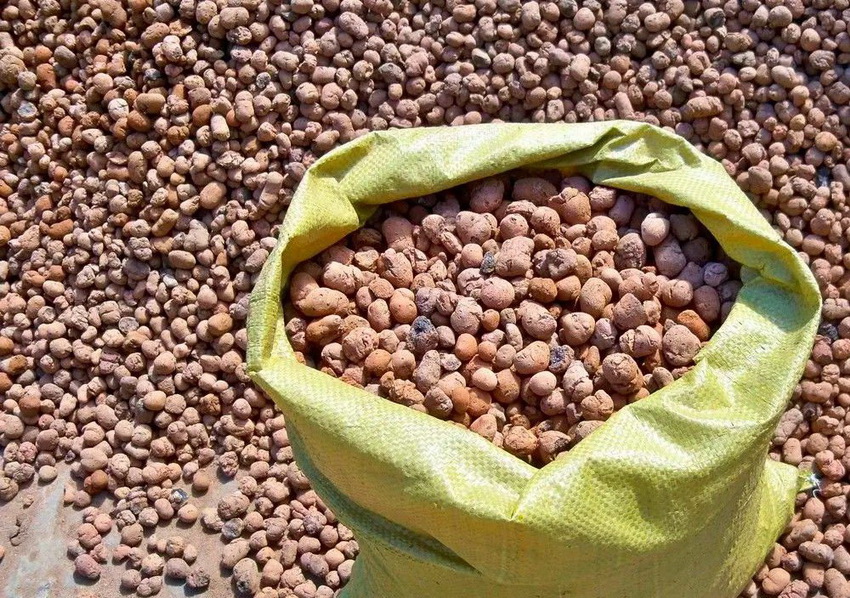

Expanded clay as a multifunctional material is common in various areas of construction. Its main advantage is a high degree of sound and heat insulation. Therefore, it is more often used as a heater. Expanded clay is widely used in agriculture and production. There are several types of material and packaging. How to choose and calculate the required amount, which is better: expanded clay in bags or in bulk? The answers to these questions are contained in this article.

Expanded clay is a multifunctional material commonly used in construction, landscape design and agricultural work

Content

- 1 Expanded clay in bags: features and positive qualities of the material

- 2 How much does expanded clay cost: what determines the price of the material

- 2.1 How much is a bag of expanded clay: factors that form the retail price

- 2.2 Expanded clay price in bags and per cubic meter: comparative table

- 2.3 The price of expanded clay blocks and its components

- 2.4 Where to buy expanded clay in bags and how to save on delivery

- 2.5 Where to buy expanded clay on favorable terms

- 3 How many cubes in a bag of expanded clay: calculation of the volume of material

Expanded clay in bags: features and positive qualities of the material

Expanded clay has long been used in various fields of production due to a number of its positive qualities. It is a lightweight, natural and environmentally friendly material made from clay. It is practical to use and provides a high degree of noise insulation and heat saving in rooms. The thermal conductivity of the material is rather low - 0.1-0.18 W / m · K.

The advantages of expanded clay include its high thermal insulation properties, as well as resistance to the appearance of fungi and mold.

Additional advantages of expanded clay are its relative moisture resistance, frost and fire resistance, as well as biostability. It does not form a fungus and does not start rodents. Correctly selected proportions, quantity and adherence to the laying technology guarantee the reliability of the expanded clay screed and its long service life.

In large volumes, expanded clay is used as drainage on roads, to create sidewalks and embankments in the garden. It's pretty easy to work with. However, before you buy expanded clay in bags or in bulk, you need to correctly calculate the required amount of material.

Expanded clay granules have different shapes. They are obtained from special types of clay, characterized by a high degree of swelling at high temperatures. Thanks to these qualities, pores appear, which provide the thermal insulation properties of the material.

Expanded clay is produced in bulk and in bags in three types. The sand has granules up to 5 mm in diameter. The gravel has a more rounded shape, and the grain size reaches 20 mm.Crushed stone is a more angular material, its fraction is 20-40 mm.

Density of expanded clay and material grade

Expanded clay is lightweight, and the density of the material determines its quality and area of use. It is this value that affects its amount in a cubic meter and, consequently, the weight of a bag of expanded clay. This indicator depends on the fraction: the larger the granules, the lower the density of the material.

Useful advice! When buying expanded clay, it is imperative to take into account the bulk density, which indicates the grade of the material.

The quality of expanded clay is determined by the index of its bulk density and the manufacturing method

Manufacturing technology affects the density of the material. There are four ways to obtain this material:

- Dry. The simplest technology applied to homogeneous clays without impurities. Humidity does not exceed 9%.

- Wet.

- Plastic. The most common method. The wet clay is formed into granules and sent to the oven. The moisture content of raw materials reaches 30%.

- Powder-plastic. It is similar to the previous method, but dry clay is taken as a basis, which is crushed, and then moistened and subjected to temperature effects.

It is the bulk density that is the brand of expanded clay. It is designated by the letter M with the corresponding number. For example, M300 means that 1 cube of expanded clay weighs from 251 to 300 kg. The lower the grade, the higher the thermal insulation properties. Such material is best suited for insulation of ceilings and floors.

Expanded clay of a lower grade (fractions 20-40) is used as a heat insulator in foundations and basements. It is widely used for landscape design. The material with the minimum density is used to insulate walls, communications and facades. The smallest expanded clay (with a fraction of up to 10 mm) is used in the preparation of expanded clay concrete for pouring floors.

Specific density and specific gravity of expanded clay

The density of expanded clay is measured using the bulk method, as well as by calculating its bulk density. This characteristic indicates the true weight of sand, crushed stone or gravel - excluding the space in the middle of the expanded clay granules. This feature underlies the differences in bulk and true density, which almost always differ from each other. True density is a constant indicator, it can be measured only in special laboratories. The specific gravity varies depending on the grain fraction.

How much a cube of expanded clay weighs is clearly shown in the table:

| Type of expanded clay | Fraction of granules, mm | Specific weight of material, g / cm³ |

| Sand | 0,1-5 | 0,55-0,6 |

| Fine gravel | 6-10 | 0,4-0,55 |

| Coarse gravel | 10-20 | 0,35-0,4 |

| Crushed stone | 20-40 | 0,2-0,35 |

The weight of sand can reach 600 kg per cubic meter, fine gravel - 450 kg, coarse - 400 kg. A cube of rubble will weigh at least 350 kg. The higher the density of expanded clay, the more weight the material has. These indicators are regulated by the existing GOST.

It is difficult to determine the exact specific gravity of expanded clay, you can only set the average value, which is 400 kg / m³ (0.4 g / cm³). This indicator is primarily influenced by the size of the fraction. For example, a bag of expanded clay with a volume of one cube and a fraction of 10-20 weighs approximately 16.7 kg.

How much does expanded clay cost: what determines the price of the material

The building supermarket chain offers a wide range of expanded clay. The product can be purchased both in bags and in bulk. In the absence of appropriate storage conditions for bulk material, it is better to choose prepackaged products.

Useful advice! When buying expanded clay, it should be noted that small granules have a lower thermal conductivity, while having the highest bulk density.

Packing facilitates easy transportation, shipping and warehousing for storage. During transportation, the material does not crumble, and its use will be waste-free.

The packaged substance is cleaner and has no foreign inclusions. You need to know that the cost of expanded clay per cube is slightly cheaper than in bags. But if a wholesale purchase of several cubes is planned, then it is more profitable to purchase expanded clay in bags with delivery.

The cost of the material, which is formed by the manufacturer, is influenced by the quality of raw materials, production methods, storage conditions and transportation costs. Of no small importance are production capacities and volumes of products, energy consumption, labor resources and the general turnover in the market.

How much is a bag of expanded clay: factors that form the retail price

There are many other factors to consider that determine how much expanded clay costs in bags. The price is formed on the basis of the following components:

- fraction of expanded clay. The main nuance is as follows: the smaller the granule size, the more expensive the bag will cost. This depends on the weight to density ratio described above. It should be noted that the costs of sand are much higher than, for example, gravel or crushed stone;

- the presence and size of pores in the material. The heat-insulating qualities of expanded clay depend on the porosity, that is, on the number of cells in the fracture of the granules. Accordingly, this factor directly affects the formation of prices;

- way of packing material. Paper bags in several layers provide good protection of the goods from dirt and moisture. In addition, in this form it is easier to carry out loading, transportation, storage and accounting of products;

- packaging. The material distribution process is a special, separate production cycle that requires the involvement of additional workers and areas. For this purpose, special equipment is purchased in the form of batchers, special scales and a bulk hopper;

- weight of a bag of expanded clay. The cost is also affected by the number of kilograms of expanded clay in the bag. Packing 25 kg will cost more than 50 kg bags with the same material;

- total purchase volume. Large batches with a significant number of bags will be cheaper. Most suppliers offer wholesale and retail prices straight away;

- payment method. Sometimes sellers make special discounts on the purchase of material for cash (or if cashless payments are made through partner banks).

Expanded clay price in bags and per cubic meter: comparative table

Specific density affects the cost of expanded clay. In addition, the price of the material depends on the manufacturer. The denser the expanded clay, the more expensive it is. The volume of purchased raw materials is also a component of the price. If we are talking about large batches, it is better to buy expanded clay in bulk. The price will be several times lower. There is a difference in the packing of expanded clay: the price for a 50 kg bag will differ from the cost of a 25 kg bag.

Useful advice! Its functionality depends on the weight of 1 m³ of expanded clay filler. The smaller it is, the higher the effect of thermal conductivity, that is, it will conduct more heat, having a lower degree of thermal protection.

The cost of expanded clay per bag and in bulk may differ slightly. This is evidenced by the table compiled based on the amount of material required.

Average prices for expanded clay:

| Type of expanded clay | Fraction of granules, mm | Price for 1 bag weighing 50 kg / rub. | Expanded clay price for 1 m3 with delivery |

| Sand | 0-5 | 100-140 | 1900-2100 |

| Fine gravel | 5-10 | 90-120 | 1800-2000 |

| Coarse gravel | 10-20 | 70-110 | 1650-1900 |

| Crushed stone | 20-40 | 60-85 | 1500-1600 |

The largest range of prices for a cube of expanded clay and packaged material is observed relative to gravel with a fraction of 10-20, since this raw material is the most popular. It is made by many manufacturers from various materials with different densities. Due to the versatility of raw materials, it is used in the insulation of various structures. Such expanded clay is light enough and reduces heat loss by an average of 70%.

The price of expanded clay blocks and its components

In order to quickly erect warm walls, expanded clay blocks are often used. Their types depend on the purpose: for external walls, walls, for additional insulation. Expanded clay blocks differ from pure expanded clay in that they contain admixtures of cement and sand. They are a monolithic product. The composition and dimensions are regulated by GOST 6133-99. When ordering material for different purposes, you should consider the width and thickness of the blocks.

In accordance with the application, the parameters of expanded clay blocks are selected, which can have dimensions of 39x18x19 cm or 40x20x20 cm. Walls made of expanded clay concrete, subject to the correct choice of material, can last over 50 years. The material for partitions is characterized by parameters 39x9x19 cm. Another name for the product is a semi-block. Sometimes blocks serve as a foundation in the construction of wooden houses.

The cost of the material depends on its type, shape, as well as on the composition and impurities. It is cheaper to purchase blocks at the manufacturing plant than from dealers. Intermediaries also regulate prices in different regions. The cost of a standard block at the plant is on average 36 rubles - and 20 rubles for a half block. The mark-up from dealers reaches 15-18 rubles per item.

When buying expanded clay blocks, you need to find out such a nuance as delivery. It should be clarified whether suppliers provide it or whether you need to organize the export yourself. It is important to take into account the number of purchased blocks, since individual factories release material only in large quantities. Therefore, if you need a small amount of material, you will have to use the services of dealers.

Useful advice! The correct choice of blocks determines not only the efficiency of the building and its strength, but also the total cost of materials.

Where to buy expanded clay in bags and how to save on delivery

The most profitable option for buying expanded clay is directly from the manufacturer. Eliminating intermediaries from the trade chain allows you to save up to 25% on a bag of material. This is due to the fact that the organizations involved in the sale include in the cost the costs of transportation, storage, rent of premises, labor of movers and sales agents, etc. In addition, resellers of products make a markup taking into account economic risks.

Related article:

Screed floor with expanded clay: the secrets of creating a warm and durable base

Advantages, features and scope of the material. Options and step-by-step instructions for the production of expanded clay screed on the floor.

In Russia there are many plants for the production of expanded clay, the most popular among them are OOO Meliz in Kursk, the Aleksinsky expanded clay plant, and the Keramzit plant located in Serpukhov. It is also worth mentioning the Azarovsky plant of wall materials in Kaluga and Experiment CJSC in Kostroma.

Buying larger bags is much more profitable. For example, a kilogram of expanded clay with a fraction of 5-10 mm in a small (kilogram) package will cost 6-8 rubles, and the price in a container weighing 50 kg is only 2 rubles.

Delivery of material is a separate item of expenses. The farther the point of sale, the more expensive the transportation. If you intend to buy small volumes of coarse gravel, then it is better to transport the bags on your own light transport. If you need to buy expanded clay 0.5 in bags of 50 kg in large volumes, then it will be quite costly to take it out yourself. After all, for this you need to find a special roomy transport and pay for its operation. In this case, it is more profitable to deal with a seller providing a cargo delivery service.

If the insulation is produced by a construction organization, it is recommended to entrust the professionals with the purchase of all building materials, including expanded clay. Specialists, as a rule, have mutually beneficial relationships with suppliers, and they also have discounts as regular customers.

Where to buy expanded clay on favorable terms

One of the options for a profitable purchase of insulation can be the purchase of used material. Recyclable expanded clay can be purchased from companies that are engaged in the dismantling of old buildings and the removal of construction waste. The price of a cube of used expanded clay can be half as much as when purchasing material from the manufacturer.

When buying recyclable materials, you should pay attention to its condition. Crushed stone of coarse fractions must undergo sorting, excluding garbage and crushed particles. Therefore, it is better to give preference to expanded clay, which served as a heater on the roof for a certain time. Such material did not succumb to excessive mechanical and weather influences, therefore, it retains well even after prolonged use. Reusable expanded clay is suitable for pouring a foundation or for thermal insulation of ceilings.

Useful advice! You can save a significant amount of money by ordering bulk material. Therefore, before starting construction work, it is advisable to calculate the total amount of insulation for the entire building.

If a decision is made to purchase independently, then it is first necessary to monitor the prices of products, study additional conditions and possible discounts in different outlets. In such matters, advice from friends and recommendations on the Internet will be useful.

If you need to reduce purchasing costs, you can purchase used material - expanded clay perfectly retains its properties

The seasonal factor should also be taken into account. So, in the spring and summer, there is a period of active construction - and prices for materials increase. Therefore, it is better to buy expanded clay in bags in advance, in autumn or winter. The price will be a quarter cheaper, and the packaged material is well stored.

How many cubes in a bag of expanded clay: calculation of the volume of material

In order for the purchase of material to be really profitable and economical, it is required to correctly calculate the required amount of expanded clay. As mentioned above, weight and volume depend on the density and fraction of the granules. The most common packing of expanded clay is 50 liters, which in a ratio is 0.05 m³. It turns out that the price of expanded clay per cubic meter is equal to the cost of 20 bags of medium fraction material.

You can calculate the required amount and calculate how much a cube of expanded clay costs based on the following parameters:

| Bag volume, l | Number of bags in a cube | Bag volume, m³ |

| 50 | 20 | 0,05 |

| 40 | 25 | 0,04 |

| 25 | 40 | 0,025 |

Different types of work require different amounts of material. For example, for a wet screed, you need a part of cement, 3 parts of sand and 4 parts of expanded clay. This means that 30 kg of concrete will require 25 kg of expanded clay. Next are determined with the total. For effective insulation, the screed layer must be at least 10 cm. This parameter is multiplied by the area of the room and divided by the volume of one bag.

An approximate calculation for a room of 20 squares will look like this: 20m² x 0.1m / 0.05m³ = 40 bags. Thus, the total price of expanded clay for flooring will be equal to the cost of 40 bags of material of the corresponding fraction.

Thus, when choosing expanded clay as a heater, you should trust manufacturers and their distributors that have proven themselves in the construction market. If we are talking about large volumes, then it is better to purchase material in bulk. However, with long-term transportation and the absence of storage conditions, it is recommended to give preference to expanded clay gravel or crushed stone in bags.In case of doubts about one's own abilities, it is better to entrust the whole process to experienced specialists.