Balusters are important architectural elements of the staircase that act as a vertical support for the railing. Products have a number of technological production features. The aesthetically pleasing wood balusters have many variations and design features. Products are produced from different types of wood. Self-production is possible.

Content

Balusters for stairs made of wood: description and purpose

The respective products are designed to fulfill a number of important functions. Among them, it is necessary to highlight the safety of using stairs, as well as ensuring the structure with reliability and additional rigidity. The attractive wooden stair rail is both decorative and supporting.

The aesthetics of wooden balusters is used not only for creating stairs, but also for decorating handrails

Product advantages:

- attractiveness and energy of natural material;

- environmental friendliness;

- great combination with various materials, accessories and styles;

- wide range of models;

- durability and strength.

A very important advantage is that the do-it-yourself baluster is a reality. By making your own stair racks, you can significantly reduce repair costs. These products have a stunning appearance. Their sophistication can envy analogues from other materials.

In addition, the environmental safety of natural materials is very important. Wood is not capable of emitting substances harmful to the human body and the environment. Essential oils and natural resins, which are part of the material, also have a healing effect. Balusters from the most valuable varieties of wood look very attractive on the photo, which, moreover, are harmoniously combined with other decorative elements in the interior of the room.

Balusters can be made from oak, beech and ash. The most accessible and easy to use are pine, birch and larch. The presence of minimal experience with wood will allow you to create the perfect balusters, which also have an original design.

You can create balusters yourself and you will need special tools and basic woodworking skills for this

What are balusters: product classification

Balusters serve as stair racks. As for the types of the respective products, they differ in production technology. Photo of wooden balusters available to consumers allows you to determine the most attractive types of products.

Varieties of products by manufacturing method:

- milling;

- chiseled;

- with thread elements.

Each option has specific features. For the production of balusters, certain types of devices are used. This is the main difference.

The main difference between milling balusters is the presence of original decorations. We are talking about longitudinal or helical cuts. Such products have a very attractive appearance. Due to this, they are in high demand from consumers. If you have a milling machine and certain skills, such products can be made independently.

A conventional lathe is used to make chiseled balusters. Such a device is at the disposal of many. In most cases, turned products are in the form of rotating bodies. Elegant appearance and ease of manufacture are the main positive aspects of this type of baluster.

Products with carved elements are much more expensive than the previous two options. They are characterized by a more complex manufacturing process. As a result, they look as solid and original as possible. Carved balusters can be made only on specialized machines. Such multi-axis devices require special skills and at least a little experience from the master.

Thread types:

- sculptural;

- deaf;

- openwork.

You can carve real paintings using sculptural carvings on wood products. Such balusters look very bright and unusual. With blind threads, the background is very important. It is present in any images and patterns. Openwork thread is mainly used for flat workpieces. More often, such products are used as decoration for various overlay elements.

Wooden balusters: varieties of products

The main feature of balusters is that they can transform any staircase with their appearance. The most inconspicuous designs are also no exception. A significant variety of sections and shapes of such products allows you to select the optimal design.

In shape, balusters are:

- flat;

- round;

- carved.

Popular are flat balusters that are made from plywood or boards. You can choose between one-piece construction or individual products. Various ornaments and patterns can be used to decorate the racks. Even beginners can cope with this task.

Wooden balusters lend themselves well to staining, which not only allows them to be used to create various decorative effects, but also significantly extends the service life

Helpful advice! For classic stairs, it is recommended to select products of a square shape. Strict forms will give the structure and the whole house more solidity. Original decorative recesses are applied to the side parts of such racks.

The simplest option are do-it-yourself round balusters, which have a strict cylindrical shape. The parameters of the section of products vary from 2.5 to 4 cm. For the manufacture of balusters, it is better to select solid wood. As a result, they will be very durable and will serve their owners for a long time.Such racks may well be combined even with metal tubes.

Carved types of balusters are stylish and spectacular. They are often called sculptural. Mostly they are made by hand. Expensive wood is taken as a basis. Therefore, the high price of such products should not surprise consumers.

To decorate stairs in a classic style, you should give preference to simple shapes and natural shades.

Today there is an opportunity to purchase ready-made products and pick up fastenings for balusters and stair posts, which are designed in the same style. They go well together and create a unique staircase look. Finding the optimal baluster is made easier by the fact that it comes in a variety of finishes and colors.

Combined balusters: characteristic features

This type of product is a vertically arranged component elements. Their task is to support the railings, as well as to add rigidity to the existing railings. Such balusters perform not only a decorative function. They also make the ladder safer.

Combined models include not only wood, but also metal areas in their own design. At the same time, they do not look too bulky. The appearance of such supports is very attractive.

Manufacturers can reasonably explain about the reliability, availability, functionality and aesthetic appeal of what these are combined balusters, and also highlight a lot of positive qualities of this type of product. It's about reliability, availability, functionality and aesthetic appeal.

They can be based on a chrome or stainless steel pipe. Its diameter can be 2.5 or 5 cm. Before use, wooden elements must undergo a drying process in a special condensation chamber. The choice of paint and the method of its application is based on the wishes of the consumer.

Related article:

How to calculate the stairs to the second floor: basic calculation parameters.

Types of stairs and their components. How to calculate the stairs to the second floor: the main stages of the calculation. Calculation of rotary and spiral staircases.

What to buy wooden balusters

In order for the staircase to serve its owners for a very long time, all its elements must be created from the same material. Moreover, you need to give preference to the same type of wood.

When choosing balusters, you should focus not only on the shape and appearance, but also on the type of wood from which they are made

Helpful advice! It is best to choose the hardest woods. Oak is one of them. This tree is famous for its strength and nobility. Any products made from it will be able to retain their original appearance and natural characteristics for a very long time.

The most common types of wood:

- oak;

- ash;

- beech;

- Pine;

- larch;

- Birch tree.

If there is a desire to buy wooden balusters, then oak models will immediately attract attention due to the unique dark shade. Oak tolerates temperature extremes and active exposure to moisture without any problems. Over time, products from this type of wood will not experience decay and cracking. An important advantage lies in the fact that oak lends itself easily to various types of processing.

Despite the fact that oak balusters have a number of positive qualities, this type of wood is far from the only one. Ash is also an attractive option. In terms of texture, this tree resembles a valuable species. Ash is characterized by increased resistance to decay and moisture.The structure of this tree is dense and elastic, due to which it is able to withstand even the most severe loads with ease. The price of balusters in a set, depending on their number and technical features, ranges from 5 to 12 thousand rubles.

In terms of processing, beech is very convenient, it is also characterized by attractive external parameters. In terms of durability and strength, this option is not inferior in anything even to oak. By using beech, you can actually make your own ladders from the highest quality wood. Among the negative characteristics of the corresponding material, one can only note the susceptibility to deformation in a too humid environment, as well as a high likelihood of subsequent decay. To extend the life of a ladder, it is necessary to choose carefully dried wood.

Birch is used much less often for the manufacture of these products. Among the main disadvantages of this tree should be highlighted the tendency to rot, severe shrinkage and the formation of cracks. On the other hand, this material is easy to process and has excellent strength parameters. In the future, birch can be painted and polished without problems. The technology of installing balusters and railings in the case of using this type of wood does not face even minimal adjustments.

To create a staircase, you should use elements from one type of wood. Such a technique will allow not only to maintain the design in a single style, but also provide uniform performance characteristics.

Larch is a very common type of wood. A feature of this type of wood is that products made from it become more durable over time. High humidity and warpage are not a problem for this type of wood.

The most budgetary option is pine. Today you can buy balusters for stairs from this type of wood at affordable prices. For one pine baluster, on average, the market will have to pay about 100 rubles. Flat products are somewhat cheaper. Although it is quite possible to make racks yourself. Moreover, using cutting mechanisms, pine is very easy to process.

Helpful advice! For the manufacture of racks, you must carefully select the wood. These should be bars without knots, cracks and other defects. Moreover, they should not be characterized by high humidity. Too dry wood, regardless of its type, will be quite fragile and lose its natural dignity.

For self-production and installation, especially if there are not many skills in working with wood, you should give preference to soft types of wood

Another tip is that it is much easier for beginners to work with inexpensive types of wood. The easiest to handle are birch and pine. Walnut and oak are very expensive, which is why not everyone can afford this luxury. In addition, only experienced professionals can handle them correctly.

Unique wooden stairs with your own hands

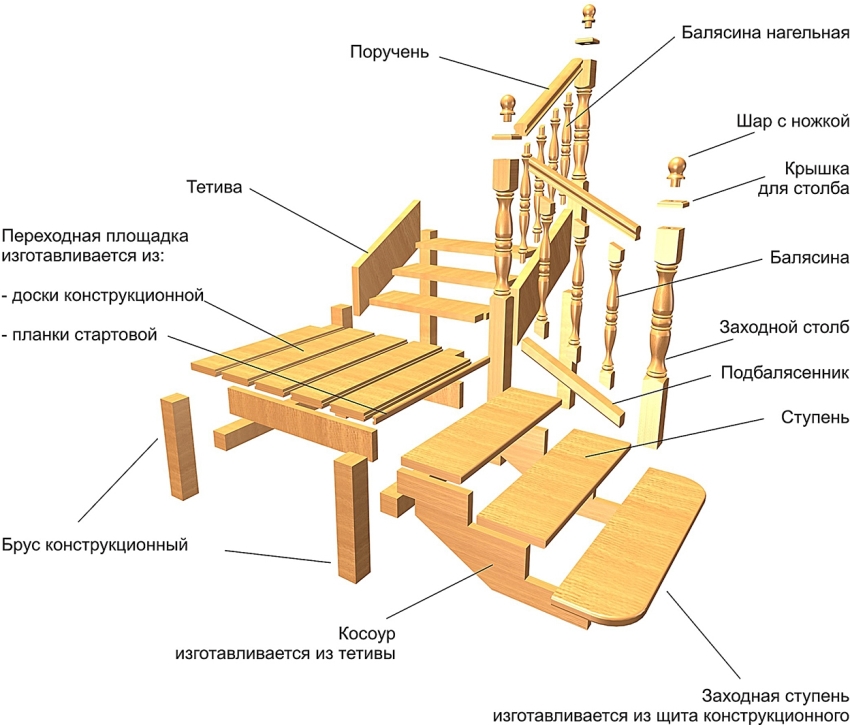

The procedure for creating attractive timber uprights is complex. One of the very first difficulties is finding the right tool. To achieve this goal, you need to demonstrate professional skills, as well as perseverance. First, you should carefully design the future structure, and then proceed directly to turning individual products on the machine.

Stages of creating balusters:

- design;

- execution of drawings;

- search for materials;

- manufacturing.

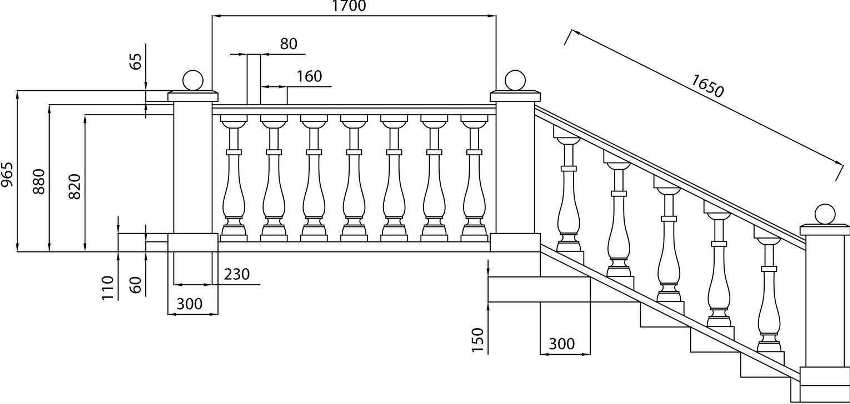

At the design stage, it is imperative to measure the height of the railing. Experts recommend that this parameter varied from 0.7 to 1 m.In order not to miscalculate with the number of racks, you need to calculate the future distance between them.Then it will be easier to install the balusters on the stairs, because all dimensions will be strictly observed.

In the previously created drawing, you must enter the exact dimensions of all slices, as well as bends. Then this data must be transferred to the workpiece of the future support. For convenience, it is recommended to number each applied mark. It is possible that certain decorative elements will require the use of an additional cutting tool.

Correct installation of handrails and balusters of a wooden staircase

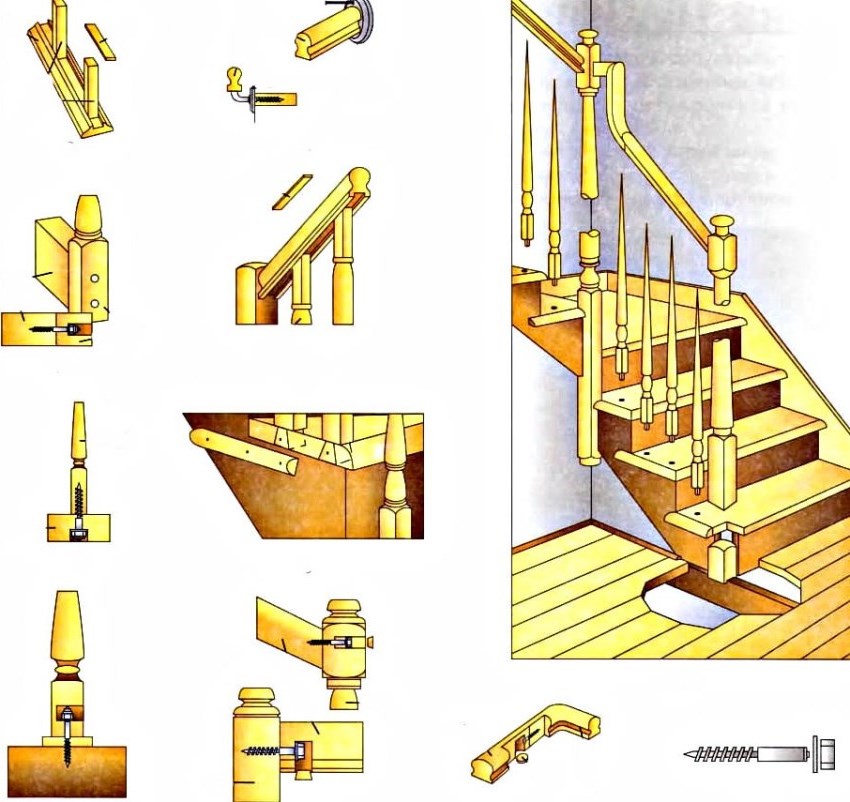

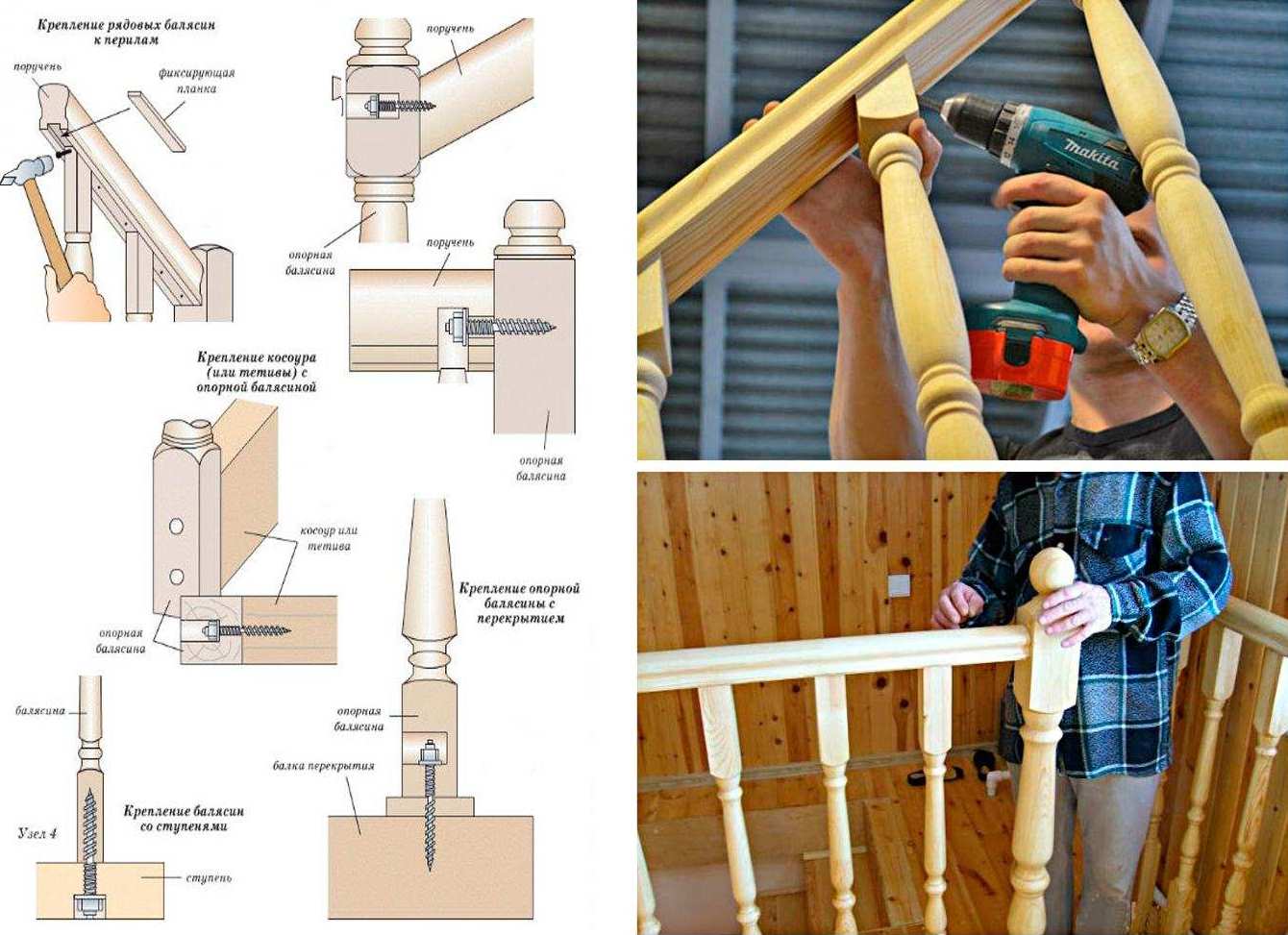

The installation of the described parts can actually be done in several ways. Each of them is effective and complex in its own way.

Baluster mounting types:

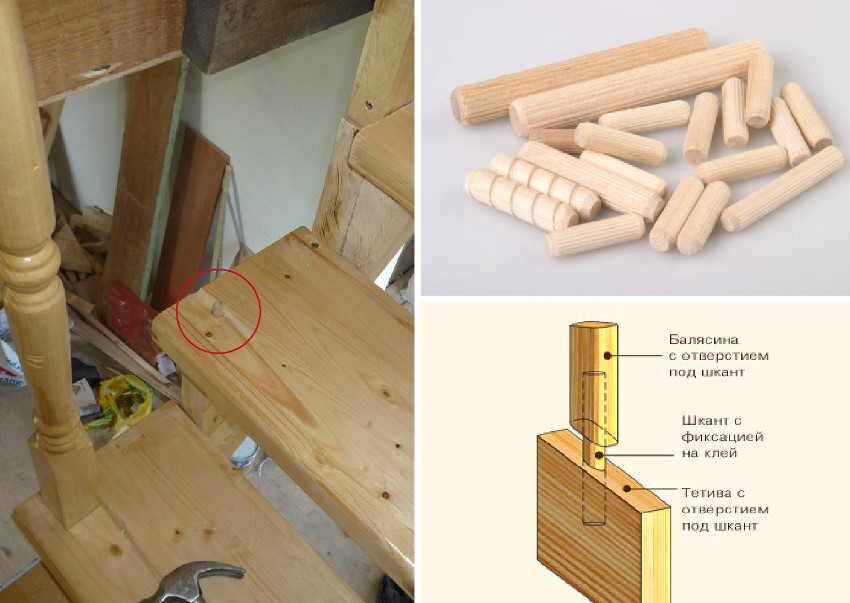

- dowels;

- hairpins;

- spike;

- screws, etc.

Dowel mounting is popular. Original photos of wooden balusters for stairs with such mounts definitely attract the attention of consumers. First, they need to be cut from a specially selected bar. Their cross section should not be less than a quarter of the total rack volume. The dowels should be of impressive length. It usually equals two diameters.

Particular attention should be paid to the main and intermediate support. Special holes should be made in the lower part. Their diameter must necessarily coincide with the same parameter of the dowel. As for the hole depth, it should be half the total length of the product. A similar action is performed on the step, where then it will be necessary to install balusters and railings with your own hands within the framework of generally accepted technology.

Additionally, the dowel is fixed with high-quality glue. In the same way, the rack itself is then mounted on it. The described procedure must be repeated for each baluster, after which the staircase will be significantly transformed. At the moment, it is easy to find a video of installing balusters and railings step by step, from which you can build on during the installation period. Such tips will help even beginners cope with the task at hand.

Features of fastening balusters to studs

It is not difficult to figure out how to fix the balusters on a wooden staircase with studs. In this case, holes must also be drilled on the bottom of the posts. Then durable metal studs are inserted into them, which belong to the wood-wood category. The diameter of each such element is 8 mm and the length is 100 mm. Another 7mm hole is drilled in the bottom step. After that, it will be quite easy to screw the baluster into it along with the hairpin.

A similar method of attaching the railing to the balusters provides that, as a result of removing the rack, the pin would remain on the lower tread. At each pre-marked place, you need to prepare a hole for the stud. The drill should be 5 mm in diameter. All elements must be placed exclusively vertically. It is necessary to check the corresponding parameter using a level. If necessary, the height of the placement of individual elements must be adjusted.

Fastening balusters to a spike: highlights and tips

There is also a fastening of balusters and railings made of wood on a thorn. This method provides that even at the stage of manufacturing the racks, a special wood spike is installed in their lower part. At the same time, a hole is already being formed in the upper part of the product for the handrail spike.

Each mounting location must be marked on the support surface. Such marks will help even beginners figure out how to fix the balusters, because the holes must be made strictly at the points marked in advance. Then they gradually expand to the desired size. The spike of the support pillar should be properly lubricated with glue. Only after that it must be inserted all the way into the hole.This procedure is repeated for each structural element.

Not only the reliability of the staircase depends on the quality of installation, but also the overall appearance

Using self-tapping screws and screws to secure the balusters

This mounting method is universal. Self-tapping screws allow you to securely attach the balusters to the floor, bowstring and steps. The screws are equally effective at securing both wood and metal products. In addition to the direct fixation method, this method provides for the use of a base plate or a support plate.

Helpful advice! To increase the level of reliability of the elements, you can duplicate each connection using self-tapping screws. This must be done precisely from the end side of the step. It is best to immerse self-tapping screws just below the surface of the board itself. Each recess must subsequently be covered with plugs.

In the end, it should be noted that carved wooden balusters, the price of which can vary significantly, are an excellent solution for a house with a staircase. The minimum cost of products can be 600-800 rubles. The maximum price reaches the level of 4-5 thousand rubles. Much depends on the size and material of the product.

The cost of balusters depends on the material of manufacture, the method of processing and the type of coating

If you purchase these elements, then you need to focus on certain criteria. This primarily concerns the materials of manufacture. As mentioned above, the most affordable option in the corresponding plan is birch and pine. Although these wood species have certain disadvantages.

The shape and type of the baluster is important. Not only the overall appearance of the structure depends on this, but also its strength and durability. For example, products with a circular cross-section are more resistant to loads than flat counterparts. At the same time, the second option is very popular among consumers due to its aesthetic appeal. It follows from this that the right choice involves finding the golden mean.