A reliable, warm and environmentally friendly home is every person's dream. However, traditional building materials such as brick, stone or wood are not available to everyone today. How can you make your dream come true and save money? There are many alternatives available today. Aerated concrete wall blocks will help you quickly build the desired house: sizes and prices per piece, important parameters and expert reviews will be useful for making the right choice and buying this material.

Content

- 1 What is aerated concrete

- 2 Technical characteristics and physical properties of aerated concrete blocks

- 3 Aerated concrete blocks: pros and cons, expert reviews

- 4 Aerated concrete or foam concrete: which is better

- 5 How to calculate the number of gas blocks for construction

- 6 Aerated concrete blocks: sizes and prices per piece from leading manufacturers

What is aerated concrete

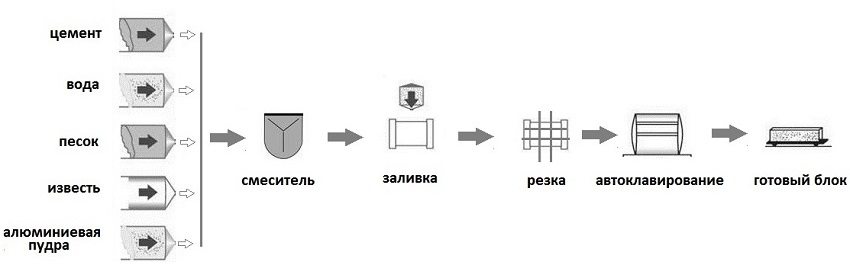

In an effort to simplify the process of constructing buildings and make building materials more affordable, manufacturers are offering new solutions. One of them is the creation of aerated concrete. Aerated concrete is one of the varieties of porous concrete, in fact, it is an artificial stone with spherical cells.

It is made from cement, quartz sand and specialized blowing agents (aluminum paste or suspension). Sometimes gypsum, ash, lime are additionally added. Then the mass is subjected to long-term heat treatment under high pressure in autoclaves. As a result of a chemical reaction, the cement slurry foams and solidifies with already formed pores.

When choosing aerated concrete blocks (sizes and prices per piece will be discussed below), the following criteria must be considered:

- total wall load;

- thermotechnical characteristics;

- proportionality of the masonry;

- ways to simplify the construction process;

- the dimensions of the gas block, depending on the design dimensions of the building;

- price.

Technical characteristics and physical properties of aerated concrete blocks

If you decide to use aerated concrete block in construction, you need to have an idea of its main technical characteristics. This will help to make the best choice and avoid irrational financial investments.

Basic dimensions. Aerated concrete blocks have different sizes, this allows you to more accurately calculate the required number. The most popular are: 600 × 300x200, 600 × 300 × 250, 400 × 300 × 200, 600 × 300 × 300, 400 × 300 × 300, 600 × 400 × 300, 400 × 400 × 300 and 500 × 400 × 300 mm ... Knowing the dimensions, you can calculate how many pieces of gas blocks are in a cube and, accordingly, how many are needed for the construction of a building with given technical parameters.

Density. Density grade is measured in kg / m³.In accordance with the requirements of GOST 25485-89 (Cellular concretes), aerated concrete is divided by density into heat-insulating (D300-D500), structural and heat-insulating (D500 - D900) and structural (D1000 - B1200). The higher the density of the aerated concrete block, the higher its bearing capacity.

Strength class. This indicator determines how much axial pressure a given block can withstand. For example, the strength class B2.5 allows the use of such a block in the construction of load-bearing walls up to 20 m high. The values of the indicators are as follows: В1.5, В2.0, В2.5 and В3.5.

Comparative table of the characteristics of the gas block and other materials:

| Specifications | Brick wall | Wall of porous large-sized ceramic blocks | Aerated concrete wall from industrial blocks | |

| Ceramic bricks | Silicate brick | |||

| Compressive strength, kg / m2 | 125 | 150 | 128 | 15-30 |

| Average density, kg / m³ | 1350 | 1750 | 830 | 400 |

| Thermal conductivity, W / (m * ° K) | 0,40 | 0,95 | 0,21 | 0,1 |

| Water absorption,% | 13 | 13 | 12 | >30 |

| Frost resistance, cycles | 35 | 35 | 50 | 25 |

| Standard wall thickness, m | 0,52 | 0,52 | 0,38 | 0,40 |

| Speed of erection of a wall of standard thickness, hour / m2 | >3 | >3 | ∼1,3 | ∼0,88 |

Coefficient of thermal conductivity. This indicator has the following values: 0.096, 0.12, 0.14 and 0.17, and means the ability of a warmer room to "share" its warmth with a cold one. The higher the coefficient, the greater the heat transfer. It is imperative to take moisture into account when determining which ratio is best for you.

Frost resistance. The frost resistance index is measured in cycles, and for aerated concrete blocks it has a value from 25 to 100. For comparison, brick has up to 50 cycles of frost resistance.

Drying shrinkage. This indicator is measured in mm / m and should be no more than 0.5, otherwise you risk seeing more shrinkage cracks on the walls of your house than is stipulated by GOSTs.

Aerated blocks are fastened together either with a special glue for aerated concrete, or with cement mortar

Useful advice! For uniform drying in order to avoid shrinkage cracks, experts recommend moistening the constructed aerated concrete structures so that drying occurs evenly.

Aerated concrete blocks: pros and cons, expert reviews

Let's see what makes aerated concrete blocks so popular and in demand in the construction industry, and what doubts arise when using them?

Related article:

Technical characteristics, sizes and prices of foam blocks. Advantages and disadvantages of building from foam concrete blocks. Sizes and prices of foam blocks. Areas of application. The choice of foam blocks: technical characteristics.

Advantages of aerated concrete blocks:

- aerated concrete blocks are easy to process: they are easy to saw, drill a hole in them, hammer in a nail, cut the required shape;

- they are lightweight with impressive dimensions. This significantly increases the speed of work and reduces labor costs in construction;

- it is an environmentally friendly material made from natural ingredients that do not emit harmful substances;

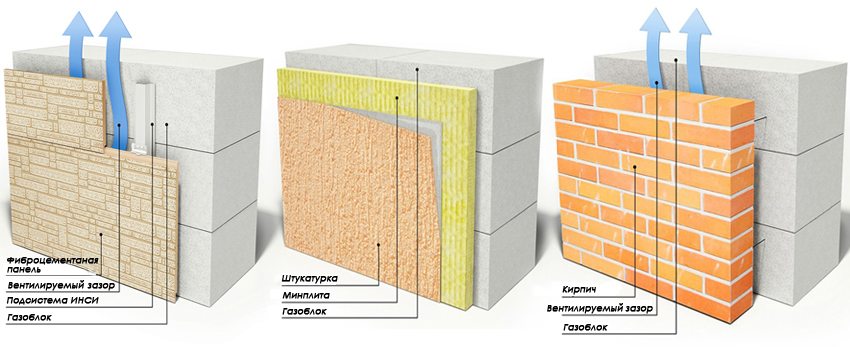

- gas blocks have a high level of heat saving. Due to the porosity, aerated concrete blocks almost do not conduct heat. This reduces the cost of heating the house in winter, and protects against overheating in summer;

- soundproofing properties are provided by cells with air. External noise will remain outside the walls of your home. They are especially good at absorbing low-frequency noise;

- aerated concrete does not burn - it is a fire-resistant material that can withstand direct exposure to open fire for a long time. The mineral composition gives it refractoriness;

- gas silicate concrete is frost-resistant. The degree of frost resistance depends on the technical characteristics of the individual blocks.

Speaking about the pros and cons of aerated concrete blocks, it is worth mentioning their shortcomings, which should be paid attention to when choosing this material for construction:

- the higher the density index of aerated concrete, the lower its thermal insulation properties;

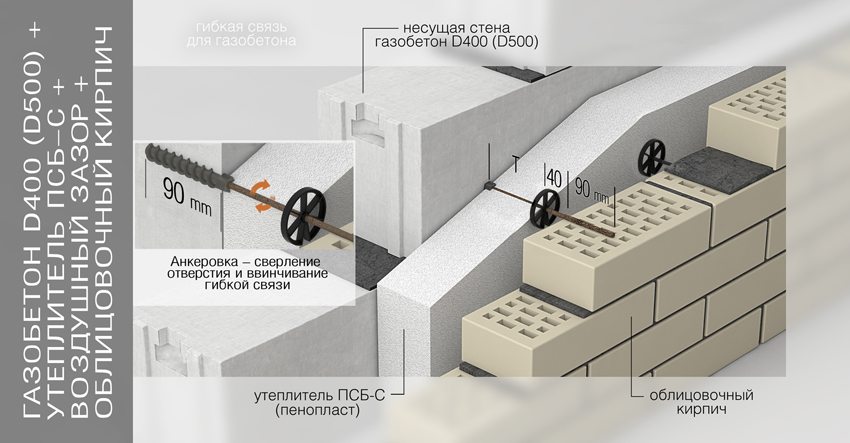

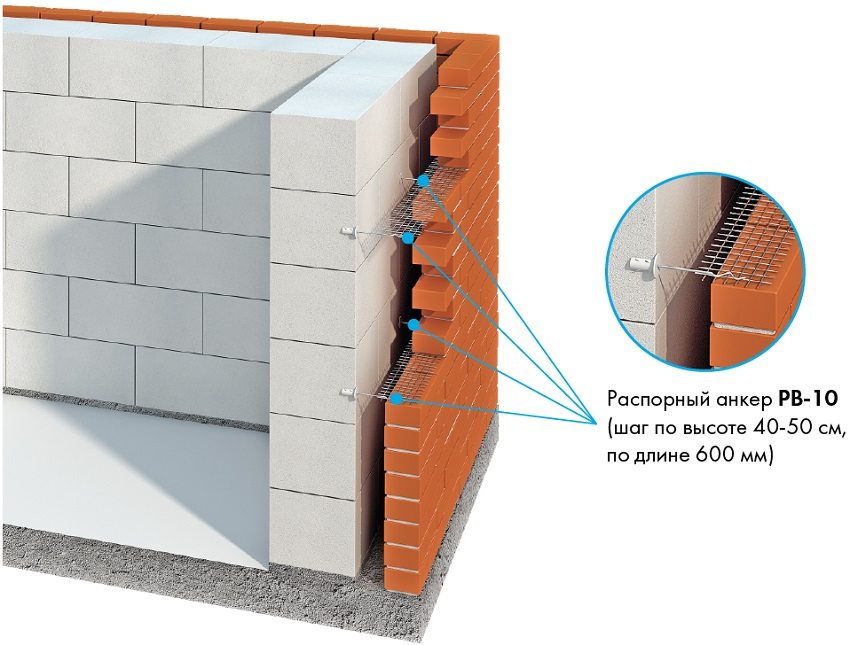

- aerated concrete blocks with a density below 500 kg / m³ can be used rather as a thermal insulation material. But the density indicator of 500 kg / m³ has a boundary definition. Ability to use building blocks with such a density in supporting structures are determined by manufacturers and test results;

- aerated concrete material is not elastic. In this regard, when the foundation is deformed, the wall made of gas blocks can crack. Therefore, structures made of porous concrete are advised to be erected on a monolithic strip foundation, which may lead to an increase in the cost of construction;

- due to the porosity of the material, ordinary fasteners will not work for fastening massive structures on the walls of aerated concrete structures. It is necessary to purchase special ones - for porous brittle structures, which may also entail additional costs;

- when laying porous blocks, use a cement-sand or special adhesive solution. In the first variant, the heat loss increases by 25%, in the second - by 10%. In addition, thermal resistance also decreases due to the use of jumpers and reinforced belts. Thus, some experts believe that the manufacturers of aerated concrete products exaggerate the statements about the high heat saving of this material, since heat losses not taken into account in the technical characteristics occur through the laying joints;

- aerated concrete absorbs moisture, therefore a vapor barrier must be made of such material in a structure. An anti-steam effect is achieved using a deep penetration primer and plastering;

The groove-comb system performs the function of a "thermal lock" and allows you not to apply glue along the vertical seam

Useful advice! To build a house with load-bearing capacity and good thermal insulation, you should choose aerated concrete blocks with a density of 500 kg / m³, take care of a solid foundation and a vapor barrier, and also use special thin-layer glue for laying.

Aerated concrete or foam concrete: which is better

Both materials are manufactured according to the same GOST standards and have similar physical and technical properties. Foam concrete also has a porous structure; it is made from a cement-sand mixture with the addition of a foaming agent. The difference with aerated concrete is that aerated concrete hardens naturally, and aerated concrete - through heat treatment. Various blowing agents are also used for these materials.

When determining what is better: gas blocks or foam blocks, you need to know that the technology for manufacturing foam blocks is simple and does not require factory conditions. Therefore, they can be made using portable equipment right on the construction site. Such availability does not always play into the hands of consumers: the manufacture of foam blocks is often carried out by unscrupulous manufacturers, which significantly affects the quality of products.

Gas blocks are manufactured at large enterprises that adhere to the required regulatory indicators.

It is important! When buying foam concrete blocks from small producers, take the trouble to check the necessary permits and quality certificates.

A foam concrete block can have toxic properties, since the hardening process occurs naturally and chemical processes may not be completed completely. The processing of gas blocks in autoclaves guarantees the completeness of the chemical process and the environmental safety of the product.

Different production methods also affect the mechanical strength of the compared building materials. With the same density, aerated concrete is stronger than foam concrete.For example, with a density of 500 kg / m³, aerated concrete can be used as load-bearing structures, while foam concrete with this indicator can be used only as insulation.

Moisture absorption and frost resistance also discourage these building materials. Gas blocks absorb more moisture, which affects the heat transfer and frost resistance. However, this problem is solved with the help of plastering work.

In addition, the sizes of foam blocks are not always standard. Foam concrete crumbles, therefore it is not as malleable in processing as aerated concrete and can crumble during operation.

A significant advantage of foam blocks in price. 1 m³ of foam concrete blocks will be 400-800 rubles cheaper than aerated concrete blocks. The price is influenced by the cost of production, production equipment, constituent components and applied technologies.

Thus, it is unambiguous to say which is better for construction houses: aerated concrete or foam concrete is impossible. The choice of this or that building material depends on the purpose of its application, the quality of materials and compliance with technological processes in its manufacture.

The reliability and durability of the structure being built depends on compliance with the technological process of laying gas blocks

How to calculate the number of gas blocks for construction

In order not to purchase an extra amount of building materials, you can make an approximate calculation of the required number of gas blocks. To do this, you can use the following formula:

(LхН-Sпр) х1.05хВ = Vwhere

L is the total length of aerated concrete walls, m;

Н - average height of aerated concrete walls, m;

Spr - total area of window and door openings, m²;

1.05 - coefficient taking into account a margin of 5% for trimming;

В - block thickness, m;

V - the volume of the required amount of aerated concrete, m³.

Based on the formula, you can compile the following table for calculating the number of gas blocks in a cube:

| Gas block sizes, mm | Pieces per cube |

| 600×200×300 | 27,8 |

| 600×250×50 | 133,3 |

| 600×250×75 | 88,9 |

| 600×250×100 | 66,7 |

| 600×250×150 | 44,4 |

| 600×250×200 | 33,3 |

| 600×250×250 | 26,7 |

| 600×250×300 | 22,2 |

| 600×250×375 | 17,8 |

| 600×250×400 | 16,7 |

| 600×250×500 | 13,3 |

This calculation is approximate and rather recommendatory. On the websites of manufacturers and sellers of aerated concrete blocks, you can find online calculators for the necessary calculations. You can also immediately calculate the cost of construction, taking into account the size of the gas blocks and the price per unit.

Aerated concrete blocks: sizes and prices per piece from leading manufacturers

Many companies producing building materials are engaged in the production of gas blocks. Aerated concrete blocks from such domestic manufacturers as EKO (Yaroslavl), GRAS (Maloyaroslavets), BONOLIT (Staraya Kupavna), Thermocube (Kostroma), DRAUBER (Elektrostal), YTONG (Mozhaisk), El-BLOCK (Kolomna), PORITEP (Novomichurinsk) are in demand. ), AeroStone (Dmitrov), LZID (Lipetsk), SilAbit (Staraya Kupavna). These companies have the necessary technological equipment and specially trained personnel. Their product is certified and of proper quality.

The price depends on the density of aerated concrete, the coefficient of thermal conductivity, the index of frost resistance and other technical characteristics. With the same density and size of gas blocks, the prices of domestic companies for products with the same technical characteristics do not differ too much. For example, the cost per cubic meter of aerated concrete blocks from the manufacturer DRAUBER is 2500 rubles / m³, SilAbit - 2600 rubles / m³, ECO - 2650 rubles / m³. Thus, with a density of 500 kg / m³, the average price per unit of a gas block 20 × 30 × 60 cm will be 92 rubles.

When making a purchase, it is imperative to inquire about the documents confirming the quality of the goods. It will also be useful to check the products for external damage (this may affect the properties of the gas blocks during operation). An overview of the types, technical characteristics, properties, sizes and prices per piece of aerated concrete blocks will definitely help you make the right choice and soon enjoy your own cozy and inexpensive home.