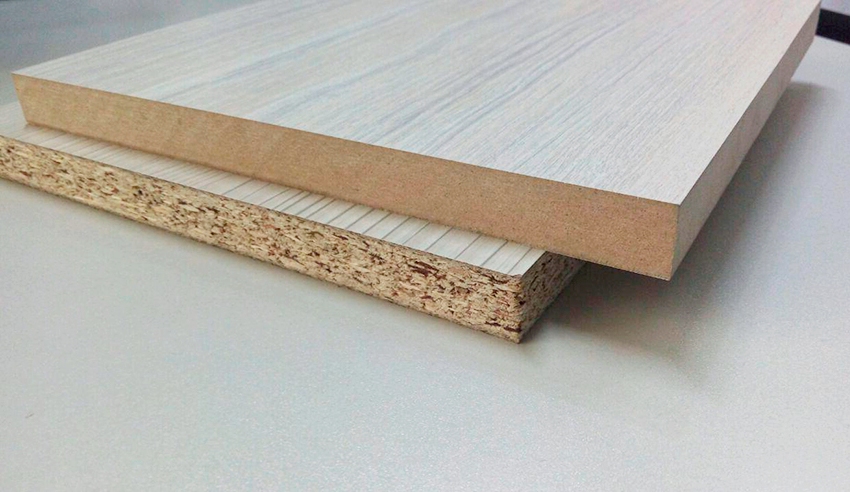

Chipboard is a type of chipboard, well-known to all. This material has long been in deserved demand among domestic and foreign builders and furniture manufacturers.

Among the main advantages of chipboard is its low cost. Due to the fact that production waste (shavings and sawdust), or even just crushed substandard trunks, are used for the manufacture of chipboard, the price for it is several times less than for MDF or natural wood.

Other undoubted advantages of this composite material are its strength, ease of processing, resistance to mechanical damage, as well as a wide variety of types, which significantly increases the scope of its application.

Among the disadvantages of chipboard is insufficient moisture resistance. When exposed to water, the slabs swell and deform. The same happens at high temperatures. In addition, their constituent resins, evaporating, can cause significant harm to human health. This composite is also not very flexible and may crumble when trying to reattach.

Types of chipboard and their scope

Depending on the level of environmental safety, there are 2 classes of chipboard - classes E1 and E2. Particleboard of class E1 is considered the safest, since it contains less formaldehyde resins. The content of harmful substances in E2 class slabs does not allow their use in the manufacture of children's furniture. Moreover, in recent years in the EU countries there has been a gradual reduction in its production. In Europe, another class of chipboard boards is distinguished - Super E. Materials of this class are absolutely safe, but they are extremely expensive.

Helpful advice! Experts focus on the fact that it is better to buy laminated chipboard sheets made according to European standards, known for their rigor in matters of safety for the environment and human health. The content of formaldehyde resins in them is several times less than that of plates made in accordance with domestic or even American standards.

In appearance, chipboard is divided into 3 grades. Plates of the first grade are made only from high-quality raw materials, they have no defects, and at the final stage of production they are covered with a special decorative film or veneer. This grade is used in the manufacture of furniture.

For slabs of the second grade, cladding is not required, minor scratches or chips at the edges are allowed. Particleboard of the third grade is often made from raw materials containing foreign inclusions or from shavings of tree bark, they have visible defects - chips, cracks, irregularities. The last two grades are used mainly in construction - as a rough finish, flooring, leveling ceilings and walls, and formwork production.

In addition, chipboard boards are:

- unprocessed (they are used for rough finishing of premises);

- polished (used in the manufacture of furniture, but only for elements hidden from the eyes);

- laminated (specially processed paper is used as a coating);

- veneered (on both sides the sheet is covered with a thin layer of natural wood, which gives them a decorative appearance and allows them to be used for the front surfaces of furniture and for interior decoration);

- laminated (chipboard sheet is covered with a polymer film).

Features of laminated particle board

Chipboard is produced exclusively from high quality sanded chipboard in accordance with GOST 10632-2007. They are devoid of the disadvantages inherent in other chipboards: durable, not afraid of steam, mold and moisture, chemical and mechanical stress, and a special melamine film and edging significantly reduce the level of hazardous fumes and increase the wear resistance of the material.

Due to these characteristics, laminated particle board can be used for the manufacture of furniture and interior decoration, including kitchens, hallways and bathrooms, wardrobes, office and children's furniture, as a floor covering.

Chipboard is presented on the market in a huge number of colors and textures that allow you to imitate any material, up to stone, marble, metal or fabric, and fit into any color scheme or style of the interior at a very modest cost.

Chipboard does not require further processing or painting. For the manufacture of furniture facades and countertops, it is enough to cut the purchased chipboard sheet in accordance with the specified dimensions and trim the edges.

Important! It is necessary to process the edge not only in order to increase the wear resistance and appearance of the material, to protect it from moisture and steam, but also in order to prevent the evaporation of harmful substances.

However, this is the main disadvantage of this material - the need for a special machine for sawing chipboard and their edge. However, at present, any hardware store or furniture manufacturing workshop provides such a service as sawing chipboard according to the customer's size.

Another disadvantage is that, due to the crumbling edge, such slabs are also not suitable for creating curved contours and complex carved elements.

Chipboard: sheet size. Main indicators of length, width and thickness

The standard dimensions of the chipboard sheet are regulated by GOST. In accordance with this standard, indicators of width, length and thickness of slabs are determined.

Main dimensions of laminated chipboard

There are 18 standard lengths: 1830, 2040, 2440, 2500, 2600, 2700, 2750, 2840, 3220, 3500, 3600, 3660, 3690, 3750, 4100, 5200, 5500 and 5680 mm. In this case, the permissible length inaccuracy is ± 5 mm.

The width of the laminated particle board is determined by 9 indicators: 1220, 1250, 1500, 1750, 1800, 1830, 2135, 2440 and 2500 mm. As with the length, the permissible error does not exceed ± 5 mm.

Chipboard thickness ranges from 3 to 38 mm with an allowable inaccuracy of ± 0.3 mm.

It should be clarified that, depending on the capabilities of the equipment, each manufacturer produces several basic sizes of chipboard, but the following are considered the most popular on the market:

- 2800x2620 mm;

- 2800x2070 mm;

- 2620x1830 mm;

- 2500x1830 mm.

Chipboard sheet thickness

Their strength and ability to resist loads, and hence the scope of application, directly depend on the thickness of the chipboard. It is important to remember that heavy thick slabs are very durable, but thin laminated chipboards bend without deformation.

Most often, chipboard thickness ranges from 8 to 38 mm. 8-10mm sheets are used for the production of containers, drawer bottoms, door and wall claddings, and furniture fronts.

The thickness of 16 mm is widely used in the manufacture of furniture, for the construction of internal partitions and as a substrate for flooring (linoleum or laminate). Sheets 18 mm thick can also serve as the basis for flooring, but they are most often used for the manufacture of cabinet furniture, including dressing rooms and wardrobes. 22 mm slabs are suitable for the manufacture of kitchen furniture, countertops, tables.

For bearing elements, window sills and doors, plates with a thickness of 25 mm are used. But for the manufacture of durable bar counters, reliable shelves and countertops, 38 mm laminated chipboard sheets will be the best choice. They will be able to withstand the strongest mechanical loads without deforming. It should be noted that the most popular are laminated chipboard sheets with a thickness of 10, 16, 18 and 25 mm.

An important characteristic in the manufacture of furniture and various construction and repair work is also the weight of the plate. It is determined by the dimensions of the sheet and its density. On average, the weight of one sheet ranges from 40 to 90 kg. For example, the weight of 1 square meter of 16 mm laminated chipboard averages 10.36-11.39 kg. With a plate thickness of 18 mm, it will be 11.65-12.82 kg, 25 mm - from 14.69 to 16.16 kg. This indicator will differ slightly from manufacturer to manufacturer.

Helpful advice! Before you buy a chipboard slab, you need to correctly calculate its size. This will not only ensure the strength and durability of the finished product, but also help avoid unnecessary financial costs, guarantee a minimum of material residues and significantly save time.

How to choose and buy laminated chipboard: leading manufacturers

As mentioned above, each manufacturer puts on the market its own options for the size of chipboard, which is due to the capabilities of its equipment.

The characteristic dimensions of a sheet of laminated chipboard Egger are 2800x2070 mm. This uniform size does not prevent the Austrian company from successfully competing in the European and domestic markets. Indeed, in addition to excellent environmentally friendly raw materials and a huge range of color solutions, it also offers its customers a good selection of board thickness options - 10, 16, 18, 25 mm and even non-standard 19 mm, which also distinguishes its products from competitors.

Unlike the only universal size of laminated chipboard Egger, the Syktyvkar plywood plant offers its customers a choice of 3 sizes of laminated chipboard Lamarty - 2800x2070, 2750x1830 and 3660x1830 mm with a thickness of 10, 16, 18 and 26 mm. Affordable prices, high-quality raw materials and a wealth of color solutions allow Lamarty laminated chipboard to successfully compete for its place in the domestic market with foreign companies.

Related article:

Chipboard: what is it? Features, advantages, manufacturers overview

How does it differ from particle board. Advantages of laminated boards. Which is better for furniture: MDF or chipboard. Domestic and foreign manufacturers.

Another Austrian company Kronospan manufactures laminated chipboard in two standard sizes - 2620x1830 and 2800x2070 mm. At the same time, Kronospan offers a solid selection of slab thickness options (8, 10, 12, 16, 18, 22, 25 and 28 mm), as well as a wide palette of shades, rich textures, durability, environmental friendliness and reliability.

SwissPan produces laminated chipboard in the following sizes:

- 2750x1830x10 mm;

- 2750x1830x16 mm;

- 2750x1830x18 mm;

- 2440x1830x16 mm;

- 2440x1830x18 mm;

- 2440x1830x22 mm;

- 2440x1830x25 mm.

The products of this company are in great demand among manufacturers of kitchen furniture and wardrobes.

The laminated chipboard of the Nevsky Laminat plant is produced in one size - 2440x1830 mm with a sheet thickness of 8, 10, 16 and 22 mm. The specified size of 16 mm thick laminated chipboard sheet is the most demanded among consumers. Good quality, low price and compliance with European standards, as well as a wider choice of colors and textures, explains the stable demand for its products in the domestic market.

What affects the cost of laminated particle board

The cost of the slab is determined not only by the dimensions and thickness of the chipboard sheet, the price of the material also depends on:

- the quality of raw materials (whether it contains, for example, foreign inclusions in the form of bark, or, on the contrary, is made from the same wood species);

- the amount of harmful substances in the composition;

- whether a decorative coating was used in its production and which one - veneer, paper, melamine film, special varnish;

- the appearance of the finished product;

- country of origin.

In the case of laminated chipboard, these factors are somewhat leveled, because only high-quality sanded chipboard sheets are used for manufacturing, without foreign inclusions, and most foreign companies have long since opened domestic production.

Important! It is worth paying attention if there is a need to buy laminated chipboard for furniture: the price per sheet and the price per meter differ significantly. However, most often manufacturers indicate both prices for the convenience of buyers.

The cost of various sizes of laminated chipboard 16 mm

The price for a 16 mm thick laminated chipboard sheet from different manufacturers will vary somewhat. So, in order to buy Egger chipboard, you will have to pay, depending on the color and decor, from 1913 to 4220 rubles. For comparison, the price for a 10 mm laminated chipboard sheet is 1,762 rubles. (white basic) and 3292 rubles. (tobacco halifax oak). The price for a 16 mm laminated chipboard sheet from the Kronospan company ranges from 1,046 to 2,080 rubles.

The price of a 16 mm laminated chipboard sheet 2750x1830 mm from Lamartie is from 204 to 457 rubles / m2 (on the official website, the cost is indicated per square meter, and not per chipboard sheet, this should be taken into account when calculating the price). You can buy a laminated chipboard sheet on a moisture-resistant basis from the Nevsky Laminat plant for approximately 1,500 rubles.

When calculating the final cost, it is also necessary to take into account the costs of cutting chipboard by size. The price of edging, respectively, will depend directly on the size of the chipboard sheet. You can buy laminated chipboard with sawing in specialized hardware stores or order a similar service in workshops where there is appropriate equipment with a program for cutting chipboard.

It is not recommended to saw the slab on your own. Considering the peculiarities of the material, its edge will simply crumble and chips form. True, large construction stores often provide their customers with free sawing and edging as a bonus when purchasing chipboard.