The process of growing vegetables and berries can be divided into two stages: building a greenhouse and caring for plants during their growth. Whether it will turn out to feast on spring strawberries, and whether crispy cucumbers appear on the table, largely depends on how and from what material the greenhouse will be built. Covering reinforced film, reinforced awning or special tarpaulin material used by gardeners create the most comfortable conditions for greenhouse plants.

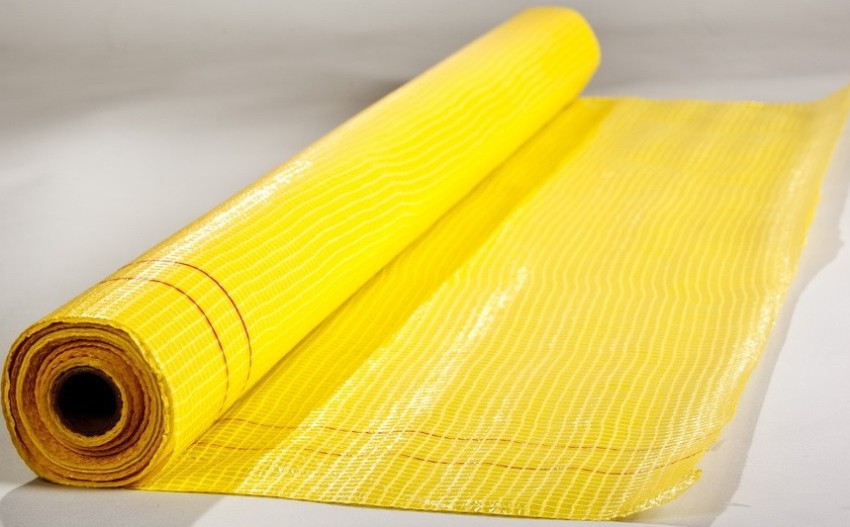

Reinforced film is a three-layer material, where a mesh frame made of lavsan is laid between two layers of polyethylene

Content

- 1 Main characteristics of reinforced films

- 1.1 Reinforced film, reinforced PE and membrane: material properties

- 1.2 What can be reinforced with a reinforcing film

- 1.3 What you need to know when choosing a reinforced film for greenhouses

- 1.4 Reinforced film for greenhouses: consumer reviews and practical advice

- 1.5 Reinforced film in industry: the purpose of building cover tents

- 2 Reinforced film prices and material manufacturers

- 3 Tarpaulin fabric manufacturing technology

- 4 Reinforcement foil: additional information for discerning buyers

Main characteristics of reinforced films

For a long time, plastic sheeting was the only covering material for greenhouses. It met many requirements, but after one year of use it became cloudy, letting in light much worse. And the integrity of the canvas most often could not be preserved within one season, it was easily damaged even with minor mechanical influences.

Reinforced polyethylene film has a very high strength, which is achieved by weaving a special mesh into the polyethylene

Reinforcing film for greenhouses that has appeared on the market has practically supplanted ordinary polyethylene. It has not lost any of the technical characteristics of this material, and the main disadvantages of conventional polyethylene have been eliminated.

The reinforced fabric is a mesh-like frame on which a polyethylene film is fused on both sides. It is the presence of a dense mesh that allows this material to be used as a reliable covering coating and gives it a number of significant positive characteristics. Benefits of reinforced film:

- resistant to stretching, withstands significant mechanical damage;

- has hydro and vapor barrier properties;

- withstands significant temperature fluctuations (from –30 to 90 ° С);

- durable in use (5 years or more).

This material is resistant to ultraviolet light, withstands difficult weather conditions, characterized by strong, up to squall, wind, rainfall and hail.

All reinforced greenhouse film has the following structure: three layers, one of which is reinforced, and the other two serve for light stabilization

Reinforced foil, reinforced PE and membrane: material properties

Several types of reinforced films are produced. They differ both in the composition and dimensions of the frame weaving, and in the quality of the deposited polyethylene layers. The frame is made by weaving threads that are created from the following materials:

- fiberglass;

- polyethylene (PE);

- polypropylene.

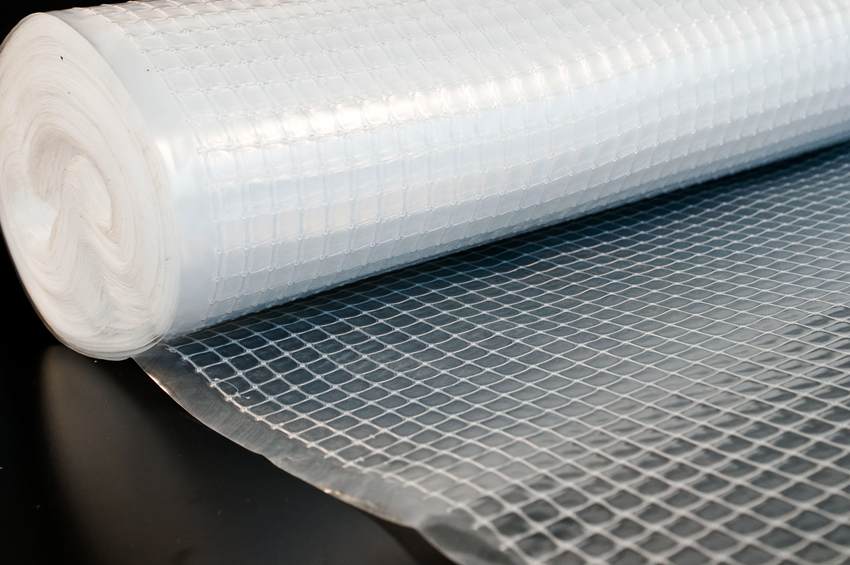

The thickness of the threads is different, which affects the strength and weight of the reinforced film. The cells can also vary in size. A film with large elements is more light-conducting, small sizes increase the strength of the covering material. In gardening, they mainly use a film with a mesh size of 1.5x1.5 cm. This format provides optimal comfortable conditions for plants in greenhouses and hotbeds.

Most of the load that acts on the film is taken up by the reinforced layer, which makes it strong and reliable

Films deposited onto the framework differ in thickness, density and additives that improve the functional characteristics of the material. Additives provide the following properties of greenhouse films:

- Hydrophilic. Prevents the formation of condensation drops on the inner side of the film, which would inevitably fall down onto the plants. Moisture flows down the walls of the greenhouse.

- Antistatic. These additives help repel dust from the outside of the film, preventing the formation of a layer of dirt that will hinder the penetration of light.

- Heat protection. Prevents heat accumulated inside the greenhouse from escaping.

- Light stabilizing. Protect the film from damage caused by sunlight.

There are also membrane films, that is, with microscopic holes in each cell through which air enters the greenhouse - the so-called "breathing" films.

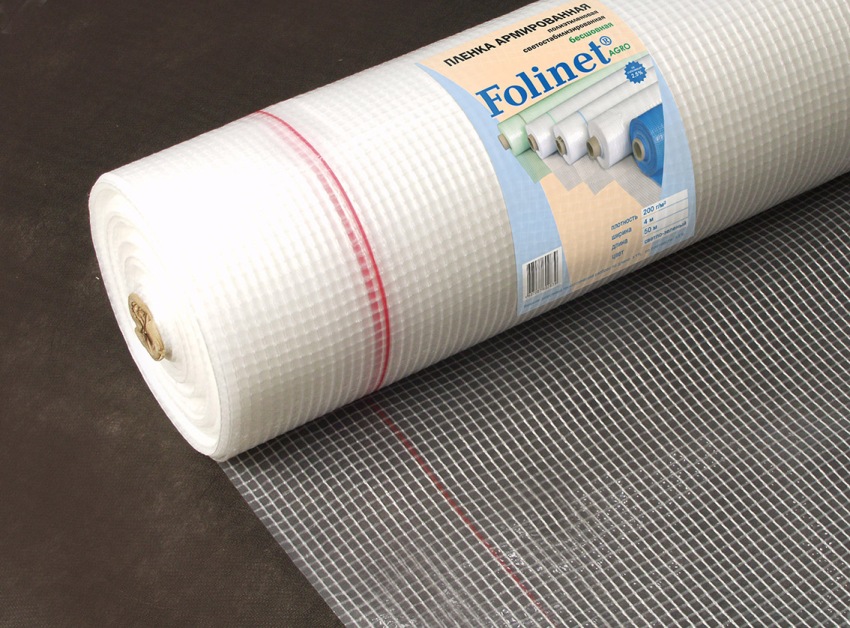

The form of release of the reinforced film is roll. The length of standard bundles is 10, 25 and 50 m.Sometimes there are rolls of 100 m in length.The width of the film can be 2, 3, 4 or 6 m.When winding up into a roll for ease of transportation, a wide fabric is folded: 3-4 meters - in half, the height of the bundles is 1.5 or 2 m, respectively; 6-meter film is folded three times, as a result of which the roll height reaches 2 m. The canvases are hermetically packed, inside there must be a sheet with the characteristics of the goods.

Helpful advice! When buying a roll of reinforced film, it is imperative to pay attention to the integrity of the packaging. If it is damaged, there is a high probability that there are defects in the material itself.

What can reinforce with reinforcing film

The scope of application of reinforced film is extensive. It is used wherever there is a need to build temporary premises, to shelter a structure, materials, objects, openings or plants from precipitation, moisture penetration, winds, low or high temperatures. The main areas where reinforced film is used:

- Industrial and private gardening and horticulture. It is a covering material for greenhouses and greenhouses; temporary vegetable stores, sheds, and silos are constructed from this film.

- Industry and construction. Warehouses of lightweight structures are made of reinforced polyethylene fabric, they are used to cover unfinished objects, equipment in production workshops is preserved, fences are made for temporary dumps, and they are laid on the floor as waterproofing. As a waterproof material, the film is used for roofing work.

- Gen. The film is applicable to protect furniture, electrical equipment and other household items from moisture and low temperatures.It is used in the arrangement of decorative ponds, to protect against the penetration of cold air and moisture into the room through wooden window frames, for waterproofing wooden structures and floorings.

The active use of reinforced film in various areas of production and everyday life is promoted by its elasticity, flexibility and low weight. It is not difficult to fix, dismantle and transport this material; complex and expensive tools are not required to work with the film, and special skills and abilities are not required.

What you need to know when choosing a reinforced film for greenhouses

Before covering the greenhouse with a film, it is necessary to carefully calculate the dimensions of the covering canvas. It is necessary to calculate the folds, bends, taking into account the features of the frame structure. The reinforced film does not stretch, it cannot be pulled even by 1–2 cm.

Pay special attention to color. In order to create optimal conditions for plants, it is better to choose a white film. It traps sunlight least of all (light transmittance - 85%). If we consider that the reinforcement already significantly reduces this indicator, then using green or blue film, you need to be prepared to lower the illumination by another 5-7%. It is possible to purchase a colored coating only if the types of crops for which such conditions are acceptable are planted in the greenhouses.

When using green reinforced greenhouse film, you need to be prepared to reduce light transmission by 80%

For light-loving plants, it is necessary to choose a film with large cells of 1.5x1.5 or 2x2 cm.

A significant indicator is density. The strength of the material, the durability of use and the price depend on it. Traditionally, materials from 120 to 200 md are chosen for greenhouses.

Helpful advice! When purchasing reinforced film for greenhouses, do not rely only on the information (regarding density) placed in the product card of the online store or heard from the sales assistant. Be sure to ask for a product quality certificate, which will indicate the exact data. It is impossible to determine visually and to the touch the density of the reinforced film, and this is often used by unscrupulous sellers.

The main characteristics to look out for when buying a reinforced film:

- cell sizes;

- Colour;

- density;

- the presence of additives that enhance the consumer qualities of the film (hydrophilic, light stabilizing, antistatic).

Reinforced film for greenhouses is presented on the modern market by both domestic and imported products

Often, preference is given to a reinforced film of 200 microns. It belongs to the middle price segment, withstands significant mechanical loads, and is easy to work with. However, you can purchase a reinforced film of 400 microns for the greenhouse. The price of such material is slightly higher - by 3-4% relative to the cost of a film with a density of 200 microns.

If you cut out blanks from the fabric, glue them hot (using a soldering iron or a blowtorch) or cold, using adhesives, you get a cover for the greenhouse made of reinforced 400 micron film, which is convenient to put on the frame at the beginning of the season and remove at the end of it. You don't have to waste time on laying, fixing the canvas, there will be no risk of damaging it during fixing.

Reinforced film for greenhouses: reviews consumers and practitioners advice

Before equipping the greenhouse, it will be useful to get acquainted with the opinions of those who have already used the film. None of the instructions take into account all the subtleties and nuances that arise during practical use.

“Leno film, 170 microns. This year I covered it for the second time. Normally, the light did not get any worse. I have a rectangular greenhouse, I always had problems with the sagging of the canvas.With this it is not so: as it is fixed, it lies - no depressions. "

Semyon, Voronezh

“Rigid mesh film, perfect. True, I had to fix the frame. I cut off the straight lines, and the curvature of the nailed slats immediately began to show through. But now I myself am satisfied: the greenhouse is excellent. The grid refracts the sun's rays, and inside the heat is not hot, but soft, moderate. While cucumbers, lettuce, radishes are developing normally. No wonder I spent money "

Nikolay Fokin, Yaroslavl

“I've heard the opinion that after a year of use, the reinforced mesh remains intact, and the film crumbles. Nothing has been damaged in two seasons, and this cannot happen, unless the net is perforated. I am satisfied with the state of the material, I am sure that for the third season (and maybe more) I will use this film. "

Christina Silina, Belgorod

In a few reviews, users provide advice worth listening to.

Reinforced film for greenhouses, the price of which is in the middle price range, can last from 3 to 6 years

“I have a 200 micron reinforced film in my greenhouse. Strong, for two years absolutely not torn anywhere. The greenhouse is large, almost 30 squares. I made some scotch tape to patch, but I didn't need it. True, he himself made a mistake. The frame is made of wood, and the film was nailed with a furniture stapler. Staples every one and a half centimeters. When I took them off, I made a hole. This is the first year of application. And this season, he put a tape, which is used to pack boxes with heavy equipment, and punched a film through it. It’s safer, and I won’t put holes in it when I shoot. Or you can just put a film of dense polyethylene. "

Alexander, Yaroslavl

The main disadvantages indicated in individual reviews mainly relate to the fragility of use.

“This reinforced film is definitely not worth that much money. When I pulled on the polyethylene, I at least knew it was for a year. And here they promised at least 3 seasons. After the first one, you already want to throw it away! The holes are full, dirty. "

Valery, Gukovo

Related article:

Covering material for beds: a good harvest without unnecessary hassle

Varieties, selection recommendations for different types of soil and plants. Practical benefits and applications. Councils for the selection of trade marks. Examples of exploitation.

“I didn't like the reinforced film. In cloudy weather, the greenhouse is generally gray. And it is not at all durable. There was a strong wind, twigs flew, still without leaves, since it was early spring. We often have dry winds at this time of the year. There are a lot of holes. I can't say that the cells are really empty, but there are many punctures. The density is not the highest - 120 microns, but expected the best. I don't know what will happen until the end of the season. Disappointed. "

Anna, Lipetsk

Opinions, of course, are different, but mostly positive. Based on the reviews (from the experience of practical application), it can be concluded that with proper use, that is, taking into account the characteristics of this material, the reinforced film still confirms the declared qualities and a guaranteed service life of 3–5 years.

Reinforced film in industry: the purpose of building cover tents

Another fairly wide area of application of reinforced film is construction. Having started an object from scratch, it is almost impossible to complete it during the spring-summer period. Stored materials, uncovered premises need protection from autumn precipitation and winter cold. And this function is performed by building awnings.

If there is a need to cover a small amount of building materials or a small room, you can purchase a film and make an awning yourself. The film should be bought with a density of 120 microns.If the awning will be used as a shelter for a short time, the film material can simply be pressed with heavy objects, but always with a smooth surface so as not to damage the polyethylene layer. When covering building materials, the bottom of the awning can be easily pulled off with vinyl packing tape.

Reinforced film is used as a waterproofing agent when performing roofing and facade works, to protect walls and foundations

It is convenient to use construction awnings with eyelets. Ready-made versions are always available with holes that can be easily threaded with a rope or rope. Eyelets can be supplied independently by purchasing them in a specialized store. And if the awning is small and the eyelets are needed small, they can be purchased at the department of the shopping center that sells sewing supplies.

When choosing a building awning, the following factors must be considered:

- intensity and duration of use;

- what weather conditions will affect the material;

- whether the presence of fixing elements is necessary.

Based on the above factors, the density and dimensions of the material are selected.

A balanced approach to the selection will allow you to save money as much as possible and get the expected result.

Reinforced films prices and material manufacturers

The trading network offers reinforced film of imported and domestic production. The main suppliers of film to the Russian market are Korea and China. The assortment is large, the material has various technical characteristics. Korean products are of high quality and appropriate price. Leno film is especially popular. The material has a different density, polyethylene films are produced both with various additives and without them.

Leno reinforced film is produced in Southeast Asia in accordance with the requirements for the quality of this category of materials

Among the Chinese products there is a reinforced film for greenhouses, the price of which is much lower than that of domestic counterparts. Naturally, the material is of low quality. But the product is available to the consumer and therefore in demand.

Among domestic manufacturers, it is worth noting the Zagorsk Experimental Plastics Plant. The products are of high quality. The skeleton thread is made of LDPE monofilament, durable. Films with additives that protect against the damaging effects of ultraviolet radiation are excellent for covering greenhouses. The plant produces canvases of various widths, including wide-format ones - 6 m. Products are protected against counterfeiting by a special type of marking - red threads.

The Stren film, which is produced by the Moscow region company OOO TD Novopolimer, is also competitive. The material is durable, the reinforcing frame is made of polypropylene. Polyethylene layers have enhanced antistatic and lightfast properties. The plant produces films with different mesh sizes, which makes it possible to choose the optimal light transmission capacity.

The price of a reinforcing film largely depends on the density of the material. The larger it is, the higher the cost. Usually the price of this product is indicated per roll, less often - per linear meter. In some cases, the price of the reinforced film per m² is negotiated.

Let's take for comparison the prices indicated by the trading companies. Reinforced film STRONG 120/2/25, cost - 26 rubles / r. m. Another type of fabric of Russian production: LLC "Liantrade", reinforced film 200 md, price - 53 rubles. per m².

Comparing prices, we can conclude that an increase in density by 80 g / m22 almost triples the price. The cost of Korean-made analogues is 3-7% higher. Products made in China and belonging to the economy class have a price 10-15% lower than the cost of domestic films with the same characteristics.

Helpful advice! When purchasing reinforced film from any manufacturer, read the product information on the package. If there is no data, the product is not certified, and it is better to refuse this.

Tarpaulin fabric manufacturing technology

Relatively recently, a new type of covering material has appeared - tarpaulin. The word "tarpaulin" is translated from English as "tarpaulin". It is made of polyethylene. The production process resembles the technology of fabric production. Threads are intertwined, only not natural, but from fused polypropylene. The threads form a dense base, which is laminated with opaque polyethylene on both sides. The result is a material that in many respects surpasses the performance characteristics used for covering tarpaulin and polyethylene. This is an imported material, it is produced in Turkey, China, Korea, Poland and other countries. The price of tarpaulin is much lower than the cost of domestic covering materials.

The fabric has a pleasant blue or green color and has a number of high quality characteristics:

- lightweight, much lighter than tarpaulin;

- hydro and vapor tight;

- tear-resistant;

- elastic;

- resistant to ultraviolet light;

- has a low cost.

The raw material for the production of tarpaulin is polyethylene, its elongated ribbons are tightly intertwined, and then laminated on both sides

Tarpaulin was originally used in road works. But almost immediately, the scope of its application expanded significantly: they began to make awnings from fabric. To date, there is no worthy alternative and competition for this covering material.

Tarpaulin construction awnings: application without restrictions

The main qualities of this covering material make it possible to use it for various industrial, commercial and domestic purposes.

Tarpaulin has different densities. The minimum is 50 g / m². Sugar bags are made from this fabric. Tarpaulin is used for the manufacture of awnings, the density of which is 65 g / m² and higher.

The elasticity of the material allows you to cover objects of various configurations. The awning can be installed on the frame - an excellent temporary shelter will appear. If you connect several tents, you get a large canvas with which you can equip a temporary large storage room. The tarpaulin canopy in construction is often used to create canopies, as well as to protect cargo during transportation.

Due to its elasticity, tarpaulin can be used to cover construction objects of various configurations

Helpful advice! Tarpaulin, which has a density of less than 120 g / m², should not be chosen as a canvas for covering building materials. Friction against a hard surface is inevitable in this case, and this can significantly reduce the life of the tarpaulin.

The edges of tarpaulin awnings are always additionally reinforced by means of a polypropylene tape soldered inside. Eyelets are inserted into the dense part of the awning (along the edge) at a distance of 1 m from each other. The extreme corner eyelets, which bear the maximum load, have additional plastic inserts.

The sizes of construction awnings can be very different. With small parameters, a low density fabric is most often used. For example, a building awning 2x3 m is made of a material whose density is 65-100 g / m². It is usually produced without eyelets and has a budget price. This is a popular shelter option for a short time. In addition to its direct purpose, the awning can be used in everyday life, during hiking, fishing, where it will function as a tent or shed.

Tarpaulin awnings have a low cost, light weight and strong structure, and they can also be used at temperatures from -40 ° C to + 80 ° C

With dimensions 4 × 5 m, the building tarpaulin already has eyelets and is made of a denser fabric (from 75 g / m² and above). Although there are also economy options with thin fabric.With significant dimensions of the canvas (100 m² and more), a reinforced film is used, the density of which starts from 170 g / m².

Tarpaulin tent: reviews positive and negative

The versatility of tarpaulin awnings has generated a significant number of reviews. Quality, cost, appearance are evaluated. As for the price, here everyone has the right to choose. Almost everyone evaluates the appearance as visually pleasing and aesthetic. There are different opinions on quality issues.

“From the point of view of water-repellent properties, this awning is not bad. If fixed well, no dirt will penetrate. But I'll argue about the strength. It does not tear, but it is easy to make a hole. I accidentally, without even exerting force, pierced the tent with a spatula. Of course, the defect was quickly eliminated, a patch was applied, but there is a fact of damage. "

Sergey Serenkiy, Maykop

“The impression is that the eyelets are held on to nothing. On the first trip, two escaped. And most importantly, you cannot replace them with the same ones, you need larger ones. And I haven't even met such people. There is nothing to replace, I'm starting to get used to the holes. Maybe someone will tell you where to look? "

Andrey, Volgograd

“An excellent awning, lightweight, durable, I use it myself, and give it to everyone who asks. I chose dense, 180 microns. I was looking for the eyelets to be metal, not plastic. Two of them have already been lost. The problem is small, it covers everything the same quality, it keeps well, but, probably, the marriage was allowed when installing these rings. I even thought about returning the goods. "

Oleg Steiko, Perm

Poorly inserted eyelets are a problem that occurs quite often in reviews. The bulk of the opinions are positive.

“Lightweight, I am the only one to cope with the dimensions of 5x8 m. I use it for six months, there are no defects anywhere yet. I heard that you need to hold less in the sun, I take off and fold when not needed. "

Evgeny Simonenko, Yekaterinburg

“When they made such a thin roof over my unfinished house, I was skeptical. But the builders were confident in the correctness of their actions, and I just watched in silence. Moreover, they connected the blue awnings together, made one of the two, a ring into a ring. The first time I resorted to check after every rain. Even these torpoulin tents survived the snow. Now I'm joking that I want to live under this blue sky.

Elena Postnikova, town of Yelets.

There are few conflicting reviews about tarpaulin. As a disadvantage, weak eyelets dominate. As a virtue, users highlight lightness, a variety of sizes, price and reliability of protection from precipitation.

Reinforcing film: additional information for discerning buyers

Sometimes it can be difficult to understand the quality of a product. You get convincing information from the seller, you buy the product, and it breaks, breaks, breaks down much earlier than the warranty period expires.

When buying a reinforced film, it is important to pay attention to its color; for use in greenhouses, the material must be white

When buying a reinforced film for greenhouses, the pitfall can be the use for the manufacture of not primary, but secondary raw materials. How can you find out? You need to understand this issue yourself: no sales manager will share such information, even if he owns it. Don't be tempted to buy a cheap product unless it is marked on it as an economy offer. Read the information about the film carefully.

Be sure to familiarize yourself with the manufacturer's information (address and phone numbers), product dimensions, technical specifications, including a description of the composition, density and other characteristics, taking into account additives.If, according to the information, it was not possible to get a complete picture of the product, it is most likely not certified, therefore, you can forget about quality guarantees.

For those who plan to buy a tarpaulin awning, it will be useful to have the following information. When cutting fabrics for the manufacture of an awning, two technologies are used, more precisely, two measurements of sizes. The first option is when the final size is the official one, that is, if the parameters of the finished product are indicated. These awnings are sold under the Tarpix brand.

Density is one of the most important parameters to pay attention to when choosing a reinforced film.

The second type of designation of official dimensions is according to the cutting of the canvas, i.e. the size of the blanks is indicated on the tent. Naturally, the canvas is bent, part goes to the seams. These are Tarpaulin tents. If you bought material with dimensions of 3x4 m, but it turned out that the sides are 20 cm smaller, this is not a deception - this is such a designation method. It is recommended to take into account the difference in size before purchasing the product.

You can list the positive characteristics and disadvantages of waterproof and vapor barrier reinforced film. You can talk about quality and disagree with the methods of designating sizes, prefer imported or domestic goods. But two indisputable advantages of the reinforced film cannot be denied: a reliable shelter is obtained from it, and the process of laying the material itself becomes much easier.