Today, FBS blocks are very popular in the construction of foundations and low structures: the size of the product and the price for it are presented in a wide range. This allows you to decide on a suitable material for construction in certain conditions. Observing the rules for selecting the type of material and its dimensions, you can create a strong and reliable structure in a short period of time.

Foundation blocks solid - these are building elements made of concrete by reinforcing it with metal rods

Content

- 1 Characteristics and features of the FBS foundation blocks

- 2 Advantages and disadvantages of reinforced concrete foundation blocks

- 3 The choice of sizes of foundation blocks for the construction of the base

- 4 FBS blocks: product dimensions according to the assortment

- 5 How to choose the right size of FBS blocks for construction

- 6 Varieties of blocks according to GOST: FBS, FBP, FBV, FL and BF

- 7 Reliable domestic manufacturers of foundation blocks: product prices

- 8 Features of installation of foundation FBS blocks

Characteristics and features of the FBS foundation blocks

The concrete block for the FBS foundation is a solid monolithic reinforced concrete product in the shape of a parallelepiped. Among other types of blocks, the material has the highest strength and performance characteristics, thanks to which it can be used in the construction of the foundation.

FBS blocks have a solid rectangular cross-section and loops that facilitate the process of transportation and stacking

FBS is a reliable, stable and durable building material characterized by increased resistance to environmental influences. The strength characteristics of the product are of particular importance, since the elements are the basis for creating the foundation of the building.

The material is made exclusively in the factory, since the quality of each product must be strictly controlled using laboratory instruments in accordance with GOST. Foundation blocks can be made of the following materials:

- silicate concrete or expanded clay concrete with a density of at least 1800 kg / m³;

- lightweight high-strength concrete of class B100;

- heavy high-strength concrete of the M50-M200 brand.

The concrete is selected based on the operating conditions of the structure being built. It takes into account temperature differences, mechanical stress and humidity levels. Concrete of the M200 brand has the maximum strength. For harsh operating conditions, you can use M150 filler, and for standard ones - M100.

Concrete of strength class from B7.5 to B15 is used as the main material for the manufacture of FBS blocks

In addition to concrete filler, reinforcement made of steel grade A1 or A111 is used, which improves the strength characteristics and reduces the effects of pressure and compression, and plasticizers, which increase the frost resistance of the material.

Advantages and disadvantages of reinforced concrete foundation blocks

Due to its high strength and performance characteristics, this concrete building material, which is reinforced from the inside with a reinforcing cage, can be used for the construction of a columnar base, in combination with a strip foundation, when erecting walls of low buildings, basements and cellars.

Concrete foundation blocks are characterized by the following advantages:

- good bearing capacity;

- high speed of installation;

FBS blocks are designed for the construction of solid and reliable foundations of various buildings, since they are capable of "holding" the highest loads

- the reliability of the material, this is ensured due to the fact that the products are manufactured in the factory using a special technology on modern equipment, in addition, they undergo strict laboratory control;

- high density of joining of elements, which is achieved due to the thoughtful design of products and the exact dimensions of concrete blocks;

- elements are equipped with special mounting grooves for easy installation;

- the versatility of the material makes it possible to erect the foundations of structures of any complexity;

- installation work can be performed at any time of the year, since the material is not afraid of temperature fluctuations and high humidity;

- high stress resistance of the material allows it to be used in the most unfavorable conditions, such as icy or acidic soils;

- after the completion of the installation of the blocks, you can immediately proceed to other construction work.

The disadvantages of the material include:

- high cost of products;

Due to the large weight of the blocks, installation work will require the involvement of special equipment

- low heat resistance;

- large weight of products, as a result of which the installation work associated with the laying of elements will require the involvement of special equipment;

- the joints of the parts will not be characterized by tightness.

The choice of sizes of foundation blocks for the construction of the base

Currently, when erecting a base, a combined method of laying with the use of FBS elements is very popular. Thanks to this technology, the cost of construction is reduced, which does not negatively affect the strength and durability of the structure. When choosing the size of the foundation FBS blocks, it should be borne in mind that the future foundation must not only withstand the weight of the structures, but also distribute it evenly over the entire base.

Important! Inconsistency in the size of the products can negatively affect the condition of the base, which will ultimately lead to the destruction of the building.

It is from the design load of the object on the foundation that the size of the blocks must be selected depends

The strength of the structure, the technological process of assembling the elements, the lead time of the "zero cycle" and the cost of the products depend on the size of the product. The dimensions of building blocks are determined based on the type of soil, its bearing capacity. It is also necessary to take into account the thickness of the walls and floors, the weight of the structure, the area and strength of the foundation. The lower the stability of the soil, the larger the foundation blocks should be. For example, for clay surfaces, you should choose the largest elements, and on coarse soils, you can arrange bases from small-sized products. To create the tightest styling, it is recommended to use products of different sizes.

Useful advice! When choosing the size of blocks for the construction of walls, it is necessary to be guided by the rule that five elements per wall length are considered optimal.

FBS blocks: dimensions products according to the assortment

Each block has its own marking, which indicates the length, width and height of the product in decimeters. These parameters must strictly comply with the requirements of GOST 13579-78.If the letter "T" is next to the numerical value, this indicates that heavy concrete was used in the manufacture of the block, the letter "P" indicates expanded clay concrete, and "C" - for dense silicate concrete.

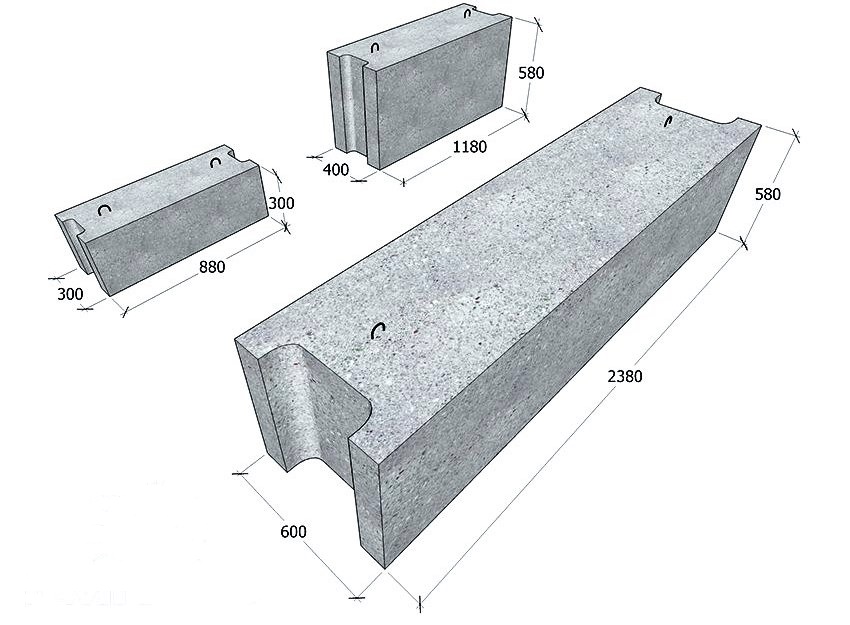

According to GOST, the FBS block is presented in 15 standard sizes, where the width of the products, which is 300-600 mm, is an important dimensional characteristic. Along the length of the FBS, the assortment is divided into three standard sizes with values of 880, 1180 and 2380 mm. The height of the products is 580 mm. Only a block 1180 mm long has a product height of 280 mm. The smallest element has dimensions of 880x300x580, and the largest foundation block FBS 24.6.6 is 2380x600x580 mm.

The marking of standard products is shown in the table:

| Designation | Width, mm | Height, mm | Length mm | Item weight, kg |

| FBS.24.6.6 | 600 | 580 | 2380 | 1960 |

| FBS.24.5.6 | 500 | 580 | 2380 | 1630 |

| FBS.24.4.6 | 400 | 580 | 2380 | 1300 |

| FBS.24.3.6 | 300 | 580 | 2380 | 970 |

| FBS.12.6.6 | 600 | 580 | 1180 | 960 |

| FBS.12.5.6 | 500 | 580 | 1180 | 790 |

| FBS.12.4.6 | 400 | 580 | 1180 | 640 |

| FBS.12.3.6 | 300 | 580 | 1180 | 460 |

| FBS.12.6.3 | 600 | 280 | 1180 | 460 |

| FBS.12.5.3 | 500 | 280 | 1180 | 390 |

| FBS.12.4.3 | 400 | 280 | 1180 | 310 |

| FBS.9.6.6 | 600 | 580 | 880 | 700 |

| FBS.9.5.6 | 500 | 580 | 880 | 590 |

| FBS.9.4.6 | 400 | 580 | 880 | 470 |

| FBS.9.3.6 | 300 | 580 | 880 | 350 |

Useful advice! The building block is a solid piece with no voids. When purchasing a material, a quality certificate should be checked with the manufacturer, which is a guarantee that the blocks comply with the requirements of the current standard.

How to choose the right size of FBS blocks for construction

When erecting foundations, different sizes of foundation blocks can be used, and the price per item of the product will depend on its dimensions. To accurately determine the size of the blocks and their number, you should unroll the base. On a special drawing, all products are conditionally laid out along the length and height of the basement wall of the building. Here you should take into account the dressing between the blocks, which is at least 25 cm.

The width of the product is selected based on the thickness of the walls of the building. In this case, minor overhangs of overhead structures are allowed. If the walls are to be built of bricks, then the size of the ledge should be no more than 40 mm on each side. Here you can use FBS 600 mm wide for 640 mm walls and 500 mm for 510 mm structures.

The length of the foundation block must be determined from the sweep, where elements of different sizes are located so that they lie flat without forming significant protrusions.

Useful advice! If the standard size pieces cannot be stacked properly, they can be split lengthwise.

When building foundations and erecting walls, products with a height of 580 mm are used. Blocks with a value of 280 mm are used as additional elements when it is necessary to make a hole in the base for air supply, input or output of networks.

The weight of FBS blocks is an important value, knowing which, you can decide on the special equipment required for stacking products, as well as on the transport that will be involved in the delivery of blocks to the construction site.

Useful advice! Today manufacturers produce small foundation blocks 200x200x400 mm, which can be installed without the involvement of special equipment.

Varieties of blocks according to GOST: FBS, FBP, FBV, FL and BF

For the construction of a technical underground, basement walls, installation of columnar and strip foundations, the construction of walls of low structures, unheated buildings and other structures operating under systematic exposure to temperatures from +50 to -70 degrees, concrete blocks can be used, which, based on GOST 13579-78 there are three types: FBS, FBV and FBP. Products are made of silicate, heavy concrete or expanded clay concrete. Their density should not be less than 1800 kg / m³.

According to the decoding, FBS is a foundation wall block with a maximum safety margin. In the manufacture of monolithic small elements, structural reinforcement is not used. Metal is used only for the manufacture of mounting hinges. In the production of dimensional blocks, longitudinal reinforcement rods are necessarily used, which increases the weight of the FBS.

Related article:

Sandwich panels: sizes and prices of roofing, wall and corner panels

Varieties of sandwich panels and their characteristics. Houses made of sandwich panels. Editing algorithm.

FBV blocks, unlike the previous type, have a longitudinal section in the product cavity. It is designed for the installation of utilities. The manufacturing process of such products is similar to the manufacturing method of the previous version. Concrete not lower than M100 grade is used here. However, in the construction of FBV blocks are used extremely rarely, therefore, they are made mainly by individual order. Products are produced in lengths of 880 mm, height of 580 mm and widths of 400, 500 and 600 mm.

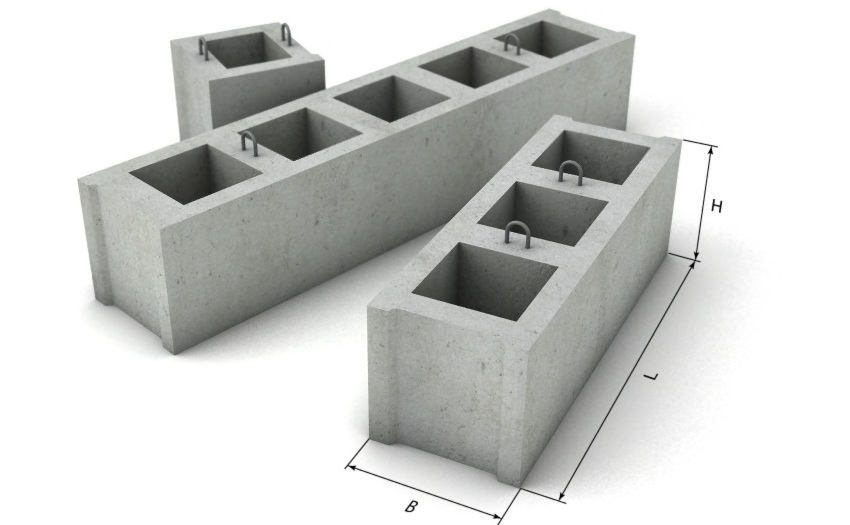

FBP blocks are hollow lightweight concrete products with open square holes in the lower part of the element. For the manufacture, concrete of the M150 brand is used. The products are manufactured in a length of 2380 mm. Other linear dimensions of foundation blocks and product prices are in a wide range. FBP blocks are used to create foundations for industrial equipment or for arranging the inner walls of the basement.

As a base for a columnar or strip foundation, trapezoidal products are used, which are marked with FL. The parameters and dimensions of the foundation cushions are regulated by GOST 13580-85. The width of the products varies from 600 to 3200 mm. The height of the elements can be 300 or 500 mm. The last value corresponds to products with a width of 2000 mm. The block length is 780-2980 mm. The largest elements have dimensions of 2980x2000x500 and 1180x500x3200 mm, and the smallest ones are available in dimensions of 1180x600x300 mm.

For the construction of internal and external walls of buildings of agricultural and industrial enterprises, reinforced concrete tape blocks BF made of heavy concrete are used, which are regulated by GOST 28737-90. All elements are divided into six varieties, which differ in their cross-sectional dimensions.

Reliable domestic manufacturers of foundation blocks: product prices

FBS concrete blocks are part of the products that are produced at any concrete plant. Very often, products are made without observing all the subtleties and stages of the technological process. Concrete of different grades can be used as a raw material. Therefore, when choosing a high-quality and reliable material, you should choose companies that have proven themselves from the best side in the global construction market.

One of the largest enterprises in Russia for the production of building material from concrete is the Factory of Industrial Building Parts. The products are distinguished by their durability and high quality workmanship, which is carried out in accordance with the requirements of GOST. The cost of foundation blocks starts from 1200 rubles / piece.

The Russian company "Vira" specializes in the manufacture of concrete products. The range of products includes more than 400 items, including wall foundation blocks. The price per piece of the product depends on its dimensions and averages 1,650 rubles.

Foundation concrete blocks of domestic manufacturers are the most reliable and practical solution for the progressive industry

Another popular domestic manufacturer is the Master company.It manufactures all types of concrete blocks, the price of which depends on the type of product and starts from 1150 rubles / piece.

The Alexandria expanded clay plant produces various types of concrete products. Small concrete blocks are in great demand, which can be used in the construction of load-bearing walls, fences and columns, or used as supporting elements in basements and semi-basements, basements. Products are made in special shapes, due to which they have precise dimensions. The price of foundation blocks 200x200x400 mm starts at 55 rubles / piece.

Another reliable manufacturer is the Zlatoust plant, which produces a wide range of FBS, FBP, FVP, stairs, panels, lintels and concrete road slabs. Products differ in acceptable cost. The price of the foundation block FBS starts from 950 rubles / piece.

Features of installation of foundation FBS blocks

The process of installing blocks under the foundation does not require special knowledge and special skills. To get a good result, it is important to strictly follow the sequence of actions, which are carried out in three stages.

The first stage is to calculate the number of elements required for the construction of the foundation. For this, the volume of the building is determined, the resulting value should be divided by the volume of one block. The second stage is to prepare the foundation. Blocks should be laid on a sand cushion 50-100 mm thick, previously leveled and tamped. The length and width of the base should be 25-30 cm more than the dimensions of the planned building. Next, the plot is broken down along the axes using construction plumb lines and a level.

The final stage is the direct laying of FBS blocks using a lifting mechanism. Beacon blocks are pre-installed at corners, intersections and foundation lintels. The level is used to check the coincidence of the upper planes of the beacons, between which the cord should be pulled. The rest of the elements of the first row are exposed on it. Between the blocks, according to the project, it is necessary to leave gaps for the passage of engineering communications.

Even at the design stage, you should take care of the purchase of blocks with large length indicators

Helpful advice! Before installation, the blocks should be cleaned of possible contamination and moistened with water.

The geometry of the entire foundation will depend on the correct installation of the first row of blocks. The placement accuracy is controlled by the level. Structural elements are fixed with a crowbar. The next row is built according to the brickwork principle. A layer of cement mortar is provided between the rows, which is compacted with a bayonet shovel. The foundation height is usually 5 rows of products.

Important! Do not install the units on a base covered with water or snow.

When building small structures at a summer cottage, you can use used foundation blocks with a size of 400x600x200 mm. And the price per piece of the product will be only 300 rubles.

Arrangement of the base includes a set of measures, on the correct implementation of which the speed and quality of laying the FSB blocks depends

The use of FBS blocks in the construction of foundations and other objects can significantly speed up the process. The correct choice of product size and adherence to the installation sequence will be the key to creating a strong, reliable and durable structure.