In modern construction, a large number of different roofing materials are used and corrugated board is one of the most popular among them. There are two main characteristics when choosing a material such as corrugated board for a roof: sheet size and price. Each of the types of construction products has its own characteristics that should be considered when purchasing and installing, and the price per sheet depends on a number of factors.

Content

- 1 What is corrugated board and what is its peculiarity

- 2 What to look for when choosing a material

- 3 Types and sizes of corrugated sheets

- 4 Advantages of different types of corrugated board

- 5 Types and characteristics of additional elements for corrugated roofing

- 6 How to mount corrugated board for the roof: sheet dimensions and cost of work

- 7 What determines the price of corrugated roofing: how much does the material for the roof cost?

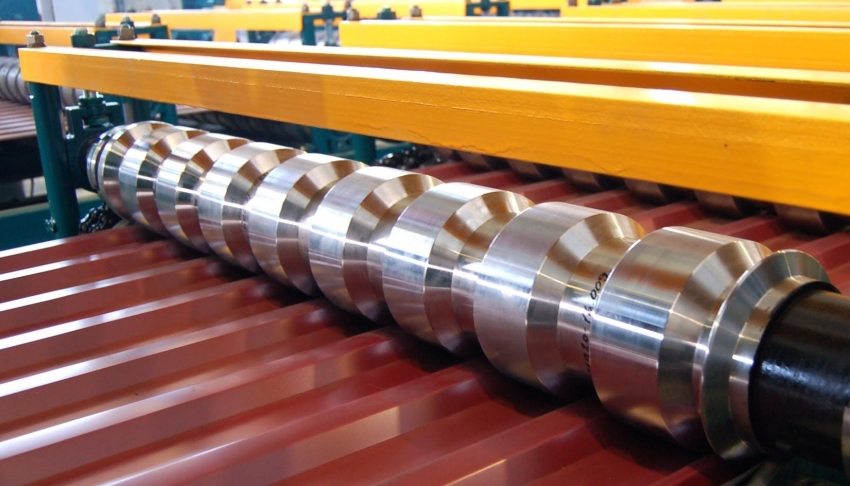

What is corrugated board and what is its peculiarity

Profiled sheeting is a metal profiled sheet that is widely used in many areas of construction. For arranging the roof, only a part of the entire variety of options for this material is used. In addition to a large number of types of corrugated roofing, there are also load-bearing sheets, which are used to create floors between floors, and wall sheets, which are used for external wall decoration.

The main differences between different types of roofing sheeting are in sheet size, corrugation height and type of polymer coating. Among the advantages of corrugated board are the following:

- lightness and compactness - the material is convenient to store and easy to transport;

- the profiled sheet is able to withstand a large load due to the corrugated shape, so it can be successfully used for arranging the roof with a different slope angle;

The corrugated board can be used both for renovation of the coatings of old buildings and for the construction of new structures

- the minimum amount of waste when cutting - the corrugated board is cut exactly to size, which allows you to save money;

- ease of installation - the roof is equipped with this material not only with little effort, but also in a relatively short period of time.

The most optimal in terms of the ratio of cost and quality is galvanized corrugated board for the roof, the prices for which are much lower than for sheets coated with polyvinyl fluoride. However, it boasts high strength and reliability.

What to look for when choosing a material

There are a number of parameters that you should pay attention to when buying corrugated board for the roof. Which is the best option to choose - depends largely on your financial capabilities, as well as on the planned type of roof.In any case, the first thing to look at is the quality of the source material. The sheets should be free of dents, scratches and other visible damage. Low-quality sheets can be noticed even in the package.

The bearing capacity of the sheet is also a very important parameter. Please note that a flat or gable roof will be subject to heavy loads, especially in winter, so the roof sheeting you are going to buy must be quite thick, and the height of the corrugation must be at least 8 mm.

It is also necessary to take into account the dimensions of the corrugated sheet and the prices for them. The size is determined by the parameters of your roof, and the price depends on the type of coating, manufacturer and other characteristics.

Helpful advice! If you do not understand the characteristics of a particular type of material, then you can request detailed information about its characteristics from the manufacturer.

Types and sizes of corrugated sheets

To figure out which corrugated board is better for a certain type of roof, you need to navigate in the main grades of material. All sheets have certain markings:

- C - corrugated board, which is usually used for wall decoration, but can also be used for roofing work. Has average characteristics of corrugation thickness and height. It is not designed for heavy loads, therefore, for roofs it can only be used where there is no risk of a large amount of precipitation;

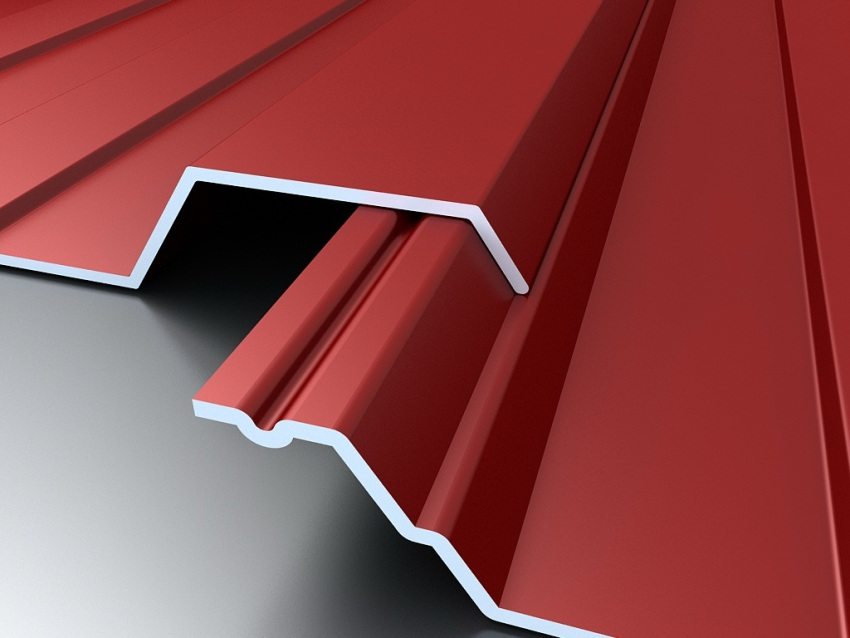

- H - sheets with high load-bearing capacity, best suited for roofing. They are characterized by the maximum thickness and height of the corrugation, and can withstand heavy loads. Some models are specially equipped with additional grooves for maximum strength;

- NS is a universal grade of material that can be used for both wall decoration and roofing. The price for a sheet of corrugated board for roofing is not much higher than that of other options, and the distinguishing characteristics are average strength indicators and a small corrugation height.

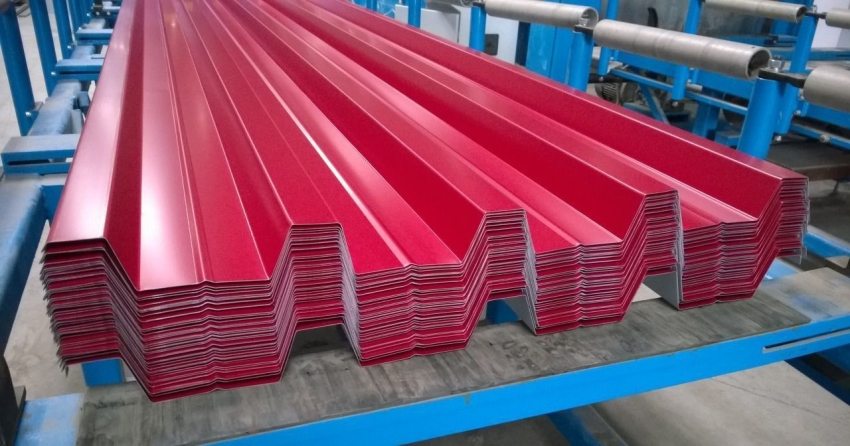

Galvanized roof sheeting: sheet sizes and prices

If we dwell on the dimensions of the sheet of roofing corrugated board and the characteristics of various brands, then it should be noted that the options discussed below are recommended for arranging the roof.

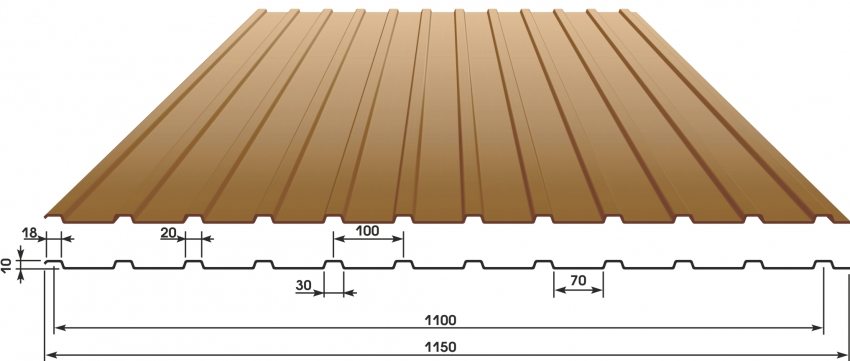

C10 - characterized by a trapezoidal corrugation, used to equip a roof with a sufficiently large angle of inclination. It is most often used for utility and pre-fabricated structures. The profile height is 10 mm, and the dimensions of the corrugated sheet for this type of roof range from 0.5 to 12 m in length and 1.15 m in width. The working width of the sheet is 1.1 m.

C20 and C21 - ribbed sheets that are coated with various types of polymers to protect against negative influences. Compared to the previous version, it is characterized by higher strength indicators, but can also be used on roofs with a large slope angle. The recommended pitch of the lathing for sheets of this type is 80 cm. The dimensions of this type of roofing sheeting are from 0.5 to 12 m in length and 1.05 m in width, and the working width of the sheet is 1 m.

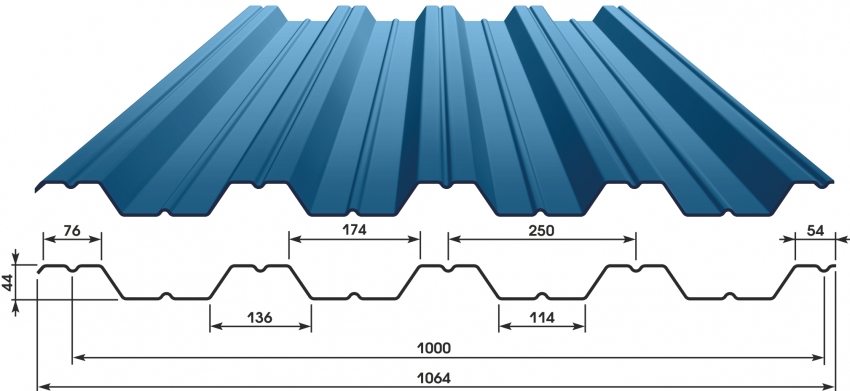

HC35 - sheets with a polymer coating and an additional ribbed surface. They are characterized by increased indicators of strength and tightness, they are used with a lathing step of up to 1.5 m. The recommended angle of inclination of the roof when using this type of corrugated board is from 15 degrees. This type of galvanized roof sheeting also has from 0.5 to 12 m in length, the total sheet width is 1.06 m, and the working width is 1 m.

HC44 - it is also supplied with additional stiffeners and is used as a roof covering at slope angles of 15 degrees.It can be used with a lathing step of 3 meters, which makes it an excellent option for arranging the roof of large buildings. Sheet length from 0.5 to 12 m with a total width of 1.07 m. Working width - 1 m.

H57 - corrugated board with increased strength characteristics, which are given to it by the presence of additional grooves. It has a large profile height, it is used on roofs with a lathing step of 3 m. If you need to buy galvanized corrugated board for roofs of industrial structures or for roofs with increased load, then this is your option. The length of the sheet can be up to 14 m, and the total width is 0.8 m with a working width of 0.75 m.

H60 - a profile with practically identical performance characteristics to the previous version, but with a greater thickness. It also has an increased corrugation size, it can be used for arranging a flat roof with a maximum lathing pitch of 3 m.The maximum sheet length is 14.5 m, the total width is 0.9 m, and the working width is 0.84 m.

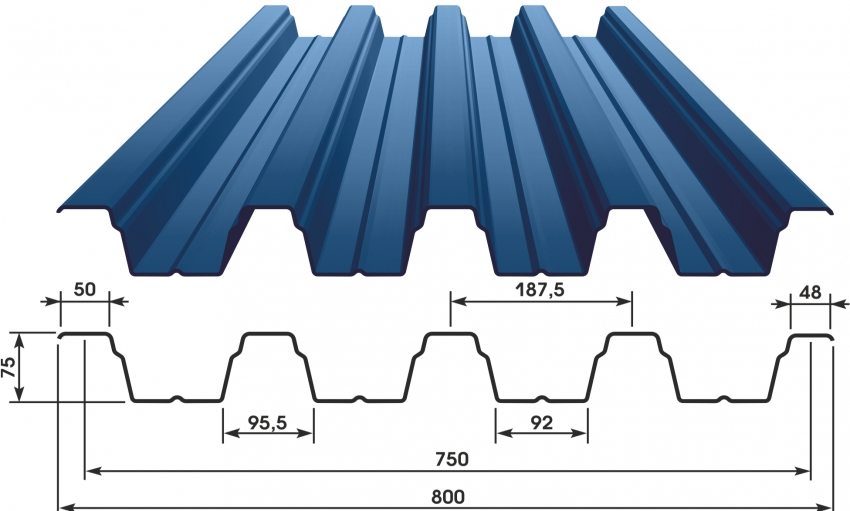

H75 - one of the most durable and reliable roofing options with the maximum profile height. It can be used on the roof with a lathing pitch of up to 4.5 m. At a relatively high sheet price, the dimensions of this type of roofing sheeting are up to 14.5 m in length, and the total and useful width of the sheet is 0.8 and 0.75 m, respectively.

H114 - the most durable and load-resistant version of the roofing sheeting. It has additional stiffeners, the height of the sheet is 114 mm, the length is up to 13 m, the total width is 0.64 m, the working width is 0.6 m. The price for a sheet of corrugated board for a roof of this type corresponds to its operational characteristics, that is, it is located on a fairly high level.

Helpful advice! When choosing one of the above options for roofing, you should also pay attention to such a characteristic as the weight of one square meter of material. Depending on this parameter, it is necessary to calculate the roofing and lathing device.

If you are going to buy corrugated board for the roof, prices per sheet largely depend on the type and thickness of the polymer coating, as well as the thickness of the sheet itself. An example of prices per square meter of material is the following table:

| Profiled sheet type | Type and thickness of the coating, mm | Price RUB / m² |

| C10 | Polyester 0.4 | 281 |

| C20 | Polyester 0.5 | 306 |

| C21 | Polyester 0.7 | 507 |

| HC35 | Galvanized 0.4 | 240 |

| From 10 | Polyester 0.7 | 442 |

As you can see from the table, the price for a sheet of roofing sheeting is directly proportional to the thickness of its coating.

For arranging the roof, you can use some options for wall profiled sheet. For example, according to GOST, the technical characteristics of corrugated board S-8 allow it to be used when arranging a roof with a large angle of inclination. Of course, it is not particularly durable and can only be used if there is a solid sheathing, but there is at least one good reason to buy corrugated board for a roof - the price per square meter of this type. In some cases, the use of a cheap version of the material is justified, although it should not be abused.

Advantages of different types of corrugated board

This material can be classified according to several parameters. Firstly, this is the scope of its application, and secondly, the type of protective coating. According to the first parameter, roofing, bearing and wall profiled sheets are distinguished, but since now we are talking exactly about which corrugated board to choose for the roof, we will consider in detail the types of coverage of this particular type of material.

Galvanized - the simplest and cheapest type of sheet corrosion protection. It is obtained by immersing the material in molten zinc, and the layer thickness is from 25 to 30 mn. Such corrugated board is used for roof construction and restoration work, it does not have high performance characteristics. The main advantage is the low price. The question of where to buy corrugated board for the roof will not be difficult, this type of coating is sold in any specialized hardware store.

Alumozinc - a more reliable coating that protects the roof well from the harmful effects of aggressive chemical environments due to the presence of aluminum in the composition.Sheets with such a coating are perfect for arranging a roof near a highway or in an industrial area where there is a large percentage of corrosive substances in the air. A photo of a roof made of corrugated board of this type shows that this material does not differ in particular variety in terms of design.

Plastisol - organic polymer, the coating of which can have a thickness of up to 200 mn. This allows the polymer-coated corrugated board to withstand mechanical stress without much harm to the integrity of the sheet and its appearance. In addition, the advantages of such a coating include a high level of resistance to negative natural and chemical influences. The weaknesses of plastisol are direct exposure to sunlight, from which it loses color, as well as sudden changes in temperature.

Profiled sheets do not require periodic painting, since the corrugated board is not afraid of sunlight

Polyester - the most common coating option with good performance and attractive appearance.

Pural - polyurethane coating, which has recently appeared on the market. It is characterized by resistance to all kinds of negative influences and a variety of design options.

Polydifluorionad - the most corrosion-resistant option for covering the profiled sheet. Differs in a rich palette of colors that do not fade over time. The disadvantages include a fairly high cost.

Helpful advice! Whichever coating option you choose, it is worth improving the sheet protection performance with a thin layer of varnish and paint. The use of special paints and varnishes and their regular renewal will reduce the likelihood of corrosion to almost zero.

Types and characteristics of additional elements for corrugated roofing

Additional elements are used in the design of corrugated roofing nodes. Such elements serve to protect the joints from water ingress, as well as to give the roof a finished look. The most common options for additional elements are:

- cornice strip - protects the cornice and prevents rainwater from entering the building facade. Attached to the last board of the crate with roofing screws for corrugated board, mounted with an overlap of 10 cm;

- end plate - mounted on the edge of the profile sheet. Installation can be carried out overlapping or exactly to the size of the sheet. The end strips can be fastened with roofing or ridge screws, and this must be done before laying the roofing material;

- gutter bar - installed under the ridge element to make it more attractive;

- the skate is a very important element that protects the upper convergence line of the rays. Always fixed at the top of the sheet wave and additionally sealed with a seal. It is recommended to fill the seams between the elements with a special sealant to ensure reliable protection against moisture ingress;

- snow retention bar - mounted about 30 cm from the cornice, serves to prevent the entire mass of snow from collecting on it;

- cover plates - serve to protect the joints of sheets, are mounted at their joints;

- endova - connects slopes with different angles of inclination, and also acts as a waterproofer.

Most of the additional elements are made of galvanized steel, which can have a polymer coating to match the color of the corrugated board. The price of elements depends on the type and thickness of this coating, and the cheapest option is simple galvanizing.

How to mount corrugated board for the roof: sheet dimensions and cost of work

The dimensions of the sheets of corrugated board can be very diverse and are in the range of 0.8-1.15 m in width and 0.5-14 m in length. Regardless of what sizes of material you have chosen for arranging your roof, their installation is always carried out in the following order:

- the crate is installed. The thickness of the boards used for this depends on the wave height of the sheet, and the step between them depends on its dimensions, as well as the maximum permissible load on the material. For example, if you use a thin C8 corrugated board with a low wave height, then the crate should be solid, and for a strong and heavy H144, the step can be about 4 meters;

- the insulating layer is mounted. For this, several layers of waterproofing material are laid overlapping, which can be an ordinary plastic film or special materials;

- a counter-lattice of wooden bars is installed. It serves to create ventilation, as well as to securely attach the waterproofing layer;

- the type of profiled sheet of your choice is attached to the crate. This is done using special roofing screws;

- in the place of the roof fracture, a valley is mounted. It protects the roof from moisture and is fastened with self-tapping screws with seals.

Helpful advice! In places where sheets are attached, it is recommended to use a special sealant for sealing gaps. This will prevent moisture from penetrating under the sheets of roofing material.

What determines the price of corrugated board for the roof: how much is the material for the roof

When choosing a type of roofing material such as corrugated board, it is important to consider your financial capabilities. The cost of installing a roof based on a profiled sheet depends on factors such as:

- the cost of the material itself;

- the cost of additional materials, for example, waterproofing;

- roof area.

On many specialized sites there are special calculators that allow you to quickly calculate the price for arranging a roof, taking into account these parameters. Remember that there are many options for corrugated boarding. Which is best for the roof of the house in your case - it's up to you to decide.