With the development of the construction industry, lightweight concrete blocks have filled a significant part of the masonry market. Today there is a fairly large number of their varieties, but the most famous of them are foam blocks and gas blocks. Both are very popular with consumers. These materials have a number of differences, so a reasonable question arises: which is better than a foam block or a gas block? To give an answer to it, it is necessary to carry out a comparative analysis of both materials in terms of various parameters.

Content

Foamed concrete blocks production technology

To understand the physical properties of materials, it is necessary to know the technology of their production. All foamed concrete blocks are produced by the formation of air bubbles in the concrete solution. The properties of the resulting blocks depend on the method of foaming and the composition of the mixture. Interesting us foam block, produced by the following technology:

- The mixture is kneaded in a special concrete mixer with inclined blades. This is to prevent the disappearance of air bubbles. The working mixture consists of Portland cement grade M 400 D 20, sand of fraction 0.02, without particles of debris and dirt with a moisture content of no more than 5%, foaming agent (there are several types), water and fiberglass for reinforcement. In this case, the fiber is first dissolved in water for better reinforcement.

- The finished mixture is poured into molds of the required size.

- Drying of products is carried out in natural conditions or in an autoclave. The latter method allows you to get better quality products.

Gas blocks are made in a different way. Here, instead of a ready-made foaming agent, gas-generating substances are added to the mixture. The most famous of these are PAP-1 and PAP-2 aluminum powders. At the moment it enters the mixture, a chemical reaction occurs with the release of hydrogen gas. The solution is poured into molds. The mixture rises like yeast dough until it fills the entire mold. After 2 hours, the excess mass is removed and the products are dried in natural conditions or in an autoclave.

Related article:

Features of projects of baths from foam blocks, photo and technology

How to build a sauna from foam blocks. Advantages and disadvantages of foam block baths. Photo of foam block baths.

These insignificant differences in the production technology of the materials in question led to the fact that the finished products greatly differ in their consumer qualities. What is better foam block or gas block, we will find out by comparing them.

Helpful advice! In the case of large construction, you can organize the production of light blocks with your own hands.This will help save money, or maybe give a start to a home business.

What is better foam block or gas block?

Before you start comparing these two popular building materials, you need to decide on what criteria you need to do this. Let's list the most significant indicators:

- strength;

- geometric;

- ecological;

- economic;

- ergonomic;

- heat insulating and waterproofing.

Let's analyze the strength characteristics of both materials.

Strength and linear dimensions

Foam blocks come in different densities. The strength of the material depends on this indicator. For the insulating wall contour, use blocks low density D400 and D500 with the corresponding strength class B0.75 and B1. Foam blocks, which can serve as thermal insulation and as load-bearing ones, have a density from B 600 to D1000 with a strength class from B2.5 to B7.5. Purely load-bearing products have a density of D1100 - 1200 and a strength of B 10 - 12.5.

Concerning aerated concrete blocks, then they also come in different grades, but with a slightly different range of density and strength. Their density starts at D300 and, in most cases, ends at D700. Strength ranges from B2 to B4.

As you can see, these two indicators intersect for both products, but for foam blocks the range is much higher. This means that it will be easier to choose foam concrete blocks of the required parameters. At the same time, aerated concrete is of much better quality, since it is produced only at large enterprises.

Helpful advice! When choosing a foam concrete masonry material, you need to pay attention to its density. The higher it is, the stronger the material, but the colder it is, since the content of air bubbles in it is less.

If we compare the geometric parameters, it can be revealed that both materials have the same range of linear dimensions. However, aerated concrete blocks have less deviation from the standards, their edges and edges are perfectly even. This is due to the fact that the material is not produced in an artisanal way, unlike foam blocks.

Ecology, economics and usability

What is better for a foam block or a gas block for environmental performance? Everything is simple here. There is such a term as the environmental factor. So, for gas blocks it is 2, and for foam blocks - 4. Therefore, according to this indicator, gas blocks come out ahead.

From an economic point of view, it is necessary to estimate the cost of a cubic meter of both materials. Foam blocks cost from 35 cu. per m³, and gas blocks from 50. But here it should be borne in mind that the construction of load-bearing walls is possible only from foam blocks with a high density class, the price of which is comparable to the price of gas blocks. In addition, glue will be much cheaper than preparing a masonry mortar. Therefore, when choosing a material for construction, this parameter does not make sense to take into account.

Ergonomics is the degree of usability of materials. Since the specific gravity of aerated concrete is somewhat less than that of the opponent, with the same dimensions, each block weighs less. This gives less stress on the foundation and more convenience when laying. It is also more convenient during transportation for this reason. Gas blocks are much easier to handle: you can saw, cut and drill them directly on site. The use of special glue when laying gas blocks, allows you to reduce the thickness of the seam to 2 - 3 mm, versus 2 cm for foam blocks.

Higher strength at the same density allows you to easily install furniture fasteners on the walls of aerated blocks. In terms of ergonomics, it is clear from the examples given that gas blocks are better than foam blocks, or at least when their identical classes are compared.

Heat and waterproofing

Thermal insulation is the most important indicator on which the possibility of building an object depends on severe winters. Thermal conductivity is inversely related to the density of the material. Gas blocks with a density of D500 have a thermal conductivity with a coefficient of 0.11 Wm * K, and foam blocks of the same density 0.12 Wm * K. The difference is small, but it should be borne in mind that D500 foam blocks are purely thermal insulating and cannot be used as load-bearing ones.

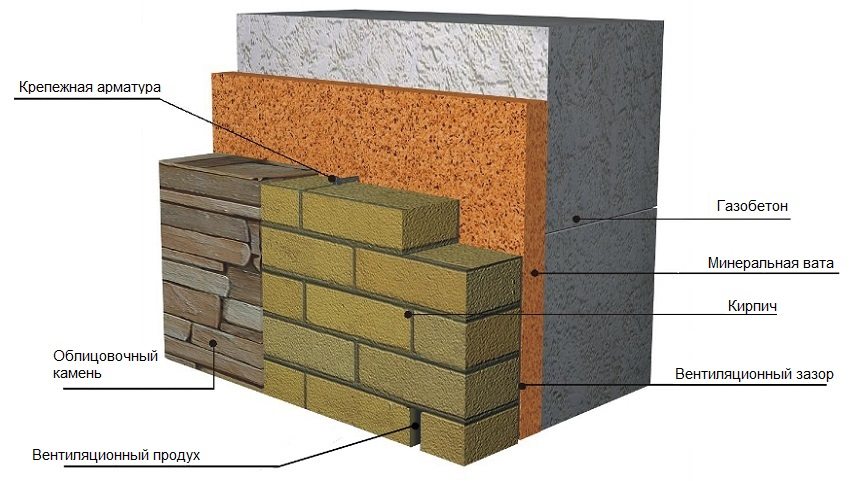

If the density is increased, then the thermal conductivity will also change upward, and this negatively affects the thermal insulation qualities of the material. Thus, a house made of aerated concrete with walls of the same thickness will be twice as warm.

Helpful advice! A good solution is to build walls from a heat-insulating foam block, which is lined with bricks. In this case, a normal combination of strength and thermal insulation is obtained.

The waterproofing properties of aerated concrete are much worse than those of foam concrete. This is due to the fact that the first has a porous capillary structure inside, and the second has closed air bubbles, into which water does not enter. Therefore, the foam block floats freely in water without getting wet, and the gas block will absorb water over time and drown. Worst of all, wet aerated concrete in winter can collapse and its thermal insulation qualities decrease. This problem, however, is solved by the construction of a waterproofing layer.

Having considered all the features of the materials, everyone for himself can answer the question of which foam block or gas block is better. Both materials are in demand. Gas blocks are more used for the construction of residential buildings, because their strength indicators, coupled with poor thermal conductivity, allow you to do this without fear for quality.

Aerated concrete house more durable. At the same time, the price of gas blocks is much higher, but the total costs will be the same. Foam concrete is cheaper and you can make it yourself, but it is worse in quality, and masonry mortar is more expensive for it than glue. That is, it is impossible to compare these two materials in general. People make their choice according to the criteria that are more important to them.