From this article, you will learn everything you need to know to choose the right roofing materials for the roof: the types and prices of modern coatings, you will be able to fully assess both the disadvantages and strengths of the materials, find out their main characteristics, and get acquainted with the field of application. As a supplement, you will find tips for choosing and using different types of roof coverings.

Content

- 1 Common types of roofing materials for roofs

- 2 Sheet roofing materials for the roof: types and prices

- 2.1 Metal roof tiles: types of materials from different raw materials

- 2.2 Types of metal roof tiles: photos and range of materials

- 2.3 Modern roofing materials for roofs: new varieties of metal tiles

- 2.4 Prices for different types of roof tiles

- 2.5 Decking: types, photo of the roof of the roof of a private house

- 2.6 Scope of the metal profile for the roof and its advantages

- 2.7 Metal profile: prices for roofing material

- 2.8 Ondulin as a roof for a roof: types, price of material

- 2.9 Features and benefits of ondulin

- 2.10 Weaknesses of the ondulin roof

- 2.11 Features of slate as a sheet for roofing

- 2.12 Specificity of installation and properties of slate: disadvantages and advantages

- 3 Seam roofing: types of roofing, roofing materials and prices

- 4 Soft roof for the roof: types of coatings and their characteristics

Common types of roofing materials for roofs

All houses are protected by such a structure as a roof. It can be created on the basis of various materials, which are selected in accordance with roof type and buildings. There are certain types of coatings used exclusively for the roofs of cottages and country houses, others are used to decorate household buildings.

To make the right choice when purchasing roofing material, you first need to decide on the purpose of the building. The range of modern roofing materials is quite extensive and includes the following varieties:

- folded;

- piece;

- leafy;

- bulk (mastic);

- soft.

Note! Each of these types of roofing combines several subspecies.Since the market offers a wide range of coatings, the grouping makes it easier to navigate the range and select products for construction work.

Sheet roofing materials for the roof: types and prices

Metal tile, as one of the most popular types of roofing, has many beneficial advantages. It is beautiful, provides a high indicator of strength, although its operation is accompanied by a certain level of noise. This type of coating is made on the basis of a steel sheet. The raw material can be of different thickness, up to 0.5 mm.

The surface of the finished products is coated with a special varnish that performs a protective function and prevents damage. This point is very important, since strong gusts of wind often bring small pebbles and branches to the roof, which can cause scratches and dents.

Debris striking the roof surface can damage the paint on the coating. In such areas, when moisture enters, corrosion forms, gradually damaging the material and reducing the life of the roof. Thanks to the varnish composition, such a possibility is excluded.

There are soil and aluminum layers under the varnish. The finished product is lightweight, which simplifies transportation and the subsequent installation procedure. The weight of 1 m² of material ranges from 3 to 5 kg, depending on the thickness.

Metal roof tiles: types of materials from different raw materials

In addition to steel sheet, other raw materials can be used for the production of metal tiles, for example, aluminum or copper. In each case, the products acquire special properties due to the material from which they are made.

Galvanized steel sheet is the most common raw material for metal roofing. The final thickness of the products in this case can be 0.45–0.55 mm. In rare cases, this figure reaches 0.6 mm. The zinc coating provides reliable protection of the metal from corrosive effects. Several layers are applied on top to increase strength, including polymer. Steel with aluzinc or zinc can also be used.

Useful advice! For maximum durability, use aluzinc coated material for roofing. Accordingly, the price for this type of coating is much higher.

There is one important advantage in aluminum products - the material does not corrode at all. Despite this, additional coating is applied to the products, but this is done in order to strengthen the metal tile and increase its service life. Aluminum shingles have another advantageous advantage - very light weight. The disadvantages include only a limited color palette and high cost.

Copper sheet tiles have an exquisite and noble appearance. Over time, a plaque characteristic of this raw material forms on the surface of the material in the form of a greenish patina. But it does not reduce the decorative properties of the coating, but, on the contrary, emphasizes them.

Like many architectural monuments, as well as old buildings, metal tiles with a green bloom look quite interesting and attractive. Patina acts as a protection against the adverse effects of external factors, so there is no need to apply additional polymer spraying. The cost of such a coating is quite high, so it is rarely used.

Types of metal roof tiles: photos and range of materials

The classification of metal tiles is based on the geometry inherent in the profiles, as well as the depth of the insole on the products.In each case, the coating offers an interesting and unusual design. Roofs with a Monterrey profile have similar features to clay tiles. This type of coating from Finland very quickly found fans, thanks to its advantages:

- ease;

- aesthetics;

- ease of installation;

- high resistance to natural factors.

Note! The material has a recognizable appearance, since different brands of metal tiles produce products similar to Monterrey with a smoothly rounded profile. The edge part is in the form of steps arranged symmetrically or asymmetrically. It depends on the design and the specific manufacturer.

The metal tile based on the Cascade profile looks like a chocolate bar. It is economical and suitable for roofing complex roofs due to its rectangular shape. The design is neat, proportional and quite strict. Therefore, metal tiles based on the Cascade profile can be considered classic. It is universal and will always remain relevant.

The modern assortment includes products with round sole and ridge parts in a classic design. These characteristics are inherent in metal tiles with the Joker profile, which outwardly resembles a ceramic coating due to its regular waves. This type of roof is considered traditional.

Modern roofing materials for roofs: new varieties of metal tiles

The metal tile based on the Bang profile belongs to the category of new products, since it was recently invented. She has unusual shapes and original external performance. The wave has increased height. Together with the non-standard structure of the profile, a kind of three-dimensional image is created. This type of metal tile is characterized by a small width, but this in no way affects the advantages of the coating. Most often, the material is used to organize the roof on tall buildings.

The new roofing options also include metal tiles with the Andalusian profile shape. It is not yet popular enough among developers and owners of country cottages, nevertheless, this material has enough advantages. The most significant and advantageous of them is the hidden fastening system, which even such a popular tile as Monterrey cannot boast of. Self-tapping screws from the outside do not look aesthetically pleasing and are striking. Andalusia metal tile completely solves this decorative problem.

Note! Due to the tight locking grip, the coating is continuous, due to which the roof acquires increased moisture resistance.

The newest and little-known metal tile is the Shanghai profile roof, which came to our market from China. It has a complex symmetrical pattern. The profile has a height of 66 mm. Often, the same equipment is used for the manufacture of profiled sheets.

Prices for different types of roof tiles

The list of materials under the category "metal tile" does not end there. Previously, only the main varieties in high demand were listed. In fact, there are much more coatings.

Prices for metal tiles of different brands:

| Brand name | Profile type | Price, RUB / m² |

| Grand Line | Classic | from 304 |

| Country | from 450 | |

| Modern | from 209 | |

| Kvinta | from 338 | |

| Ruukki | Finnera | from 660 |

| Monterrey | from 490 | |

| Elite | from 1260 | |

| Adamante | from 815 | |

| Armorium | from 815 | |

| Metal Profile (metal tile standard) | Monterrey | from 345 |

| Surepmonterrey | from 345 | |

| Maxi | from 345 | |

| Standard | from 340 |

Metal tiles as a roofing material are quite durable. Its service life is almost 50 years. The average cost is in the range of 500–1200 rubles / m².

General benefits:

- simple and fast system mounting;

- the presence of only one person is sufficient for installation;

- high strength indicator;

- resistance to mechanical properties;

- light weight and simple transportation system;

- affordable price.

There are not so many disadvantages of the material. During the installation process, a large amount of construction waste is generated, which affects costs. In addition, the products have high sound conductivity.

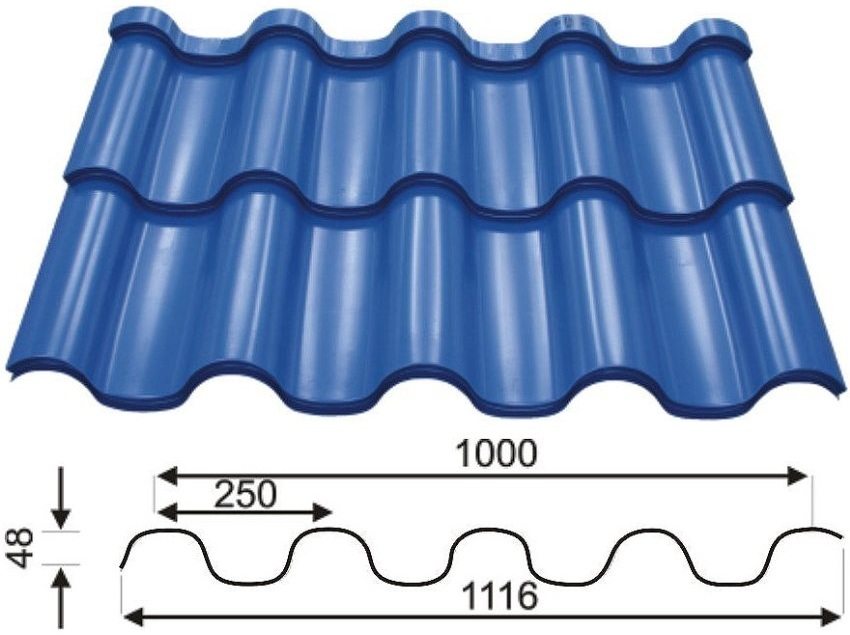

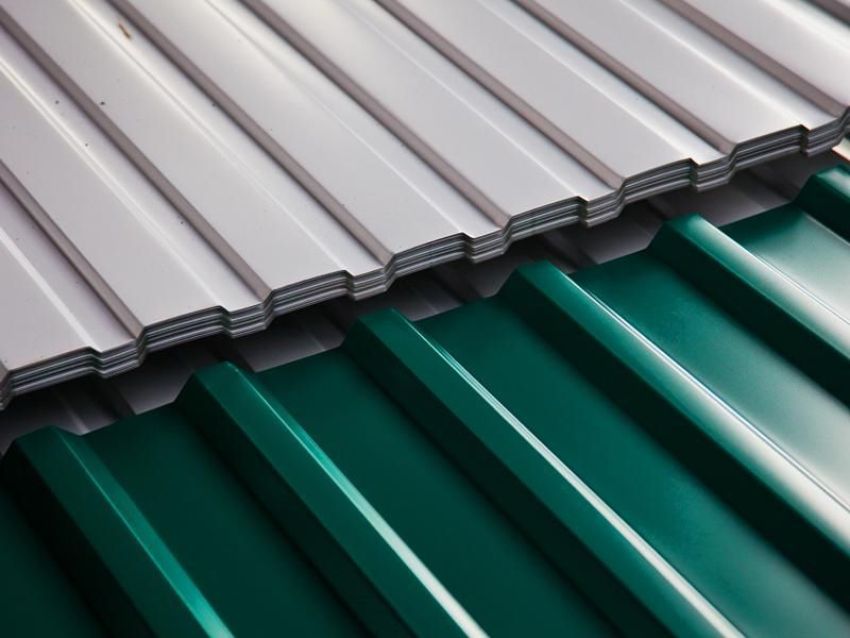

Decking: types, photo of the roof of the roof of a private house

Profiled decking or corrugated sheet is made from the same raw materials as metal tiles. The production uses cold-rolled steel, which is covered with a layer of hot zinc. In some cases, thicker sheets are used that have a wavy or rectangular profile.

Note! The profiled sheet has a wide range of applications. For the organization of the roof, special grades of material are produced: H60, C8, C44, C21, H57, HC35.

On each side, the steel blank is covered with a protective layer of zinc or aluzinc. An interlayer of polymers is used as additional protection. The following forms of profiles are used in the production of corrugated board:

- wave;

- trapezoid;

- rectangle.

Work on the installation of a metal profile is easy enough. But here, too, it is not complete without certain requirements that must be observed. Installation can only be carried out on a surface with a slope of at least 10 °. The maximum allowable slope is unlimited.

The material is overlapped by about 20 cm. Subsequently, this gap will be filled with a sealant. Reliable fixation is carried out by self-tapping screws. Consumption of fasteners per 1 m² is 6–8 pcs. In some cases, the installation of the profiled sheet is carried out over the old roll roofing.

Scope of the metal profile for the roof and its advantages

The profiled sheet belongs to the category of durable and reliable materials, and due to its affordable cost it is quite popular. The scope of application of the metal profile as a roof extends to household buildings, for example, barns, awnings, garages, etc. Often it covers shops, industrial enterprises, car washes. Decking is able to serve for almost 50 years.

To organize the roof, sheets are used in a single color, which can be very diverse.

Note! In production, corrugated board with imitation of stone or wood is produced: a pattern is applied over the steel sheet, then a protective layer of polymers. However, this version of the material is usually used for the construction of fences.

Such a wide range of applications is explained by a large list of advantageous characteristics and advantages of the material:

- high resistance to corrosion;

- durability;

- simple installation system;

- high degree of strength;

- the ability to maintain its appearance throughout the entire operational period;

- resistance to weather changes;

- low weight of the roof, which eliminates the need to strengthen the load-bearing part of the building;

- resistance to the effects of physical properties (mechanical and deformation damage).

Metal profile: prices for roofing material

Just like metal tiles, profiled sheets are classified as noisy roofs. Therefore, you will definitely need to perform high-quality sound insulation. The rest of the material does not have serious drawbacks.

Prices for the purchase of a metal profile:

| Brand name | Name of product | Price, RUB / m² |

| Interprofile | C8 | 376 |

| Roof 4 seasons (polyester covering) | C8 | 240 |

| C21 | 275 | |

| Roofing 4 seasons (print covering) | C8 | 558 |

| C21 | 669 | |

| Grand Line (Atlas coverage) | C8 | 436 |

| C21 | 497 | |

| H60 | 580 | |

| CH35 | 496 | |

| Grand Line (Velur coating) | C8 | 450 |

| C21 | 514 | |

| H60 | 599 | |

| CH35 | 513 | |

| Grand Line (Cover Print) | C8 | 578 |

| C21 | 659 | |

| H60 | 769 | |

| CH35 | 658 |

Ondulin as a roof for a roof: types, price of material

Ondulin is one of the materials related to the sheet type of roofing. This coating is popular with consumers due to its naturalness and affordable cost. The material is created on the basis of fine cellulose fibers, which are impregnated with polymer additives and bitumen.

Note! Ondulin has other names that are used in the construction market: aqualin or euro slate.

The coating is painted with polymer paint, which is resistant to temperature effects. Ondulin is on sale with one-layer and two-layer staining. The standard sheet weight is 6.5 kg. The workpieces are made in the form of waves, the height of which reaches 36 mm. Sheets 2 m long have a width of 0.96 m. These parameters are considered standard, but there are other sizes, for example, 0.76x1.95 m.

Average prices for the purchase of ondulin:

| Manufacturer country | Name of product | Price, rub / piece |

| Ondulin (Russia) | Green leaf | 328 |

| Leaf red | 331 | |

| Leaf brown | 331 | |

| Ridge element brown | 308 | |

| Ridge element red | 308 | |

| Ridge element green | 321 | |

| Nail brown, green (pack of 100 pcs.) | 140 | |

| Ondulin (France) | Green leaf | 455 |

| Leaf red | 437 | |

| Leaf brown | 437 | |

| Zinc sheet | 370 | |

| Ridge element red | 288 | |

| Ridge element green | 299 | |

| Ridge element brown | 288 | |

| Ridge element black | 288 | |

| Red, brown, green nail (pack of 100 pcs.) | 139 |

When buying ondulin, color is important. The final cost of the material depends on the color of the sheets and other elements for the roof.

Related article:

Ondulin: price per sheet, dimensions and properties of a soft roof. Euroslate properties. Material specifications. Price per sheet of ondulin SMART. How much is ondulin shingles? Features of installation.

Features and benefits of ondulin

Ondulin is used to organize roofing in garages, sheds and baths... Due to its increased flexibility, this material is optimal for the formation of complex roofs. The characteristics of ondulin will also come in handy when repairing an old roof.

When working with ondulin, it is very important to comply with the installation requirements:

- the minimum angle of inclination of the working surface is 6 °;

- the angle of inclination does not exceed 10 ° - the crate is made with a solid structure;

- tilt angle 10-15 ° - lathing on the basis of a bar, installation of elements with a step of 45 cm;

- the angle of inclination exceeds 15 ° - lathing with a step of 60 cm.

Useful advice! When installing ondulin, be sure to use special nails. They will not only provide high-quality fixation, but will also be invisible against the background of the roof, if you choose the corresponding colors of the fasteners for the sheets.

The advantages of roofing material:

- high rate of water resistance;

- ecological cleanliness, safety and hygiene;

- resistance to aggressive chemicals;

- the ability to withstand a high level of loads (almost 960 kg / m², provided that all installation rules are observed);

- light weight;

- simple installation and transportation system;

- easy to process (easy to cut even with a hacksaw designed for working with wood);

- complete noiselessness;

- democratic prices.

Weaknesses of the ondulin roof

In terms of water resistance, ondulin can effectively serve for 40 years. During this period, the appearance of the coating may deteriorate, since the paint fades before the material completely becomes unusable.

Disadvantages of coverage:

- paint on the surface is prone to fading;

- low flammability limit (only 110 ° С);

- if the coating is under low light, moss grows on top of it after 2-3 years;

- in the heat it is impossible to carry out work on the roof; under the influence of temperature, the coating exudes a strong smell of bitumen and softens.

There is another type of material on the market - onduvilla. It has similar features and characteristics with ondulin, but at the same time it has a higher decorative effect and an expanded size range. Onduvilla leaves have a smaller width.

Features of slate as a sheet for roofing

Slate is one of the most affordable roofing coatings. Sheets of this material are 85% Portland cement and 15% asbestos.

Standard sheet parameters:

- weight - 10-15 kg;

- length - 1.75 m;

- width - 0.98–1.13 m;

- number of waves - 6 pcs., 7 pcs. or 8 pcs.

Slate is used as a roof covering for outdoor bathrooms, baths, outbuildings and sheds.

Note! This type of material can also be used in the construction of private houses. As a rule, it is applied if the budget for the construction of the building is limited.

Average cost of slate:

| Number of waves on a sheet, pcs. | Sheet thickness, mm | Price, rub / piece |

| 8 | 5,2 | 186 |

| 8 | 5,8 | 222 |

| 8 (color) | 5,2 | 274 |

| 7 | 5,2 | 190 |

| 7 | 5,8 | 213 |

| 7 (color) | 5,2 | 262 |

Colored types of slate look more attractive and aesthetically pleasing, but their cost is much higher than that of conventional sheet material.

Specificity of installation and properties of slate: disadvantages and advantages

Installation work on laying slate is carried out strictly on an inclined surface. The permissible tilt angle is between 12 ° and 60 °. The sheets are overlapped by about 1–2 waves.

For ordinary slate, a crate made of a square bar with a cross-section of 50 mm is suitable. Structural elements are laid in increments of 0.5-0.55 m. If a material with a reinforced profile was purchased, a more reliable crate should be made. To do this, you need to take bars with a cross-sectional size of 75 mm and increase the step of their installation to 0.75-0.8 m.

To install the slate, a special lining made of glassine or roofing material is pre-laid on the roof. A soft underlay should also be laid under each fastener (nail).

Coating advantages:

- low cost;

- ease of processing (cutting of the material can be performed using a grinder);

- absolute incombustibility.

The effective service life of slate covers a period of 30-40 years.

Negative sides of using slate:

- fragile structure;

- one of the constituents of the material is asbestos, which is a source of danger to human health;

- a high level of hygroscopicity provokes the accumulation of moisture in the sheets, which is why moss begins to grow on their surface.

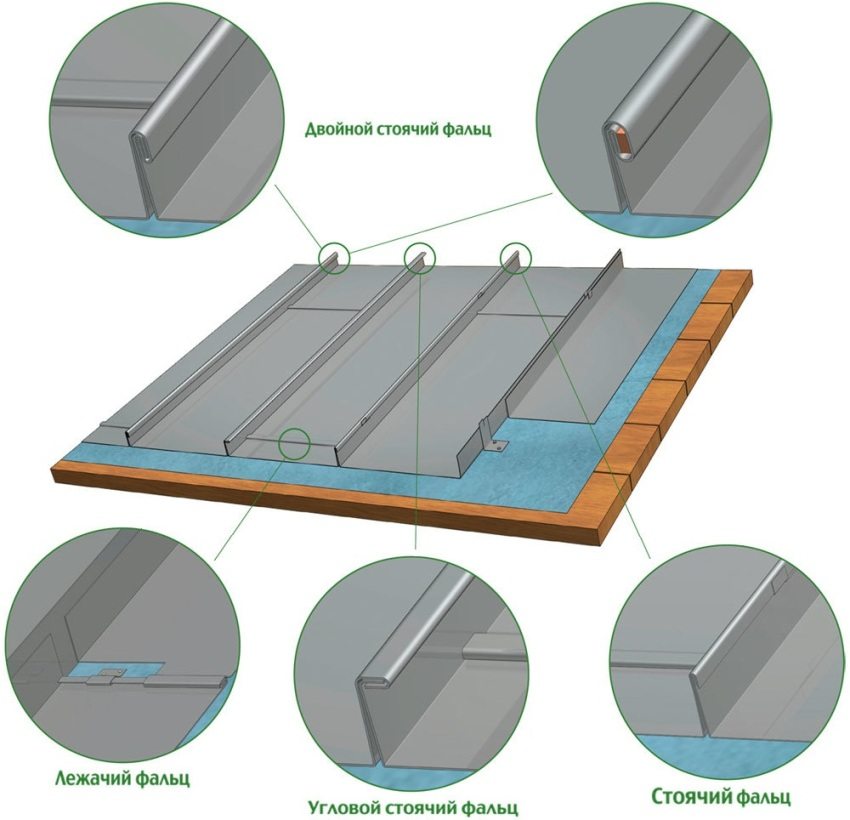

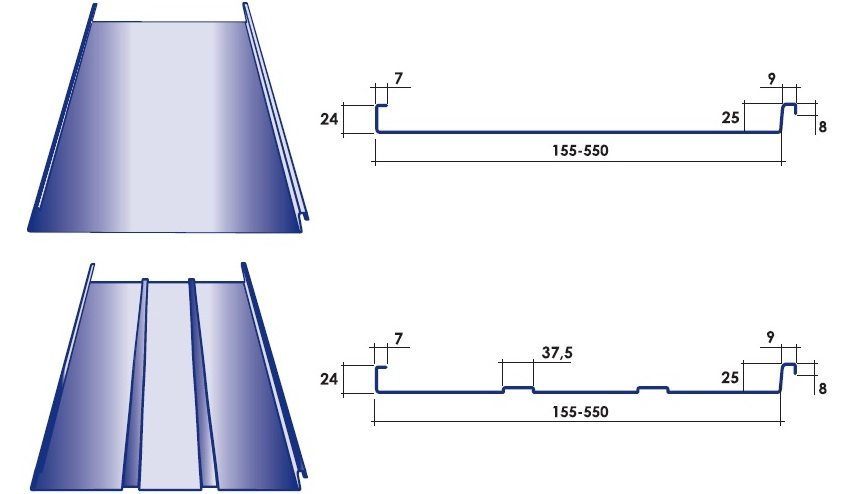

Seam roofing: types of roofing, roofing materials and prices

The popularity of seam roofing grows every year. This is due to the reliability of the coating, a high level of protection against the negative effects of weather factors, as well as excellent quality.

Note! The seam roof is often used to organize the roof on buildings, the architecture of which is made in the style of Russian classicism. Today this type of coating is actively involved in the reconstruction of old buildings.

The blanks for the folded roof covering are created using a special technology. Special seams are used, which are formed as a result of the connection of the roofing parts. Varieties of seam seams:

- single;

- standing;

- double;

- recumbent.

During the installation process, a coating is obtained on the basis of metal sheets fastened by folding. This roofing system is considered the most reliable and durable among developers.

Seam roofing based on steel elements

The steel roof is formed from zinc coated sheets. Often, elements are additionally protected with a polymer layer. Depending on the type of fold that is on the sheets, a certain type of fastening is carried out. The material must be laid on an inclined surface. The minimum permissible tilt angle is 14 °. In addition to the lathing, which is used as a base for the installation of the covering, a special film is laid on the surface. It eliminates the formation of condensate under the folded roof.

For the manufacture of the lathing, square bars with a section size of 200-400 mm are required. If the roofing surface has a slope within 7-14 °, the base is made in the form of a solid structure.

Advantages of steel seam roofing:

- absolute incombustibility;

- a high rate of flexibility, which makes it possible to finish roofs with a complex structure;

- aesthetic appearance;

- light weight (weight within 4–5 kg does not require reinforcement of the rafter system);

- resistance to low temperatures.

Useful advice! Despite the fact that the main area of application of this roofing extended to manors and cathedrals, the seam covering can also be used in modern construction. Use it to organize roofing on industrial buildings.

Disadvantages of coverage:

- vulnerability to blows;

- mandatory insulation is required (seam roofing is very cold);

- self-assembly is not possible;

- limited market for installation services;

- the material accumulates static electricity;

- high noise level.

The service life of the coating is about 25-30 years.

Other types of rebate roofing

Blanks for forming a folded roof can be made not only of steel. For these purposes, copper and aluminum are used. Such a coating is not afraid of corrosion, from which other types of metal roofing suffer so much.

Copper Billet Standard Parameters:

- thickness - 0.3 mm or more;

- length - 110 cm;

- width - 70 cm;

- weight - 5-10 kg (aluminum roof has a light weight of 2-5 kg).

During operation, a film coating is formed on the surface of copper and aluminum roofs. It prevents the destruction of the material by corrosion. This ensures increased service life. Copper is able to last about 100 years, aluminum a little less - 80 years.

Advantages of aluminum and copper plating:

- there is no need for thorough care (it is enough to perform the cleaning procedure 2 times a year);

- complete incombustibility;

- environmental friendliness;

- cleanliness and safety;

- invulnerability to corrosive and chemical attack (acid rain).

Among the shortcomings, only the high cost can be distinguished, which is in the range of 2000-2700 rubles. per m².

The cost of steel seam roofing of roofs of private houses: types of protective coatings

Steel blanks for standing seam roofing can have a different type of protective coating. Each of them has its own advantages, properties and decorative characteristics.

Note! The type of protective coating directly affects the cost of the fold.

The table shows the average prices for the purchase of folded blanks with a thickness of 0.45 mm for the roof, taking into account the difference in the protective coating.

Prices for steel seam roofing:

| Name of product | Type of protective coating | Price, RUB / m² |

| Double standing seam | Galvanized | 274 |

| Polyester | 363 | |

| Atlas | 459 | |

| 595 | ||

| Velours | 473 | |

| Quartzite Light | 515 | |

| Quartzite | 652 | |

| Double standing seam (Pro) | Galvanized | 274 |

| Polyester | 363 | |

| Safari | 516 | |

| Velours | 473 | |

| Quartzite Light | 515 | |

| Quartzite | 652 | |

| Self-locking fold (clickfold) | Galvanized | 316 |

| Polyester | 419 | |

| Atlas | 529 | |

| Velours | 544 | |

| Quartzite Light | 594 | |

| Quartzite | 752 | |

| Safari | 600 |

Soft roof for the roof: types of coatings and their characteristics

First of all, when installing the roof, more importance is given to weight. Even if at first glance it seems that sheet material weighing 3-4 kg is not capable of overloading the rafter system, the total weight of the coating should be taken into account, which in fact will not be so small. On the other hand, if you want to start installing the roof yourself, the purchased material should have a simple installation system, be easy to process, cut and repair.

All these requirements are met by various types of soft roofing, photos of which you could more than once come across on the net or even see these materials on the street.

A soft roof has the following advantages:

- resistance to negative environmental influences (the material retains its properties even under the influence of high and low temperatures);

- excellent strength characteristics, especially tensile strength;

- simple installation system;

- the minimum number of tools required to organize the roof;

- installation of coverings on roofs with a complex structure, without complex preparatory measures;

- no noise during further operation;

- fire safety;

- long service life - up to 15 years.

Note! Roofing material, which belongs to roll types of roofing, is not a fire-resistant coating. This version of the material is rather an exclusion from the list.

Roll and membrane materials, soft tiles: roof photos

In the soft flooring category, there are other products besides soft tiles. Roof types are distinguished based on the raw materials used for their manufacture:

- different types of mastic;

- membrane made of polymeric materials;

- soft or bituminous shingles;

- roll-type coatings.

Most of these materials are able to offer very favorable characteristics, not only technical, but also operational:

- high strength;

- flexibility;

- anti-corrosion properties;

- water resistance;

- high quality sound insulation;

- anti-fungal properties;

- good thermal insulation.

Thanks to all these advantages, soft roofing coatings are so widespread. Their scope:

- private houses;

- cottages;

- warehouses;

- objects of the production area;

- large commercial buildings.

If you are choosing a soft roofing material, first of all, you should pay attention to the level of heat resistance, and only then consider other characteristics: the level of elasticity, flexibility and strength in relation to mechanical stress.

As for the mastic, the primary indicator here is the percentage of solids content, the level of adhesion, as well as the time it takes for complete curing. Durability plays an important role when choosing any coating option.

Features of soft tiles: photos, characteristics and prices

Soft shingles, called bitumen shingles, are produced by cutting roll material. Each such sheet contains 4 rectangular, diamond-shaped or hexagonal elements. Thanks to the use of various dyes, there are several material options on the market:

- natural covering in the form of tiles;

- aged surface overgrown with moss;

- aged surface overgrown with lichens.

Note! Despite the fact that bituminous tiles in their characteristics are close to piece materials, they are still classified as a roll type of coating, due to their structure and scope.

Prices for the purchase of bituminous tiles:

| Brand name | Product name (color) | Price, RUB / m² |

| MIDA | Quadro (brown, red) | 510 |

| Prima (green, red, brown) | 645 | |

| Chord (green, red, brown) | 710 | |

| Trio (antique) | 710 | |

| Ridge-cornice (red, brown, green) | 1140 | |

| Shinglas | Square dance Sonata (whiskey, red-brown) | 1150 |

| Quadrille Accord (sandalwood) | 1150 | |

| Ridge-cornice (whiskey, sandalwood) | 1860 | |

| Tegola (Top Shingle) | Futuro (green, brown, red, gray) | 299 |

| Smalto (green, brown, red, gray) | 238 | |

| Premier (red brown, light brown, dark brown) | 455 | |

| Vintage (green, red, brown, gray) | 273 |

The service life of shingles is about 15–20 years. Installation is carried out on an inclined surface. The minimum tilt angle is 10 °. Soft tiles can be used not only for the organization of the roof, but also as a covering on the adjacent vertical zones of the walls.

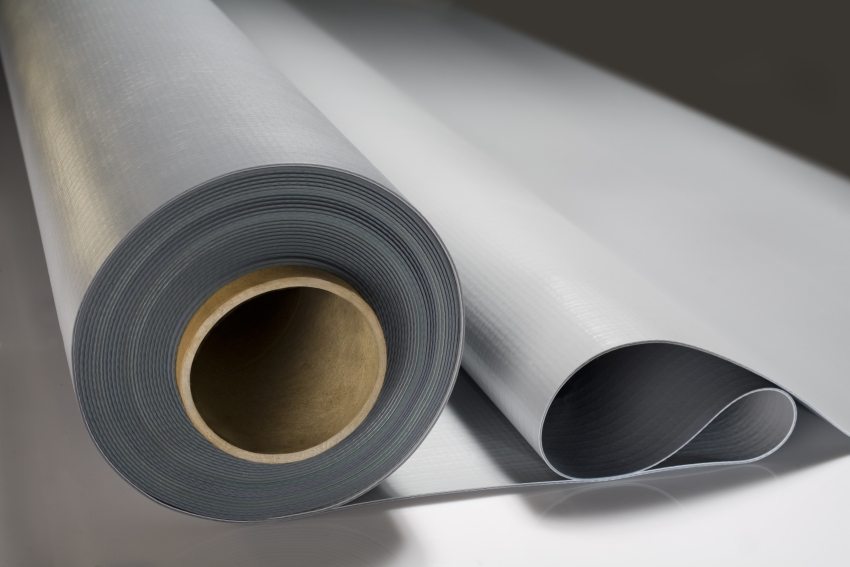

Membrane coating: features and price of a soft roof for 1 sq. meter

The roof membrane has a thickness of 0.8–2 mm. This type of material has several varieties, depending on the raw materials used in production. Types of membrane coating:

- PVC - made of polymer raw materials (provides protection against fire and ultraviolet radiation);

- EPDM - rubber was used as the material for the manufacture, the coating is reinforced with a mesh made of polyester (strength, environmental safety);

- TPO - thermoplastic olefins reinforced with mesh (environmental friendliness) are used as raw materials for coating production.

Note! Since the PVC membrane covering is made of polymer materials, this type of roof cannot be called environmentally friendly.

Prices for PVC membrane coating:

| Brand name | Material name | Price, RUB / m² |

| Eco Plast | V-GR | 300 |

| V-RP | 400 | |

| Logicroof | T-PL | 400 |

| T-SL | 510 | |

| V-PR | 570 | |

| V-PR Arctic | 460 | |

| V-SR | 460 | |

| Ico pal | Monarplan D | 680 |

| Monarplan FM | 499 | |

| Monarplan W | 953 |

The service life of a membrane roof covering is about 50 years. Due to the large width, it is convenient to cover the roof with the material, and this can be done at any time of the year. There is no need for additional waterproofing.

Among the minuses, only a difficult preparatory stage can be noted, since the membrane roof does not tolerate debris and pebbles on the surface. Organic solvents and oils can damage the material.

Specificity of a soft roll roof: types and prices

Soft roll roofing offers several different roof materials. The most popular and affordable is roofing material. The following production scheme is used in production:

- forming a blank from roofing cardboard;

- impregnation with bitumen;

- double-sided processing with a mixture based on bitumen with a high level of hardness and mineral filler;

- application of an outer coating in the form of a special bulk material.

The service life of such material is 5 years. In addition to the roll, there is also a tiled roofing material, but it has a completely different manufacturing scheme and properties.

Useful advice! If you want to get longer service life, it is worth purchasing roofing material made using modern technology. Thanks to the use of polyester fabric or fiberglass sheet, the service life is doubled.

Rubemast also belongs to the category of roll coatings. This type of roofing is a bituminous deposited material with a higher percentage of binder than roofing material.

There are a number of similar fiberglass-based coatings:

- glass mat;

- glass roofing material;

- glass insulation;

- euroruberoid.

The cost of roll roofing materials:

| Material type | Name, coverage area in a roll | Price, rub / roll |

| Roofing material | RPP-300-0 (0), 15 m² | 234 |

| RKP-350 (02), 15 m² | 285 | |

| RKP-350 (0), 15 m² | 344 | |

| RKK-350 TU, 10 m² | 370 | |

| Stekloizol | R HPP-2.10, 9 m² | 304 |

| R KhKP-3.5 granulate, 9 m² | 485 | |

| R TKP-3.5 granulate, 9 m² | 585 | |

| Gidrostekloizol | TPP03.0 glass fabric, 9 m² | 564 |

Fiberglass based materials are characterized by a long service life. The minimum operating period is 20 years. This category of roofing has only one drawback - vulnerability to low temperatures. But the problem is easily solved due to multi-layer installation (3-4 layers of material).

Modern roofing materials: risolin

Rizolin belongs to the materials of the modern generation with a flexible and soft structure. The coating is self-adhesive and is made on the basis of reinforcing fabric, which is filled with a mixture of bitumen-polymer substances and special additives.

Note! Thanks to the foil surface, the material can be dyed with any synthetic dyes in order to improve its appearance.

Varieties of risolin:

• А - double-sided self-adhesive surface;

• P - self-adhesive surface on one side and polymer base on the other;

• F - aluminum foil base and standard adhesive surface.

The material with a foil-coated surface provides risolin with reliable protection against premature destruction, and also slows down these processes. The assortment includes options for products with a copper base, which are covered with a very thin layer of foil.

Rizolin purchase prices:

| Name | Material type | Price, RUB / m² |

| AS | Self-adhesive on both sides | from 200 |

| FSA | Self-adhesive + aluminum interlayer (30 MCN) | from 230 |

| Shumka-F | Hydro-noise insulation coating | from 230 |

| Bitumen primer | Cold waterproofing coating (liquid) | from 350 (bank) |

| Vapor barrier | Vapor barrier bitumen-polymer coating | from 90 |

| Sandwich | Three-layer coating with risoline lining | from 950 |

Each of the considered coatings has certain advantages and disadvantages. When choosing a roofing material, it is worth considering the characteristics, scope, and also rely on your own taste preferences and financial capabilities.