The production of new building materials does not stand still. Every year the manufacturer increases and improves the range of its products. Not so long ago, tongue-and-groove chipboard appeared on the building materials market. This material is highly resistant to moisture. Its peculiar design allows it to be used in various fields. The main characteristics and areas of application of the material can be found in this article.

Content

What is moisture-resistant tongue-and-groove chipboard

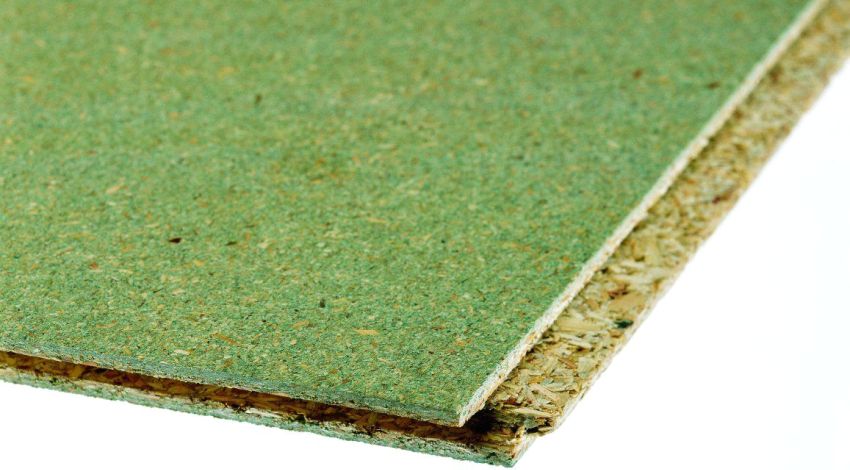

Chipboard with tongue and groove is the result of hot pressed wood chips mixed with thermosetting resins. Due to its layered structure, this material is resistant to deformation changes as a result of changes in temperature and humidity.

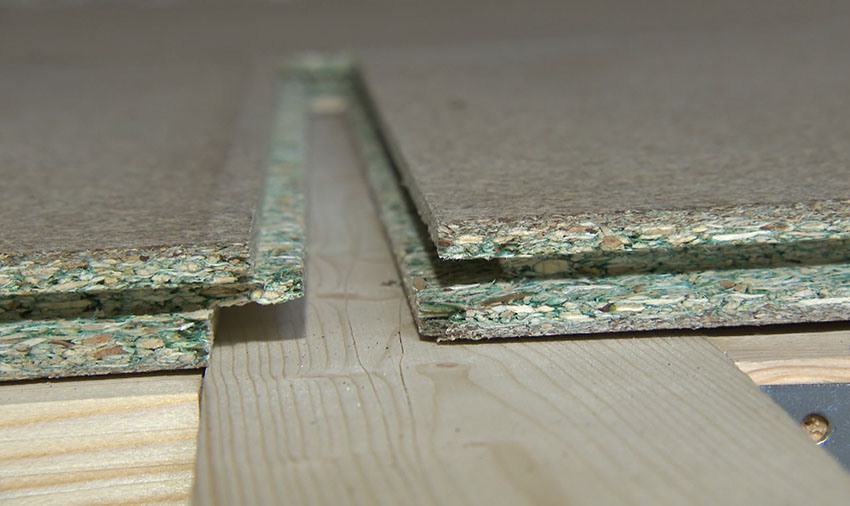

The thickness of chipboard sheets with a tongue can be 12-22 mm. For easy installation of the boards, which is carried out by the tongue-groove, each end side of the chipboard has a pre-cut tongue-and-groove connection: two ridges and two grooves. Plates fit evenly and tightly to each other. This construct allows the installation of plates without tools and special skills.

The structure of grooved chipboard includes waterproof polymers, which give the finished product a high coefficient of moisture resistance. This allows the stoves to be used in unheated rooms with high humidity (loggias, balconies, change houses, warehouses). This material can be used as a basis for future tiles in bathrooms, but provided that special glue and grout are used for tile joints.

Moisture-resistant tongue-and-groove chipboards have high strength indicators (bending, breaking, stretching). This makes it possible to use grooved chipboard for the floor. Plates installed on logs are able to withstand a high load without emitting a squeak and without bending over the entire area.

Useful advice! For installation of a floor with an area of less than 100 m² made of chipboard with tongue and groove, it is not necessary to leave technical gaps between the plates.

The tongue-and-groove chipboard for the floor is characterized as moisture-resistant laminated chipboard.

The price of a sheet of laminated chipboard with dimensions and thickness of 1200x900x16 mm is 680 rubles, and the cost of chipboard 1830x600x16 without coating is 335 rubles.

Varaints of moisture resistant colors laminated chipboard

Advantages of chipboard with tongue and groove

The main advantages of grooved chipboard:

- Thanks to the convenient tongue-and-groove connection, the floor tiles can be laid easily, quickly and without the use of special tools. As a result, you can get a perfectly flat surface without differences in height and gaps.

- Plates have a high level of moisture resistance, which makes it possible to use them in rooms with high humidity.

- Plates withstand fracture loads, bending and pressure well. Ideally handle point loads without sagging or squeaking. Distributes the load evenly, which contributes to the high strength and rigidity of the floor.

- The composition of this building material does not include harmful substances, which makes the product environmentally friendly and suitable for use in children's institutions, medical institutions, and residential premises.

- The slabs have large dimensions, but low weight, which makes them simple, easy and quick to assemble without the involvement of experienced workers.

- Chipboard plates are affordable. For a reasonable fee, you can get a good, high quality and durable coating.

- Chipboard products with tongue-and-groove piles are resistant to mold, fungus and various microorganisms.

Scopes of tongue-and-groove moisture-resistant chipboard

Experts identify several main areas of application of moisture-resistant chipboard with tongue-and-groove:

- the most in demand is moisture-resistant chipboard for the floor. With its help, a raised floor, a "floating" floor, a prefabricated dry screed, which has compartments for insulation, without the use of water-based mixtures for pouring, can be mounted;

Useful advice! For the construction of treadmills, tennis courts, podiums and other structures that require reinforcement, moisture-resistant tongue-and-groove chipboard is successfully used.

- moisture resistant boards are ideal for leveling wall surfaces. They are safely used as a basis for the subsequent finishing (decorative plaster, wallpaper, wall paneling, plastic). Chipboard panels, possessing heat and sound insulating properties, are perfect for the construction of an interior partition. Plates are fastened with self-tapping screws to a pre-assembled frame made of strips;

- moisture-resistant tongue-and-groove chipboard with a thickness of 12 mm can ideally replace the ceiling plasterboard. It is much lighter and more convenient to use than its fragile counterpart. It is used for a leveling base for a topcoat;

- the plate is indispensable for roofing work. Low weight of the sheet, high density (820 kg / m³) and moisture resistance allow using the material for the construction of an inner insulating layer of the "roofing pie";

- foundation. Ideal for removable formwork for casting at the initial stage of construction work.

Useful advice! During the device of any design using grooved chipboards, all joints must be treated with a sealing material (glue, mastic, liquid nails).

The grooved chipboard is impractical to use for the manufacture of furniture. For these purposes, you can buy chipboard for furniture, the price per sheet in this case will depend on the size and type of material. You can also order an individual sawing of chipboard according to the dimensions that are necessary to create a specific furniture product.

Subfloor device using chipboard with tongue and groove

All installation work can be performed independently without the involvement of specialized workers. Work should be done in a clear sequence.

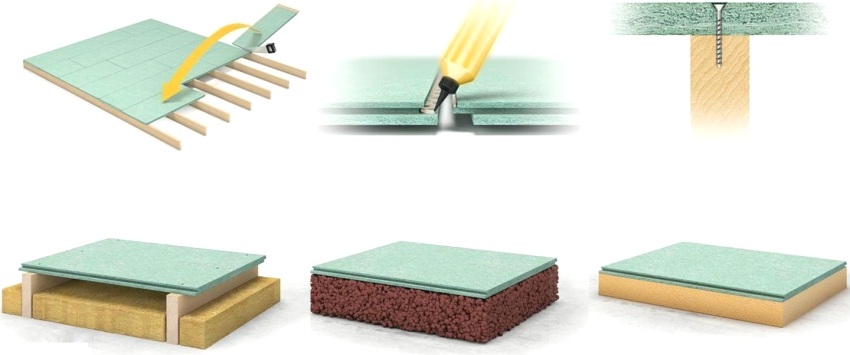

The first step is to lay the lag with a distance that corresponds chipboard sheet thickness... For slabs with a thickness of 16 mm, the step is 30-40 cm. If you use slabs with a thickness of 22 mm, then the step will be about 60 cm. All voids between the lags are filled with a sealant, the gaps as a result of unevenness in the floor are filled with sand.

Further, starting from the far opposite wall door, the laying of chipboard sheets begins with self-tapping screws. The next sheet is inserted into the groove and fastened with self-tapping screws to the logs, similar to the first plate.

Useful advice! Installation of sheets should be carried out so that the seam between adjacent slabs falls on the beams. In a narrow long room, the logs are laid across the direction of movement.

Installation of "floating" floor

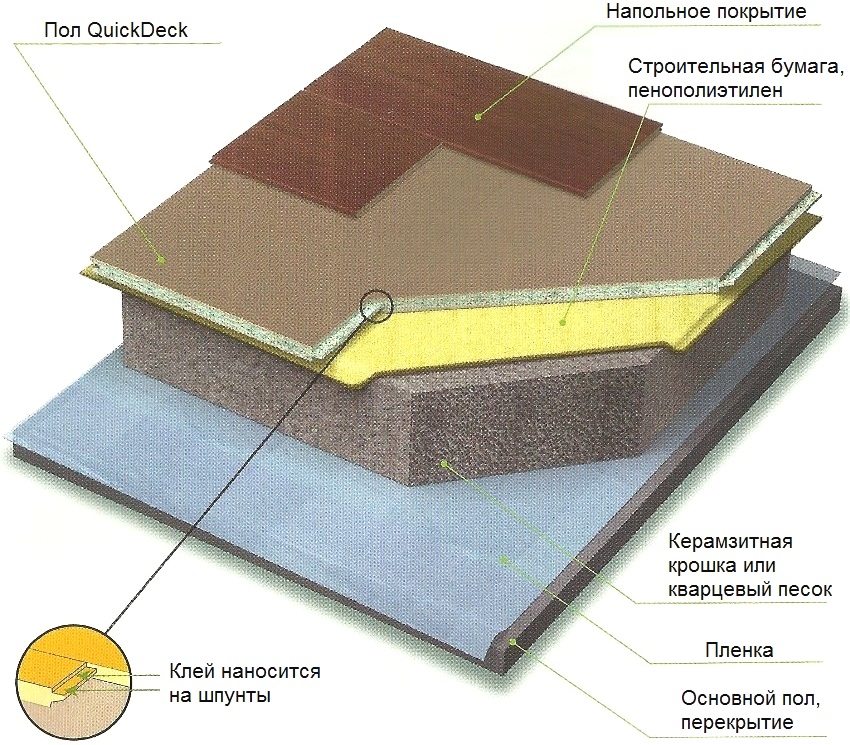

This method allows you to equip floors using a dry screed. The result is a multi-layer structure, which ends with the laying of grooved chipboard. This method consists of several stages:

- A layer of vapor barrier is laid on the concrete base.

- Fitted with expanded polystyrene plates or expanded clay base.

- The next layer is the backing. For it, plastic, construction paper, membranes can be used.

- The final layer is moisture resistant chipboard with tongue and groove.

Installation of material on the ceiling and walls

Installation of a sheet of grooved chipboard on the wall is carried out using self-tapping screws with a pitch of 30-40 cm without the use of lathing. If using nails, then they must be driven in at a 45 degree angle.

For mounting chipboard on the ceiling, plates with a thickness of 12 mm are used. They are attached to a pre-equipped frame made of wooden slats using self-tapping screws, nails, special staples. The joints of the slabs must be sealed with special mastic or glue.

How much is a chipboard sheet: material price

Moisture-resistant chipboards with tongue-and-groove are made in two standard sizes: 1830x600 mm and 2440x900 mm, the thickness of which can be 12, 16 and 22 mm. The price of a moisture-resistant chipboard directly depends on the dimensions of the material and the thickness of the product.

Useful advice! The thickness of the material should be selected based on its further purpose. Thin material should be used for sheathing the ceiling or roof, and chipboard with a thickness of 22 mm is ideal for flooring and partitions.

The price of a moisture-resistant chipboard for a sheet of 2440x600 mm in size and 12 mm thick will be about 450 rubles. While the price for a chipboard sheet for furniture measuring 2440x1830x16 mm will be 575 rubles. A plate with a size of 2440x600 with a maximum thickness can be purchased for 635 rubles. The largest slab measuring 2440x900x22 mm will cost about 800 rubles. per product sheet. Moisture-resistant grooved chipboards are used mainly in solid sheets.

Manufacturers and prices

On the modern market, the material is presented in a wide range. Each manufacturer produces products for every taste and desire of the consumer.

The most popular manufacturers of moisture-resistant tongue-and-groove chipboard are:

- "QuickDeck". Plates can be purchased from 335 rubles;

- "StroyExpert". The price starts from 365 rubles;

- "SPHERE". The cheapest stove will cost 410 rubles;

- Plywood Plus. The price range starts from 380 rubles per sheet;

- "PlitTorg-S". Prices rise from 570 rubles.

Manufacturer QuickDeck

QuickDeck is one of the most popular manufacturers of waterproof boards. The products of this company are in great demand in Russian cities. The product is suitable for all the jobs mentioned above.

Feature of QuickDeck products:

- the material has a high level of wear resistance. According to the European standard EN 13229, the material has a 33 service class and AC6 abrasion class. These indicators allow the finished material not to lose its characteristics for 6 years. And this is only when using it in shopping malls, educational institutions, sports clubs. For residential premises, the service life can be up to 20 years;

- according to European standard EN 312, the material has a water resistance class P5. This indicates that the board has a good swelling resistance.It will swell by only 10% after a day in the water;

- moisture resistant chipboard with tongue and groove are completely environmentally friendly. The material belongs to the E1 hazard class, according to the European standard EN 13896. This means that the product does not emit harmful substances like natural wood;

- the surface of the material is resistant to direct exposure to ultraviolet rays;

- the material has a high rate of fire resistance. Leaving a lighted match will not cause a fire or surface marks;

- slabs have increased sound insulation properties. The grooved chipboard floor will not squeak underfoot. And partitions made of such material will provide adequate heat and sound insulation;

- the coating does not require any special care. The material is able to withstand the influence of various household chemicals.

Related article:

Particleboard: what is this? Scope of use and material classification

History of creation. Chipboard classification. Scope of the material. The main differences between chipboard and other sheet materials.

Moisture-resistant grooved chipboard: reviews of the material

Good technical characteristics and high quality of the material make it indispensable for many construction works. This is confirmed by numerous consumer reviews. Due to the practicality of use, many experts opt for moisture-resistant tongue-and-groove chipboard. This concerns the question of when it is necessary to carry out work in rooms with high humidity, for finishing the floor, ceiling and walls. Simple and easy installation can be performed by a minimum number of people without special skills, which significantly reduces the cost of repair work.

And the fact that the sheet pile chipboard is used with great success in a considerable number of television projects, such as Dachny Answer and Fazenda, puts this material at the top of the rating list.

The opinion of experts indicates that chipboard is a popular material in the modern construction market. For a moderate price, you can get a good product that has a high strength index, is able to withstand significant loads without bending or breaking. Thanks to the easy tongue-and-groove connection, you can get a perfectly flat, rigid, strong and stable base that will last for many years. Easy and quick installation will allow you to restore the structure after its possible dismantling.

Strength, durability, good appearance, significant savings in money and time when performing repair and construction work make the moisture-resistant tongue-and-groove chipboard the leader in the market for budget proposals for interior decoration.