In modern construction, the installation of several roof types, different in appearance and design. One of the most popular and aesthetic ones is Dutch. The rafter system of a half-hip roof can be performed with either two or four slopes. Let us consider in detail all the features of such a design and methods of self-assembly of a half-hip roof.

Content

Semi-hinged roof for a residential building

All pitched roofs have one thing in common - the presence of an attic space, which, with proper finishing, can be used as a living room. This design allows you to significantly expand the living space without an extension. The semi-hip roof also has excellent technical characteristics: it can withstand powerful wind loads and provides reliable protection of the fronts of the house from precipitation.

Depending on the design features, half-hip roofs are divided into two main types:

- semi-gable gable roof;

- semi-hipped hipped roof.

Photos of houses with a half-hipped roof are presented in large quantities both on specialized sites and on construction forums.

Advantages and disadvantages of a half-hipped roof: photos of beautiful houses

What distinguishes a half-hip roof from a hip roof? At the hip roof, two large slopes are trapezoidal, and the smaller slopes are triangular. In a half-hip roof, everything is arranged a little differently, and the ramp line takes on a broken shape.

The design of such a sloping roof largely depends on the shape of the house itself, the presence or absence of living space in the attic, the type of roofing material that will cover the surface, and even the climatic features of the region.

Moreover, it is the climate that plays a decisive role in creating the structure, because in regions with snowy winters, precipitation will accumulate especially strongly on the surface of the slope, forming a kind of "snow cap". Therefore, for such an area, roofs with a steep slope and minimal overhangs are more relevant. If snow drifts are an irrelevant problem, then the minimum angle of inclination is quite acceptable.

Among the advantages of a half-hip roof are:

- the presence of an additional room that can be used as a residential or attic;

- aesthetic appearance, with the possibility of unusual home decoration by creating an original form of construction;

- reliable protection of the house from the influence of weather conditions: snow, rain, strong wind.

Helpful advice! In order to increase the usable area of the attic, you can use a structure with different slope angles.

Among the disadvantages of a half-hip crumb, it is worth noting:

- the presence of certain difficulties in the construction process: a large number of ribs, struts and stops makes the construction of the rafter system a long and laborious process;

- in the process of building such a rather complex structure, not only more forces are consumed, but also materials;

- the process of installing roofing also takes on some difficulties.

But, despite the shortcomings, houses with a half-hipped roof look unique. All the difficulties and expenses are worth giving the roof an original and memorable appearance. If you are not afraid of the complex installation of the rafter system, you can safely get down to work. Among the photos of private houses, half-hip roofs are quite common, so it will not be difficult to choose the option you like.

Mansard semi-hip roof

A mansard roof means a structure that has two vertices, in the form of cut triangles. If the house is square, then the roof will be pyramidal. This type of roof has increased strength. On rectangular houses, the mansard roof has two triangular sides and two trapezoidal ones. The slopes are located at the same slope, which allows them to be mounted symmetrically to the axial beams.

This type of roof has the following advantages and disadvantages:

- increased strength allows this structure to be used in regions with extreme climatic conditions, for example, on the seashore or places where strong winds are characteristic;

- the aesthetic appearance allows such a roof to look appropriate against the background of absolutely any landscape;

- Low profile provides increased roof vibration resistance;

- due to the shape of the structure, certain difficulties may arise with cleaning and repairing the surface;

- the attic space of a half-hip roof can be used to equip living rooms;

- additional forced ventilation needs to be considered, which entails costs.

How the truss system of a half-hip roof is arranged: diagram and photo examples

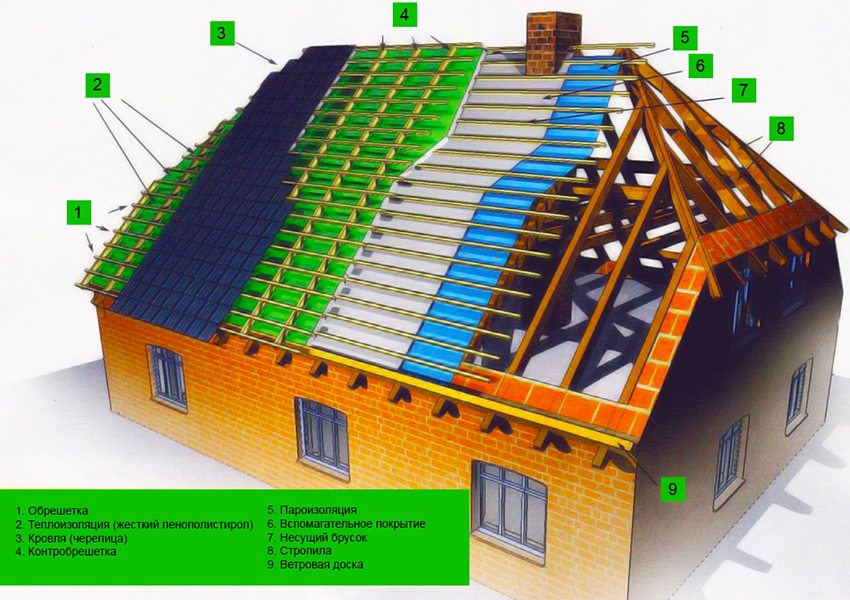

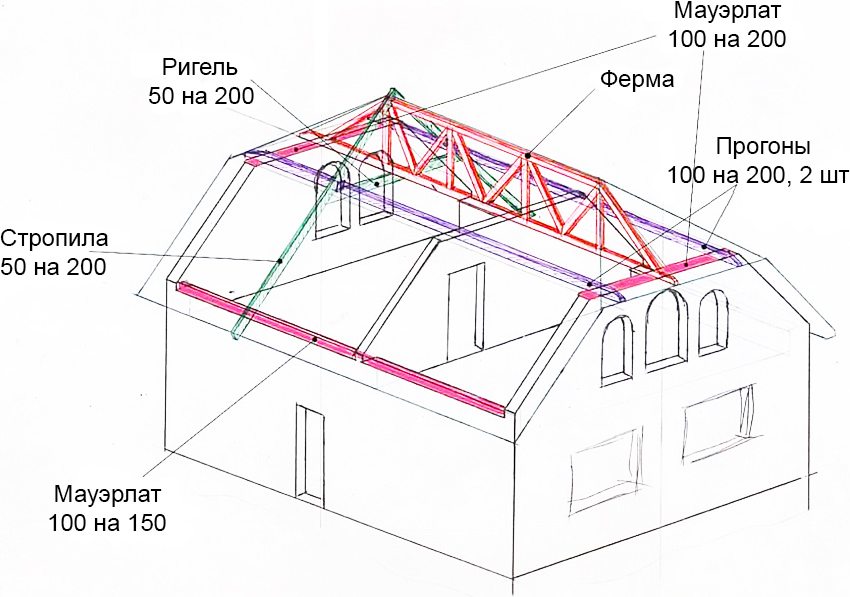

Like any other roof structure, a half-hip roof consists of many layers, which are superimposed one after the other. Among these structural elements are:

- rafter system, which acts as a base for holding all elements;

- Mauerlat - lower support beam for rafters;

- materials providing heat, hydro and vapor insulation of the roof;

- a roof covering that provides mechanical protection.

The rafter system itself also has several constituent elements: a ridge, rafter legs, racks, struts, crate and much more. Each of these elements performs a different function, providing the roof with additional rigidity and strength. This is especially important when creating a semi-hip roof attic.

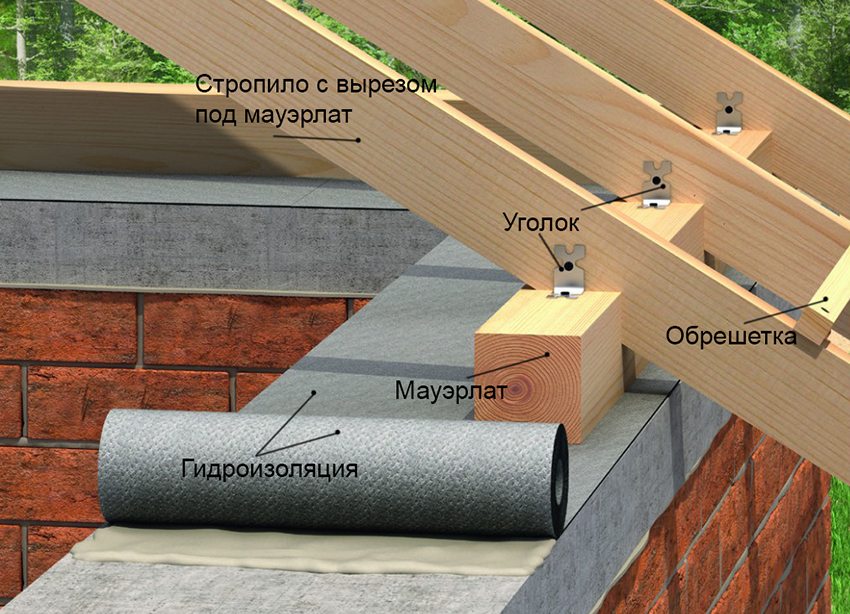

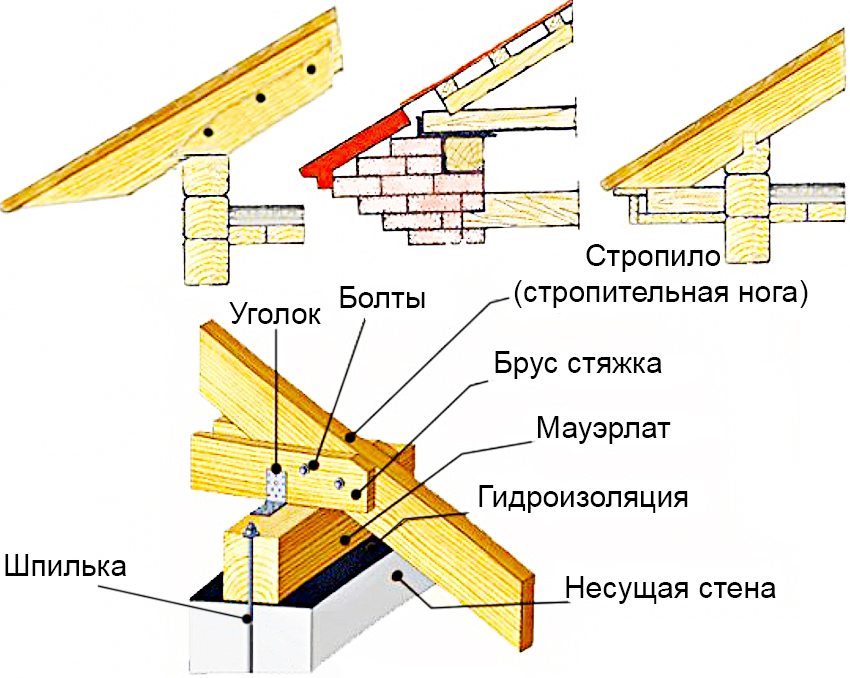

The installation of a half-hip roof should start with laying the Mauerlat on the load-bearing walls of the house. For brick buildings, a reinforced belt is installed, which provides additional strength and evenly distributes the load.At the stage of concreting, vertical studs made of galvanized metal are inserted into it. Mauerlat is attached to the reinforcement by pushing.

Related article:

Do-it-yourself shed roof step by step: installation features. Design advantages and disadvantages. Selection of materials, their preparation and calculation of the quantity. Slope angle. Maintenance of the structure.

The length of the studs must be sufficient to provide a 2–3 cm protrusion from the timber. In this case, the fixing step should be 120 cm. The minimum diameter of the reinforcement used for fastening the beams is 10 mm.

Useful advice! It is worth placing the pins in such a way that they are between the rafters and in the future do not complicate the work process.

To protect the reinforced belt, it is covered with at least two layers of roofing material and only after that the beam is placed on the studs. How to do this can be seen in the drawings. Thanks to this stage, a half-hip roof is more durable.

The selection and installation of the Mauerlat is one of the most important stages of the preparatory work. The cross-section of the timber used for this purpose should be 150 × 150 mm or, in extreme cases, 100 × 150 mm. All the necessary holes are drilled in the ground, after which the wood is treated with specialized antiseptic agents to protect it from moisture and the development of fungi.

Rafter system of a half-hip roof: installation basics

The device of a half-hip roof includes the installation of a ridge, rafters (both oblique and diagonal) and fasteners, for example, metal brackets and special cuttings.

Ideally, the diagonal rafters should be an extension of the ridge, which at the top seems to be divided into two parts and descends to the corners of the house. The rafters are also attached to the diagonal rafters, which forces these elements to take on all the main load and weight of the structure. That is why double boards of 50 × 150 mm are used for their manufacture, thus providing a reinforced base.

This increases the load-bearing capacity of the slant rafters, making it possible to use long whole beams for very large roofs. In addition, the same boards can be used for diagonal and ordinary rafters, which makes it possible to facilitate the work process.

Useful advice! It is better not to fill the space remaining under the ridge with polyurethane foam. This will not disrupt air circulation, and the likelihood of rotting the wooden part of the ridge will significantly decrease.

When the stage of installing the rafters is over, and all the elements are securely fastened to the Mauerlat and the ridge beam, it's time to start installing ordinary rafters. The upper part will rest against the ridge, and the lower part against the Mauerlat. Before starting work, be sure to familiarize yourself with the available projects of houses with a half-hip roof.

Useful advice! The distance between the rafters should take into account the width of the insulation material you will be using.

In order for the structure to be stable, cutouts are made at both ends of the rafters. This allows the elements to be fixed. As an additional fastening, metal brackets and corner plates are used. If the roof of the house is very long, then it is imperative to create additional supports in the form of struts. Truss trusses are used to support the diagonal rafters.

If the floor slab is made of reinforced concrete, then all props and struts can be supported directly on it. Otherwise, it is necessary to install additional tightenings on the floor beams, otherwise the structure of the half-hip roof will turn out to be unreliable.

Useful advice! Before installation, all wooden elements of the roof must be treated not only with an antiseptic that protects the wood from moisture, but also with a fire-fighting liquid.

How to make a half-hip roof with your own hands: calculating the number of rafters and the step between them

In order for the rafter system to turn out to be reliable and to fully function for many years, before starting work, it is necessary to carry out calculations that will become the basis for installation. As an example, you can use a photo of a half-gable gable roof with a house width of 9 meters.

A step is the distance between two rafter legs, and usually for residential country houses this indicator ranges from 0.6-1 m. It depends on many factors, therefore, calculations must be made individually based on your own indicators. Use the following algorithm to calculate the required number of rafters:

- Measure the length of the roof slope and divide by the required pitch factor.

- Then add one to the result obtained, round the resulting number up. This will be the number of rafter legs that are needed to finish one roof slope of a given length.

- If the entire length of the ramp is divided by the resulting integer, then as a result you will get the distance that must be adhered to between the axes of the rafters (this is the step of the rafters).

It is useful to know that although ideally the axis should pass through the center of the rafters, in practice errors are permissible, depending on changes in the slope angle of the surface of the future roof. This is clearly seen in the photo of a half-gable gable roof.

Before starting work, it is necessary to calculate the exact number of beams used based on the project

Consider as an example such a calculation: the length of the roof slope is 16 m. In this case, the step between the rafters will be 0.6 m. Based on the above algorithm, 16 ÷ 0.6 + 1 = 27.66 = 28. This means that for slope 16 m long, we need 28 rafters.

Useful advice! The width of the rafter step directly depends on the angle of inclination of the roof. So, the greater the steepness of the roof, the greater the pitch of the rafters must be maintained. This is due to the fact that the load distribution on steep roofs is uneven, and to a greater extent falls on the load-bearing walls.

As an option, you can use special online calculators for calculations, although it is much better if you have a plan or drawing of a half-hip roof with your own hands, because having a visual example it is much easier to carry out calculations and work.

Installation of a half-hip roof: the final stages of construction

When all the wooden elements are laid and fixed, all that remains is to worry about the heat, steam and waterproofing of the roof. For this, a crate is made, and the selected material is rolled out from above.

It is difficult to say which materials are best to give preference to, but in terms of vapor barrier, aluminum foil will definitely perform its function well. With the help of a construction stapler, the foil is attached to the rafters in such a way that the glossy side faces inward, that is, into the attic.

For insulation, synthetic wool (mineral or stone) is most often used, which is sold in rolls or mats. The insulation is laid out in the gaps between the rafters and covered with a layer of waterproofing. Previously, roofing material was used for this purpose, but today it has given way to a diffusion membrane.

If the space under the roof ridge has not been sealed, then natural ventilation will prevent fungi and mold from developing inside the "pie".

Of course, in terms of installation, a gable half-hipped roof is significantly superior to a hipped roof due to its simpler design and lower installation costs. But in terms of the end result, nothing beats the intricate beauty of a four-pitched roof. Photos of a half-hipped hipped roof demonstrate well the beauty of such a solution.

And with all this, the second option gives much more space for equipping the attic space, which will help to equip the instructions, photos and videos of the half-hip roof rafter system provided on the Internet.

The choice of roofing material for a half-hip roof

The choice of roofing material plays a significant role in creating a beautiful and reliable roof. Let's look at a few of the most popular solutions and how they meet the requirements.

During installation and operation, roofing has to deal with a number of external factors that affect it in different ways. Among them: precipitation, strong winds, "snow caps", exposure to ultraviolet radiation and significant temperatures. The selection of suitable material should be guided by these data.

Asbestos cement sheets, or slate, is an inexpensive and fairly durable roofing material. It has a number of advantages such as fire safety, high resistance to temperature changes, resistance to corrosion and the development of mold and mildew. Slate will never rot or lose its appearance in the sun. Asbestos-cement sheets can be painted to give a more aesthetic appearance and improve technical characteristics.

For a half-hip roof, this material is not suitable for two reasons:

- such an inexpensive coating will not look advantageous on such a complex structure;

- slate is a rather fragile material and its precise cutting will take a lot of time and effort.

Metal tile - also quite affordable material, but much more attractive. Long service life (up to 30 years including maintenance) and excellent technical characteristics have made this coating a leader in its price category. The material is absolutely not afraid of temperature changes or mechanical stress. A wide range of colors on the market allows you to choose a shade for every taste.

The main plus metal tiles - this is its low weight and, accordingly, a small load on the rafter system of a half-hip roof.

Of the shortcomings of this material, one can single out the integrity of the sheets, the cutting of which for a half-hip roof requires a certain skill and dexterity. And, of course, a very low sound insulation rate. After all, we all know the sound of raindrops hitting the metal coating.

Composite roof tiles - one of the subspecies of metal tiles, which are widely sold. Such coverage is more expensive, however, it also has better technical characteristics. Of the shortcomings, only the large weight of the material is noted.

Flexible roof - ideal for a half-hip roof. Bituminous shingles are sold in rolls and can be easily cut into pieces of the desired size. This makes it easy to design areas of high architectural complexity. Among the technical characteristics are:

- low material weight;

- fire resistance and water resistance;

- a huge selection of colors and stylistic solutions;

- resistance to mold and rot.

Ceramic tileis perhaps the oldest of the proposed materials.The roof is laid out from individual elements that have been fired at a very high temperature. It is an environmentally friendly material that is resistant to both high and low temperatures. Undoubtedly, it is this material that has the longest service life - up to 150 years.

Such a coating is excellent for a half-hip roof, subject to the high strength and reliability of the rafter system, since the ceramic tile is very heavy.

Another feature of this material is the fragility of individual elements. However, this is offset by the ease of repair and the ability to replace each individual part.

Wooden covering or shingle... An environmentally friendly and very beautiful option. The constituent elements are small planks made of all kinds of wood - oak, beech, aspen and all kinds of conifers.

Corrugated board... This material owes its popularity to good characteristics combined with an affordable price. The main advantage of such a roof is efficiency, but there are other advantages:

- light weight;

- ease of transportation and stacking;

- long service life;

- resistance to corrosion damage;

- a large selection of shades.

However, like metal tiles, this material is quite noisy in rain and hail. It can also corrode if there is mechanical damage as a result of improper transportation and installation. In addition, the installation of corrugated board on a half-hip roof, like other sheet materials, is complicated by the need to cut out individual elements.

As we can see, creating a half-hipped roof with your own hands, although not an easy one, is quite a feasible task. Having thought over all the steps and gradually following the algorithm, you can give your home an original look, making it even more comfortable and beautiful.